Glass magnesium board demoulding machine and demoulding method

A glass magnesium plate demoulding machine and glass magnesium plate technology are applied in unloading devices, metal processing equipment, stripping devices, etc., which can solve problems such as low efficiency and high labor intensity of workers, and achieve simple and convenient operation, saving manpower, and avoid crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0051] Those skilled in the art can understand that unless otherwise defined, all terms (including technical terms and directional terms) used herein have the same meanings as commonly understood by those of ordinary skill in the art to which the present invention belongs.

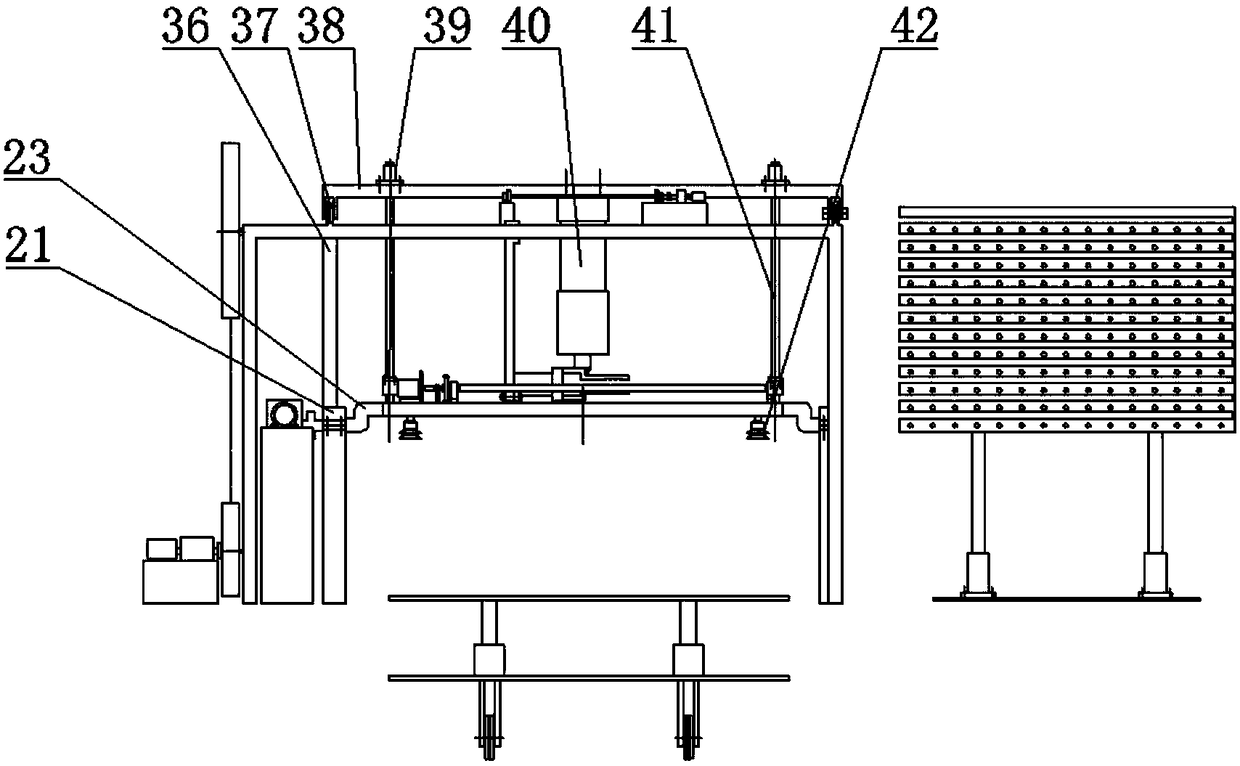

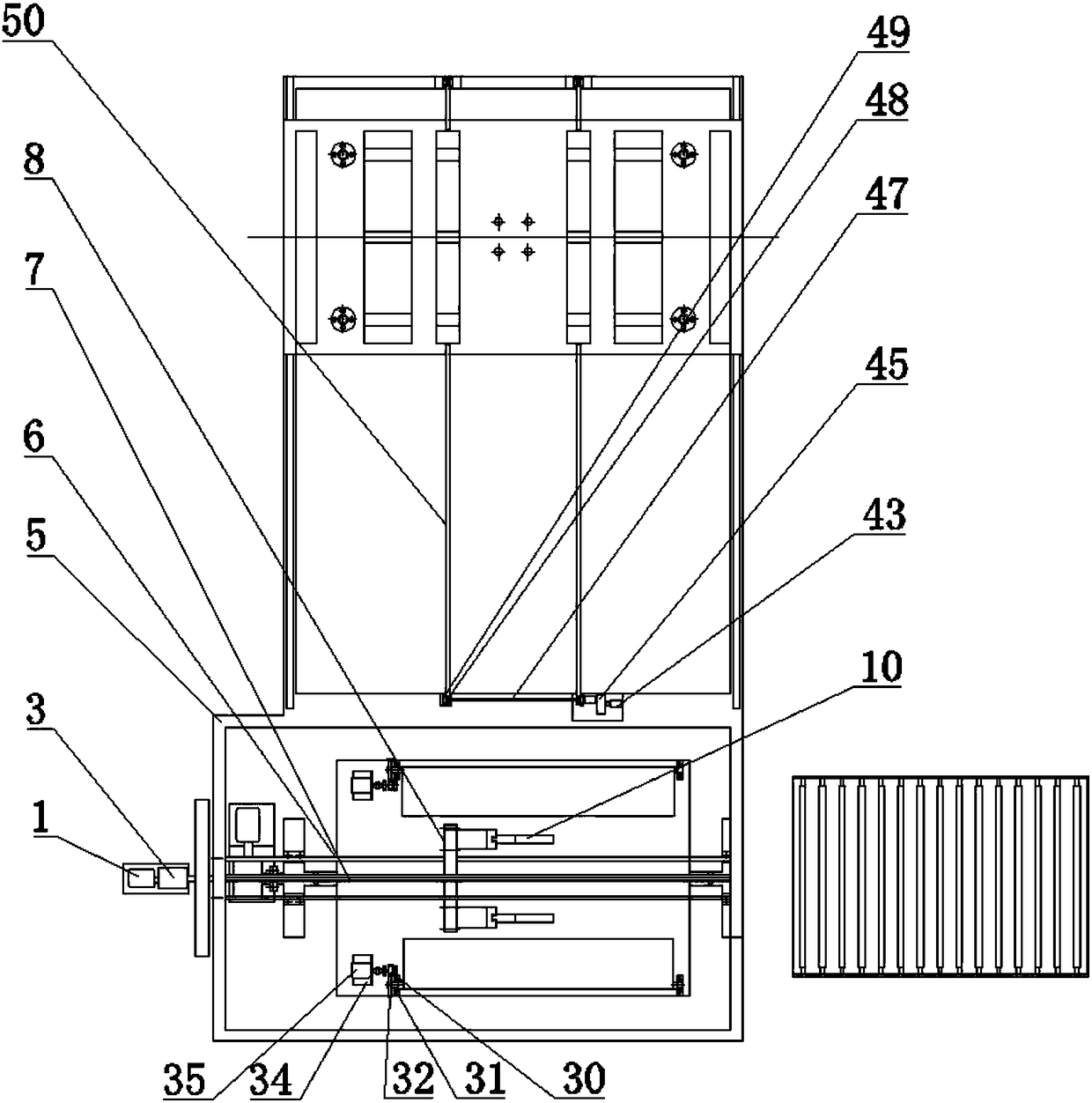

[0052] Such as Figure 1 to Figure 3 As shown, a glass magnesium plate demoulding machine includes a pumping plate assembly, a flip assembly, a separation assembly, a three-dimensional plate frame 19 and a mobile trolley;

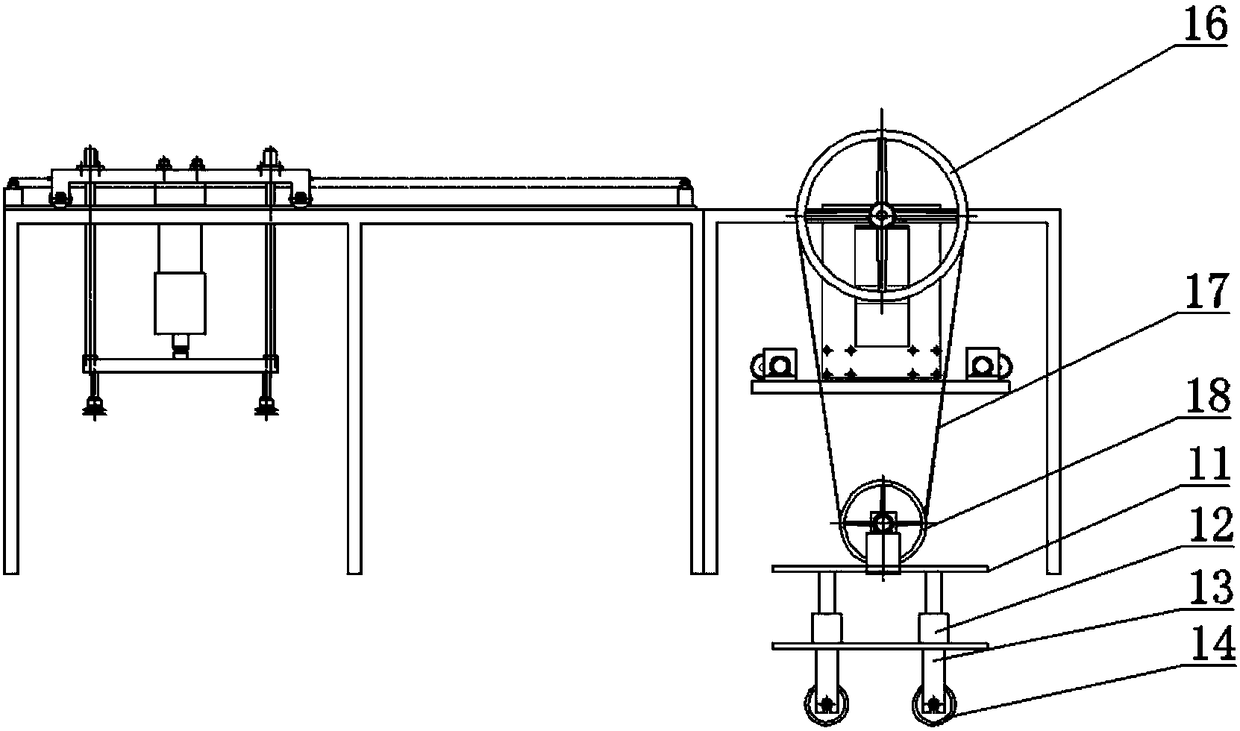

[0053] Such as Figure 4 to Figure 6 As shown, the pumping plate assembly includes pumping plate motor 1, pumping plate nut 2, pumping plate reducer 3, pumping plate large pulley 16, pumping plate small pulley 18, pumping plate belt 17, frame 5, pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com