Patents

Literature

35results about How to "Stereotype stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

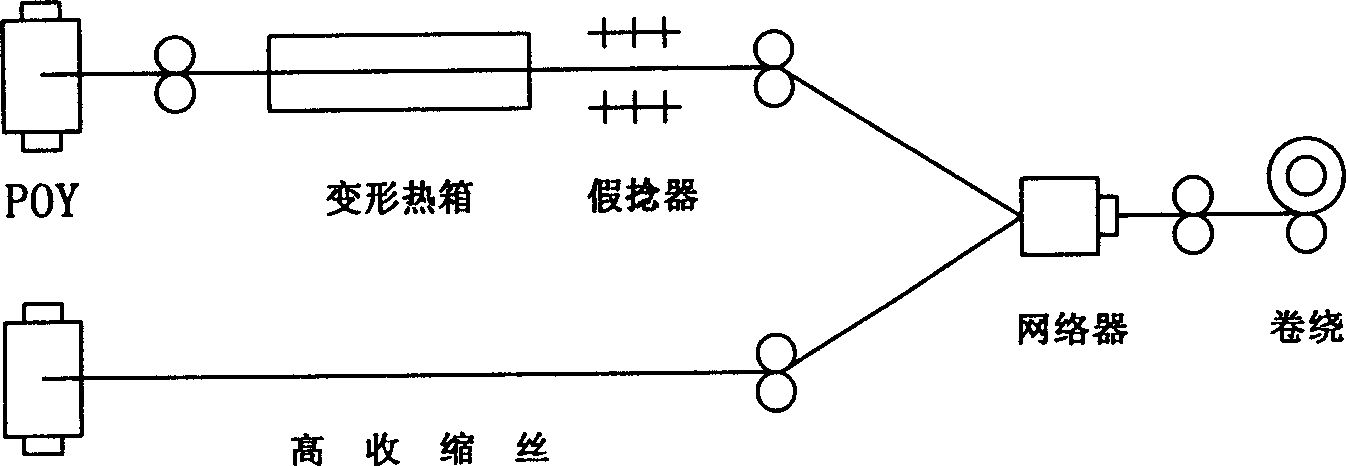

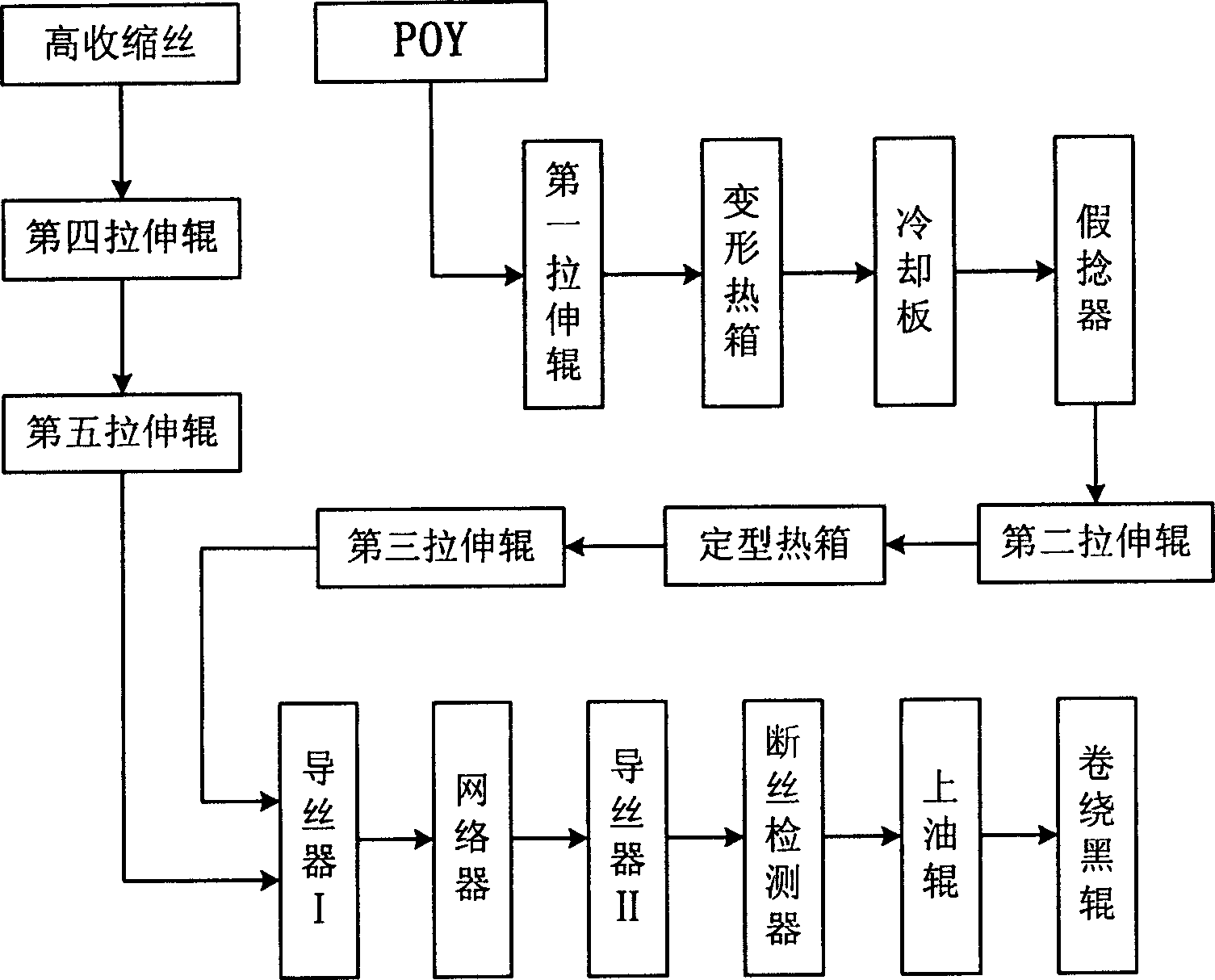

Process for preparing plied yarn by one-step process using textured yarn and highly retractable yarn

The invention relates to a process for preparing plied yarn by one-step process using textured yarn and highly retractable yarn, comprising: having the draw texturising machine as main processing device, drawing and deforming the pre-oriented yarn POY, heating moulding the produced deforming yarn by the heat moulding box and the third drawing roll; meanwhile, setting the fourth and fifth drawing roll on the draw texturising machine, feeding and drawing the highly retractable yarn, sending into network device for combining with the deformation yarn, detecting and oiling by guide, detector and oiling roll, finally winding to obtain the resultant yarn. The invention increases the moulding procedure of the deformation yarn, solves the problem the moulding the yarn combining in a single step. The resultant yarn has a good fastness and uniformity of the network degree, little yarn breakage which can be used to produce the material like wool fabrics, polyester peach skin, suede nap.

