Corrugated pipe ball valve

A technology of bellows and ball valves, applied in valve details, valve devices, shaft seals, etc., can solve problems such as normal use of bellows, damage of bellows, unsuitable torsion deformation of bellows, etc., to achieve long-term safe and reliable use and quick maintenance Convenience, solve the effect of medium leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

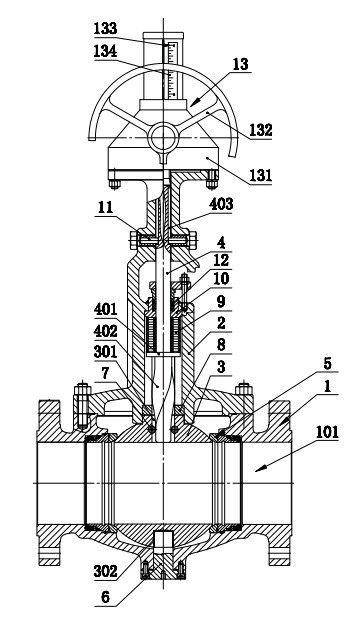

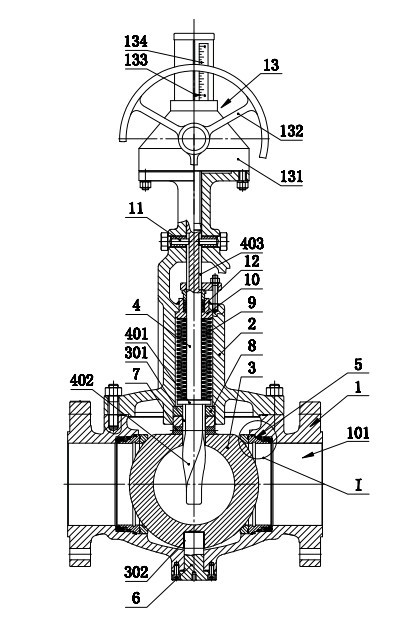

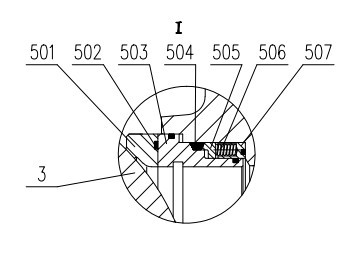

[0017] like figure 1 , 2 , 3 shows a bellows ball valve, including valve body 1, valve cover 2, ball 3, valve stem 4, valve cover 2 is fixed on valve body 1, and ball 3 is installed in the inner cavity of valve body 1 On the flow channel 101, a sealing valve seat 5 is provided between the sphere 3 and the valve body 1, the valve stem 4 passes through the valve cover 2 and is connected with the sphere 3 in the valve body 1, and the upper and lower ends of the sphere 3 are provided with coaxial valves. The upper shaft hole 301 and the lower shaft hole 302, the upper shaft hole 301 of the sphere 3 is a through hole, the lower shaft hole 302 of the sphere 3 is a blind hole, the central axis of the upper shaft hole 301, the lower shaft hole 302 and the valve body 1 The central axis of the inner chamber flow channel 101 is perpendicular to each other, and the vertical intersection point is the center of the sphere 3. The lower end of the valve body 1 is pierced with a lower shaft 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com