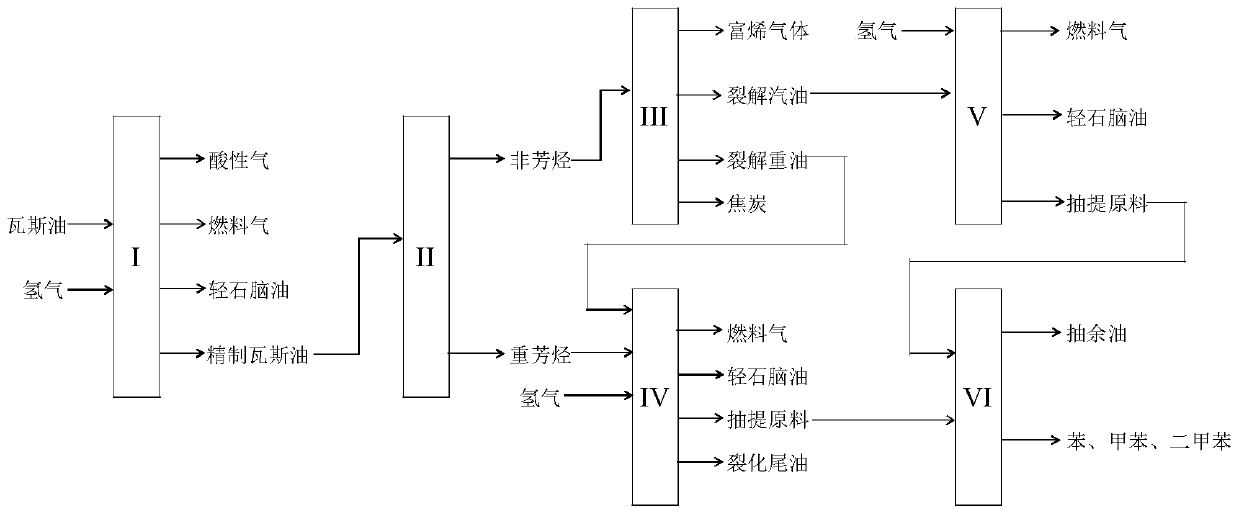

Integrated process method of producing low-carbon aromatic hydrocarbons and olefins from gas oil

A process method and technology of low-carbon aromatics, applied in the petroleum industry, hydroprocessing process, hydrocarbon oil treatment products, etc., can solve the problems of low yield of high value-added products, harsh process operating conditions, poor adaptability of raw materials, etc., to achieve The effect of strong raw material adaptability, low processing energy consumption, and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The paraffin-based gas oil from a refinery was used as the raw material, and the properties of the raw material are shown in Table 1.

[0031] Gas oil hydrotreating unit: the catalyst uses Ni-Mo-P / Al 2 o 3 (Based on the catalyst, MoO 3 Content 10wt%, NiO content 4wt%, P2 o 5 Content 2.5wt%, the balance is alumina), reaction conditions: temperature 360 ℃, pressure 8.5MPa, volume space velocity 1.2h -1 , The volume ratio of hydrogen to oil is 600:1.

[0032] Hydrocarbon adsorption and separation unit: the adsorbent is Cu-modified MCM-48 molecular sieve (CuO content 4wt%), and the separation conditions are: adsorption temperature 120°C, pressure 1.5MPa, mass space velocity 0.5h -1 .

[0033] Non-aromatic hydrocarbon cracking unit: adopt moving bed catalytic cracking process, cracking catalyst is P modified molecular sieve catalyst (based on catalyst, P 2 o 5 content of 4wt%, Y-type molecular sieve content of 40wt%, ZSM-5 molecular sieve content of 25wt%, and the b...

Embodiment 2

[0039] Raw material is identical with embodiment 1. The conditions of the gas oil hydrofining unit, hydrocarbon adsorption separation unit, heavy aromatic mild hydrocracking unit, pyrolysis gasoline hydrofinishing unit, and aromatics extraction unit are the same as in Example 1, and the conditions of the non-aromatics cracking unit are as follows:

[0040] The steam cracking process is adopted, and the cracking conditions are: cracking furnace temperature 790°C, outlet pressure 0.2MPa, steam / oil mass ratio 0.75, residence time 0.18 seconds.

[0041] Through the above process, its material balance is shown in Table 2.

Embodiment 3

[0043] The intermediate base gas oil from a refinery is used as raw material, and the properties of the raw material are shown in Table 1.

[0044] Gas oil hydrotreating unit: the catalyst uses Co-Mo / Al 2 o 3 (Based on catalyst, CoO content 8wt%, MoO 3 Content 6wt%, the balance is alumina), reaction conditions: temperature 375 ℃, pressure 9.0MPa, volume space velocity 1.0h -1 , The volume ratio of hydrogen to oil is 700:1.

[0045] Hydrocarbon adsorption separation unit: The adsorbent is Mg-modified bentonite (MgO content 3wt%), and the separation conditions are: adsorption temperature 140°C, pressure 0.5MPa, mass space velocity 0.4h -1 .

[0046] Non-aromatic hydrocarbon cracking unit: fixed-bed catalytic cracking process is adopted, and the cracking catalyst is a molecular sieve catalyst modified by Mg (based on the catalyst, the MgO content is 2.5wt%, the β-type molecular sieve content is 45wt%, the ZSM-5 molecular sieve content is 20wt%, and the balance is alumina), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com