Method for producing low-sulfur methyl tert-butyl ether product

A technology for methyl tertiary butyl ether and products, which is applied in the field of producing low-sulfur methyl tertiary butyl ether products, can solve the problems of difficult desulfurization of sulfides, difficult to produce, and easy-to-dissolve molecular structures of sulfides, so as to improve the ability of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described with the following examples, which are only used to help those skilled in the art understand the present invention, rather than to limit the scope of application of the present invention.

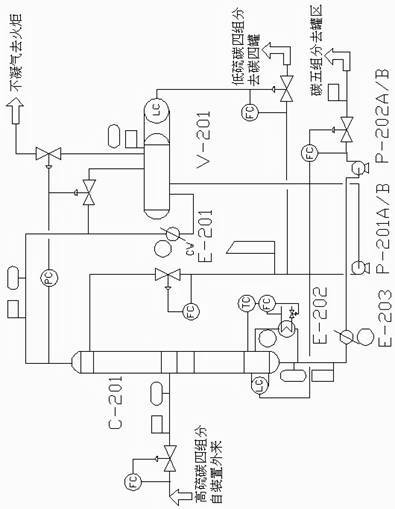

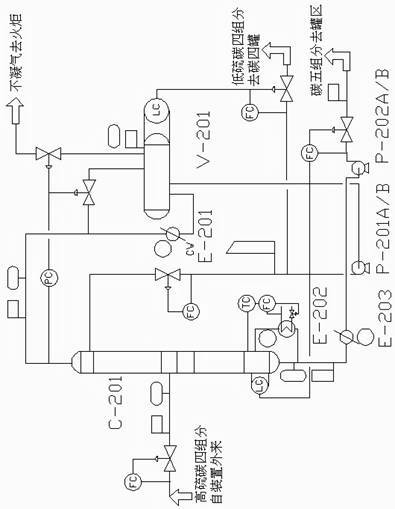

[0022] The method for producing the low-sulfur methyl tert-butyl ether product of the present invention can adopt a traditional depentanizer or a depentanizer with improved rectification effect according to the requirements of the sulfur content of the MTBE product.

[0023] The present invention adopts the above-mentioned depentanizer to carry out distillation and separation (30,000 tons / year MTBE device depentane sulfur reduction system), examples of which are as follows:

[0024] (I) Depentanizer system composition

[0025] (a) Equipment

[0026]

[0027] (b) safety valve

[0028] Installation Location

release medium

spring constant pressure

Specifications

Bleed temperature

Depentanizer overhead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com