Electro-deposition preparation method of Ni-Co-C alloy substitute hard chromium plating

A ni-co-c, 1.ni-co-c technology is applied in the field of preparation of Ni-Co-C alloy substitute hard chrome plating, which can solve the problems of carcinogenicity, harm, genetic deletion, etc., and achieve corrosion resistance. It has good bonding force, solves heavy pollution of hexavalent chromium, and has good wear resistance and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

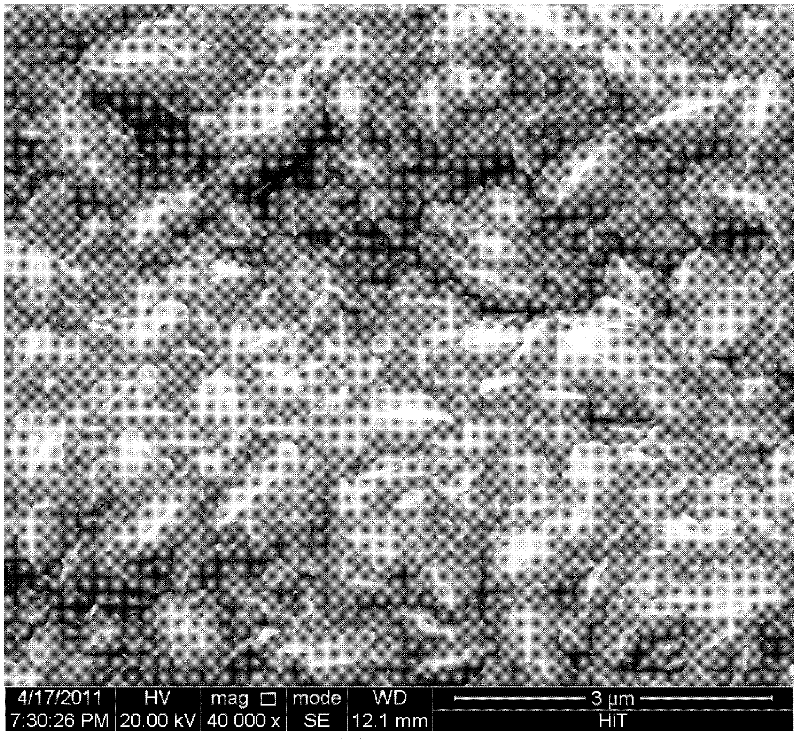

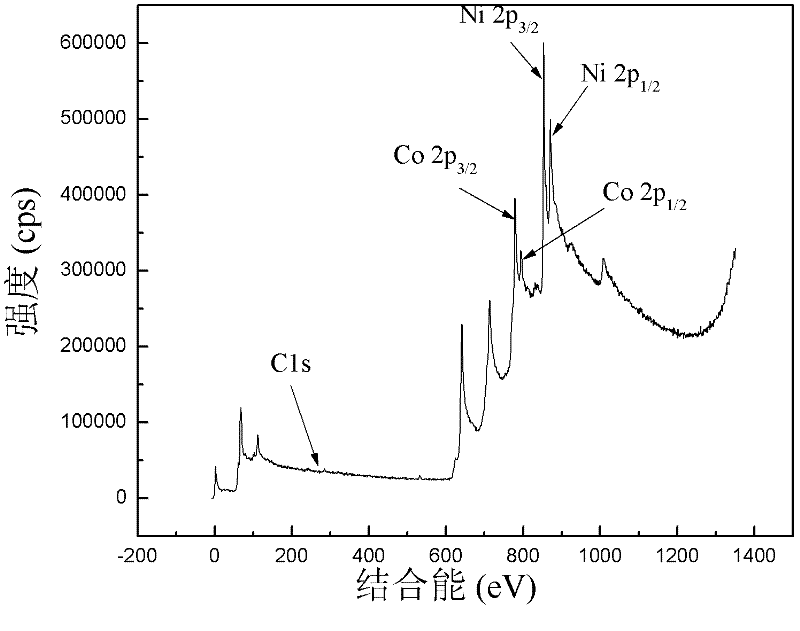

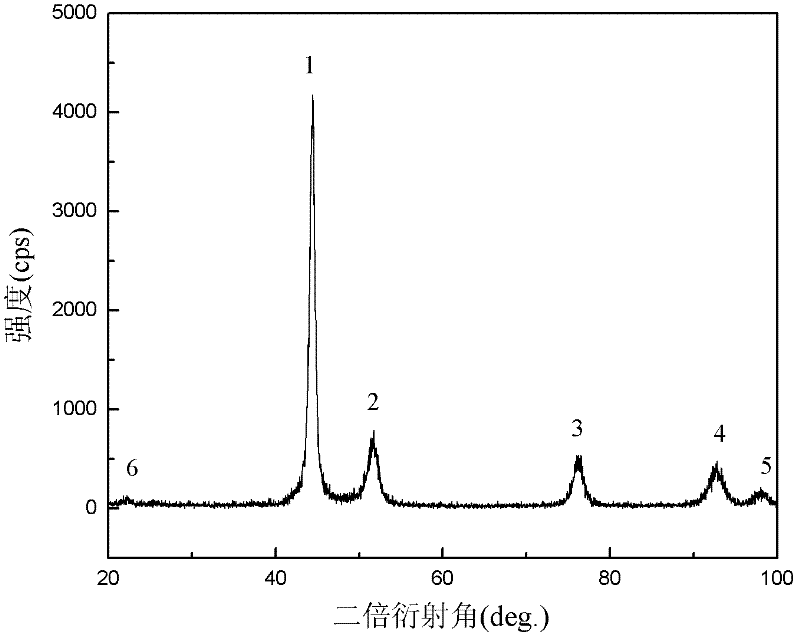

[0013] Specific embodiment 1: The electrodeposition preparation method of Ni-Co-C alloy substitute hard chromium coating of this embodiment is carried out according to the following steps: 1. Weigh 50~150g nickel salt, 5~15g cobalt salt, 1~10g NiCl 2 ·6H 2 O, 20-50g boric acid, 100-300g ammonium citrate, 5-50g carbon-containing compounds, 1-10ml NI3 # Fast high leveling nickel plating gloss agent A, 0.15~1.5g stress reliever; 2. Dissolve weighed ammonium citrate in 400~600ml water at 30~60℃, add nickel salt and cobalt Salt and stir until dissolved, then add boric acid and NiCl 2 ·6H 2 O and stir until dissolved, then add the carbon-containing compound and stir until dissolved, then add NI3 # Quick high-leveling nickel plating gloss agent A and stress reliever and stir until dissolved, then add water to make the volume to 1L to obtain Ni-Co-C alloy plating solution; 3. The plating parts are removed by conventional alkaline degreasing or electrochemical degreasing After the oil is...

Embodiment 1

