An oiling device for downwind ball production

A downwind ball and oil tank technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of low oiling efficiency and low coverage of the downwind ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

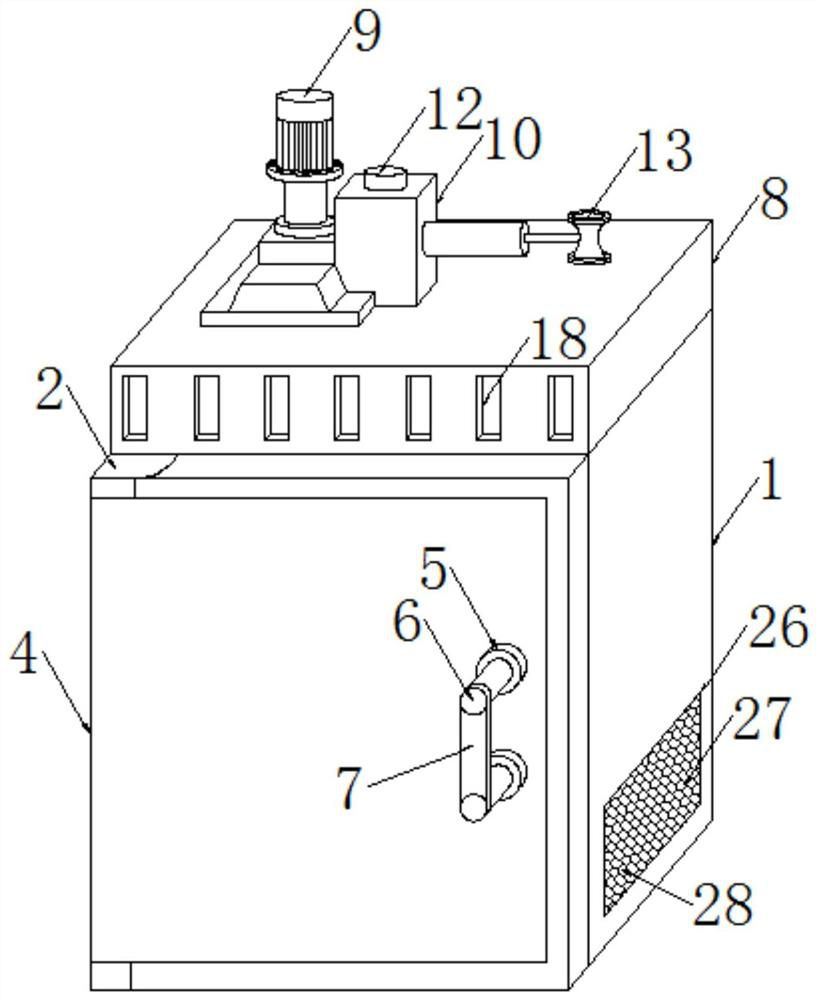

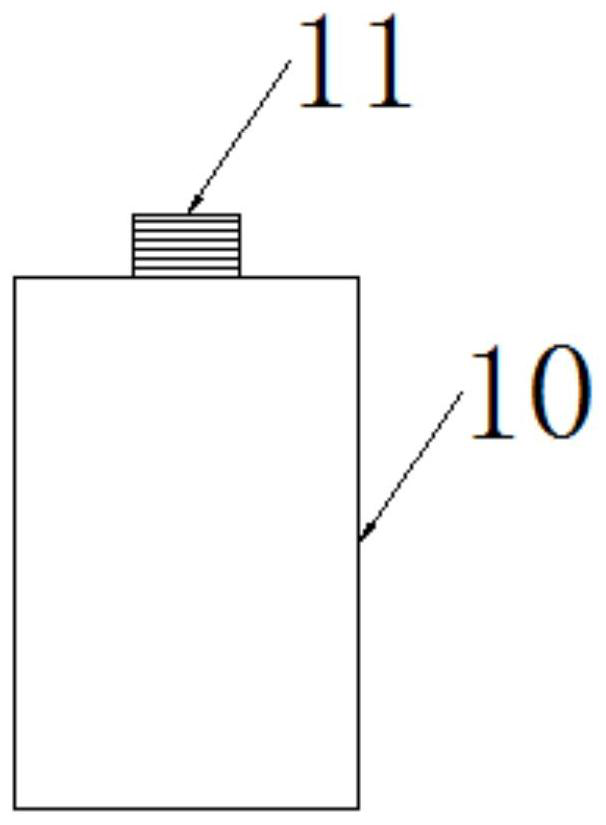

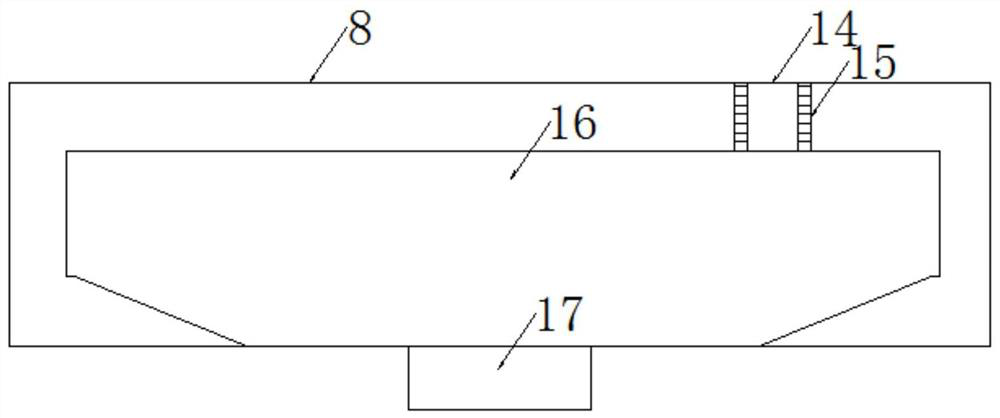

[0026] Such as Figure 1-10 As shown, this embodiment adopts the following technical solutions:

[0027] An oiling device for downwind ball production, comprising an upper oil tank 1, two corners of one side of the upper oil tank 1 are fixedly equipped with fixed blocks 2, and two fixed blocks 2 are fixed with respect to the lateral center of the upper oil tank 1 side. The spools are symmetrically distributed, the specifications of the two fixed blocks 2 are the same, the corners on one side of the two fixed blocks 2 are arranged in an arc shape, and the center of the circle on the opposite side of the two fixed blocks 2 is provided with a rotation hole 3 One side of the upper fuel tank 1 is provided with a box door 4, and the upper and lower ends of the box door 4 are fixedly equipped with rotating columns 32 near the sides, and the two rotating columns 32 are respectively connected with the two rotating holes 3 Compatible design, and the two rotating columns 32 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com