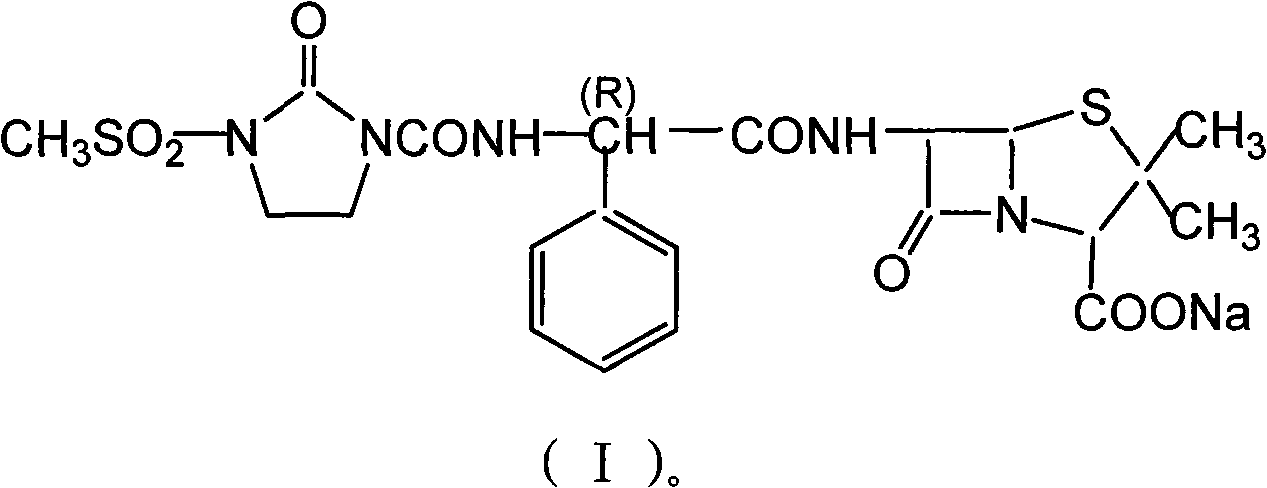

Preparation method of mezlocillin sodium solvent crystal

A technology of mezlocillin sodium and mezlocillin acid, applied in the direction of effective components of heterocyclic compounds, organic chemistry, antibacterial drugs, etc., can solve the problems of low production efficiency, difficult recovery of reaction crystallization mixed solvent, low purity, etc. Achieve obvious implementation value and society, low production cost and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The feed molar ratio is mezlocillin acid: sodium isooctanoate=1.0:1.2, the reaction solvent is acetone, and the poor solvent is isopropanol.

[0033] Weigh 53.9 g (0.1 mol) of mezlocillin acid, put it into a 250 ml beaker, add 118.6 g of acetone, and stir until completely dissolved. Then weigh 19.9 g (0.12 mol) of sodium isooctanoate, put it into a 2000 ml beaker, add 150.9 g of acetone, and stir. The acetone solution of mezlocillin acid was slowly added to the acetone solution of sodium isooctanoate at 20°C, and after 0.5 hours of reaction, 1500 g of isopropanol was slowly added. A white solid was continuously separated out, the addition of isopropanol was completed, and the mixture was stirred for 1 hour. After filtering, the filter cake was washed with 50 g×2 isopropanol, and dried with dry air at 60° C. for 6 hours to obtain 53.3 g of mezlocillin sodium white solid, with a yield of 95.0% and a content of 98.0% (HPLC). The acetone and isopropanol in the filtrate are sepa...

Embodiment 2

[0035] The feed molar ratio was changed to 1.0:2.0 of mezlocillin acid: sodium isooctanoate, the reaction solvent was acetone, and the poor solvent was isopropanol, and the dosage was 100 times the mass of mezlocillin acid. The actual dosage is 53.9 grams (0.1 mol) of mezlocillin acid, dissolved in 432 grams of acetone, 33.2 grams (0.2 mol) of sodium isooctanoate dissolved in 265 grams of acetone, and 5390 grams of isopropanol. The preparation steps under other conditions are the same as those in the example 1. Obtained 54.0 g of white solid of mezlocillin sodium, with a yield of 96.2% and a content of 98.1% (HPLC).

Embodiment 3

[0037] The feed molar ratio is mezlocillin acid: ethyl acetoacetate sodium 1.0:1.2, the reaction solvent is acetone, the poor solvent is isopropanol, and the dosage is 60 times the mass of mezlocillin acid. The actual dosage is 53.9 grams (0.1 mol) of mezlocillin acid, dissolved in 432 grams of acetone, 18.2 grams (0.12 mol) of ethyl acetoacetate dissolved in 146 grams of acetone, and 3234 grams of isopropanol. The preparation steps under other conditions are the same. Example 1. 51.2 g of mezlocillin sodium white solid was obtained, with a yield of 91.3% and a content of 97.4% (HPLC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com