Lubricating oil automatic applying device for gear shifting device

A shifter and lubricating oil technology, which is applied in the direction of engine lubrication, lubricating oil input, lubricating parts, etc., can solve the problems of affecting the shifting life of the shifter, low oiling efficiency, uneven coating, etc. Achieve the effect of improving oiling efficiency, oiling evenly and without dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

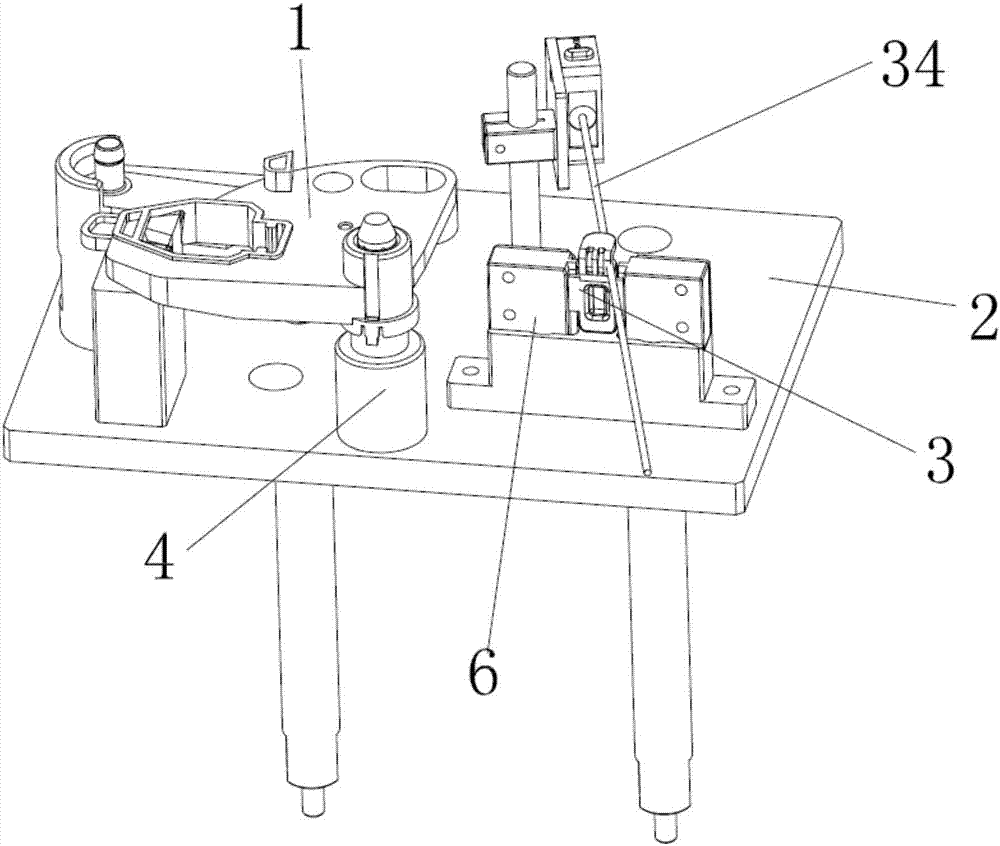

[0024] Such as Figure 1-4 As shown, this embodiment discloses an automatic lubricating oil device for shifters, which is used for such as Figure 5 , 6 Shown foot plate 1 and slide block 3 carry out lubricating oil, and it comprises machine platform 2, the first oiling tooling 4 that is all arranged on machine platform 2 and the second oiling tooling 6 pass oil circuit and the first oiling tooling 4 and the oil supply mechanism 8 internally connected with the second oiling tool 6;

