Method for resource recycling of phosphorus in breeding waste

A breeding waste and recycling technology, applied in the field of agricultural resources and the environment, can solve the problems of difficulty in recycling organic phosphorus, loss of phosphorus, interference with inorganic phosphorus recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1, resource recycling of phosphorus in livestock and poultry breeding waste

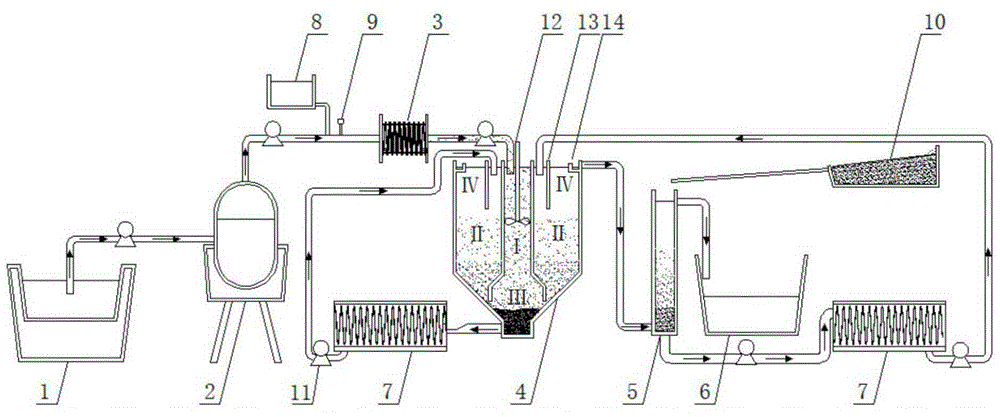

[0061] like figure 1 As shown, follow the steps below to recycle the phosphorus in the farming waste:

[0062] (1) Control the solid content rate of 20 mg / g phosphorus content 20 mg / g livestock and poultry breeding waste at 30%, introduce ultrasonic pre-oxidation tank 1, under the condition of power 100W, temperature 40 ℃, frequency 30MHz, pulse type ultrasonic action 120min (operating 1min, stop 1min).

[0063] (2) According to the ratio of the volume of waste: the volume of the wet chemical oxidizer 1:3, the waste treated in step (1) is introduced into the wet chemical oxidizer 2, and the sequence batch reaction is carried out at a temperature of 300°C for 240 minutes , using ozone as an oxidant, with a partial pressure of 1.5MPa, the amount of phosphorus released after the reaction reaches 20mg / g, the phosphorus release rate reaches 100%, the amount of inorganic phosphorus is 2...

Embodiment 2

[0068] Embodiment 2, resource recycling of phosphorus in livestock and poultry breeding waste

[0069] like figure 1 As shown, follow the steps below to recycle the phosphorus in the farming waste:

[0070] (1) Control the solid content rate of livestock and poultry breeding waste with a phosphorus content of 100mg / g at 50%, introduce ultrasonic pre-oxidation tank 1, and perform pulsed ultrasonic action for 10min under the conditions of power 30W, temperature 30°C, and frequency 50MHz (operating 2min, stop 1min);

[0071] (2) Then add the waste according to the volume of the waste: the volume of the wet chemical oxidizer 2:3, introduce the waste treated in step (1) into the wet chemical oxidizer 2, and sequence the batch at a temperature of 150°C After reacting for 180 minutes, using oxygen as the oxidant, the partial pressure is 10MPa, the amount of phosphorus released after the reaction reaches 97mg / g, the phosphorus release rate reaches 97%, the amount of inorganic phosph...

Embodiment 3

[0076] Embodiment 3, resource recycling of phosphorus in livestock and poultry breeding waste

[0077] like figure 1 As shown, follow the steps below to recycle the phosphorus in the farming waste:

[0078] (1) Control the solid content rate of 200mg / g livestock and poultry breeding waste with a phosphorus content of 70%, introduce ultrasonic pre-oxidation tank 1, and perform pulsed ultrasonic action for 60min under the conditions of power 150W, temperature 20°C, and frequency 10MHz (operating 2min, stop 2min).

[0079] (2) According to the volume of the waste: the volume of the wet chemical oxidizer is 1:3, the waste treated in step (1) is introduced into the wet chemical oxidizer 2, and the sequence batch reaction is carried out at a temperature of 200°C for 120 minutes , with 30wt% hydrogen peroxide as oxidant, hydrogen peroxide: waste volume ratio is 1:10, phosphorus release after reaction reaches 196mg / g, phosphorus release rate reaches 98%, inorganic phosphorus is 196m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com