Process for mfg. industrial phosphoric acid by low-grade phosphorus deposit in hydrogen chloride decomposition

A manufacturing industry, low-grade technology, applied in phosphoric acid, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of impurity content failing to meet industrial-grade standards, calcium chloride has little use, and concentration is thin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

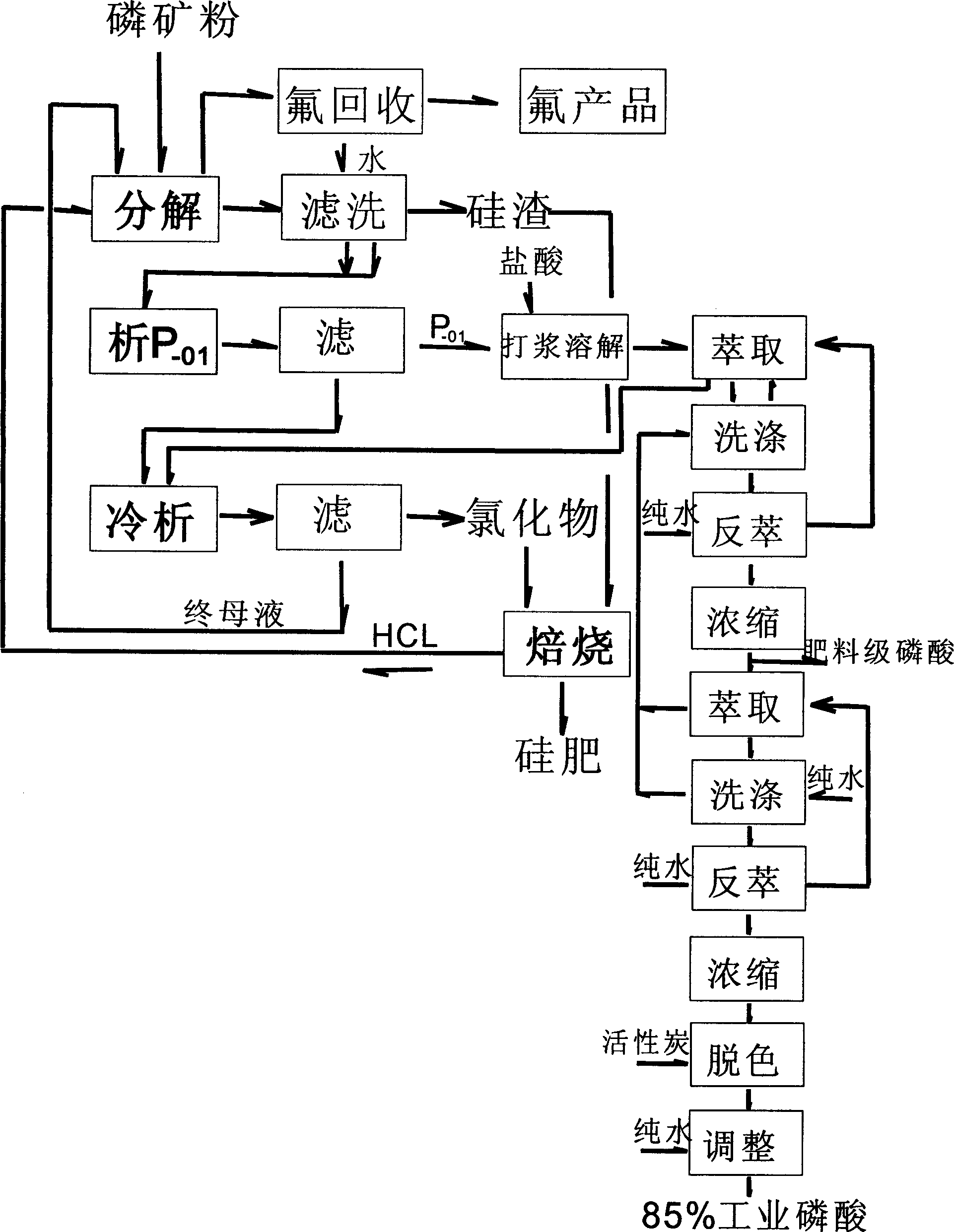

[0025] according to figure 1 The process flow of hydrochloric acid decomposition of low-grade phosphate rock to produce industrial phosphoric acid