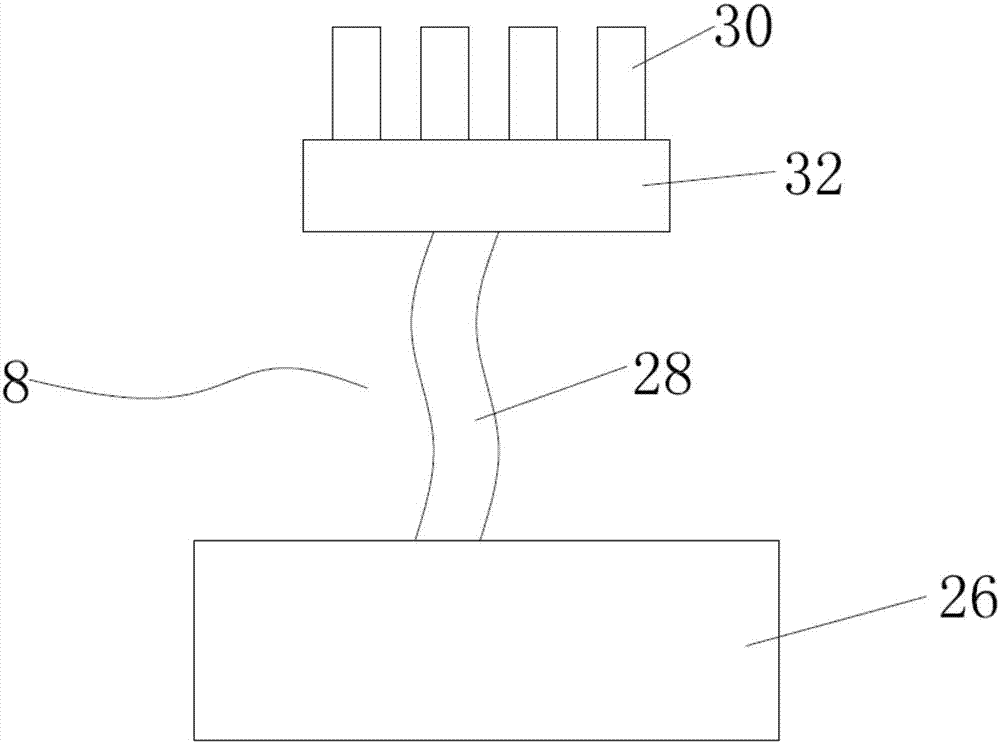

[0025] The above-mentioned oil supply mechanism 8 includes an oil supply tank 26, an oil supply main pipe 28 and a plurality of oil supply branch pipes 30, the above-mentioned oil supply main pipe 28 is connected with the oil supply tank 26, and the above-mentioned oil supply main pipe 28 is connected with each oil supply branch pipe 30 through a diverter valve 32, An oil pump is provided on the oil supply main pipe 28 .

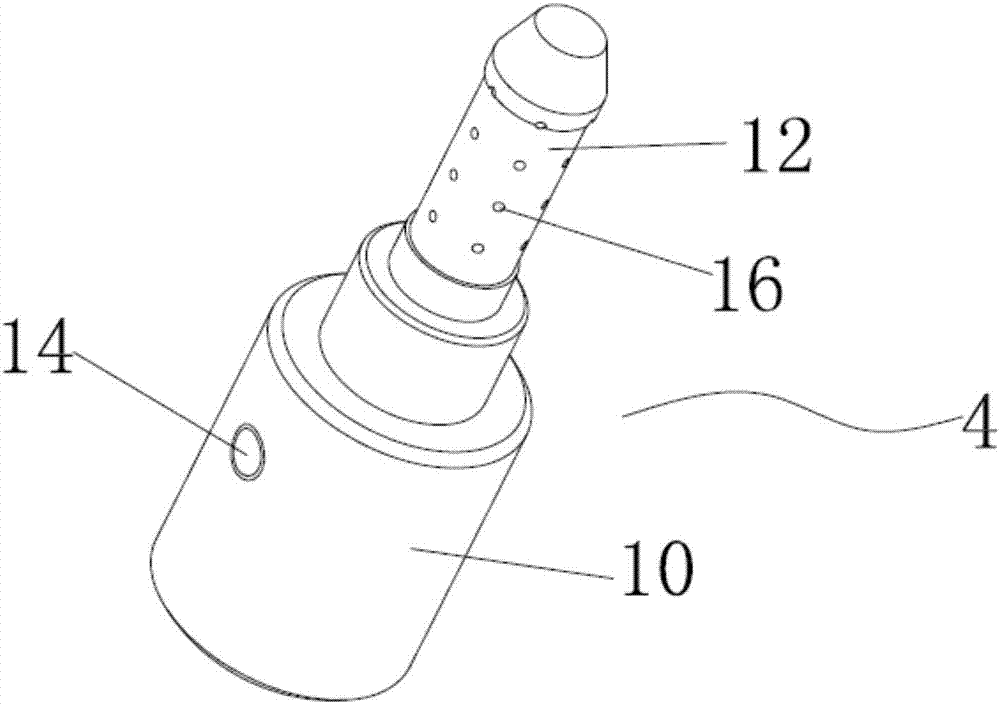

[0026] The above-mentioned first oiling tool 4 includes a connecting bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com