Methyl tert-butyl ether crude product purification method and methyl tert-butyl ether production method

A technology of methyl tert-butyl ether and crude products, which is applied in the field of purification of crude methyl tert-butyl ether products, can solve the problems of difficult separation, multiple plate numbers, high energy consumption, etc., and achieve reduction of investment and maintenance costs, The effect of reducing the process and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

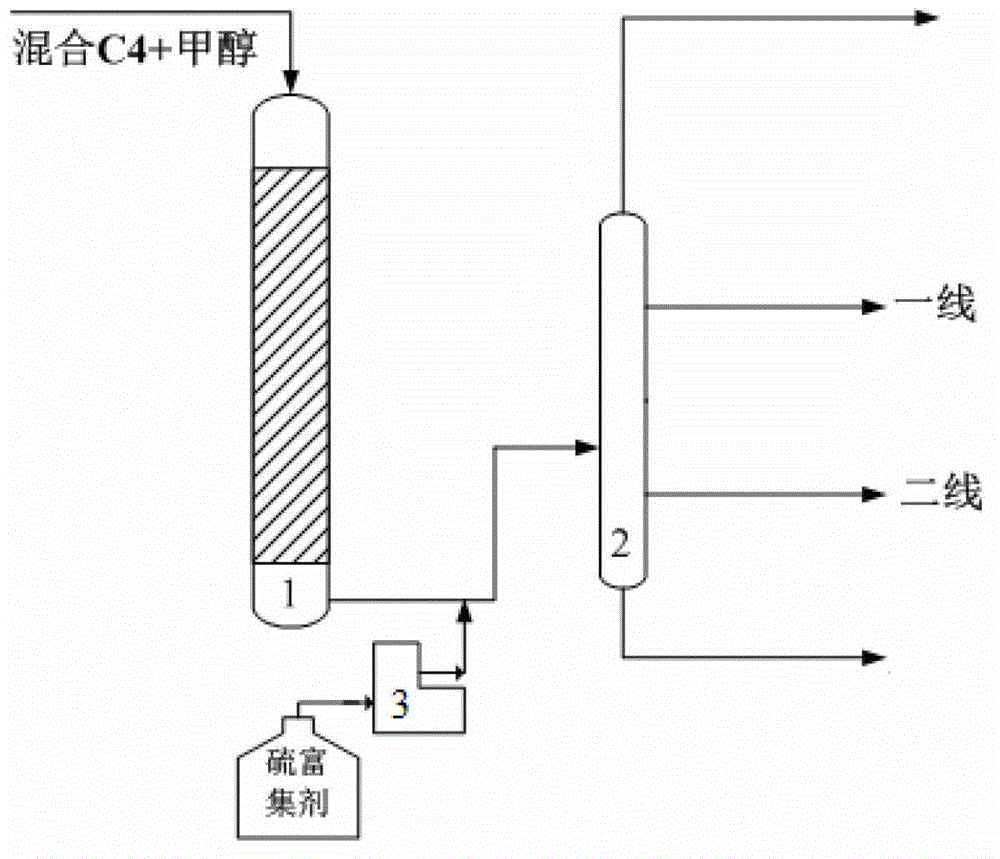

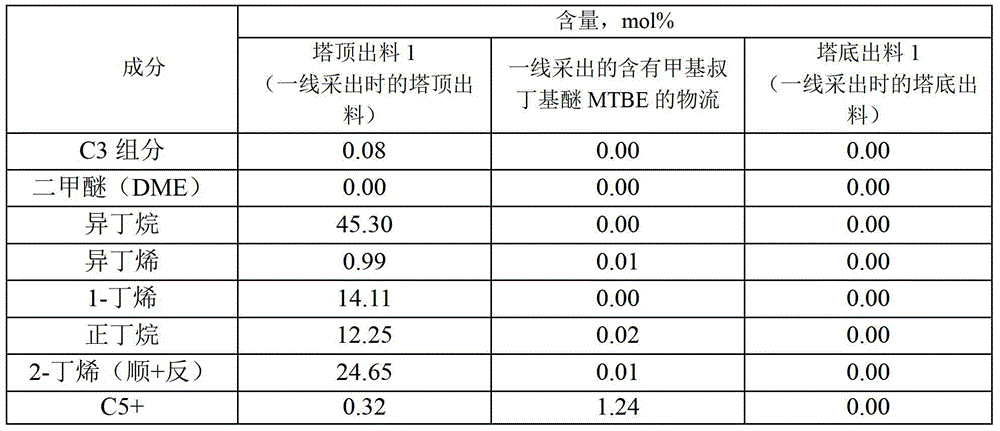

[0068] according to figure 1 Shown flow process produces ultra-low sulfur methyl tert-butyl ether, concretely carries out as follows:

