Sleeper bolt automatically greasing device

A technology of oiling device and driving device, which is applied in the direction of track lubrication, transportation and packaging, engine components, etc., which can solve the problems of uneven oiling, low oiling efficiency, waste, etc., to improve efficiency, improve quality, and save use volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

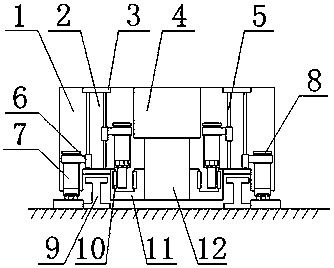

[0019] An automatic oiling device for sleeper bolts, comprising a car body 1, an electric wrench 7 and an oiling device 11, the car body 1 is provided with a driving device 4 inside, an oil tank 12 is located below the driving device 4, and the electric wrench 7 Set on both sides of the car body 1, the electric wrench 7 is fixed on the lifting device 6 through the rotating mechanism 8, the lifting device 6 is arranged on the guide rail 5 on the rotating shaft 2, and the rotating shaft 2 is fixed inside the car body 1 through the rotating mechanism 3, The oiling device 11 is arranged on the inner side of the rotating shaft 2, and the position of the oiling device 11 corresponds to the position of the inner electric wrench 7. The oiling device 11 is provided with an oil injection hole 10, and the oiling device 11 is connected with the vehicle body 1. The oil tank 12 at the bottom is connected. An application method of an automatic oiling device for sleeper bolts is as follows: a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com