Recycling and processing equipment of waste and old fluorescent lamp

A technology for recycling and processing fluorescent lamps, which is applied in the field of recycling and processing equipment for waste fluorescent lamps, and can solve the problems of environmental pollution caused by waste fluorescent lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

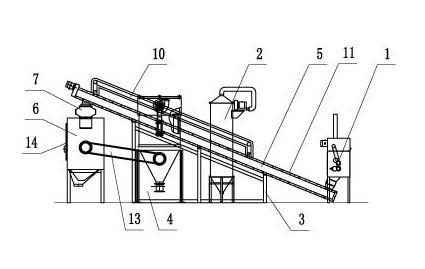

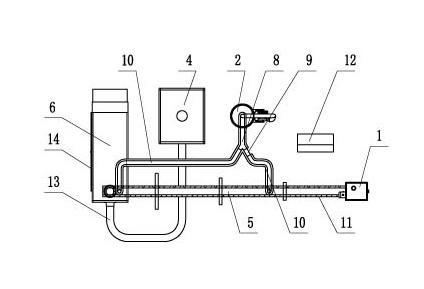

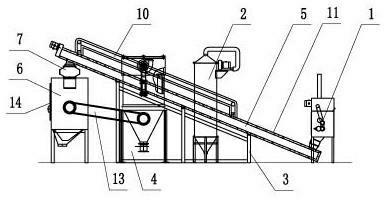

[0011] The waste fluorescent lamp recycling and processing equipment consists of a crushing device 1, a separating device 2, a bracket 3, a bag filter 4, a screw conveyor 5, a winnowing device 6, an air-closing discharge valve 7, a three-way joint 8, a butterfly valve 9, and mercury vapor The recovery pipeline 10, the heating element 11, the electrical control device 12, the fluorescent powder recovery pipeline 13 and the winnowing control panel 14 constitute. The two ends of the bracket 3 are respectively equipped with a pulverizing device 1 and a winnowing device 6, and a screw conveyor 5 is installed on the top of the bracket 3, and a heating element 11 is installed on the cylinder of the screw conveyor 5, and the outer wall of the cylinder is equipped with a 50mm thick insulation layer. One end of the screw conveyor 5 is connected with the outlet of the crushing device 1, the other end of the screw conveyor 5 is connected with the feed port of the winnowing device 6 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com