Novel process and synthesis device for preparing glyphosate by hydrolyzing by-product acid instead of hydrochloric acid

A technology of glyphosate and by-product acid, which is applied in the field of new glyphosate preparation process and synthesis device by hydrolysis of by-product acid instead of hydrochloric acid, which can solve the constraints of glyphosate synthesis process optimization, difficulty in transporting to the reaction system, and difficulty in hydrogen chloride Problems such as metering, to achieve the effect of reducing raw material and equipment investment costs, shortening condensation reaction time, increasing production capacity and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

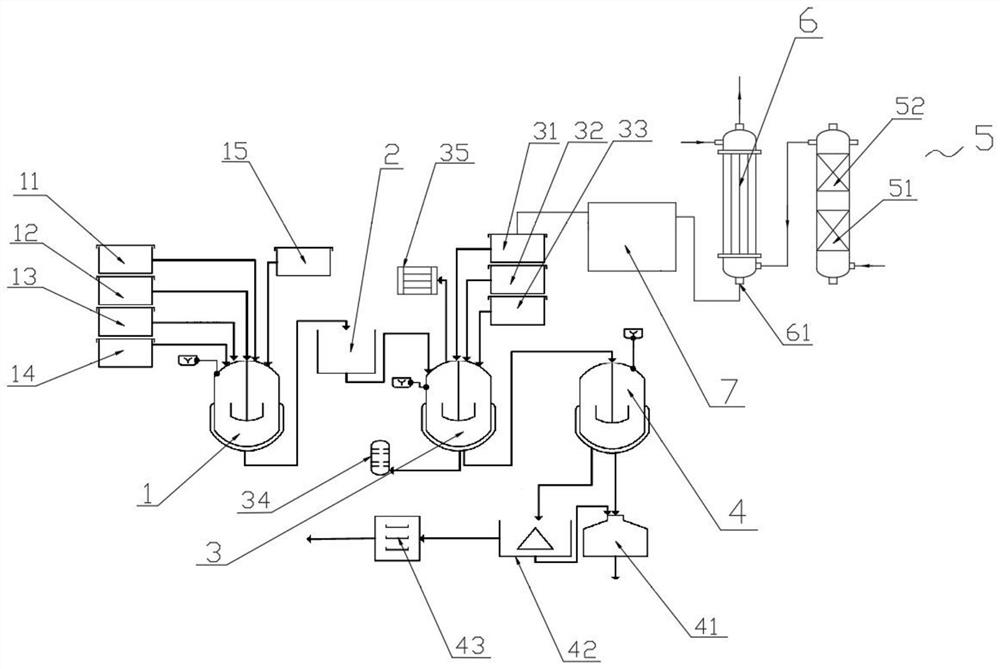

[0023] A synthesis device for preparing glyphosate by hydrolysis of hydrochloric acid instead of by-product acid, comprising a first synthesis reactor 1, a balance tank 2, a hydrolysis reactor 3 and a crystallization reactor 4 connected in series in sequence; the first synthesis reactor 1 Feed inlet is communicated with methanol metering tank 11, triethylamine metering tank 12, paraformaldehyde metering tank 13, glycine metering tank 14 and dimethyl phosphite metering tank 15 respectively through feed pipe; The feed port of the hydrolysis reactor 3 is communicated with the hydrochloric acid metering tank 31, the liquid alkali metering tank 32 and the water metering tank 33 respectively through pipelines; and tail gas absorption tank 35; the bottom outlet of the crystallization reactor 4 is connected to the mother liquor large tank 41 and the washing machine 42 through pipelines respectively, and the liquid outlet of the washing machine 42 is connected to the mother liquor large...

Embodiment 2

[0026]Prepare 4.5mol and 0.41mol of the raw materials in the methanol metering tank and the triethylamine metering tank respectively, put the measured solvent methanol and catalyst triethylamine into the first synthesis reaction kettle, and start stirring; then put the prepared material in the paraformaldehyde metering tank 0.12mol of paraformaldehyde is put into the first synthesis reaction kettle, and the temperature is controlled at 32-42°C to start the depolymerization reaction. After the paraformaldehyde is completely dissolved, put 0.43mol of glycine prepared in the glycine metering tank into the first synthesis reaction kettle, and react at a temperature of 37-52°C for 30-55min; mol dimethyl phosphite is quickly added to the first synthesis reaction kettle in batches, the temperature is controlled at 47-60°C, and triethylamine and dimethyl phosphite are added after holding the temperature for 8-10 minutes to adjust the pH of the system to 7.5-7.8. After 50-100 minutes, ...

Embodiment 3

[0028] Prepare 4.5mol and 0.41mol of the raw materials in the methanol metering tank and the triethylamine metering tank respectively, put the measured solvent methanol and catalyst triethylamine into the first synthesis reaction kettle, and start stirring; then put the prepared material in the paraformaldehyde metering tank 0.12mol of paraformaldehyde is put into the first synthesis reaction kettle, and the temperature is controlled at 36-40°C to start the depolymerization reaction. After the paraformaldehyde is completely dissolved, put 0.43mol of glycine prepared in the glycine metering tank into the first synthesis reaction kettle, and react at a temperature of 37-52°C for 30-55min; mol dimethyl phosphite is quickly added to the first synthesis reaction kettle in batches, the temperature is controlled at 47-60°C, and triethylamine and dimethyl phosphite are added after holding the temperature for 8-10 minutes to adjust the pH of the system to 7.5-7.8. After 50-100 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com