Method for preparing high-purity nickel salt by recycling industrial nickel-containing wastewater

A nickel wastewater, high-purity technology, applied in metallurgical wastewater treatment, chemical instruments and methods, water pollutants, etc., can solve problems such as inability to achieve high-purity nickel sulfate, reduce outsourcing, high safety, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

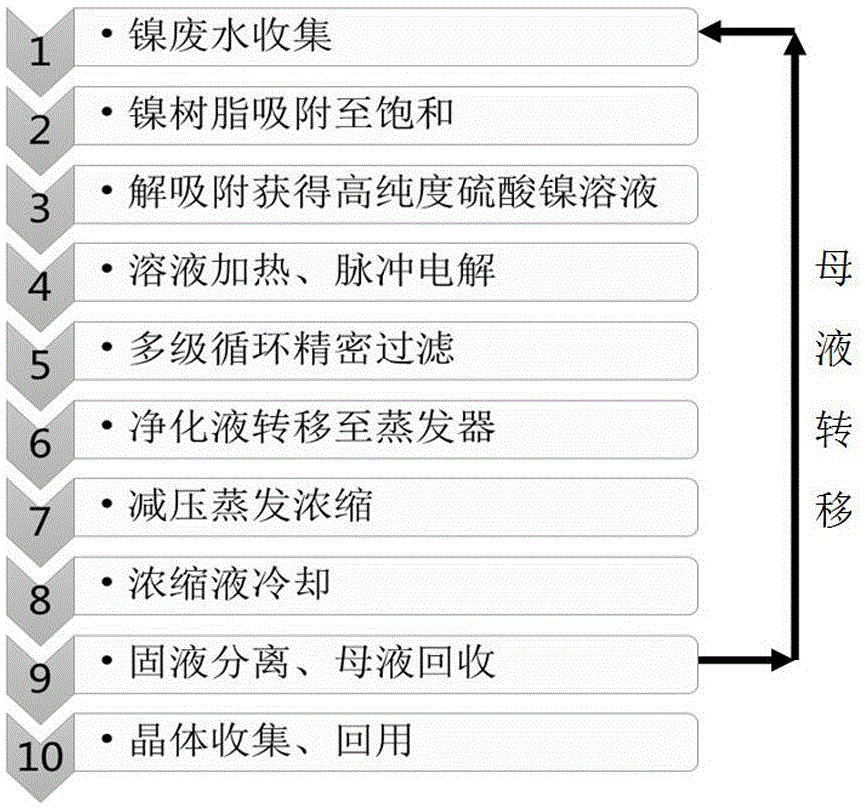

[0039] The method for the recovery of industrial nickel-containing waste water as above to prepare high-purity nickel salt, the specific steps are as follows:

[0040] (1) Collect industrial nickel-containing wastewater;

[0041] (2) Pass the nickel wastewater through a cation exchange resin that selectively adsorbs nickel to adsorption saturation;

[0042] (3) Carry out resin desorption regeneration to the cation exchange resin in step (2) with strong acid to obtain nickel salt solution; wherein Ni 2+ Concentration is 50g / l, pH value 2; Described strong acid is 5wt% sulfuric acid;

[0043] (4) Carry out gradient type pulse electrolysis to the nickel salt solution that step (3) obtains, the process parameter of electrolysis is:

[0044] Power supply: high frequency double pulse power supply, maximum peak current: 80A; maximum output voltage: 12V;

[0045] Anode: The electrolytic anode adopts DSA anode, and the DSA anode is an iridium-based or iridium-tantalum-coated titani...

Embodiment 2

[0057] The method for preparing high-purity nickel salt by reclaiming industrial nickel-containing wastewater, the specific steps are as follows:

[0058] (1) Collect industrial nickel-containing wastewater;

[0059] (2) Pass the nickel wastewater through a cation exchange resin that selectively adsorbs nickel to adsorption saturation;

[0060] (3) Carry out resin desorption regeneration to the cation exchange resin in step (2) with strong acid to obtain nickel salt solution; wherein Ni 2+ Concentration is 70g / l, pH value is 4; Described strong acid is 20wt% hydrochloric acid;

[0061] (4) Carry out gradient type pulse electrolysis to the nickel salt solution that step (3) obtains, the process parameter of electrolysis is:

[0062] Power supply: high frequency double pulse power supply, maximum peak current: 80A; maximum output voltage: 12V;

[0063] Anode: The electrolytic anode adopts DSA anode, and the DSA anode is an iridium-based or iridium-tantalum-coated titanium an...

Embodiment 3

[0075] The method for the recovery of industrial nickel-containing waste water as above to prepare high-purity nickel salt, the specific steps are as follows:

[0076] (1) Collect industrial nickel-containing wastewater;

[0077] (2) Pass the nickel wastewater through a cation exchange resin that selectively adsorbs nickel to adsorption saturation;

[0078] (3) Carry out resin desorption regeneration to the cation exchange resin in step (2) with strong acid to obtain nickel salt solution; wherein Ni 2+ The concentration is 60g / l, the pH value is 3; the strong acid is 12wt% sulfuric acid;

[0079] (4) Carry out gradient type pulse electrolysis to the nickel salt solution that step (3) obtains, the process parameter of electrolysis is:

[0080] Power supply: high frequency double pulse power supply, maximum peak current: 80A; maximum output voltage: 12V;

[0081] Anode: The electrolytic anode adopts a DSA anode, and the DSA anode is an iridium-based or iridium-tantalum-coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com