Iron oxide/graphene oxide nanocomposite, its preparation method, and its application in supercapacitor

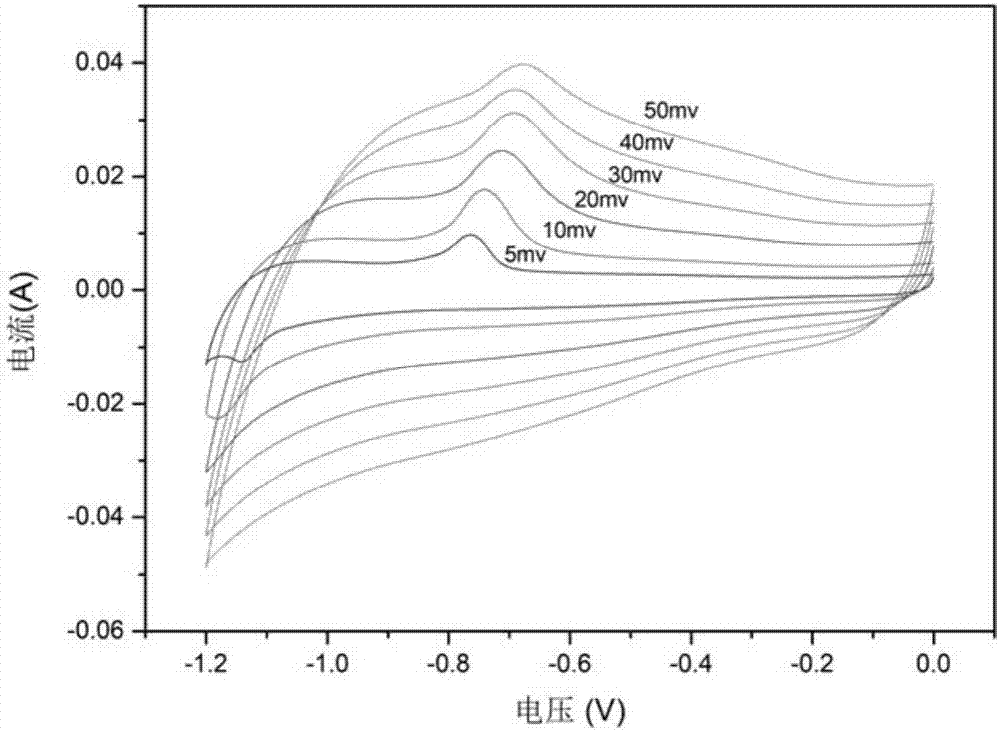

A nanocomposite material and graphene technology, applied in the field of functional materials, can solve the problems of large size, unsatisfactory electrochemical performance, uneven shape, etc., and achieve uniform size, high cycle charge/discharge stability, and reaction The effect of simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

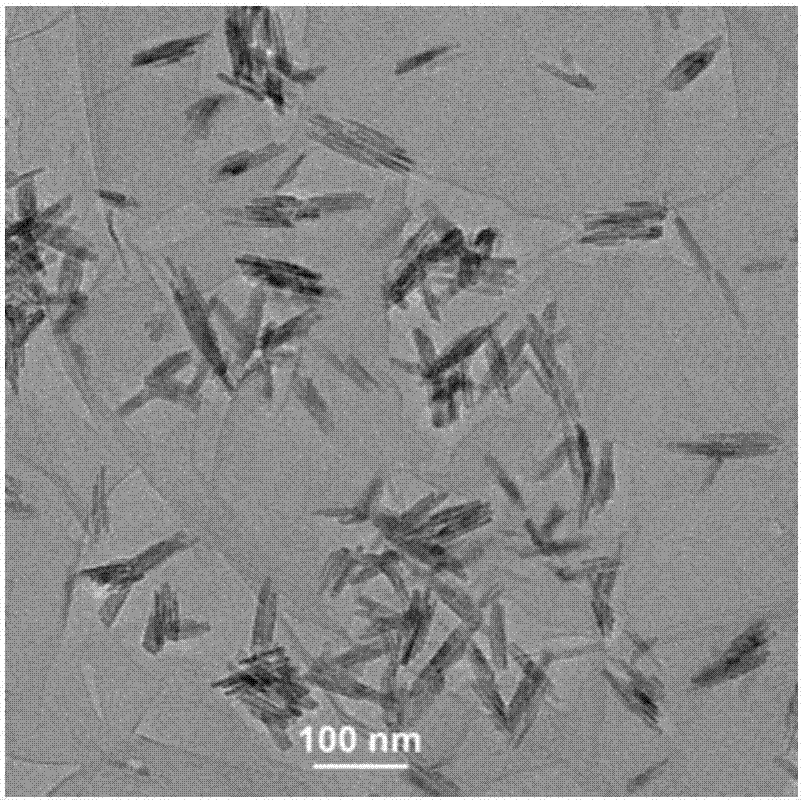

[0041] Example 1: Preparation of ultrafine iron oxide nanorods supported by graphene oxide