[0069] Among them, "1" is the main reactor, "2" is the azeotropic distillation tower, and "3" is the pump;

[0070] (1) Under the condition of converting methanol and isobutene into methyl tert-butyl ether, methanol and mixed C4 are sent to the main reactor 1 to contact with the catalyst to obtain methanol, mixed C4, sulfide and methyl tert-butyl Ether solution;

[0071] (2) At the injection port behind the main reactor, use pump 3 to inject according to the ratio of 1000mg / kg of MTBE theoretical yield (that is, relative to 1kg of MTBE theoretical yield, the amount of sulfur enrichment agent solution is 1000mg). Sulfur enrichment agent solution (composed of: 80% aviation kerosene + 15% sec-butyl acetate + 5% copper naphthenate, sulfur content <2mg / kg) with methanol, mixed C4, sulfide and methyl tert-butyl After the ether solution is mixed, ...

Embodiment 2

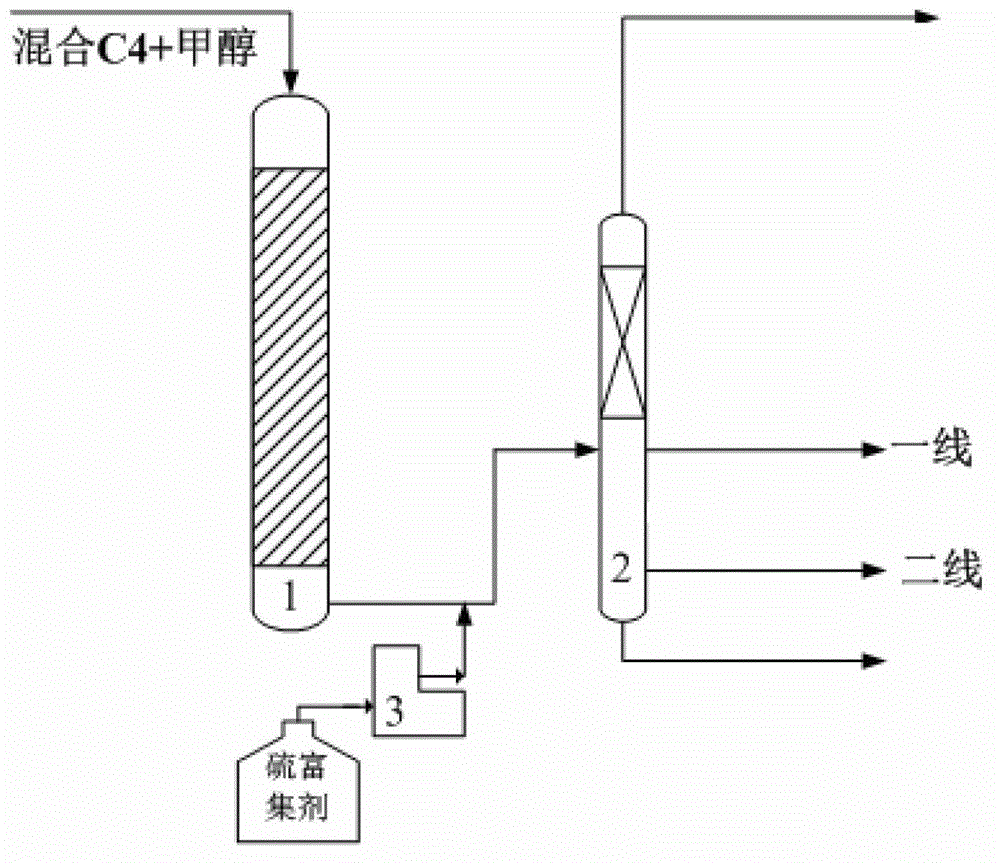

[0083] according to figure 2 Shown flow process produces ultra-low sulfur methyl tert-butyl ether, concretely carries out as follows:

[0084] Among them, "1" is the main reactor, "2" is the catalytic distillation tower, and "3" is the pump:

[0085] (1) Under the condition of converting methanol and isobutene into methyl tert-butyl ether, methanol and mixed C4 are sent to the main reactor 1 to contact with the catalyst to obtain methanol, mixed C4, sulfide and methyl tert-butyl Ether solution;

[0086] (2) At the injection port behind the main reactor, use pump 3 to inject according to the ratio of 8000 mg / kg of MTBE theoretical yield (that is, relative to 1 kg of MTBE theoretical yield, the amount of sulfur enrichment agent solution is 8000 mg). Sulfur enrichment agent solution (composed of: 80 mass% vehicle diesel + 15 mass% soybean oil + 2.5 mass% zinc naphthenate + 2.5 mass% copper chloride, sulfur content 5mg / kg) and methanol, mixed C4, The solution of sulfide and me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com