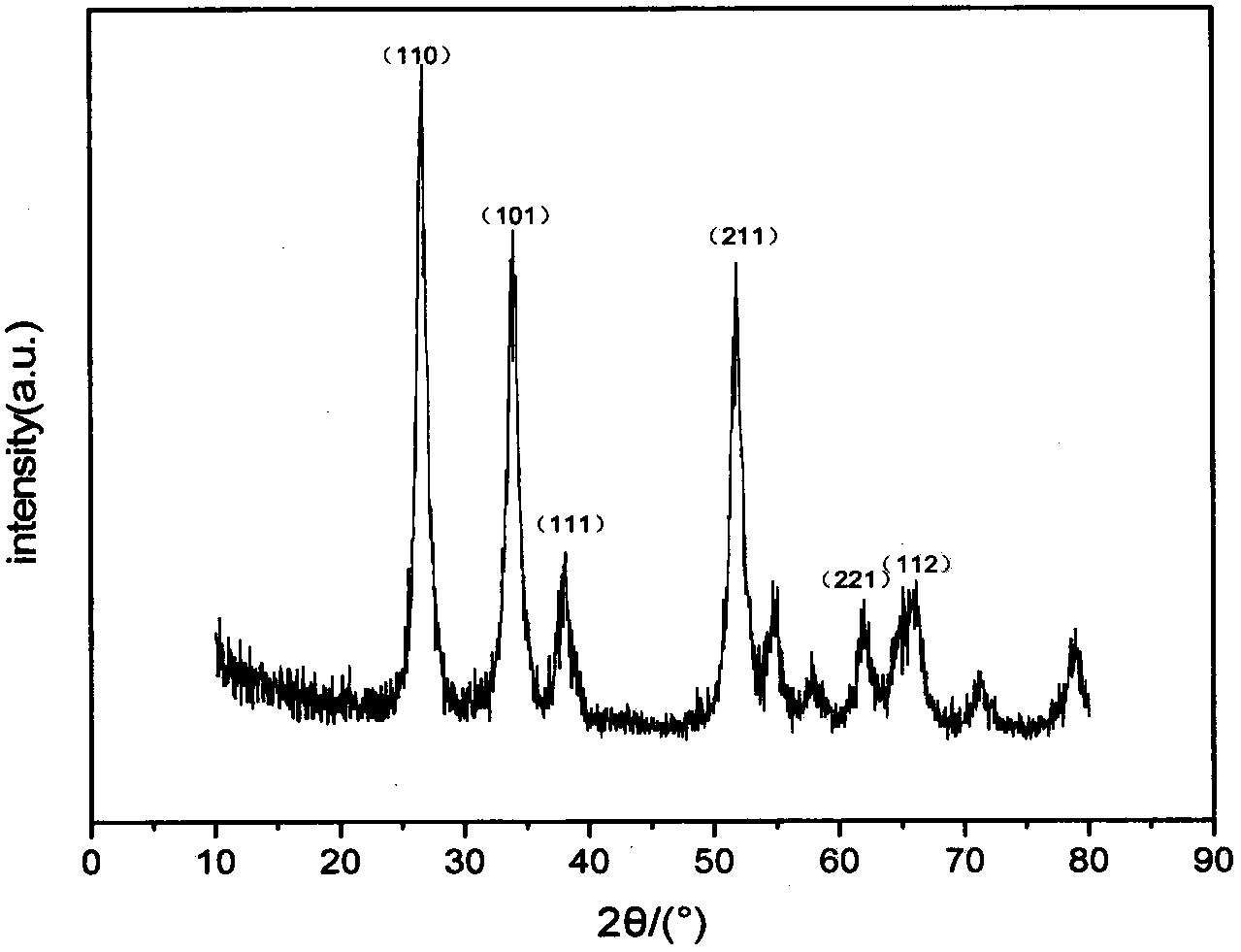

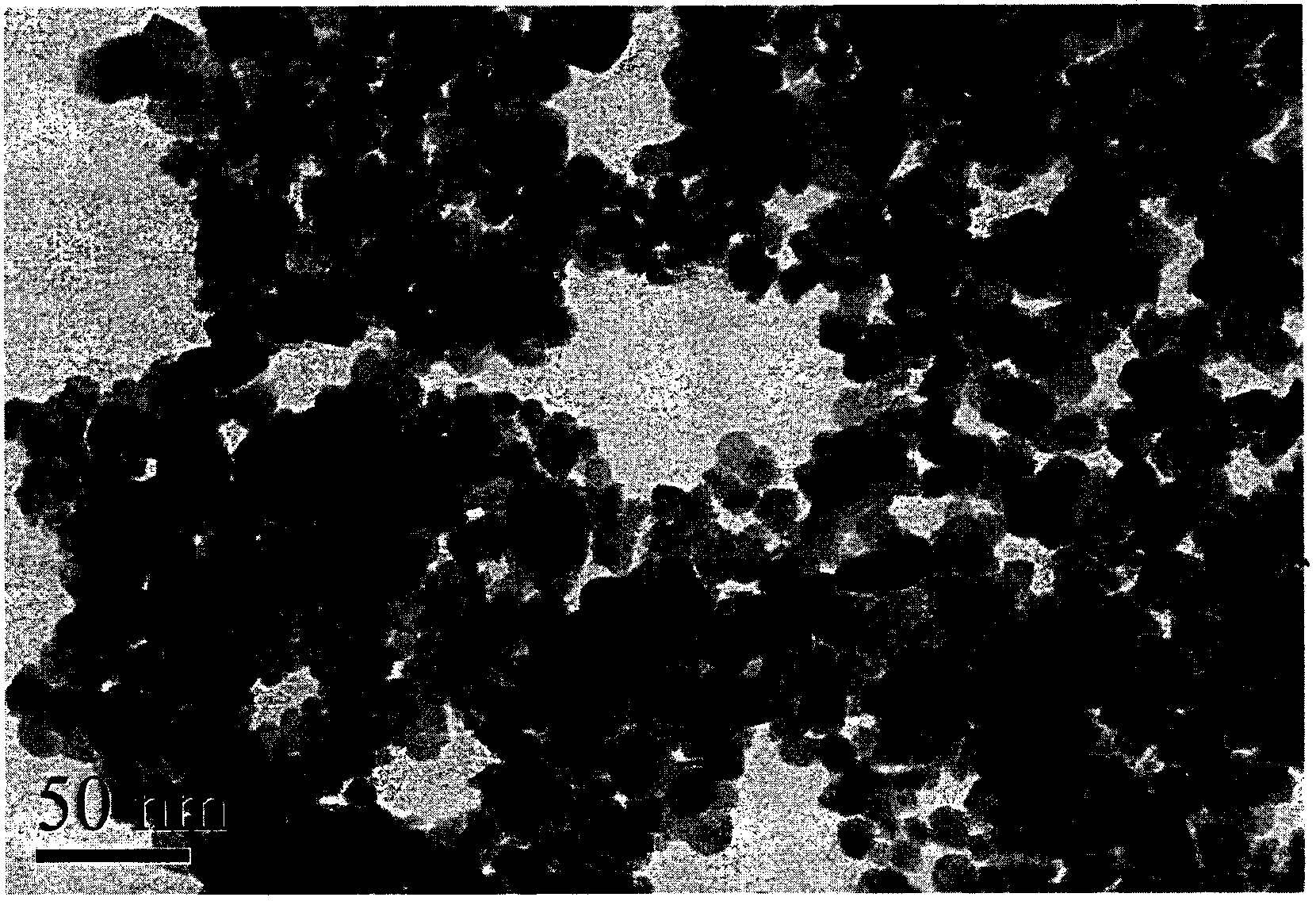

Method for preparing monodisperse antimony-doped tin oxide nano-powder

A technology of antimony-doped tin oxide and nanopowder, which is applied in the direction of tin oxide and nanotechnology, which can solve the problems of wide particle size distribution and easy agglomeration, and achieve the effects of reducing agglomeration, increasing dispersion and preventing hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1 Weigh 1g of citric acid and dissolve in 500mL of deionized water, add ethylene glycol to form a solution; add 10.26gSbCl 3 Dissolve in the above mixed solution, then add 52.59g SnCl while stirring 4 ·5H 2 O, finally weigh 0.6g of urea and add it to the solution under constant temperature stirring.

[0035] Step 2 Heat the mixed solution oil bath obtained in Step 1 to 90° C., heat it for 5 hours with strong magnetic stirring, and let it stand for 20 hours after precipitation is formed.

[0036] Step 3 Use a Buchner funnel to suction filter the product of step 2 standing still, wash it with distilled water 5 times during suction filtration, and add a small amount of 0.05mol / L dilute nitric acid solution dropwise, adjust the pH to 3, and then wash with absolute ethanol 4 times, get light yellow precursor;

[0037] In step 4, the light yellow precursor filter cake obtained in step 3 is placed in a vacuum drying oven at 90°C for 24 hours, taken out and ground, and heat-treat...

Embodiment 2

[0041] Step 1 Weigh 1g of tartaric acid and dissolve it in 500mL of deionized water, add ethylene glycol to form a mixed solution; add 3.42g of SbCl 3 Dissolve in the above mixed solution, then add 52.59g SnCl while stirring 4 ·5H 2 O, finally weigh 0.6g of urea and add it to the solution under constant temperature stirring.

