Separation method applicable to both propylene hydration and acetone hydrogenation for isopropyl alcohol preparation

A technology of propylene hydration and separation method, which is applied in the separation/purification of hydroxyl compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., and can solve problems such as failure to achieve effective separation and purification of high-purity isopropanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

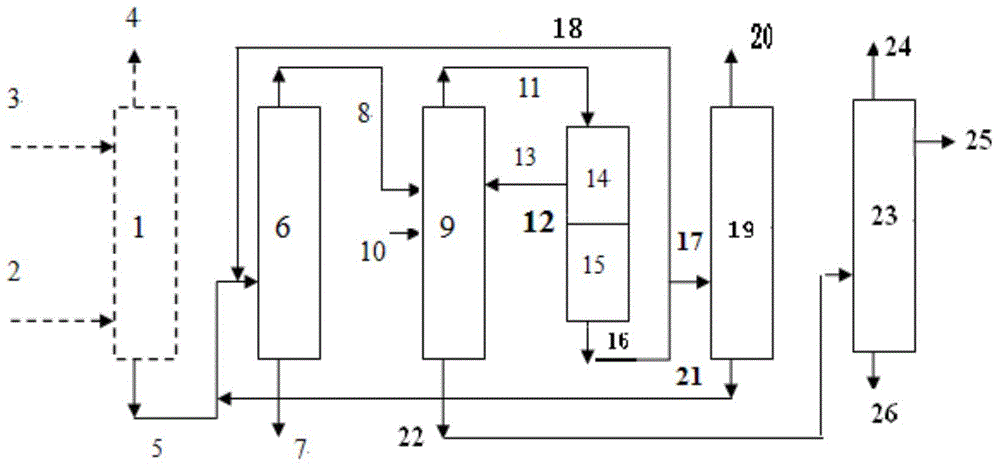

[0060] Propylene hydrated isopropanol crude alcohol 2 is treated in the deether tower 1, isopropanol and propylene dimer 4 are discharged from the top of the deether tower, and the bottom material 5 of the deether tower enters the concentration tower 6. Feed composition: water injection 3 is 70000 kg / hour; isopropanol is 12500 kg / hour; n-propanol is 125 kg / hour; 4-methylpentanol is 125 kg / hour; acetone is 32 kg / hour. The waste water 7 at the bottom of the concentration tower 6 is treated with cationic resin and anion resin and reused. The top material 8 of the concentration tower 6 enters the dehydration tower 9 from the 9th theoretical plate. The top material 8 is azeotropic alcohol (90# alcohol ). The dehydration tower 9 is provided with 35 theoretical plates, and the dehydrating agent is n-hexane. The material 11 at the top of the dehydration tower enters the water separation tank 12 after being cooled, the material 11 at the top of the dehydration tower is mainly a ternar...

Embodiment 2

[0062] Propylene hydration isopropanol crude alcohol production and composition are the same as in Example 1. Acetone hydrogenation isopropanol crude alcohol composition: 5000 kg / hour of isopropanol; 50 kg / hour of water; 6 kg / hour of isopropyl ether; 50 kg / hour of acetone; 50 kg / hour of 4-methylpentanol. The 11th theoretical plate of this material enters the dehydration tower 9. 17200 kg / hour of 99.99% m / m isopropanol is obtained in the side line of the weight-removing tower 23. Under this working condition, the heating load of the dehydration tower 9 is 14580 kilowatts, and the heating load of the weight removal tower 23 is 10090 kilowatts.

Embodiment 3

[0064] Acetone hydrogenation crude isopropanol enters dehydration tower 9 from the 9th theoretical plate, and other conditions are identical with embodiment 2, and weight removal tower 23 side line obtains 99.99% m / m isopropanol 17200 kilograms / hour. Under this working condition, the heating load of the dehydration tower 9 is 15380 kilowatts, and the heating load of the weight removal tower 23 is 10100 kilowatts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com