Novel gasoline refueling system for automobile

A technology for refueling systems and automobiles, which is applied to vehicle parts, large containers, containers, etc., and can solve the problems of gravity valve immersion, closure, and design limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

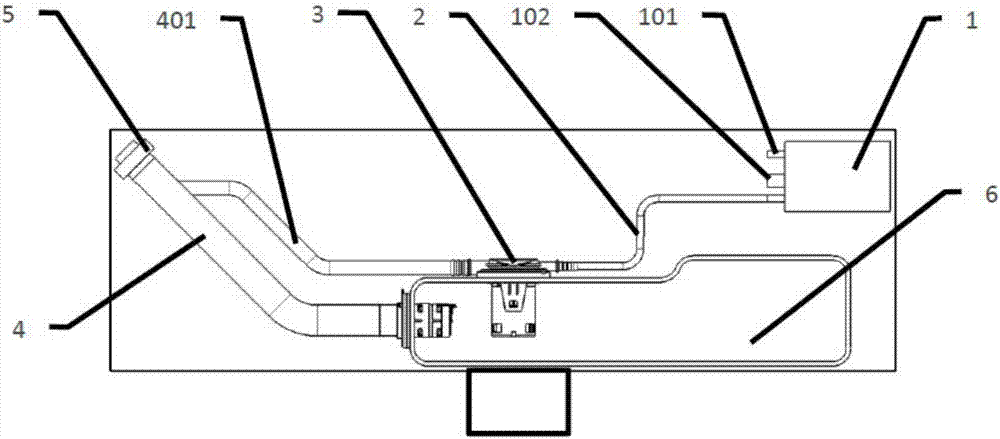

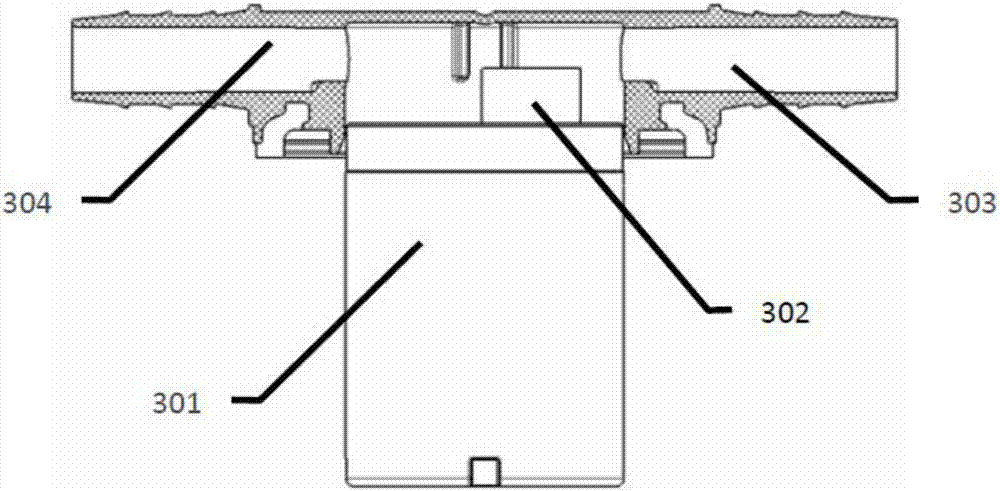

[0012] Such as figure 1 with 2 As shown, the present invention provides a novel automobile gasoline refueling system, which includes a fuel tank 6 and a carbon canister 1, wherein: a combined gravity valve 3 is arranged in the fuel tank 6, and the combined gravity valve 3 includes: a large flow gravity 301 Valve and small flow gravity valve 302, the closing plane of described small flow gravity valve 302 is higher than the closing plane of described large flow gravity valve 301, and described large flow gravity valve 301 is connected with described fuel tank 6; channel 303 and refueling flow channel 304 , and the carbon canister flow channel 303 is connected to the carbon canister 1 , and the refueling flow channel 304 is connected to the fuel filler pipe exhaust pipe 401 .

[0013] The realization of the present invention through the combined gravity valve is to simultaneously realize the control of the refueling process and the evaporative emission control process through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com