[0042] Step 2 Heat the mixed solution oil bath obtained in Step 1 to 90° C., heat it for 5 hours with strong magnetic stirring, and let it stand for 12 hours after precipitation is formed.

[0043] Step 3 Use a Buchner funnel to suction filter the product of step 2 standing still, wash with distilled water 4 times during suction filtration, and add a small amount of 0.02mol / L dilute nitric acid solution dropwise, adjust the pH to 3, and then wash with absolute ethanol 3 times, get light yellow precursor;

[0044] In step 4, the light yellow precursor filter cake obtained in step 3 is placed in a vacuum drying oven at 90°C for 48 hours, taken out and ground, and...

Embodiment 3

[0046] Step 1 Weigh 1g of citric acid and dissolve it in 500mL of deionized water, add ethylene glycol to form a solution; add 17.11gSbCl 3 Dissolve in the above mixed solution, then add 52.59g SnCl while stirring 4 ·5H 2 O, finally weigh 0.8g of urea into the solution under constant temperature stirring conditions.

[0047] Step 2 Heat the mixed solution oil bath obtained in Step 1 to 90° C., heat it for 5 hours with strong magnetic stirring, and let it stand for 24 hours after precipitation is formed.

[0048] Step 3 Use a Buchner funnel to suction filter the product of step 2 standing still, wash it with distilled water 3 times during suction filtration, and add a small amount of 0.04mol / L dilute nitric acid solution dropwise, adjust the pH to 3, and then wash with absolute ethanol 2 times, get light yellow precursor;

[0049] In step 4, the light yellow precursor filter cake obtained in step 3 is placed in a vacuum drying oven at 90°C for 48h, taken out and ground, and heat-treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com