Beneficiation method for complex copper-zinc sulfide ore

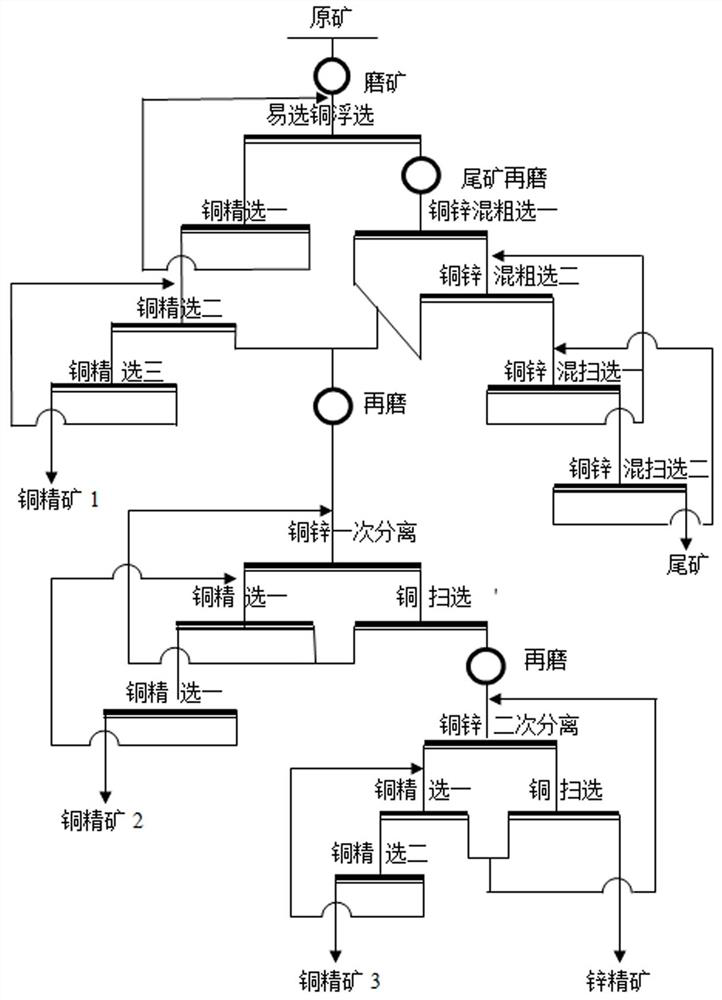

A technology of copper-zinc sulfide and ore dressing method, which is applied in separation of copper and zinc, flotation separation of copper-zinc sulfide ore with complex coarse and fine grains, and beneficiation of complex copper-zinc sulfide ore, to achieve good selectivity and good separation Effect, effect of improving product quality and recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

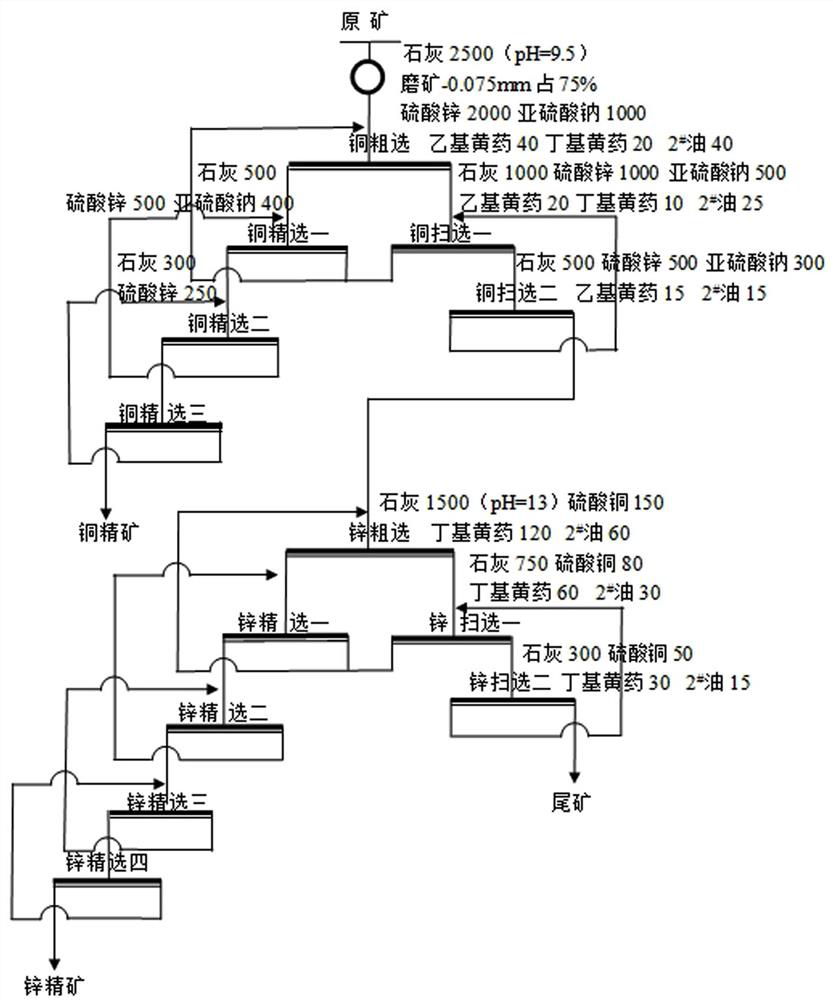

Embodiment 1

[0069] Embodiment 1 A copper-zinc ore ore beneficiation process.

