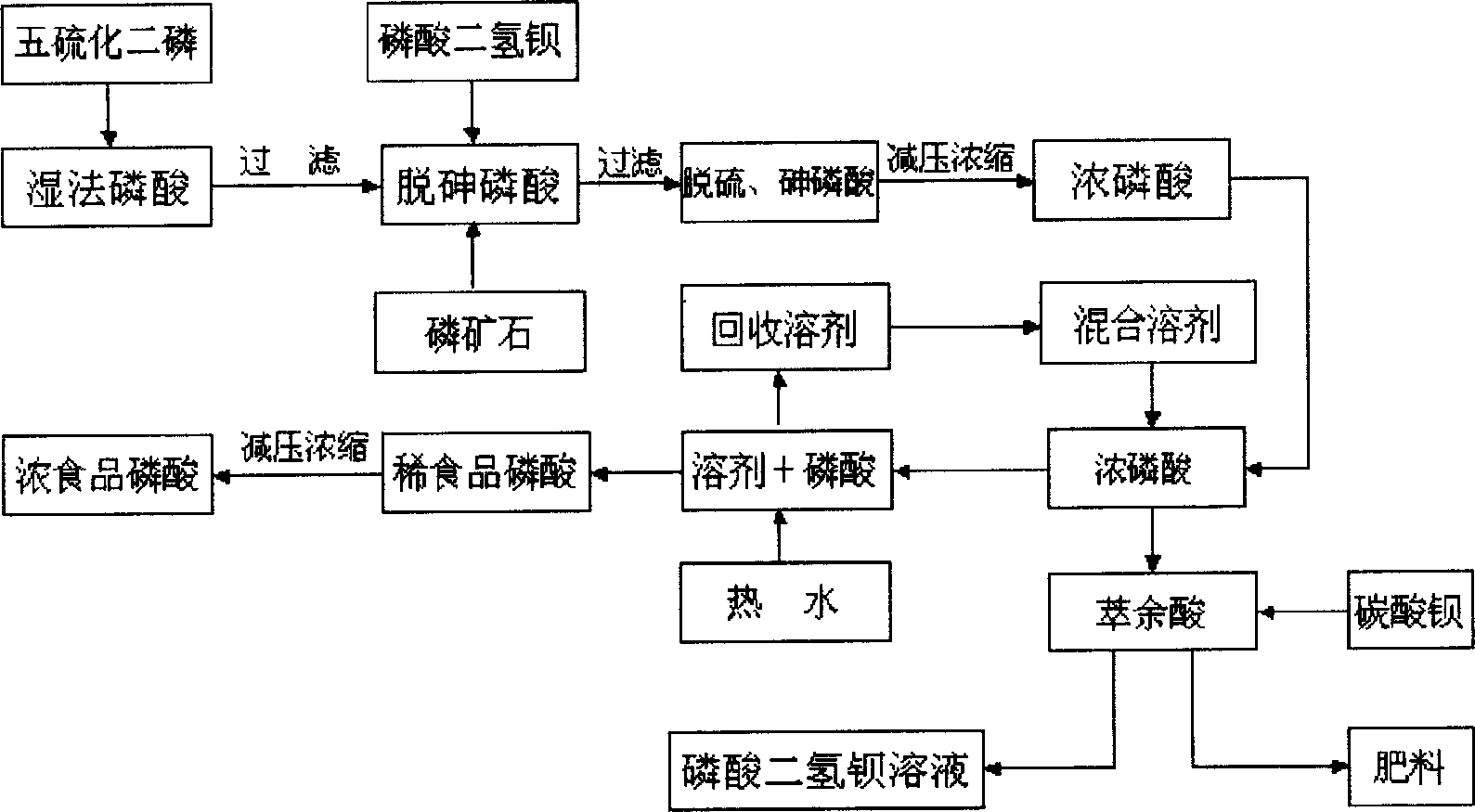

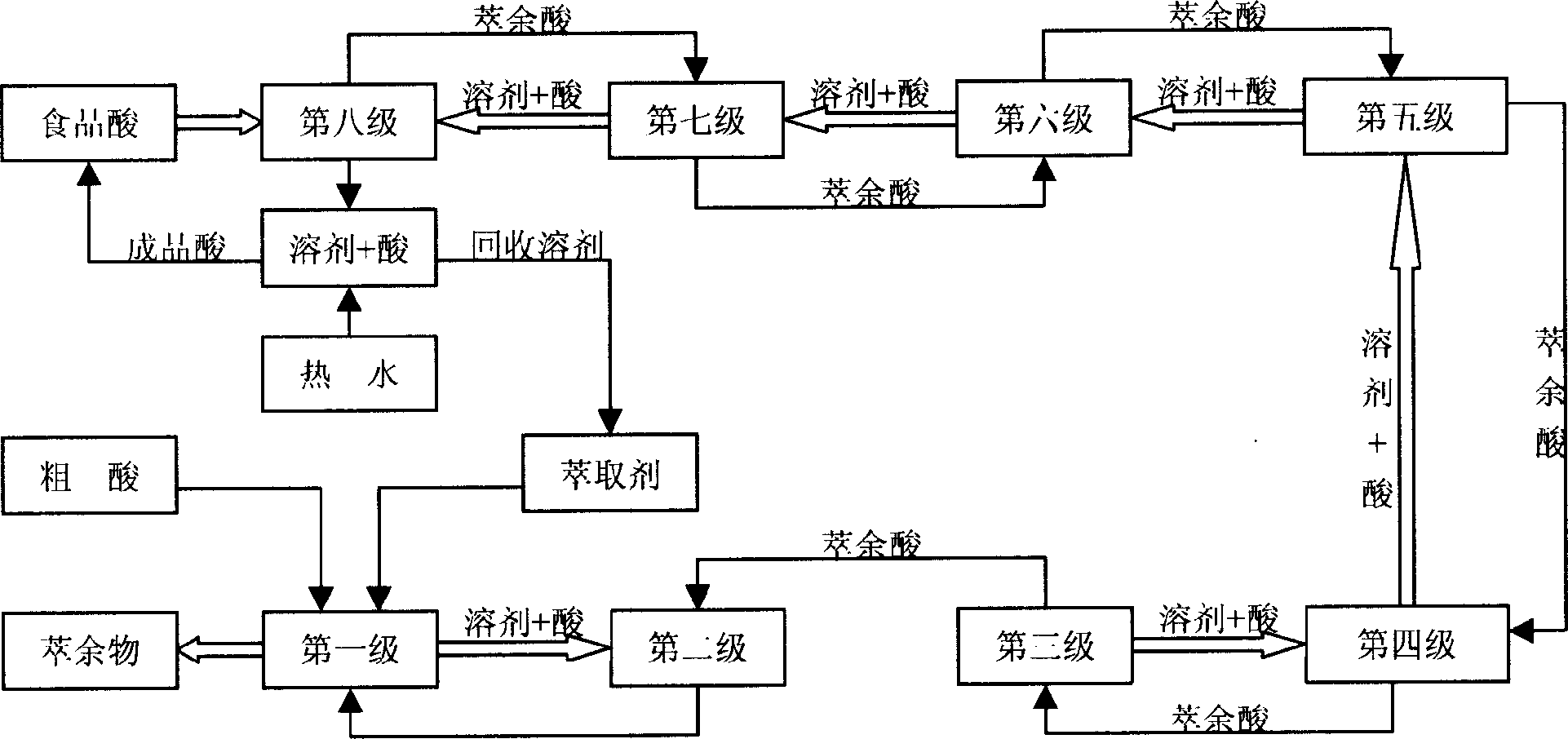

Process for purifying producing extracting solvent of food grade phosphoric acid by wet method phosphoric acid and extracting process thereof

A technology for extracting solvents and wet-process phosphoric acid, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., and can solve problems such as high concentration of crude phosphoric acid, low solvent, and ineffective separation of iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

2.3ppm

[0069] The indicators meet the requirements of GB2091-92 industrial-grade phosphoric acid and GB3149-82 food-grade phosphoric acid, which are better than the indicators of the Israeli IMI method. Used as an additive in the food industry, or used in the manufacture of instrument-grade phosphate.

[0070] 3230 g of refined acid was obtained with a yield of 81%.

[0071] Add solvent 3000ml. 2973ml of solvent was recovered, and the recovery rate was 99.1%.

Embodiment 3

[0074] indicators are better. Used as an additive in the food industry, or used in the manufacture of instrument-grade phosphate.

[0075] 3205 g of refined acid was obtained with a yield of 80.37%.

[0076] 3600ml of solvent was added, 3560ml of solvent was recovered, and the recovery rate was 98.9%.

Embodiment 4

[0079] indicators are better. Used as an additive in the food industry, or used in the manufacture of instrument-grade phosphate.

[0080] 3278g of refined acid was obtained with a yield of 82.2%.

[0081] 4200ml of solvent was added, 4160ml of solvent was recovered, and the recovery rate was 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com