Oil coating device for railway sleeper bolt

An oiling device and bolt technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of heavy labor, many required personnel, and low efficiency, so as to reduce personnel, improve the degree of automation, The effect of improving oiling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

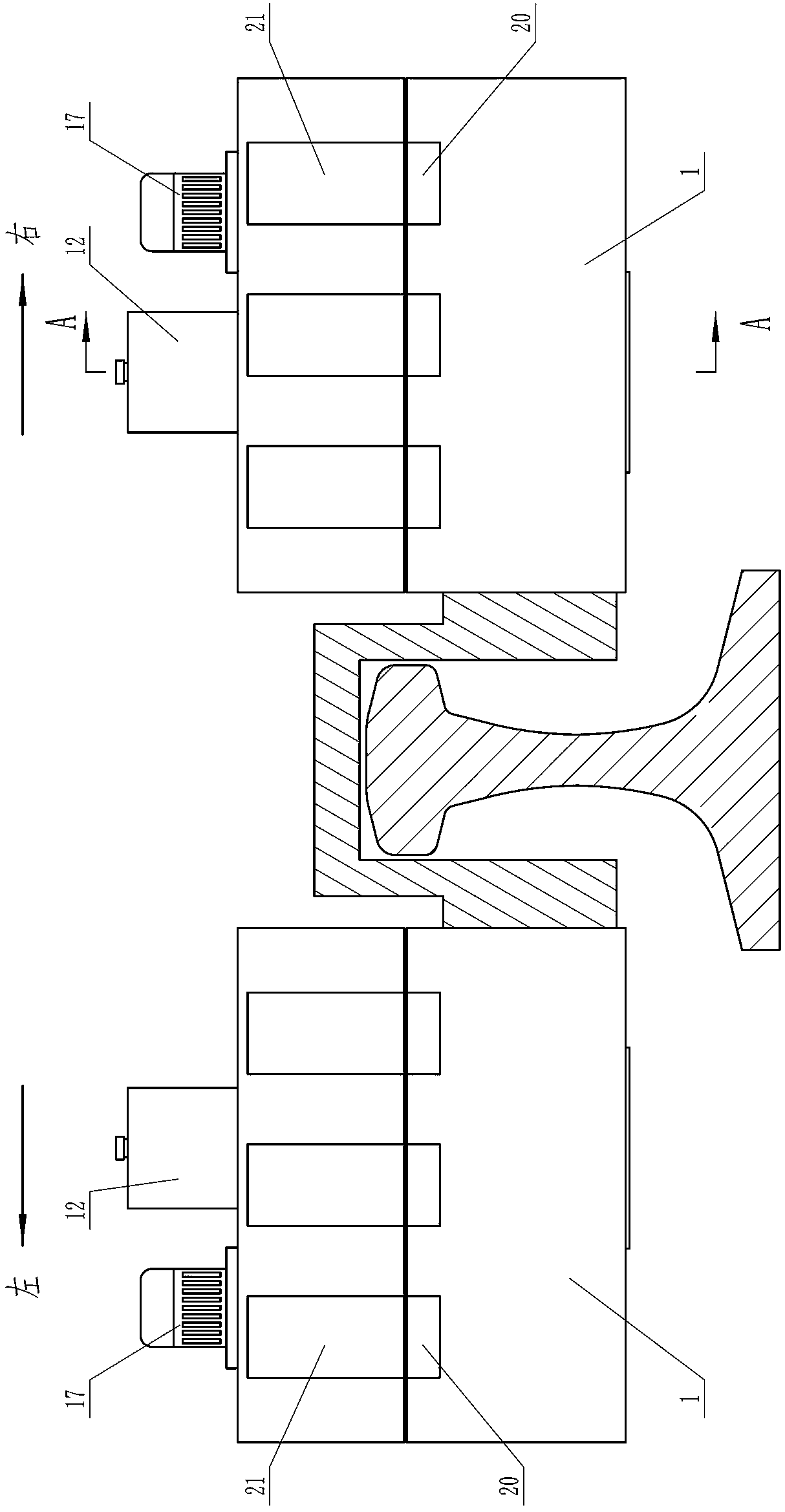

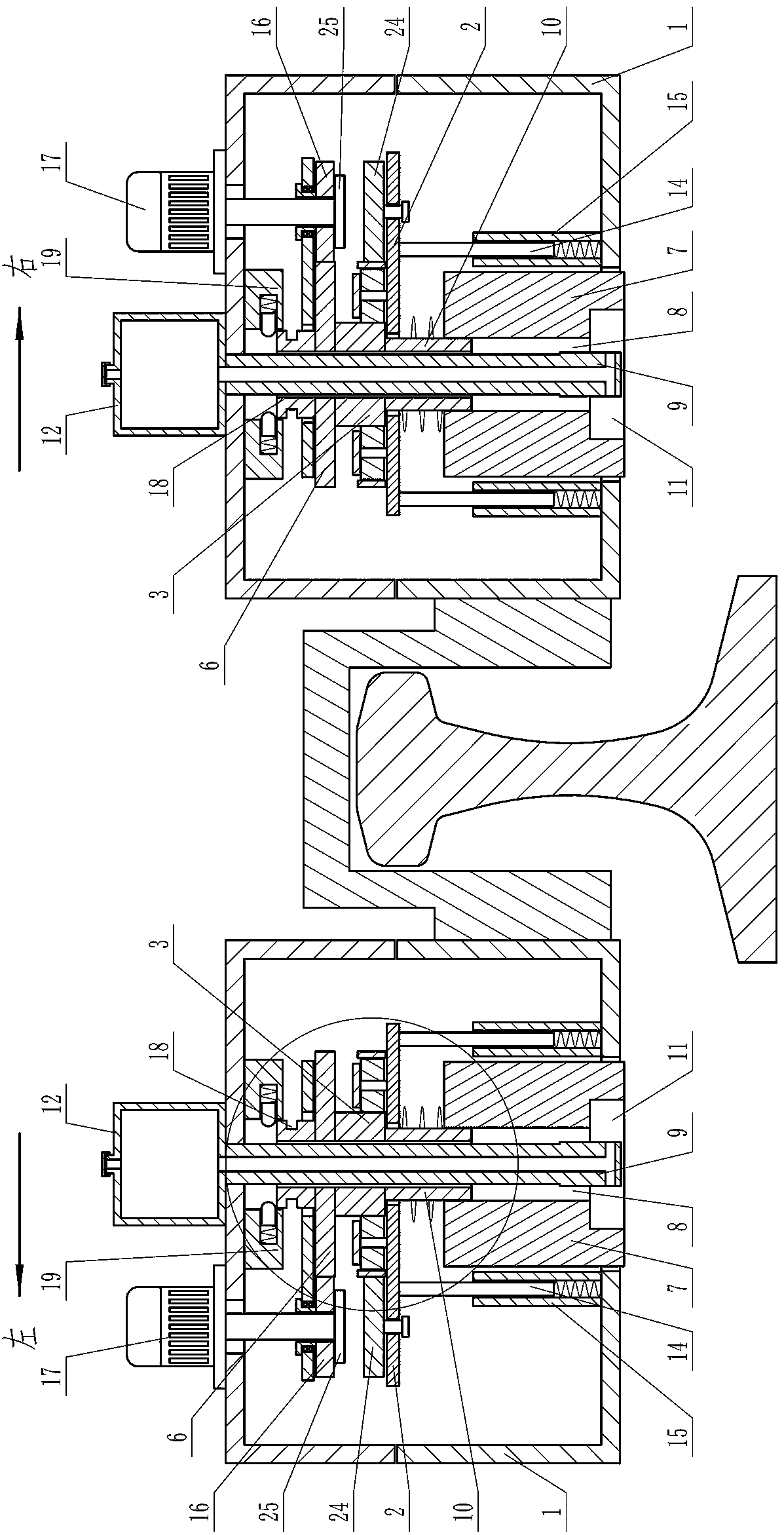

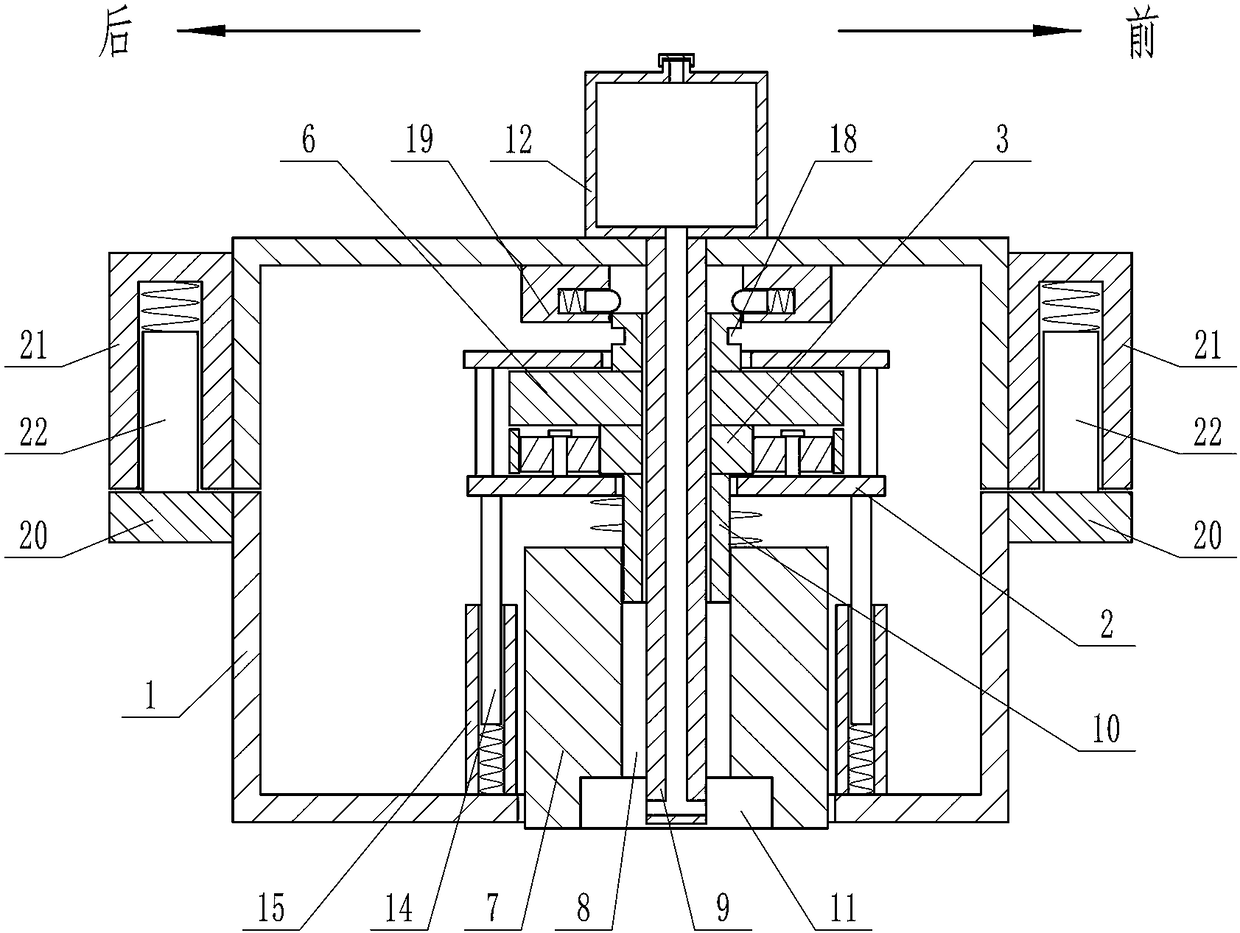

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] Depend on Figure 1 to Figure 13 Given, the present invention includes a horizontally placed rectangular housing 1, in which there is a horizontally placed flat plate 2 that can only move up and down. 5. The outer side of the planetary gear 5 is meshed with the inner ring gear 4 that is coaxial with the sun gear 3 and can rotate. The planetary gear 5 can rotate itself but cannot revolve. Rotating first gear 6;

[0026] There is a cylindrical block 7 coaxial with the sun gear 3 in the housing 1, a vertical spline hole 8 is arranged on the cylindrical block 7, and a vertical hollow tube 9 is arranged in the spline hole 8, and the hollow tube 9 is from bottom to bottom. And the top runs through the plate 2, the sun gear 3, the first gear 6 in sequence and is fixed with the upper side plate of the housing 1. The hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com