Coking fly ash/coke powder blast furnace blowing synergy utilizing system and technology

A coking dust and coke dust removal technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of high energy consumption, secondary pollution, negative benefits, etc., and achieve long life, low energy consumption, and mature equipment technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

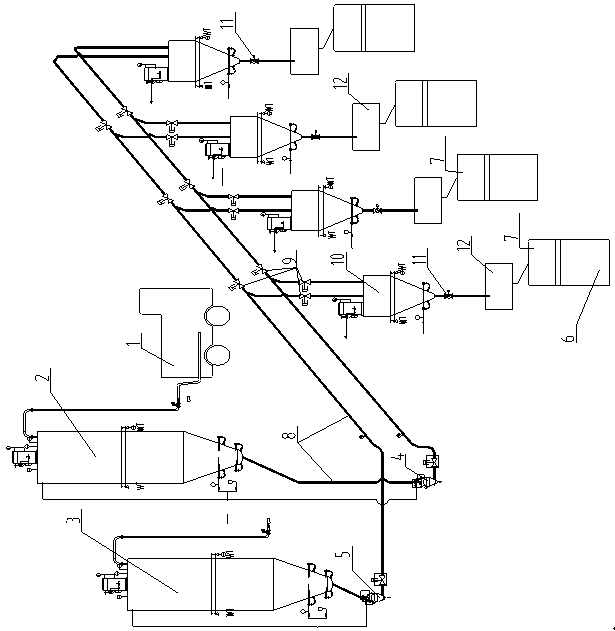

Image

Examples

Embodiment Construction

[0019] A coking and dedusting ash coke powder blast furnace injection efficiency utilization system, including a fully sealed suction and discharge tank car 1, a centralized powder bin, a warehouse pump, a buffer bin, a feeder, a mill, and a blast furnace, and the centralized powder bin includes a centralized powder bin I 2 and centralized powder bin II 3, the bin pump includes bin type pump I 4 and bin type pump II 5, the coke powder is transported to the entrance of centralized powder bin I 2 and centralized powder bin II 3 through fully sealed suction and discharge tanker 1, and centralized The outlets of the powder bin I 2 and the centralized powder bin II 3 are respectively communicated with one end of the bin pump I 4 and the bin pump II 5 through the delivery pipeline, and the other ends of the bin pump I 4 and the bin pump II 5 are connected with the bin pump II 5 respectively. The delivery pipelines 8 are connected, and the delivery pipelines 8 of the warehouse pump I4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com