Battery structure and battery module

A battery and cell technology, applied in the field of battery structures and battery modules, can solve problems such as the decomposition of battery electrolyte, and achieve the effects of improved sealing, high mechanical strength, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

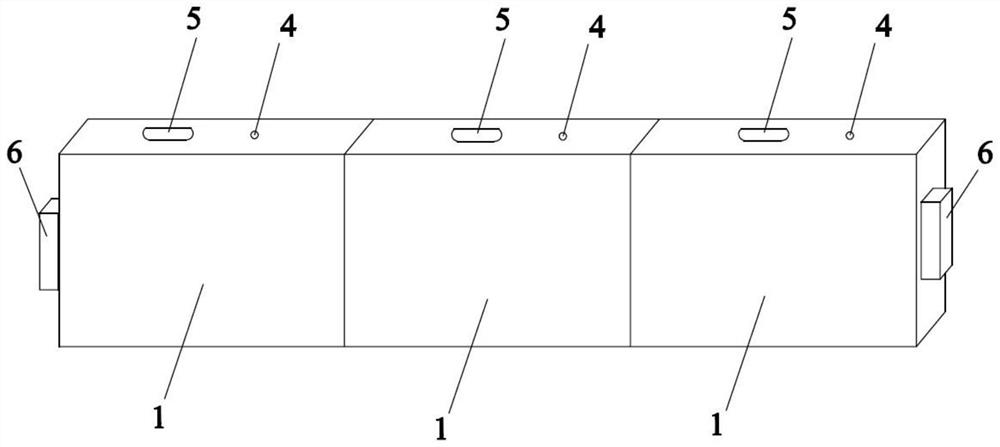

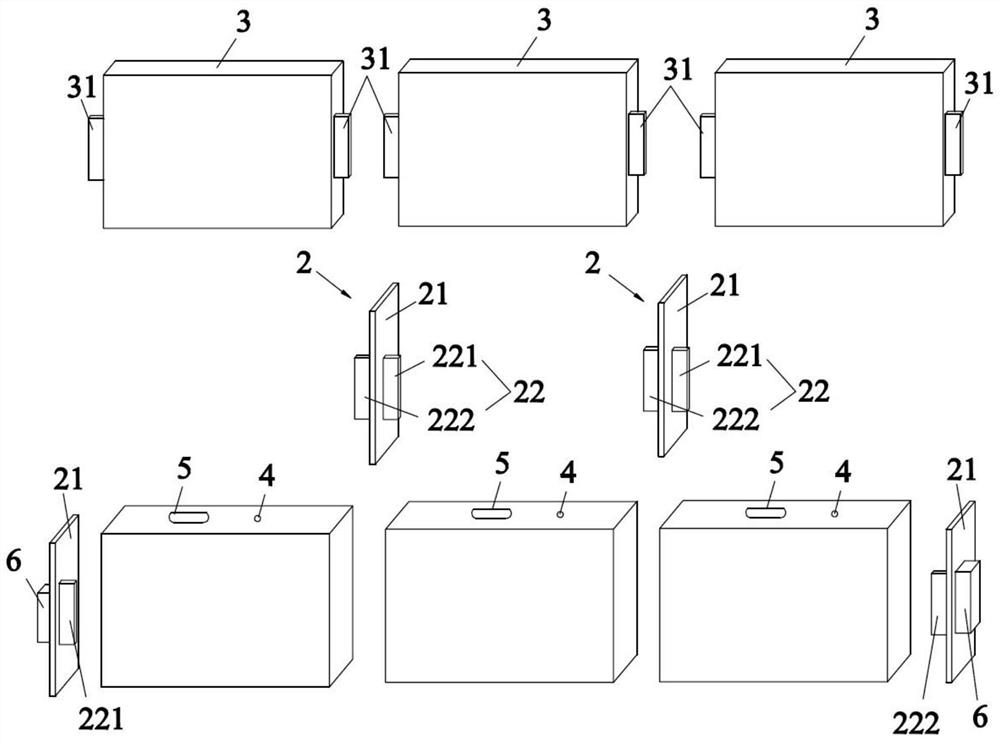

[0029] A battery structure, including several shells 1 with two ends connected, and conductive connectors 2 are fixed between adjacent shells 1, and the shells 1 and the connectors 2 are surrounded by several shells for accommodating batteries. 3, the adjacent cells 3 are electrically connected through the connector 2. Since the battery pack is connected in series, the voltage of the battery will increase with the number of cells inside the battery, resulting in a higher voltage at both ends of the battery. There is a risk of decomposition of the electrolyte inside the battery, which will affect the performance of the cells and even lead to battery safety. questions such as Figure 1~2As shown, therefore, a conductive connecting piece 2 is fixed between adjacent shells 1, and the connecting piece 2 adopts a metal plate structure, which is fixed on both ends of the shell 1 by welding, compared with insulating plates fixed on adjacent Between the shells 1, the shell 1 and the c...

Embodiment approach 2

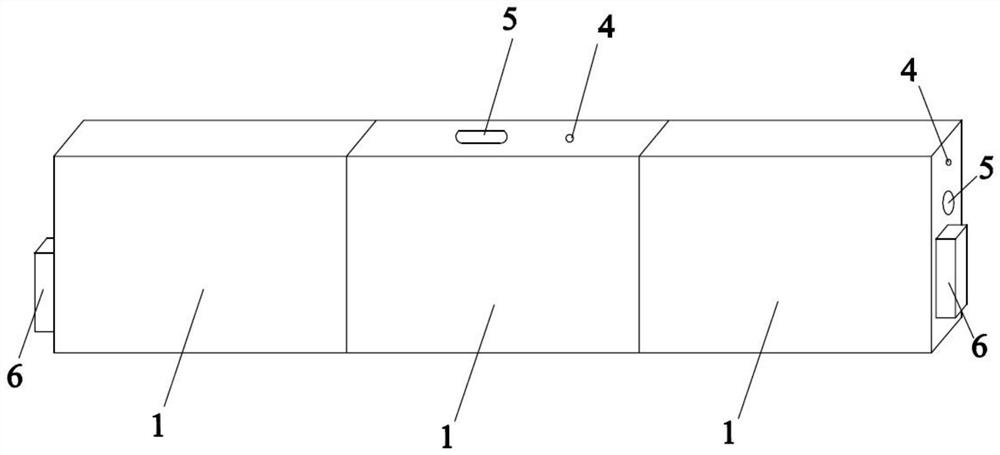

[0038] Such as Figure 3-5 As shown, the difference from the first embodiment is that the first connection part 221 and the second connection part 222 of this embodiment are arranged on both sides of the body 21 in a staggered manner, and correspondingly, the tabs 31 on both sides of the battery