Voice diaphragm pressure bearing piece stamping and laser irradiation composite forming machining device and method thereof

A sound film pressure-bearing part and laser irradiation technology, applied in metal processing and other directions, can solve the problems of difficult to solve the problem of welding seams, reduce the strength of the formed parts, and difficult to fill and form, and achieve significant heating effect, good forming accuracy, and equipment Simple and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

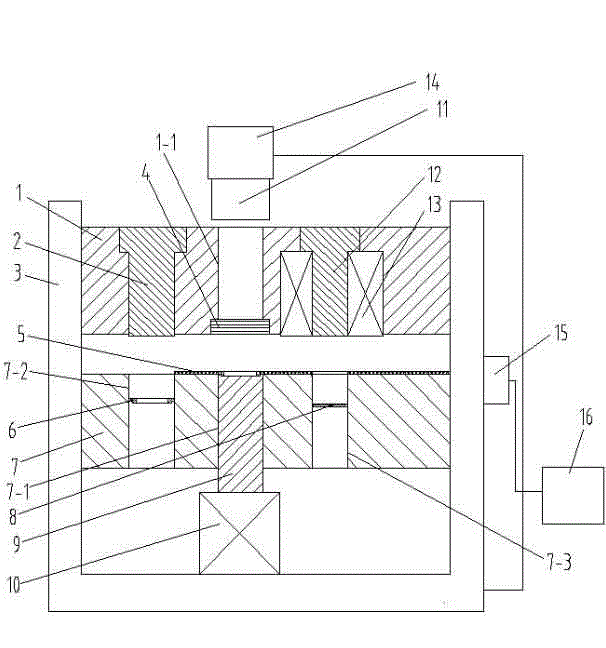

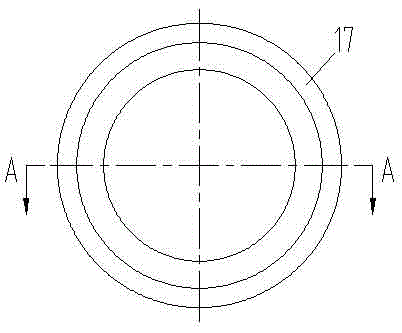

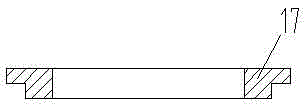

[0048] Embodiment 1: see attached figure 1 ~ attached image 3 , sound film pressure bearing stamping and laser irradiation compound forming processing device, including laser system, stamping die, automatic feeding device 15 and control system 16, laser system includes laser 14, optical path shaping mechanism 11 connected with laser 14, stamping die It includes the mold base 3, the fixed mold plate 7 fixed in the mold base 3, the movable template 1 movably connected in the mold base 3 and located above the fixed mold plate 7, the pressure mechanism 10 fixed in the mold base 3, and the pressure mechanism 10 controls the connected forming punch 9, the punching punch 12 fixed on the movable template 1 and the blanking punch 2, and the movable template 1 is also provided with a blank-holding mechanism 13 fixed on the circumference of the punching punch 12. The middle part of 7 is provided with a forming station hole 7-1, and the forming punch 9 is slidably connected in the form...

Embodiment 2

[0052] Embodiment 2: see attached figure 1 , attached Figure 4 , attached Figure 5 , sound film pressure parts stamping and laser irradiation compound forming processing device, the pressure mechanism 10 is a pneumatic device, and the rest of the structure is the same as in Embodiment 1.

[0053] This embodiment takes the processing of the rectangular ring-shaped sound film pressure-bearing part 18 as an example, the rectangular ring-shaped sound film pressure-bearing part 18 is made of PC material, the design size is 15×10×0.5mm, and the wall thickness is 0.5mm; the laser 14 is a fiber laser . The forming process steps are: a. First prepare the PC strip material 5, determine the laser irradiation parameters and stamping forming process, the laser output from the laser 14 is shaped by the optical path shaping mechanism 11, the shape of the laser beam is a rectangular ring, and the rectangular ring-shaped sound film The pressure-bearing parts 18 are consistent, set the wor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com