Owner:中国石化仪征化纤股份有限公司

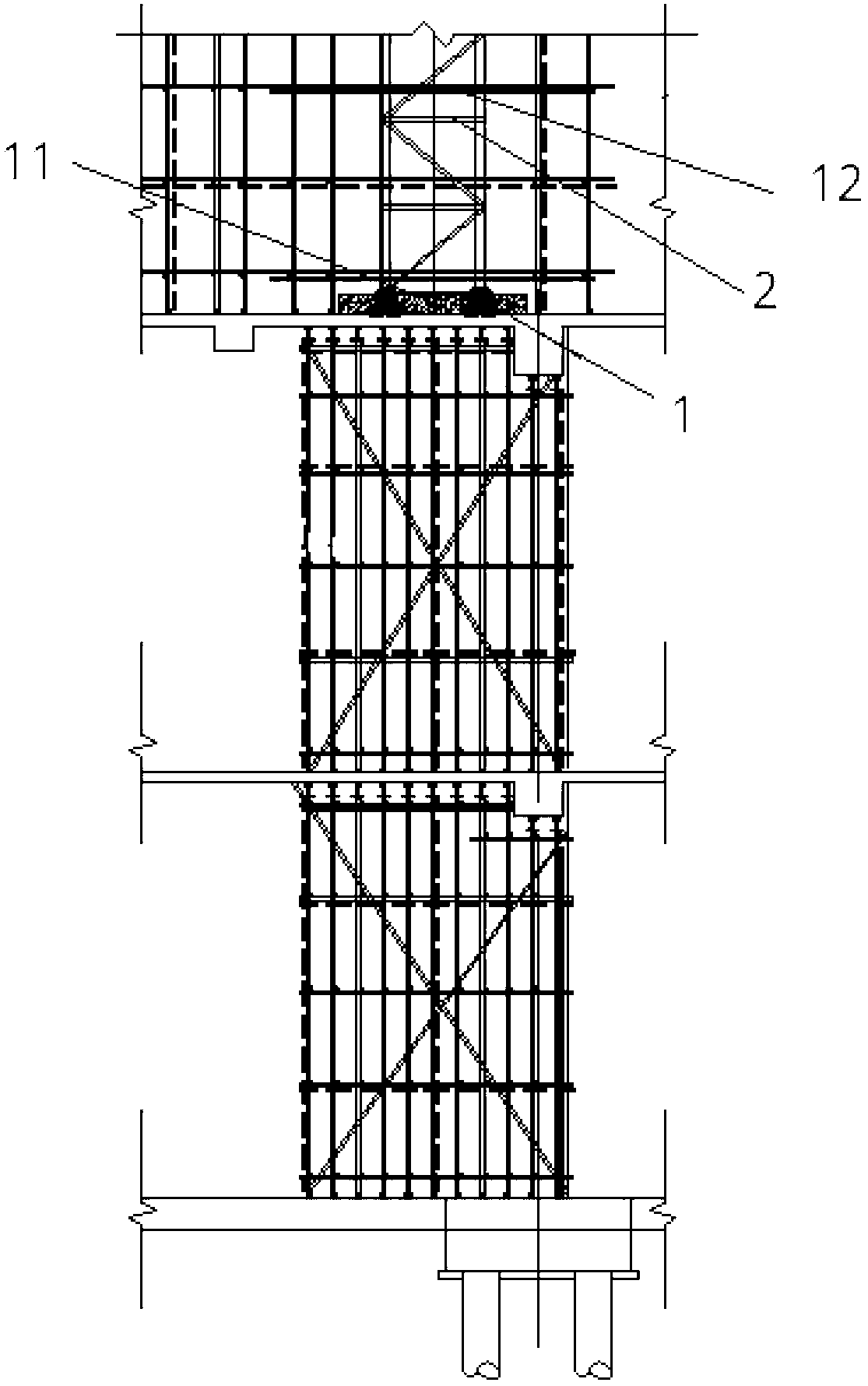

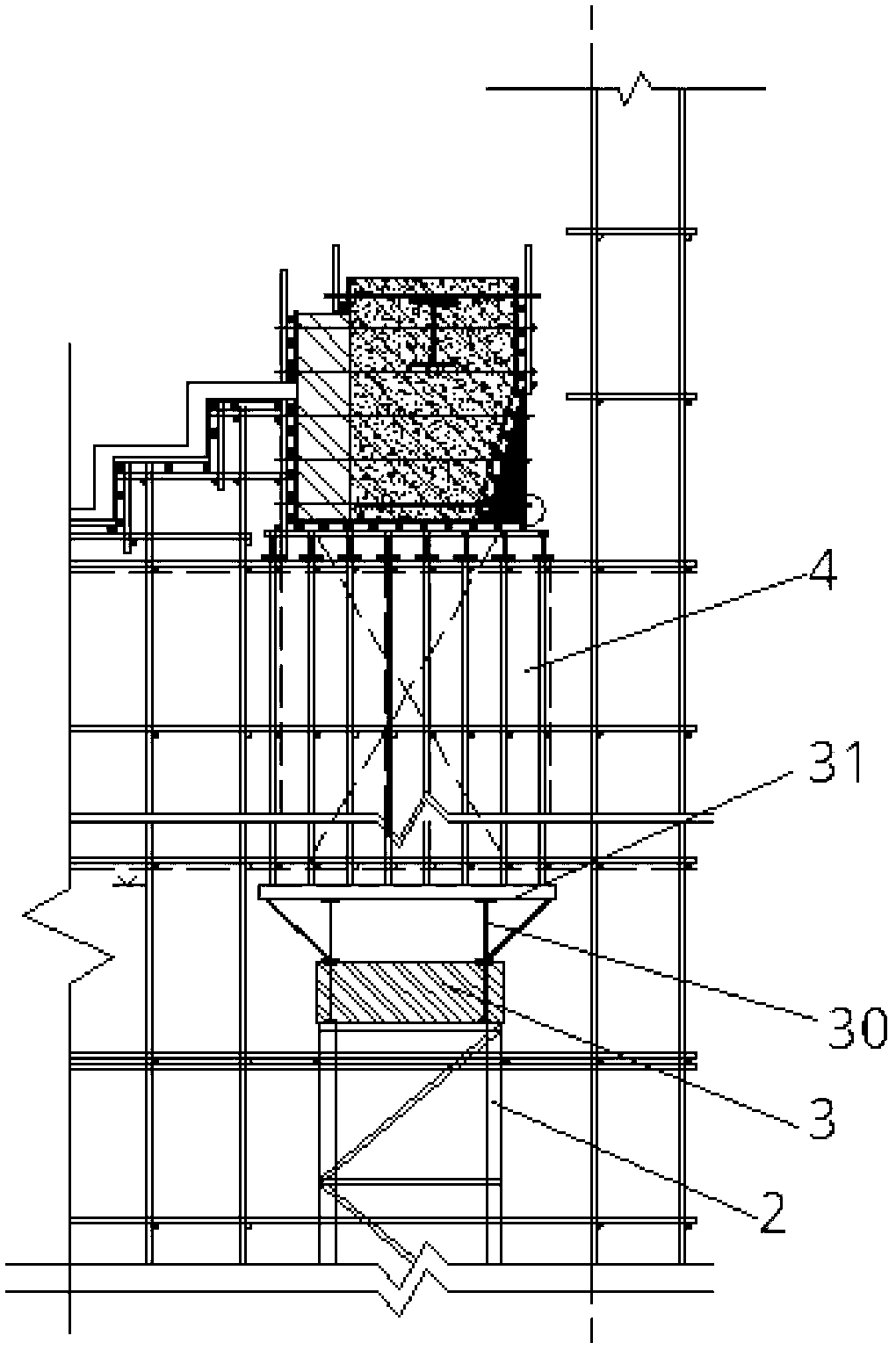

