Method and system for producing heavy naphtha rich in light aromatics from heavy aromatics

A technology for heavy naphtha and heavy aromatics, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problem of low purity of light aromatics and achieve the effect of high aromatics content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

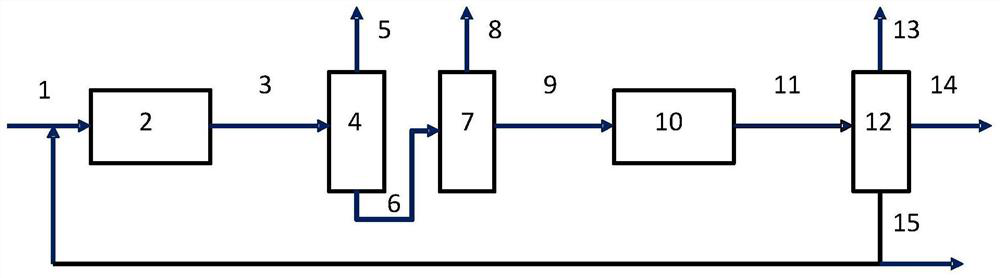

[0129] Process flow: In this embodiment, the process flow for producing heavy naphtha rich in light aromatic hydrocarbons by catalytic diesel oil is as follows: figure 1 shown. Including the separation of fractions including dry gas, light hydrocarbons, heavy naphtha fractions and heavy tail oil after catalytic diesel is hydrorefined, separated from impurities, and hydrocracked, and part of the heavy tail oil > 210°C is recycled back to the hydrotreating unit. The raw material oil is the same as that of comparative example 1 raw material oil 1 (catalytic diesel oil).

[0130] catalyst:

[0131] The hydrofinishing catalyst is the same as the hydrofinishing catalyst A1 of comparative example 1, and the hydrofinishing catalyst A1' after presulfurization under the same conditions. The hydrorefining catalyst and reaction conditions are the same as in Comparative Example 1 (see Table 2).

[0132] Hydrocracking catalyst B2:

Embodiment 2

[0150] Process flow: In this embodiment, the process flow for producing heavy naphtha rich in light aromatic hydrocarbons by catalytic diesel oil is as follows: figure 1 shown. Including the separation of fractions including dry gas, light hydrocarbons, heavy naphtha fractions and heavy tail oil after catalytic diesel is hydrorefined, separated from impurities, and hydrocracked, and part of the heavy tail oil > 210°C is recycled back to the hydrotreating unit. The properties of the raw materials are shown in Table 10. The catalytic diesel aromatics content of the raw material oil 2 is 79.50wt%.

[0151] catalyst:

[0152] Hydrofining Catalyst A2: 100g of pseudo-boehmite, add 2g of fenugreek powder, 9ml of nitric acid and 60ml of water, knead into a dough, extrude, keep at room temperature for 24h, dry at 100°C for 12h, and roast at 550°C for 3h in air atmosphere A hydrorefining catalyst carrier is obtained. 10.32g of nickel nitrate hexahydrate, 20.96g of ammonium molybdate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com