Encapsulation method for electric core of flexible packing lithium battery

A packaging method and technology for lithium batteries, which are applied in battery pack parts, circuits, electrical components, etc., can solve problems such as bulging, lithium battery leakage, and falling off, and achieve the effects of improving service life, convenient operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

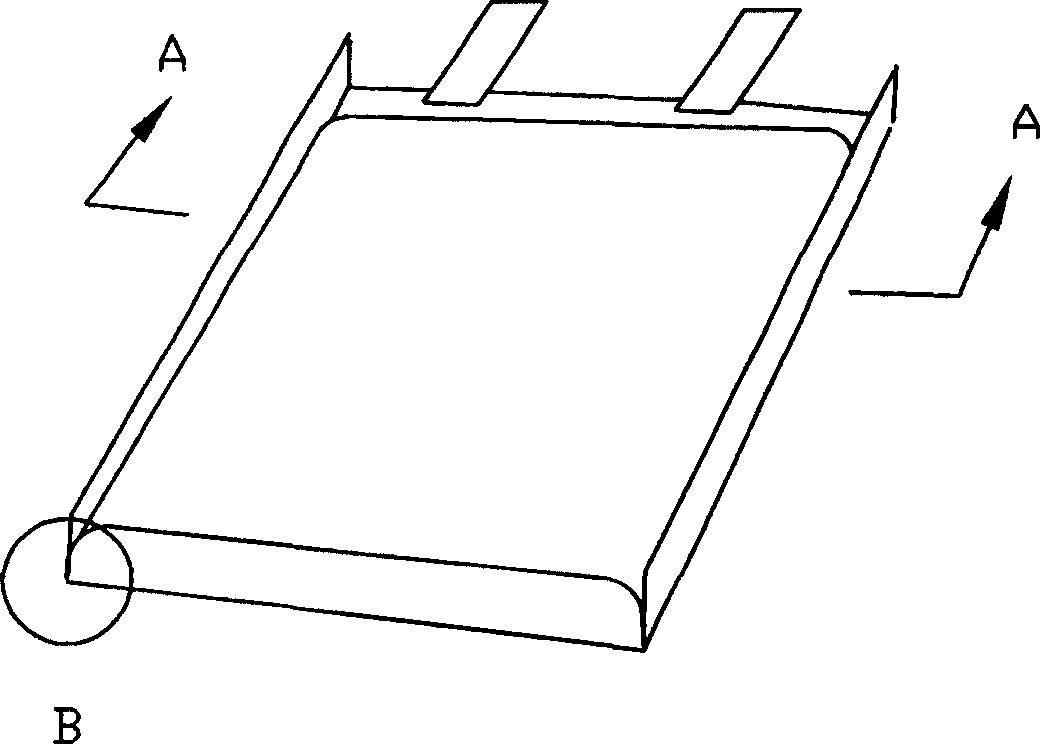

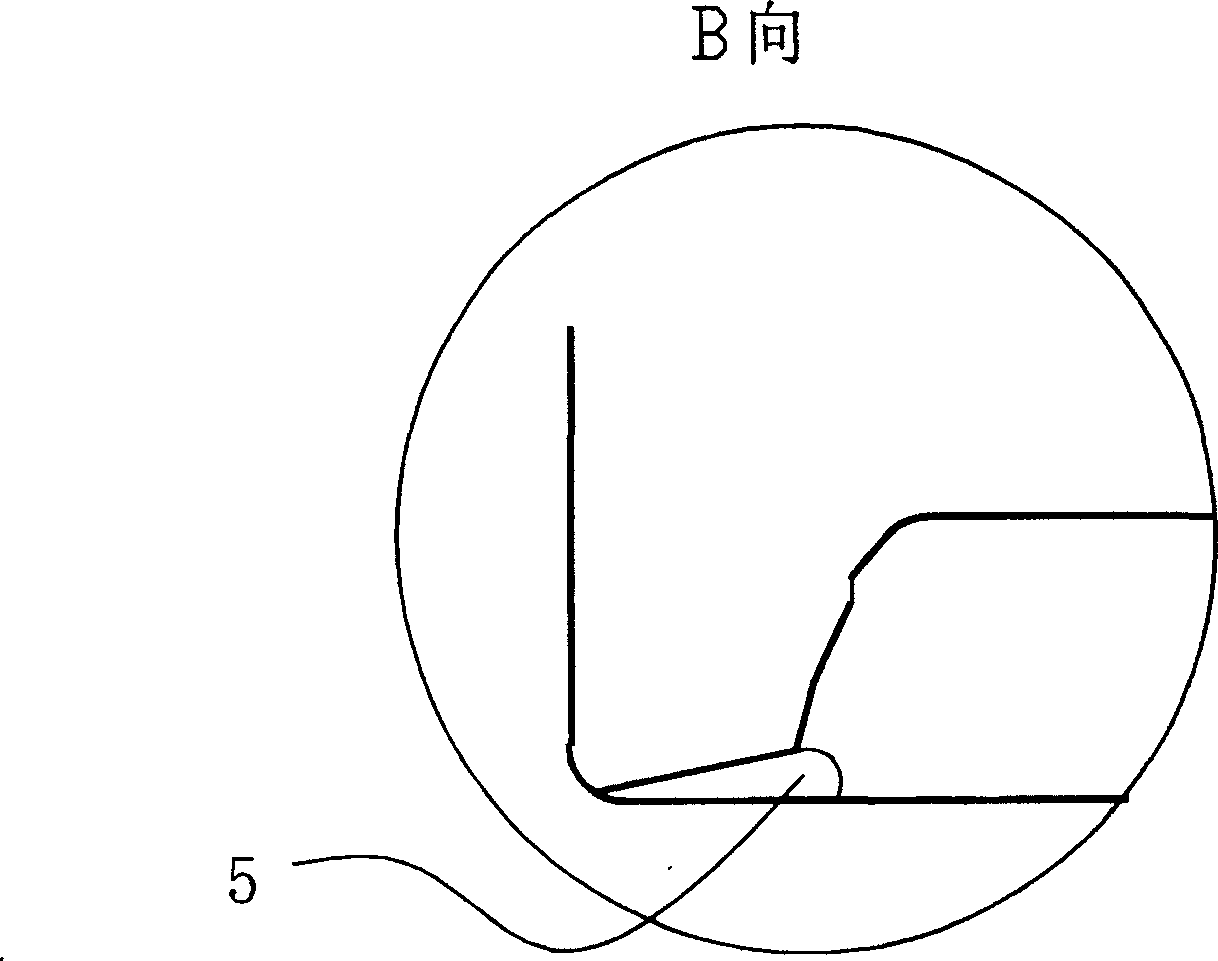

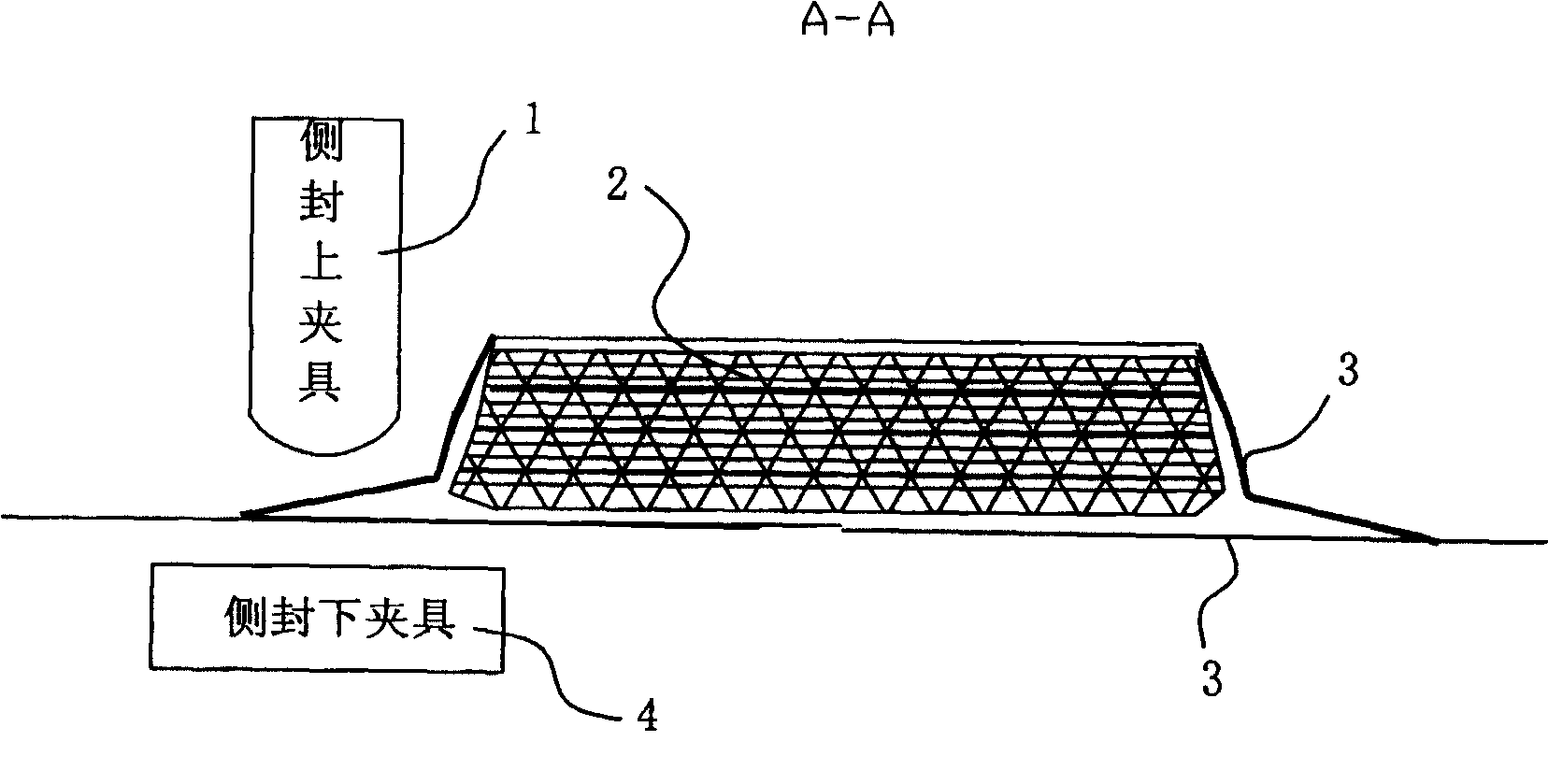

Image

Examples

Embodiment 1

[0023] Example 1: Paste several layers of 0.01 mm thick adhesive tape (or a substitute similar to the adhesive tape) on the side of the side sealing jig close to the core, and then heat-press the side seal, and compare the indentation of the soft-packed lithium battery with the standard film , select the 0.05 mm standard to meet the requirements.

[0024] The heat-sealing jigs involved in the present invention are known technologies.

[0025] The heat-sealing temperature, time, pressure etc. that the present invention relates to are all known technologies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com