Separation and pressure reduction combining system for suspended bed hydrocracking reaction products

A technology for hydrocracking and reaction products, which is applied in the multi-stage series refining process, etc., can solve the problems of rapid valve loss, pressure difference of core decompression components, uneconomical, etc., and achieves moderate operating conditions and good adaptability. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

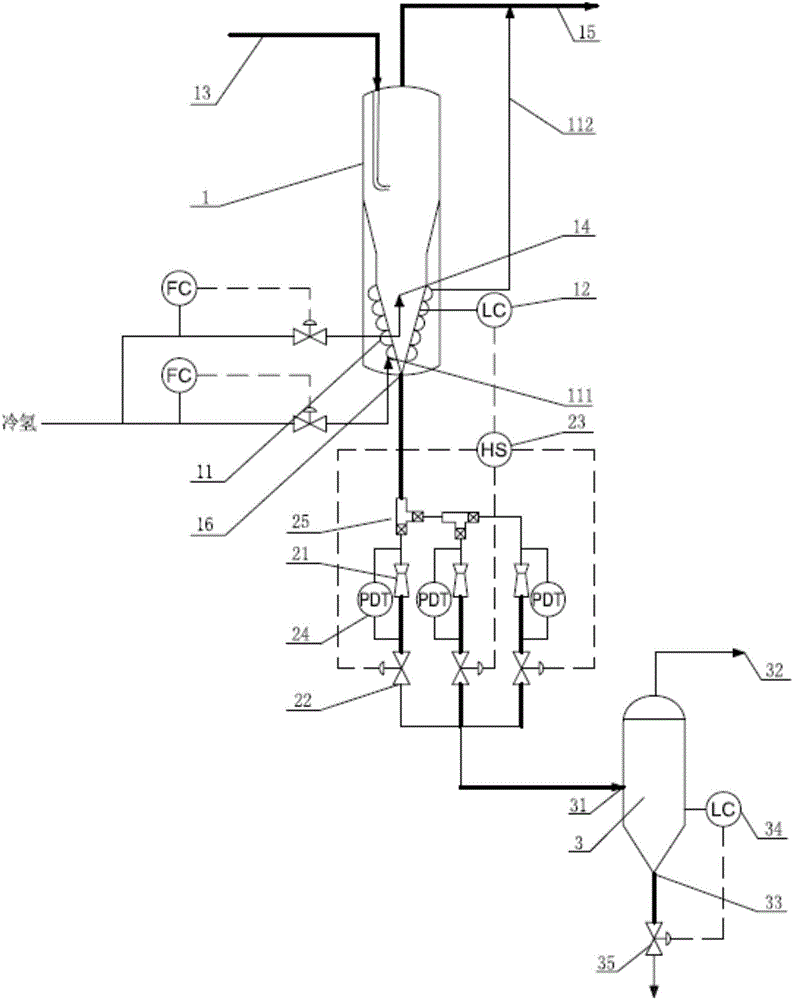

[0042] This embodiment provides a suspension bed hydrocracking reaction product separation and decompression combination system, such as figure 1 As shown, the system includes a hot high-pressure separator 1, a pressure reducing valve group, a hot low-pressure separator 3, a cooling coil 11, a first liquid level controller 12, a liquid level control selection switch (DCS) 23, and a hot low-pressure separator. Regulating valve 35 and second liquid level controller 34;

[0043] The hot high-pressure separator 1 is a jacketed device with a conical bottom structure, and a cooling coil 11 is arranged in the jacket. The cooling coil 11 is arranged on the periphery of the cone bottom of the hot high-pressure separator 1. The cooling coil 11 includes A cold hydrogen inlet 111 and a cold hydrogen outlet 112; the inside of the hot high-pressure separator 1 is a separation chamber, the upper part of which is provided with a suspension bed hydrocracking reaction product feed port 13, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com