Oil immersion type sulfur hexafluoride degradation treatment device and treatment method based on medium discharging

A technology of sulfur hexafluoride and processing device, which is applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve the problem of not realizing the decomposition and safe discharge of sulfur hexafluoride, the safety of reactor cooling, and the increase of reactor temperature, etc. problems, to slow down the aging and breakage process, increase lifespan, and improve energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

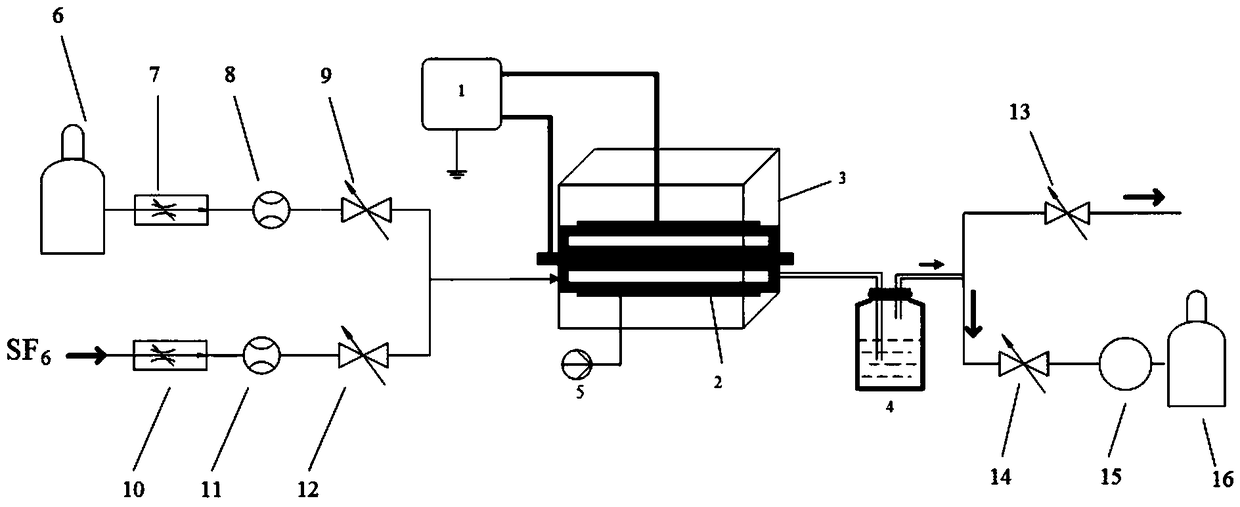

[0030] An oil-immersed sulfur hexafluoride degradation treatment device based on dielectric discharge, which includes a dielectric barrier discharge reactor 2, a high-frequency AC voltage source 1 connected to the external electrode and internal electrode of the dielectric barrier discharge reactor through wires; The air inlet at one end of the discharge reactor 2 is connected to the air inlet pipe; the air outlet at the other end is connected to the lye absorption pool 4; the dielectric barrier discharge reactor 2 is placed in the closed oil tank 3, which is filled with transformers Oil.

[0031] During the degradation process, due to the application of high voltage in the dielectric barrier discharge reactor, a dense plasma area will be generated in the discharge quartz tube. Problems such as pipe wall rupture and gas leakage pose threats to the stable operation of the equipment and the personal safety of operators. Therefore, by immersing the reactor in transformer oil, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com