Method for treating alkali residue liquid waste and three-sludge of oil refineries

A technology of alkali residue waste liquid and treatment method, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of increasing the treatment load impact of subsequent oily sewage systems and low COD removal rate , the problem of high energy consumption for cooling and heat exchange, to achieve the effect of saving processing difficulty, saving pharmaceuticals, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

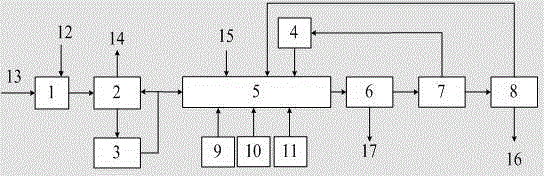

Image

Examples

Embodiment 1

[0029] Alkali slag waste liquid is the mixed waste lye of a refinery during the petroleum refining process (catalytic gasoline waste lye, liquid hydrocarbon waste lye and ethylene cracking waste lye), with an average COD value of 175850mg / L, S 2- The average is 48230mg / L, and the pH value is greater than 14.

[0030] The third mud is the sludge tank of the refinery sewage treatment plant (the tank is a mixture of scum, bottom sludge and residual sludge), with an average water content of 92.0wt%, oil content of 5.9wt%, and solid content of 2.1 wt%.

[0031] The operating conditions of the wet oxidation process are: reaction temperature 150°C, pressure 0.8MPa, residence time of alkali slag waste liquid in the empty tower of the wet oxidation reactor is 2h, and the amount of oxygen is 130% of the theoretical oxygen demand.

[0032]The operating pressure of the washing tower is 0.15MPa, the temperature at the top of the tower is 40°C, and the temperature at the bottom of the towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com