Environment-friendly rubber oil and preparation method thereof

An environment-friendly rubber oil and rubber oil technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrogenation process, etc., can solve the problems of poor compatibility of styrene-butadiene rubber and low content of aromatic hydrocarbons, and achieve mild operating conditions and low raw material Easy to obtain, good effect at low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The hydrogenation reaction catalysts are loaded into the fixed-bed reactors of the first-stage hydrogenation and the second-stage hydrogenation respectively for pre-sulfurization, and the pre-sulfurized catalysts are ready for use. The hydrogenation catalyst is HRK558.

[0034] The pre-sulfurization process conditions are: use carbon disulfide CS accounting for 2% of the weight of the vulcanized oil 2 And the remaining kerosene is used as vulcanized oil, and hydrogen gas is passed under the hydrogen partial pressure of 6MPa, the vulcanization temperature is 280°C, and the space velocity is 0.5h -1 , the volume ratio of hydrogen to oil is 1000:1, and the vulcanization time is 50 hours.

[0035] With the boiling range of 280~530℃ Karamay naphthenic vacuum distillate oil as raw material, its %C A is 10, %PCA is 9.7, preheated to 60°C, enters the fixed bed reactor for hydrogenation reaction, the hydrogenation process conditions are: reaction pressure 5MPa, reaction temper...

Embodiment 2~9

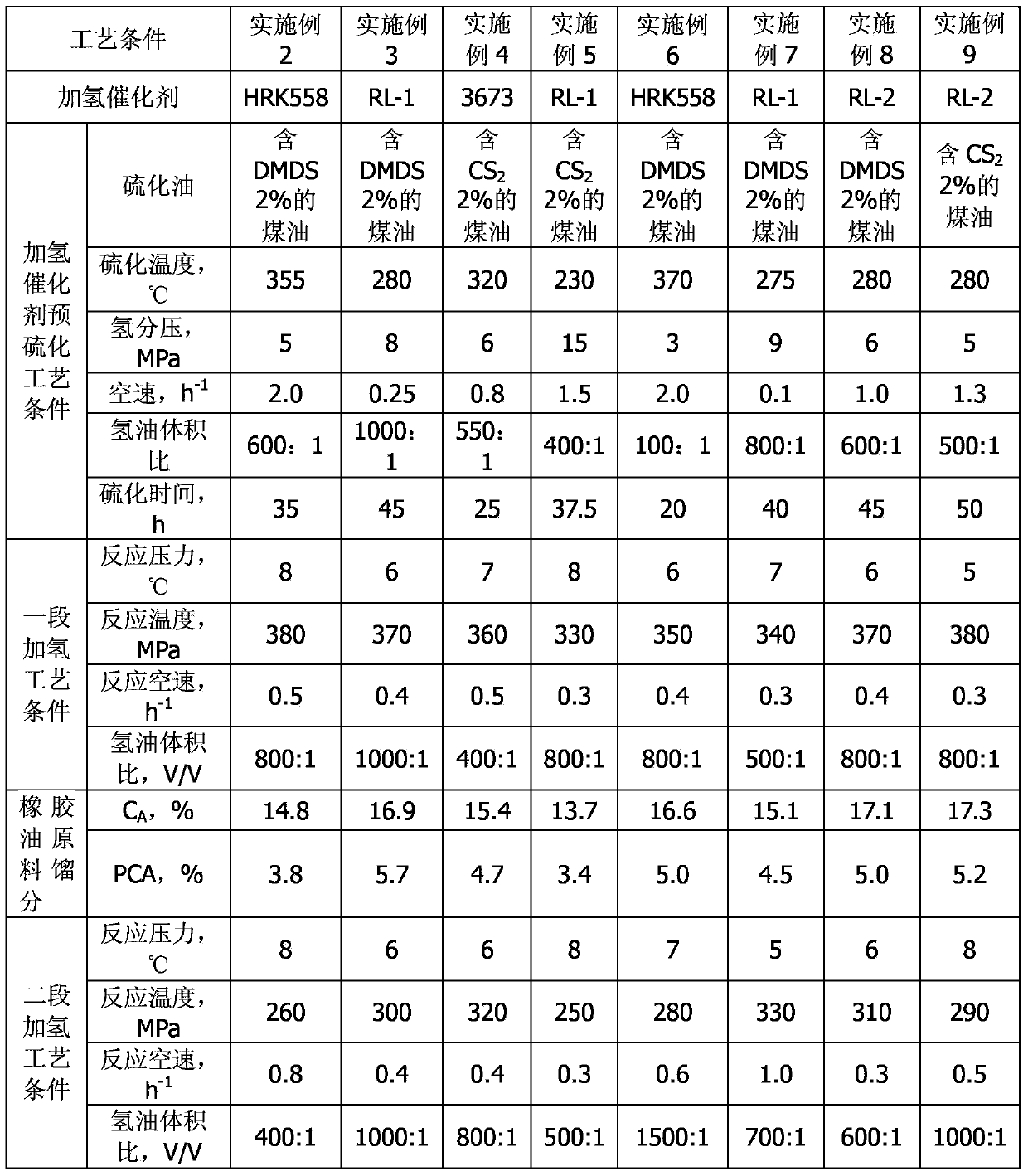

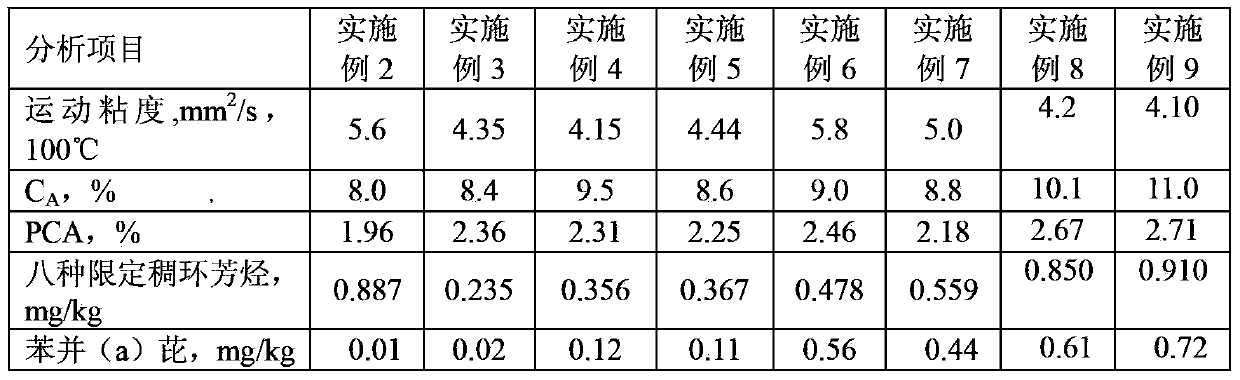

[0038] According to the raw materials, preparation process and environmental protection rubber operation oil property analysis method of Example 1, the preparation of Examples 2 to 9 is carried out, wherein the preparation process conditions of "one-stage hydrogenation-two-stage hydrogenation" are shown in Table 1, after one-stage hydrogenation The cutting boiling range of the resulting oil and the cutting process conditions of the resulting oil after the second-stage hydrogenation are the same as in Example 1, and the properties of the prepared environmentally friendly rubber operating oil are shown in Table 2.

[0039] Table 1 embodiment preparation process conditions

[0040]

[0041] Table 2 The properties of environment-friendly rubber oil prepared by different processes

[0042]

[0043] The present invention is not limited by the above examples, and the production process parameters can be optimized according to the above technical solutions and actual production ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com