A kind of coal combustion accelerant

A combustion-supporting agent and coal-burning technology, applied in the field of coal-burning combustion-supporting agent, can solve the problems of unenvironmental protection, deactivation of salts or oxides, and little effect of fuel combustion promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

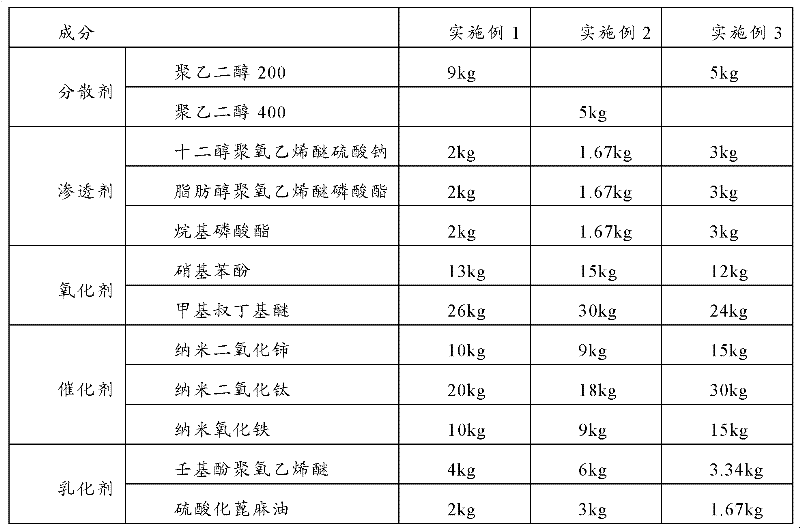

[0053] The present invention also provides a method for preparing a coal-fired combustion accelerant, comprising: mixing 35-50% of the catalyst and 5-10% of the dispersant by weight percentage, and stirring at a high speed to obtain a catalyst solution;

[0054] Mix the catalyst solution with 5-10% of the emulsifier, 35-50% of the oxidant, and 5-10% of the penetrant, and shear emulsify to obtain a coal-burning combustion aid;

[0055] Wherein the oxidant is a mixture of nitrophenol and methyl tert-butyl ether; the catalyst is a nanoscale metal oxide.

[0056] According to the present invention, the catalyst is mixed with the dispersant to obtain a catalyst solution; the preparation of the catalyst solution is carried out in a high-speed stirring device, preferably a high-speed mixer, and the speed adjustment range of the high-speed mixer is preferably 80rpm-1250rpm, and more preferably the speed is 100 rpm. ~200rpm, most preferably 150rpm to mix the catalyst solution with emul...

Embodiment 1

[0059] According to the raw material formula of Example 1 in Table 1, nano-cerium dioxide, nano-titanium dioxide, nano-iron oxide and polyethylene glycol 200 were mixed and stirred at a high speed to obtain a catalyst solution, and nonylphenol polyoxygen was sequentially added to the catalyst solution. Vinyl ethers and sulfated castor oil, m-nitrophenol, methyl tert-butyl ether, sodium laureth sulfate, fatty alcohol polyoxyethylene ether phosphates, alkyl phosphates, shear emulsified, high speed Stir to obtain the coal-fired combustion accelerant. The above operations were all carried out under normal temperature and pressure. When preparing the catalyst solution, the speed of the high-speed stirrer was 150 rpm. During shear emulsification, the rotational speed of the emulsifier is 8000rpm. The processing speed of the emulsifier is 3000L / H.

Embodiment 2

[0061] According to the raw material formula of Example 2 in Table 1, nano-cerium dioxide, nano-titanium dioxide, nano-iron oxide and polyethylene glycol 200 were mixed and stirred at a high speed to obtain a catalyst solution, and nonylphenol polyoxygen was sequentially added to the catalyst solution. Vinyl ethers and sulfated castor oil, m-nitrophenol, methyl tert-butyl ether, sodium laureth sulfate, fatty alcohol polyoxyethylene ether phosphates, alkyl phosphates, shear emulsified, high speed Stir to obtain the coal-fired combustion accelerant. The above operations were all carried out under normal temperature and pressure. When preparing the catalyst solution, the speed of the high-speed stirrer was 150 rpm. During shear emulsification, the rotational speed of the emulsifier is 8000rpm. The processing speed of the emulsifier is 3000L / H.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com