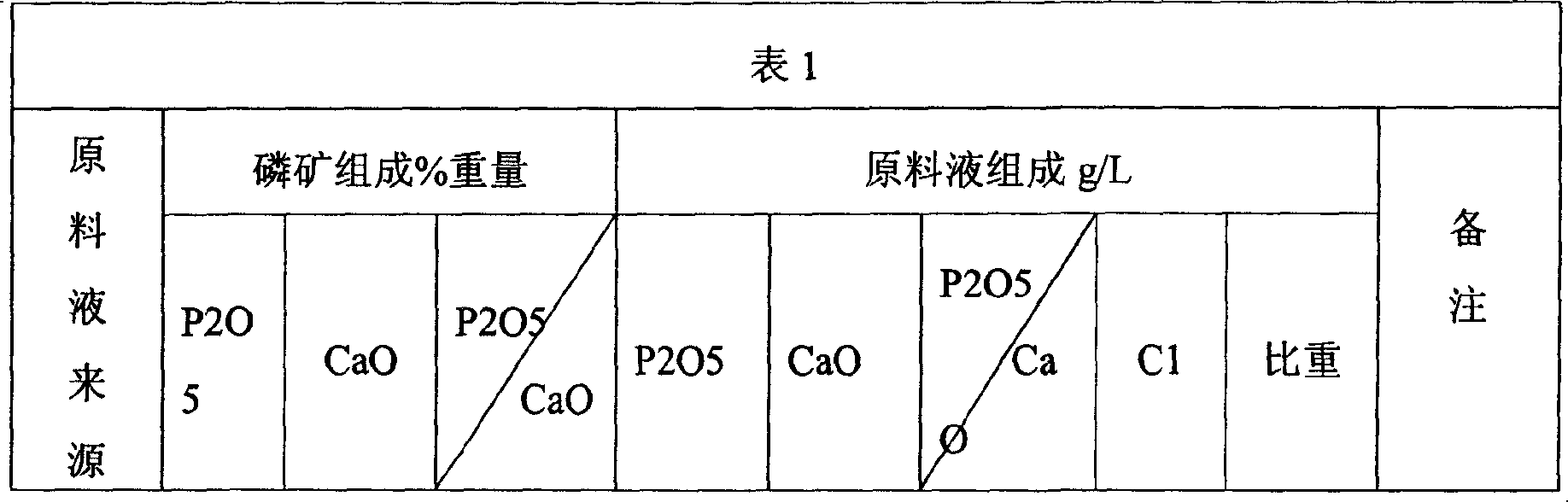

[0026] name

[0027] 1000 grams of phosphate rock powder, passed through 40 meshes, decomposed by hydrochloric acid (the final mother liquor established by circulation operation), discharged 150 grams of dry silicon slag, and analyzed at 10±2°C for P- o1 1182 g (its P 2 o 5=19.5%), 3 ± 2 ℃ cold analysis chloride 1890 grams, P- 01 Add 591 grams of 30% concentrated hydrochloric acid with hydrochloric acid in a weight ratio of 2:1, heat and stir the beating agent to completely dissolve, extract the beating liquid three times at 15-30°C with TBP: kerosene=1:1 extractant, the following extractant Wash the organic phase twice with the extraction washing water + raffinate water phase, each time the water volume is 3% of the volume of the extracted organic phase, the washing temperature is 15 ° C, and the washing time is 4 m...

Embodiment 2

[0031] according to figure 1 The process flow of hydrochloric acid decomposition of low-grade phosphate rock to produce industrial phosphoric acid

[0032] name

[0033] 1000 grams of phosphate rock powder, passed through 40 meshes, decomposed by hydrochloric acid (the final mother liquor established by circulation operation), discharged 341 grams of dry silicon slag, and analyzed at 20±2°C for P- o1 745 grams (including P 2 o 5 =19.2%), -15 ± 2 ℃ cold analysis chloride 1290 grams, P- 01 Add 373 grams of 30% concentrated hydrochloric acid in a weight ratio of 2:1 with hydrochloric acid, heat and stir the beating agent to completely dissolve, use TBP+kerosene=1:1 extractant 2980ml, extract the beating liquid three times under normal temperature, and extract and wash with the following extractant: Wash the organic phase twice with water + raffinate water phase, the amount of water is 4% of the volume of the extracted organic phase, the washing temperature is 40°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com