A process based on hydrothermal reaction treatment of agricultural and forestry wastes to prepare carbonized products for blast furnace coal injection

An agricultural and forestry waste, blast furnace coal injection technology, applied in blast furnaces, waste fuels, blast furnace details, etc., can solve the problems of high ash content, not meeting the requirements of blast furnace coal injection, and low calorific value of biochar, achieving low cost and high heat. Improve the performance of blast furnace coal injection technology and the effect of promoting cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

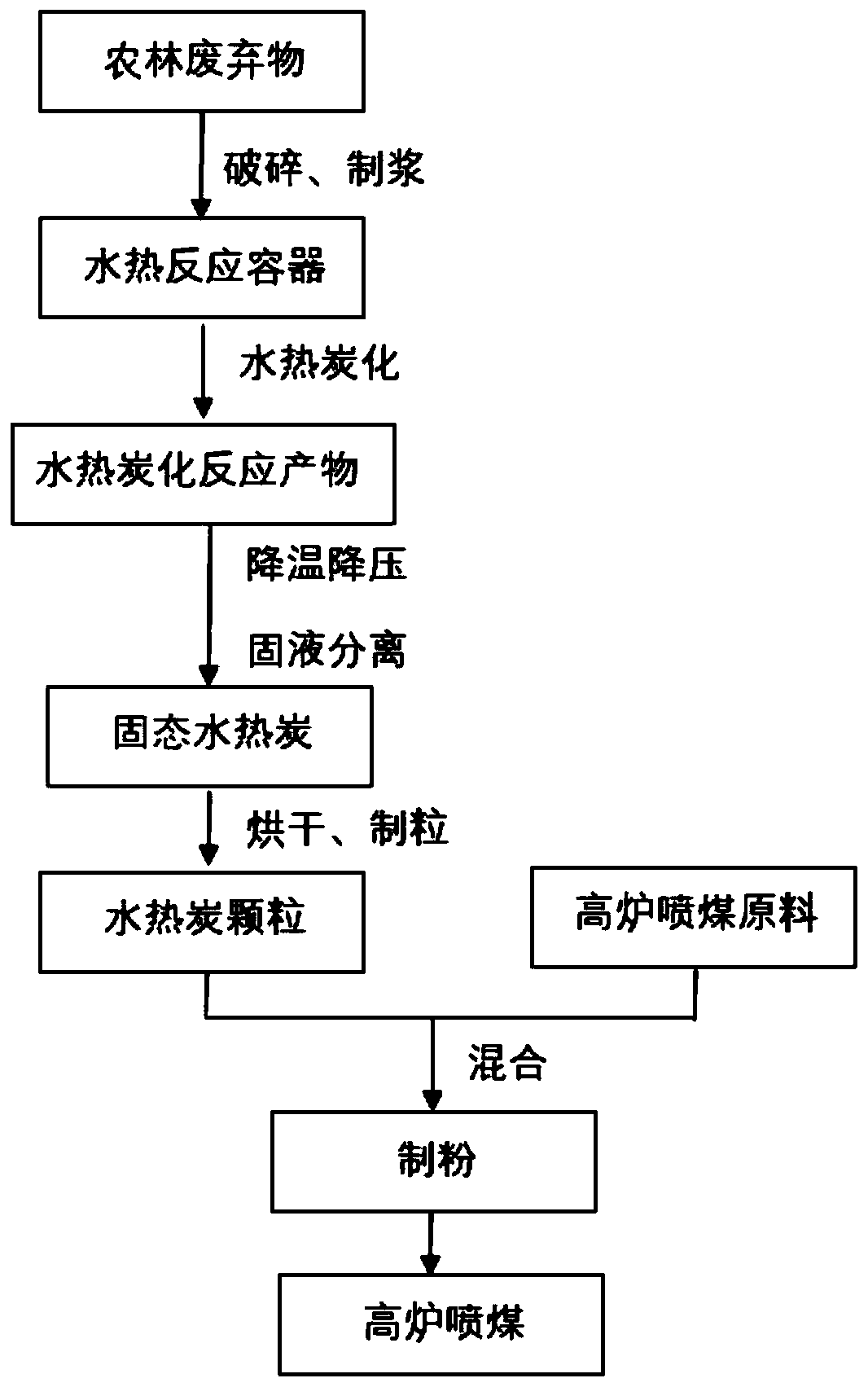

[0037]This embodiment provides a process based on hydrothermal reaction treatment of agricultural and forestry wastes to prepare carbonized products for blast furnace coal injection, including the following steps:

[0038] (1) After crushing corn stalks (dry base volatile matter 79.5%, ash content 5.76%, calorific value 17250kJ / kg) to a particle size of less than 1cm, the crushed material is transported to the slurry storage tank through a pipeline, and water is added to the slurry storage tank Stir and mix well to control the moisture content to 60%; and use a high-pressure slurry pump to transport the slurry to a heat exchanger for preheating to 120°C, and then transport the preheated slurry to a high-pressure hydrothermal reaction vessel for hydrothermal carbonization Reaction, control the temperature in the hydrothermal reaction vessel to be 220°C, the corresponding saturated vapor pressure is 2.3MPa, and the hydrothermal carbonization time is 100min to obtain the hydrother...

