Modifying method for naphtha and light hydrocarbon aromatization

A naphtha and aromatization technology is used in the production of aromatic hydrocarbons or clean gasoline components, and the production of high-quality liquefied gas. The effect of increased operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0061] (1) Preparation of composite carrier

[0062] Get 67.6 kilograms of pseudo-boehmite powder (production of Sasol company, Aluminum oxide content 74 mass %), under stirring condition, join 300 kilograms concentration in the nitric acid aqueous solution of 1.1 mass %, after stirring for 2 hours peptization, add 55.0 kilograms of silica / alumina molar ratio is the HZSM-5 zeolite of 60 powder (91% zeolite content), stirred at high speed for 3 hours. Drop the prepared slurry into an oily ammonia column containing 8% by mass of ammonia water, take out the wet bulb formed in the oily ammonia column, dry at 60°C for 10 hours, and roast at 550°C for 3 hours to obtain a composite carrier, which is a composite carrier containing HZSM- 5 zeolite 50% by mass alumina pellets.

[0063] (2) Preparation of catalyst

[0064] Get 50 kilograms of composite carriers, use 50 kilograms containing 4.7 mass % of zinc nitrate, 3.0 mass % of mixed rare earth chloride (wherein lanthanum oxide ac...

example 2

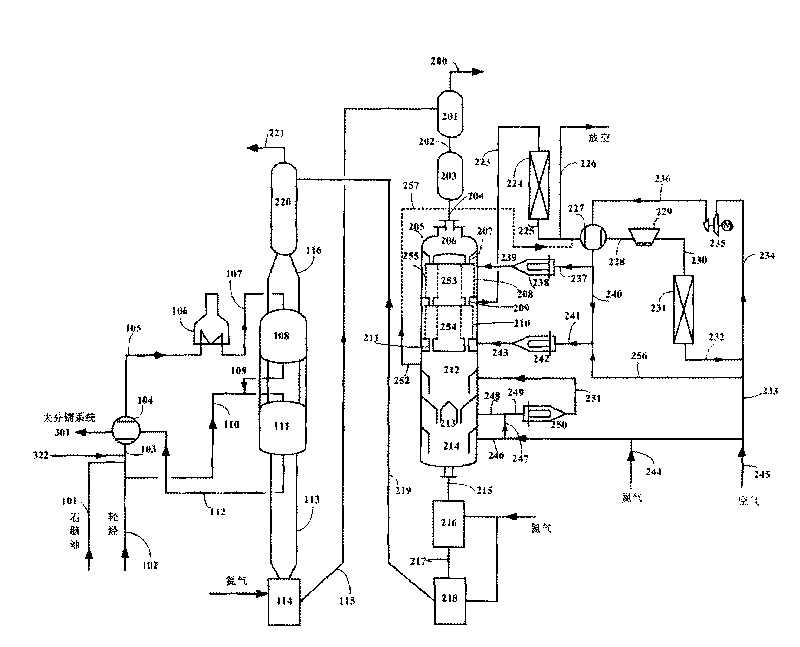

[0067] according to figure 1The technological process shown, uses catalyst A, carries out the aromatization reaction test with the straight-run naphtha shown in 60 mass % table 1 and the light hydrocarbon shown in 40 mass % table 2 as raw material, reacts in the cycle of hydrogen-containing gas Under conditions, the content of hydrogen in the hydrogen-containing gas is 21.4% by volume, and the volume ratio of hydrogen to naphtha is 150. Control the raw material inlet temperature of each reactor to be 400°C, the reaction pressure to be 0.5MPa, and the mass space velocity of raw material feed to be 0.5h -1 . The light hydrocarbons are equally divided into two streams, one stream is mixed with straight-run naphtha and enters the first reactor 108 through the heating furnace 106, and the other stream of light hydrocarbons directly enters the second reactor 111 in the form of cold material. The pressure of the regenerator is 0.7MPa, the inlet temperature of regeneration gas in th...

example 3

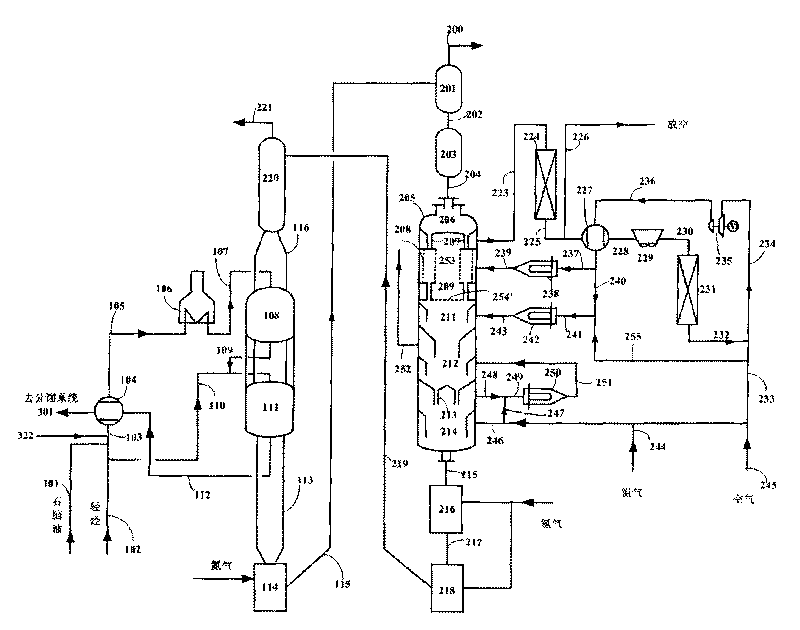

[0069] according to figure 2 The technological process shown, uses catalyst A, carries out the aromatization reaction test with the straight-run naphtha shown in 60 mass % table 1 and the light hydrocarbon shown in 40 mass % table 2 as raw material, reacts in the cycle of hydrogen-containing gas Under conditions, the content of hydrogen in the hydrogen-containing gas is 22.0% by volume, and the volume ratio of hydrogen to naphtha is 150. The operating conditions of the reaction part and the regenerator, the residence time of the ungenerated catalyst in the coking zone, the temperature of the drying zone and the cooling zone are all the same as in Example 2, the difference is that the regeneration gas enters the two-stage coking zone from the middle, and the test results are shown in table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com