Process and special apparatus for electrogalvenizing inner and outer walls of steel pipe

A special equipment and technology for steel pipes, applied in the field of electroplating process for the inner and outer walls of pipes and special electroplating tank structural parts, can solve the problems of general deep plating ability, unsuitable inner wall galvanizing of small-diameter steel pipes, narrow current density range, etc., and achieve The effect of promoting automatic cycle renewal, excellent oil stain resistance, and good deep plating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

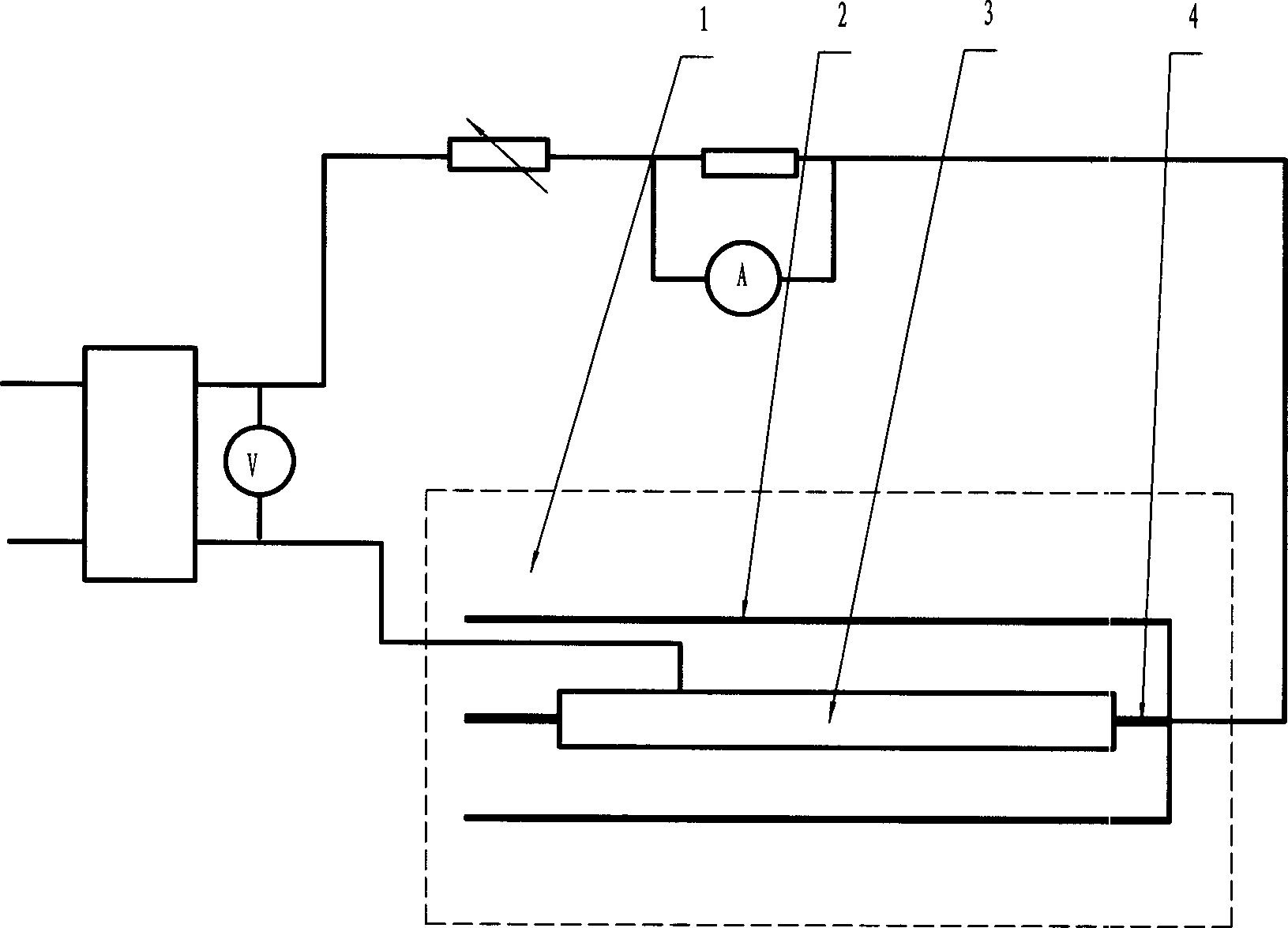

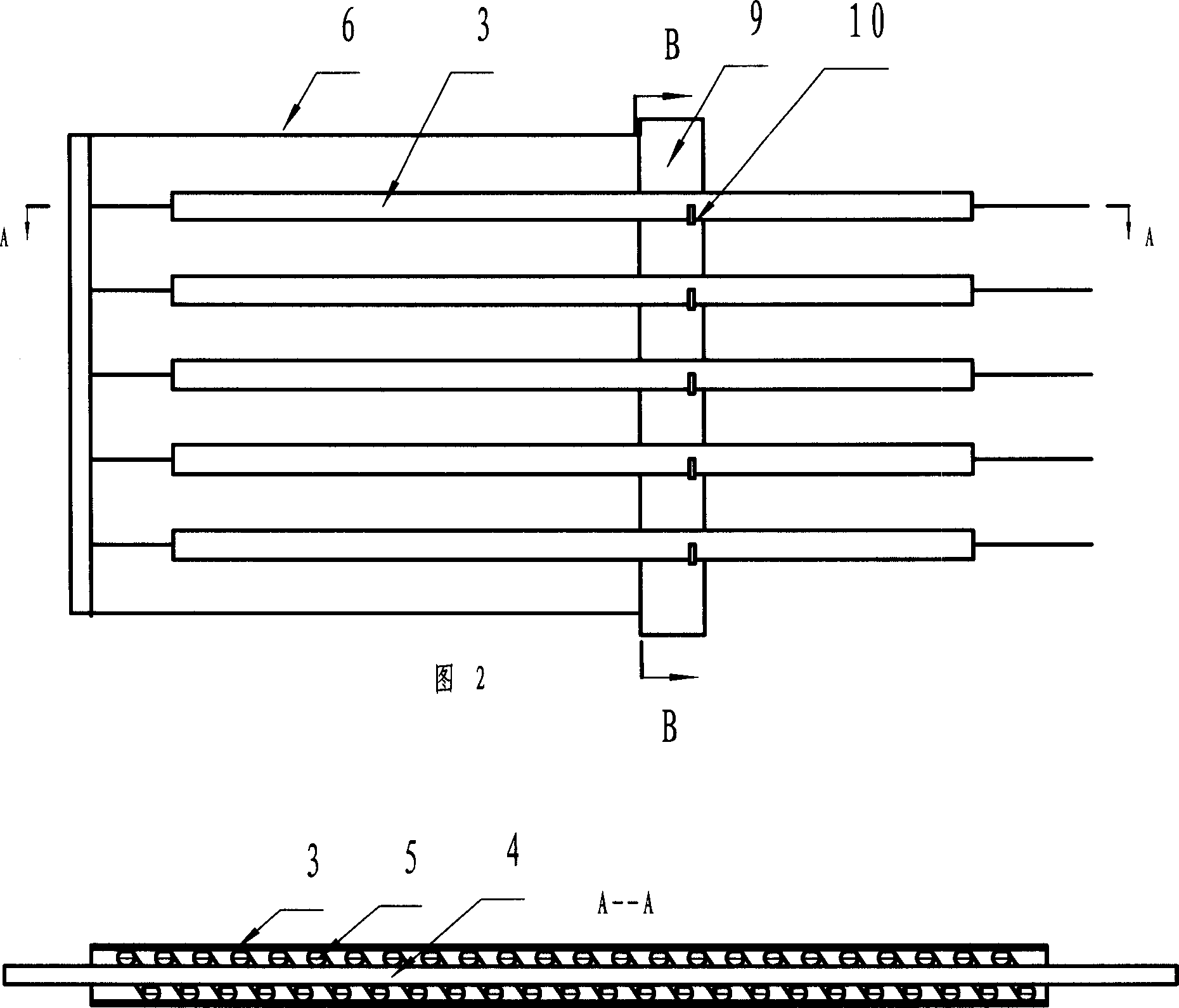

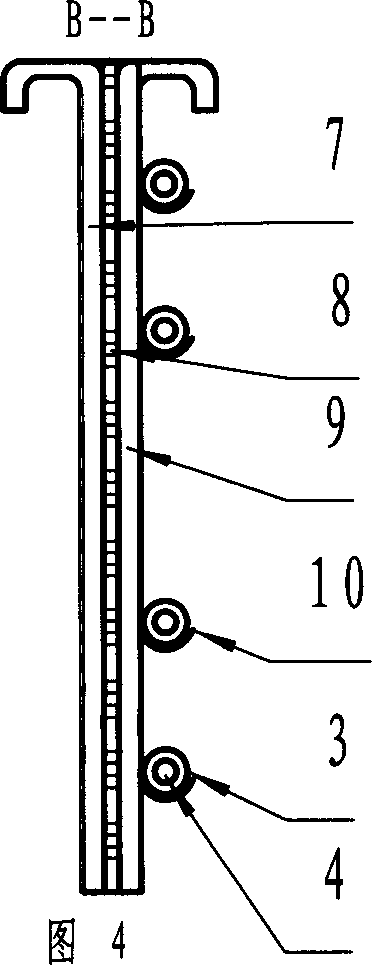

[0022] The present invention will be further described below in conjunction with the embodiments. A process of electrogalvanizing the inner and outer walls of steel pipes, including dilute alkali degreasing, upper hangers, galvanizing, lower hangers, cleaning, passivation, cleaning and natural drying processes, and upper hangers The process is to penetrate the auxiliary anode into the plated steel pipe, place the plated steel pipe on the V-shaped hook of the cathode copper plate of the hanger, connect the anode steel plate of the hanger with the anode bar with copper wires, and hang the cathode copper plate of the hanger on the cathode bar , the formula of galvanizing solution used in the electroplating process is:

[0023] Galvanizing solution formula:

[0024] Zinc Oxide (ZnO) 10-14 g / L

[0025] Sodium hydroxide (NaOH) 100-120 g / L

[0026] Sodium cyanide (NaCN) 20-30 g / L

[0027] DPE-III Additive 1-3ml / L

[0028] ZB-80 additive 1-3 ml / liter,

[0029] The temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com