Embodiment 2~5

[0046] Embodiments 2-5 provide a process based on hydrothermal reaction treatment of agricultural and forestry wastes to prepare carbonized products for blast furnace coal injection. Compared with Example 1, the difference is that the water content and the water content of the slurry in step (1) are changed. Preheating temperature, the concrete values of the corresponding slurry moisture content and preheating temperature of each embodiment are as shown in table 1:

[0047] Table 1 Example 2-5 Corresponding slurry moisture content and slurry preheating temperature value

[0048] Example Moisture content of slurry (%) Slurry preheating temperature (°C) Example 2 70 120 Example 3 80 120 Example 4 80 130 Example 5 80 140

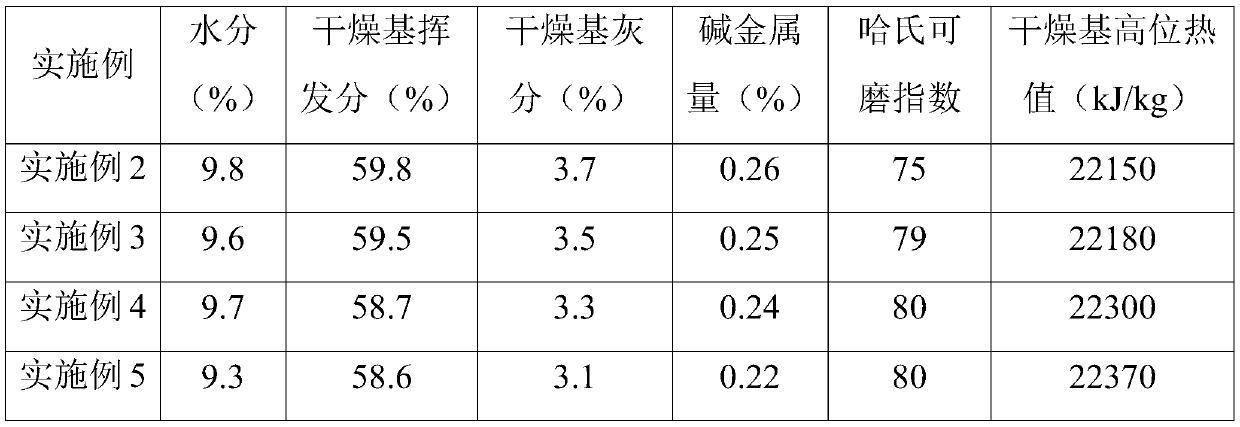

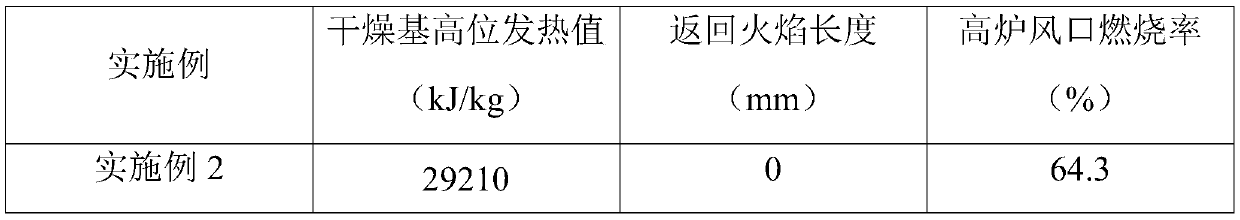

[0049] The performance of the hydrothermal charcoal particles and the mixed fuel prepared in each embodiment are tested, and the results are shown in Table 2 and Table 3 respectively:

[0050] The performance of ...

Embodiment 6~9

[0058] Embodiments 6 to 9 provide a process based on hydrothermal reaction treatment of agricultural and forestry wastes to prepare carbonized products for blast furnace coal injection. Compared with Example 1, the difference is that the hydrothermal reaction vessel in step (1) is changed. temperature, saturated vapor pressure and hydrothermal carbonization time, the concrete values of hydrothermal carbonization temperature, hydrothermal carbonization pressure and hydrothermal carbonization time corresponding to each embodiment are as shown in table 4:

[0059] Table 4 The corresponding hydrothermal carbonization temperature, hydrothermal carbonization pressure and hydrothermal carbonization time of Examples 6-9

[0060] Example Hydrothermal carbonization temperature (℃) Hydrothermal carbonization pressure (MPa) Hydrothermal carbonization time (min) Example 6 220 2.3 60 Example 7 220 2.3 40 Example 8 280 6.4 60 Example 9 340 14.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com