Immersed filter

A filter, submerged technology, applied in the direction of fixed filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problems of high operating cost, large floor space, high energy consumption, and achieve the water consumption rate of backwashing The effect of low energy consumption and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

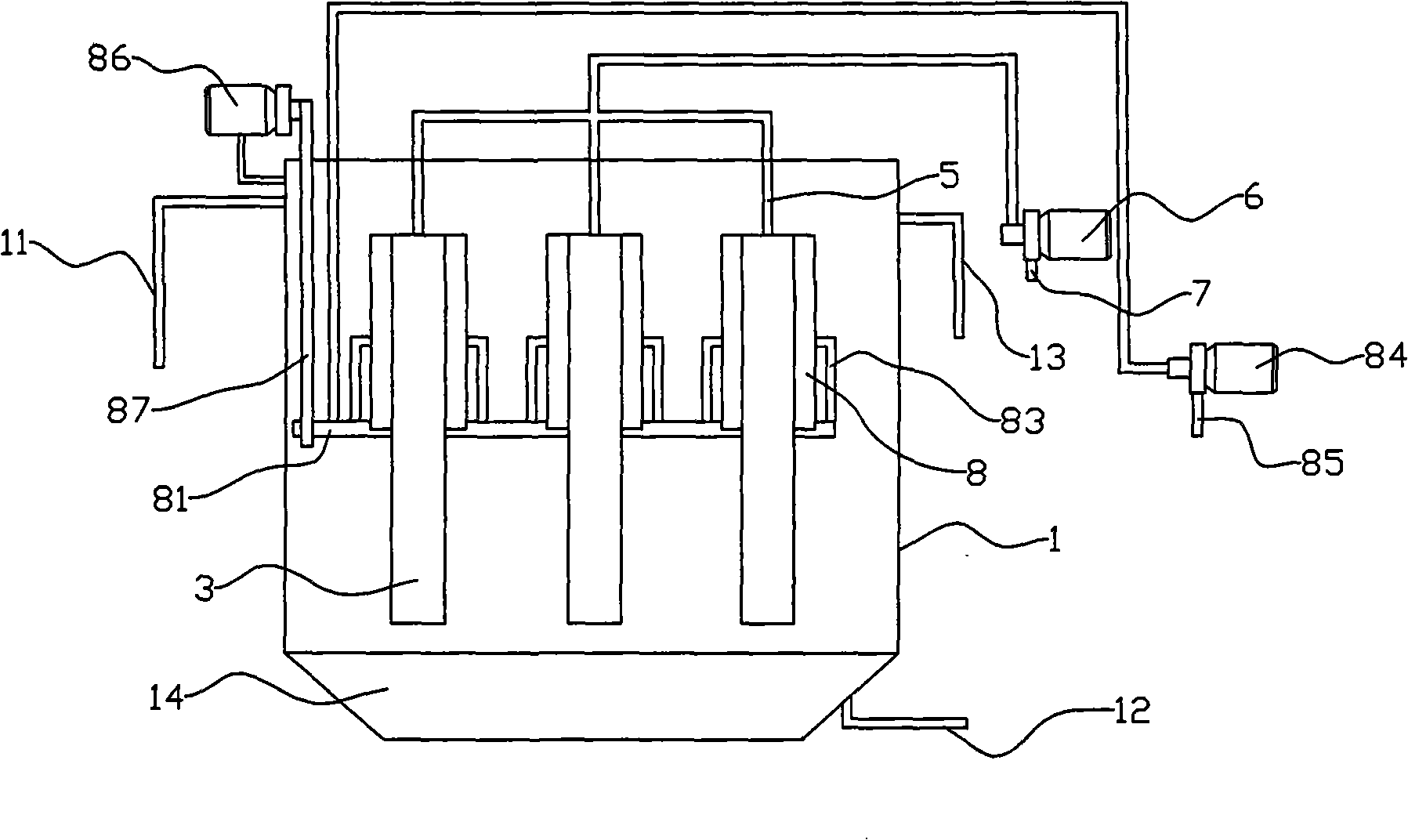

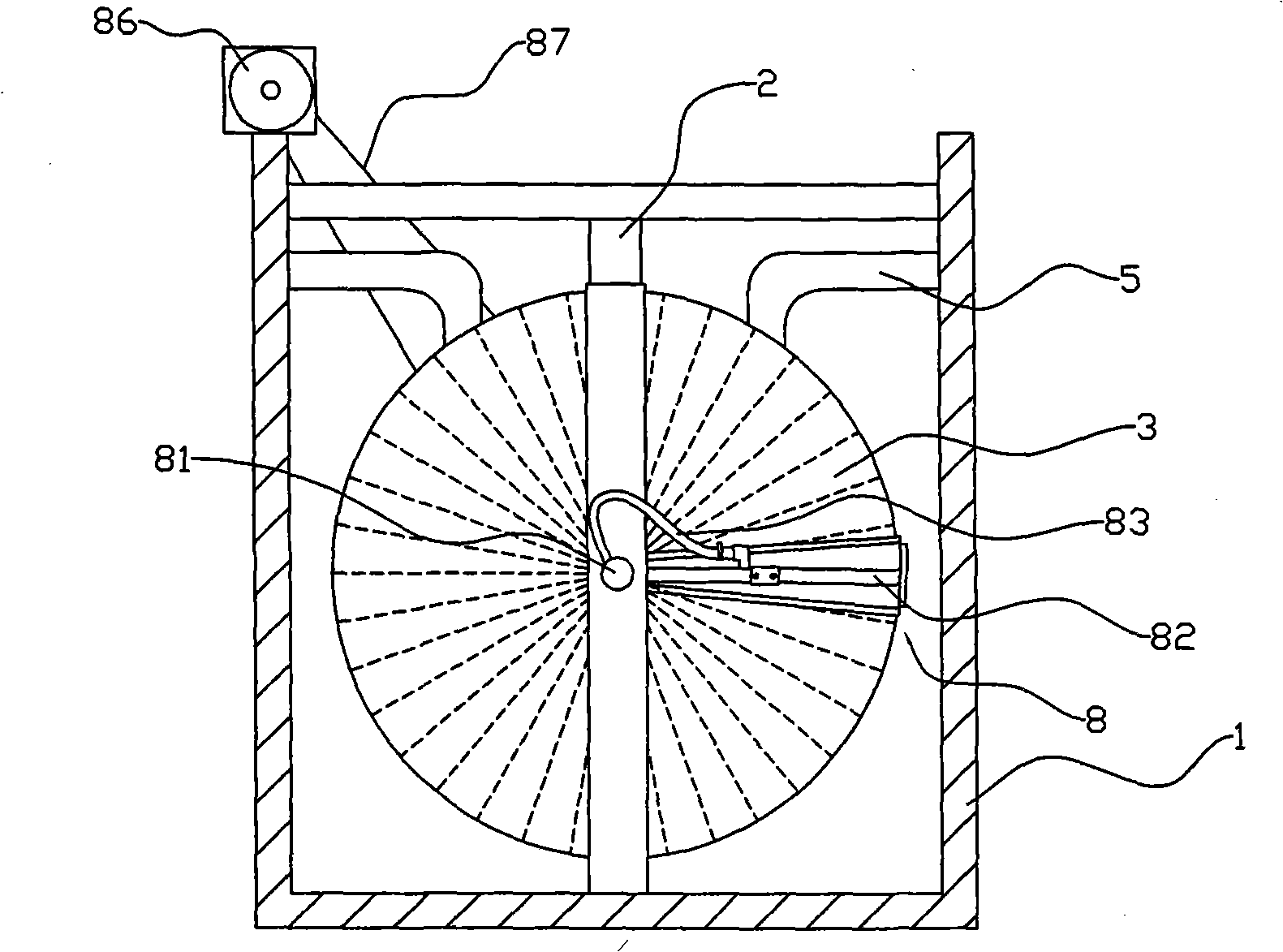

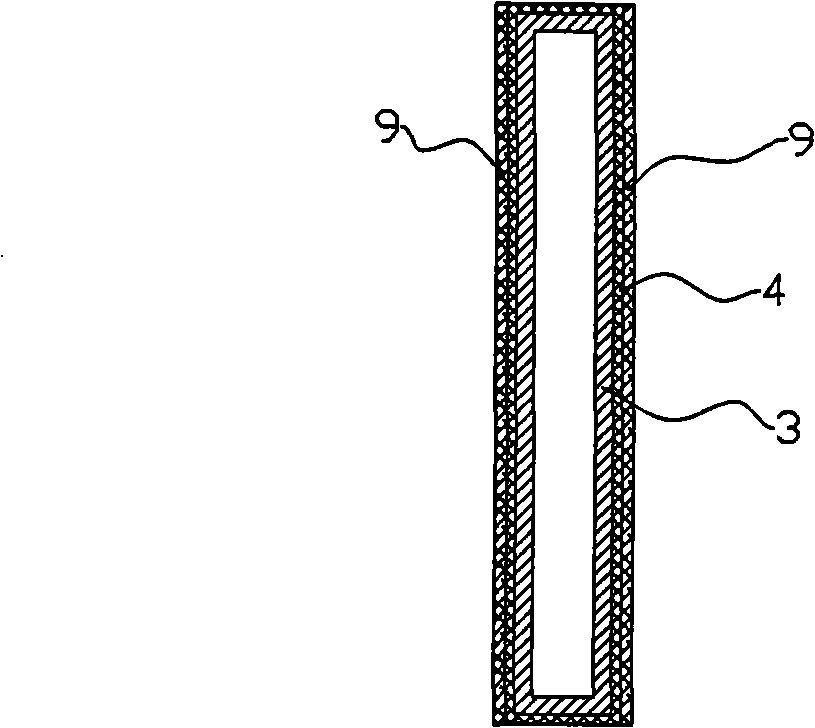

[0015] refer to Figure 1 to Figure 3 , a submerged filter of the present invention, comprising a water storage tank 1, a support frame 2 is arranged in the water storage tank 1, and one or more filter discs 3 are fixedly installed on the support frame 2, and the surface of the filter disc 3 is laid There is a filter medium 4, and the inner cavity of the filter disc 3 communicates with the discharge port 7 through the water outlet pipe 5 and the water pump 6. When working, the water to be treated enters the water storage tank 1 to immerse the filter disc 3 in it. After the water pump 6 is started, the inner cavity of the filter disc 3 forms a negative pressure, and the water to be treated enters the inner cavity of the filter disc 3 through the filter medium 4 to realize filtration. The water is discharged through the outlet pipe 5, the water pump 6 and the discharge port 7. Due to the adoption of the above structure, this submerged filter has a small footprint, low operating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com