Preparation method for high-capacity lithium ion battery positive electrode tab

A technology of lithium ion battery and positive electrode sheet, which is applied in electrode manufacturing, battery electrode, electrolyte storage battery manufacturing and other directions, can solve the problems of low charging voltage and cumbersome manufacturing process, and achieve high compaction density, simple process and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

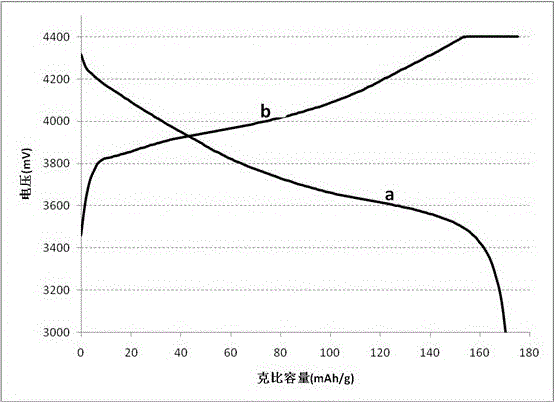

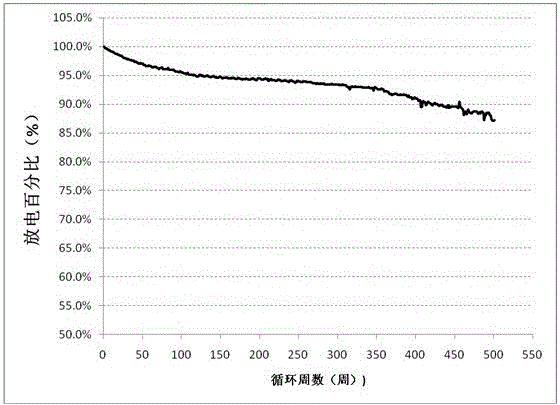

Image

Examples

Embodiment 1

[0042] 1. Prepare positive electrode slurry according to the following steps

[0043] Weigh the following solid raw materials according to the mass fraction ratio: 94.5% lithium cobaltate, 2% SP, 1% VGCF, 2.5% Solef5130, and then weigh the organic solvent NMP whose mass fraction is 1 / 3 of the sum of the above solid raw materials; and Put each solid raw material into a vacuum oven at 120°C for 4 hours to dry, and the vacuum is -0.1 MPa; then add lithium cobaltate, SP, VGCF and Solef5130 into the mixing tank of the planetary mixer, and stir at high speed for 60 minutes; then add 60% of Organic solvent NMP, vacuum high-speed stirring for 120min, stirring temperature is 45 degrees; then add 30% organic solvent NMP, vacuum high-speed stirring for 60min, stirring temperature is 30 degrees; finally the remaining 10% organic solvent NMP, slurry viscosity adjustment, viscosity The range is 5000-8000 cPa.

[0044] 2. Prepare negative electrode slurry according to the following steps

...

Embodiment 2

[0060] The steps and procedures for preparing the assembled battery in this example are the same as in Example 1, except that the mass ratio of the positive electrode is: 95% lithium cobalt oxide, 2% SP, 1% VGCF, 2% Solef5130, and the mass ratio of the negative electrode is: 95% % silicon-carbon alloy material, 1% SP, 1.3% CMC, 2.2% SBR, and the addition of cyclohexylbenzene (CHB) in the electrolyte is 3%.

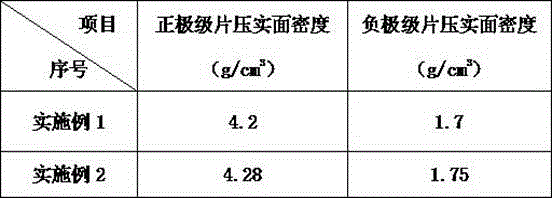

[0061] The table below shows the compacted densities of the battery-grade sheets of Example 1 and Example 2.

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com