[0042] 1. Dissolve ferrous acetate in deionized water, mix and stir until it is completely dissolved, and obtain an aqueous solution of 0.02mol / L ferrous acetate;

[0043] 2. Add 388ml of the ferrous acetate solution obtained in step 1 dropwise into 435mL, 10mg / mL graphene oxide hydrosol, and stir at the same time to obtain a stable and uniform suspension. Among them, the mass ratio of iron element to graphene is 10:100;

[0044] 3. Pour the suspension obtained in step 2 into a hydrothermal reaction kettle, react at a temperature of 120°C for 12 hours, naturally cool to room temperature, wash with deionized water for 5 times and perform suction filtration to obtain graphene oxide Composite with hydrated iron oxide nanoparticles, and finally dried in an oven at 60°C for 12h. Graphene oxide-supported ultrafine iron oxide nanorod composites were obtained.

[0045] 4. The composite obta...

Embodiment 2

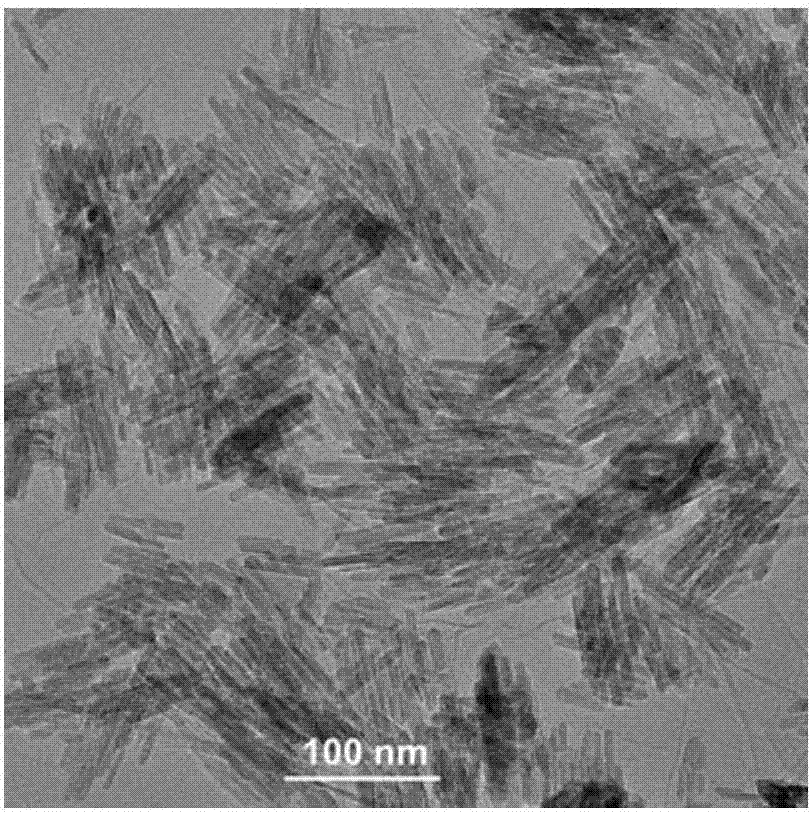

[0049] Example 2: Preparation of ultrafine iron oxide nanorods supported by graphene oxide

[0050] 1. Dissolve ferrous chloride in absolute ethanol, mix and stir until it is completely dissolved, and obtain an ethanol solution of 0.03mol / L ferrous chloride;

[0051] 2. Add 147ml of the iron salt solution obtained in step 1 dropwise into 225mL, 10mg / mL graphene oxide hydrosol, and stir at the same time to obtain a stable and uniform suspension. Among them, the mass ratio of iron element to graphene is 11:100;

[0052] 3. Pour the suspension obtained in step 2 into a hydrothermal reaction kettle, react at a temperature of 130°C for 24 hours, naturally cool to room temperature, wash with deionized water for 5 times and perform suction filtration to obtain graphene oxide Composite with hydrated iron oxide nanoparticles, and finally dried in an oven at 80°C for 12h. Graphene oxide-supported ultrafine iron oxide nanorod composites were obtained.

[0053] 4. The composite obtaine...

Embodiment 3

[0055] Example 3: Preparation of ultrafine iron oxide nanorods supported by graphene oxide

[0056] 1. Dissolve ferrous sulfate in dimethylformamide, mix and stir until it is completely dissolved, and obtain a solution of 0.05mol / L ferrous sulfate;

[0057] 2. Add 289ml of the iron salt solution obtained in step 1 dropwise into 450mL, 10mg / mL graphene oxide hydrosol, and stir at the same time to obtain a stable and uniform suspension. Among them, the mass ratio of iron element to graphene is 18:100;

[0058] 3. Pour the suspension obtained in step 2 into a hydrothermal reaction kettle, react at a temperature of 130°C for 24 hours, naturally cool to room temperature, wash with deionized water for 5 times and perform suction filtration to obtain graphene oxide Composite with hydrated iron oxide nanoparticles, and finally dried in an oven at 80°C for 12h. Graphene oxide-supported ultrafine iron oxide nanorod composites were obtained.

[0059] 4. The composite obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com