Method for designing and processing wheel spoke structure

A technology of structural design and processing methods, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as material waste, achieve good comprehensive mechanical properties, increase input-output ratio, and improve material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

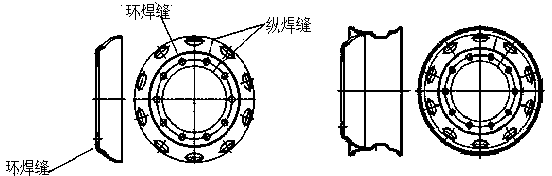

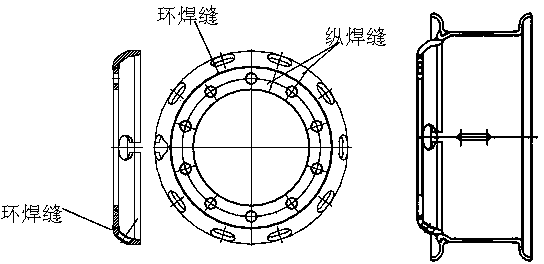

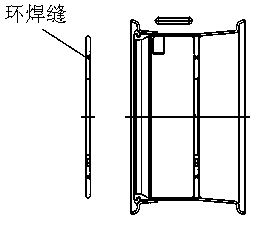

[0017] The ultra-wide spoke is designed as a structural part composed of two or more ring materials welded from a single piece of material, that is, two or more strips are cold-processed into ring materials, and then assembled and welded. The round cake material is reshaped and then assembled on the rim to form the wheel.

[0018] The specific width size, geometry, bolt hole distribution circle diameter and bolt hole diameter of the super-wide spoke are the basis for designing whether there are two or more ring welds, and the number of ring materials is obtained; in short, a single circle The ring material width should be less than 130. The position of the ring weld must avoid the inflection point of the geometry, as well as the positions of the bolt holes and air holes.

[0019] The number of longitudinal welds is determined by the ring material, and there are as many longitudinal welds as there are ring materials; the position of the longitudinal welds must avoid bolt holes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com