[0019] The electrodeposition preparation method of Ni-Co-C alloy substitute hard chromium coating is carried out according to the following steps: 1. Weigh 100g of nickel salt, 10g of cobalt salt, and 1g of NiCl 2 ·6H 2 O, 30g of boric acid, 250g of ammonium citrate, 15g of carbon-containing compounds, 3ml of NI3 # Quick high-leveling nickel plating gloss agent A, 0.5g stress reliever; 2. Dissolve weighed ammonium citrate in 600ml water at 40℃, add nickel salt and cobalt salt and stir until dissolved, Then add boric acid and NiCl 2 ·6H 2 O and stir until dissolved, then add the carbon-containing compound and stir until dissolved, then add NI3 # Quick high-leveling nickel plating gloss agent A and stress reliever and stir until dissolved, then add water to make the volume to 1L to obtain Ni-Co-C alloy plating solution; 3. The plating parts are removed by conventional alkaline degreasing or electrochemical degreasing After the oil is washed with water, and then activated in hydroch...

Embodiment 2

[0027] The electrodeposition preparation method of Ni-Co-C alloy substitute hard chromium coating is carried out according to the following steps: 1. Weigh 150g of nickel salt, 15g of cobalt salt, and 1g of NiCl 2 ·6H 2 O, 40g of boric acid, 150g of ammonium citrate, 30g of carbon-containing compounds, 7ml of NI3 # Fast high leveling nickel plating gloss agent A, 0.4g stress reliever; 2. Dissolve weighed ammonium citrate in 400ml of water at 50℃, add nickel salt and cobalt salt and stir until dissolved, Then add boric acid and NiCl 2 ·6H 2 O and stir until dissolved, then add the carbon-containing compound and stir until dissolved, then add NI3 # Quick high-leveling nickel plating gloss agent A and stress reliever and stir until dissolved, then add water to make the volume to 1L to obtain Ni-Co-C alloy plating solution; 3. The plating parts are removed by conventional alkaline degreasing or electrochemical degreasing After the oil is washed with water, and then activated in hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com