cell 3 are arranged in a staggered manner. At least one of a pole 6 , a liquid injection hole 4 and an explosion-proof valve 5 is provided outside the connectors 2 at both ends of the battery structure. The first connecting part 221 and the second connecting part 222 are staggered and placed on both sides of the body 21, which can avoid excessive stress concentration of the first connecting part 221 and the second connecting part 222 at the same position, and contribute to the service life of the connecting part 22. Correspondingly, in order to cooperate with the staggered structure of the first connecting part 221 and the second connecting part 222, the tabs 31 on both sides of the ba...

Embodiment approach 3

[0041] The difference from Embodiment 1 is that the material of the connecting portion 22 in this embodiment is the same as the current collector material of the pole piece of the electric core 3 to which it is electrically connected, openings are provided at both ends of the housing 1, and the adjacent housing 1 The openings are arranged correspondingly in sequence, the connecting piece 2 is arranged between the two openings, an insulating sheet is arranged under the liquid injection hole 4 and the explosion-proof valve 5, and the insulating sheet is provided with a hollow structure. In this embodiment, the connection part 22 connected to the negative electrode tab 31 is made of copper, and the connection part 22 connected to the positive electrode tab 31 is made of aluminum, so as to ensure that there is no pressure drop caused by material differences and reduce the pressure of the connection part. The production cost of 22; the openings of adjacent shells 1 correspond one by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com