[0070] There are many types of minerals in the ore of a copper-zinc mine, and the mineral composition is relatively complex. The ore mainly recovers valuable elements as copper and zinc, and a small amount of gold is associated with it. The copper minerals are mainly chalcopyrite, whose content is 4.25%, chalcocite bornite and copper blue content are less; the zinc minerals are sphalerite, whose content is 5.33%. The characteristic of this ore is that the chalcopyrite is distributed unevenly in coarse and fine grains, and the sphalerite is mainly distributed in fine grains. Gangue minerals mainly include quartz, feldspar, muscovite, sericite, tremolite, actinolite, biotite, carbonate minerals, chlorite, kaolin and so on. The gold and silver minerals in the ore mainly include gold and silver ore and silver-gold ore. The copper grade in the ore is 2.75%, the zinc grade is 3.26%, and the gold grade is 0.76g / t. ...

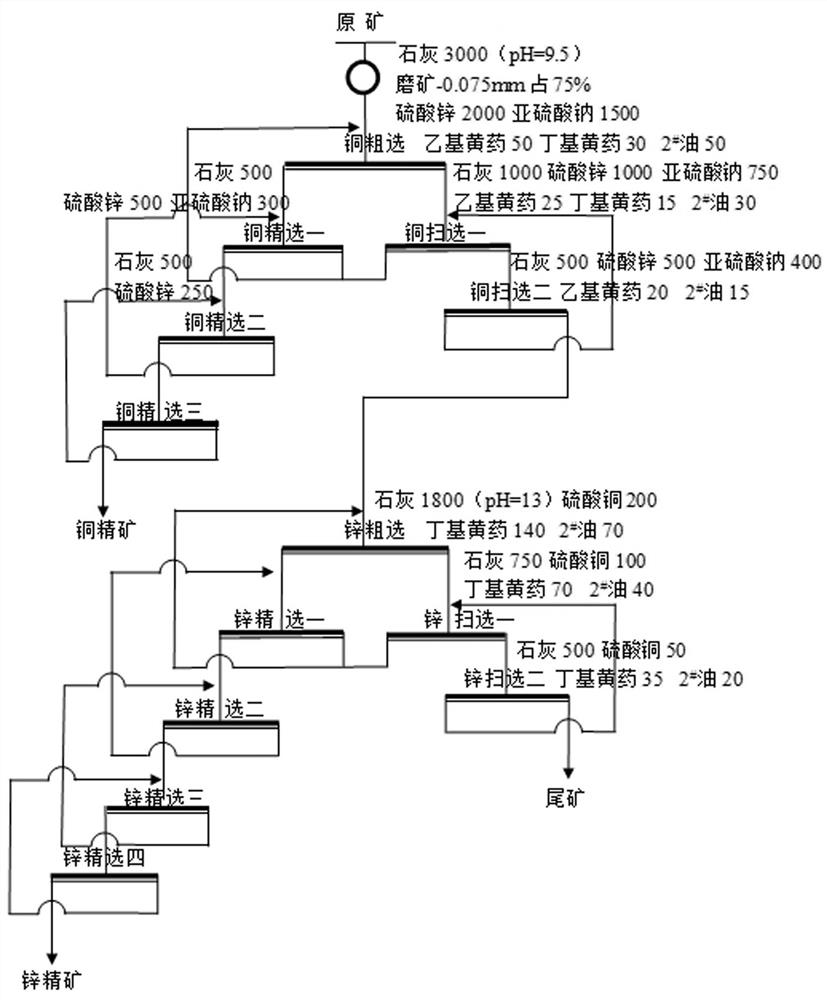

Embodiment 2

[0090] Embodiment 2 ore beneficiation process of a certain copper-zinc ore.

[0091] The mineral composition of a copper-zinc ore is relatively complex, and there are many types of minerals. The ore mainly recovers valuable elements as copper, zinc, and associated gold. Copper minerals are mainly chalcopyrite with a content of 4.03%, chalcocite, bornite and copper blue content are less; zinc minerals are sphalerite with a content of 5.85%. The characteristic of this ore is that the chalcopyrite is distributed unevenly in coarse and fine grains, and the sphalerite is mainly distributed in fine grains. Gangue minerals mainly include quartz, feldspar, sericite, tremolite, actinolite, carbonate minerals, chlorite, kaolin and so on. The gold and silver minerals in the ore mainly include gold and silver ore and silver-gold ore. The copper grade in the ore is 3.02%, the zinc grade is 4.55%, and the gold grade is 0.88g / t. The copper oxidation rate accounts for 2.86%, and the zinc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com