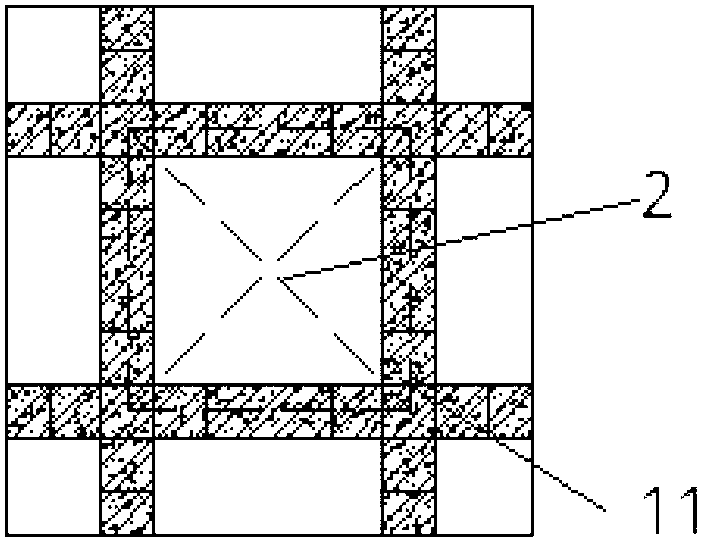

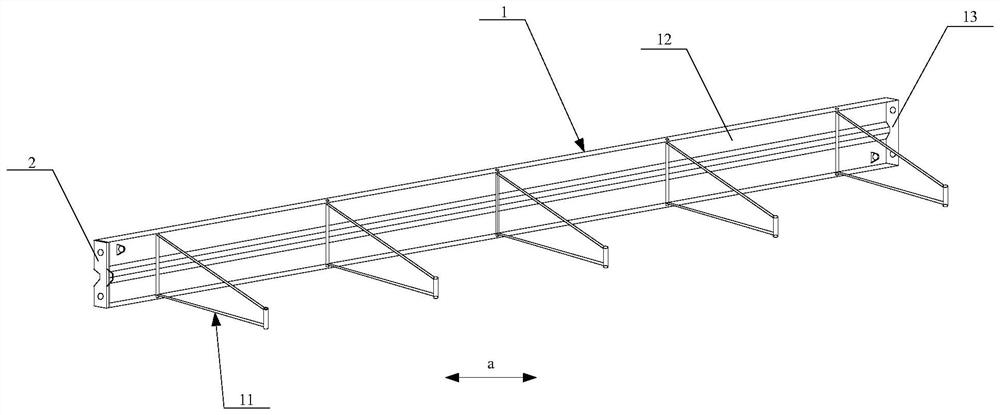

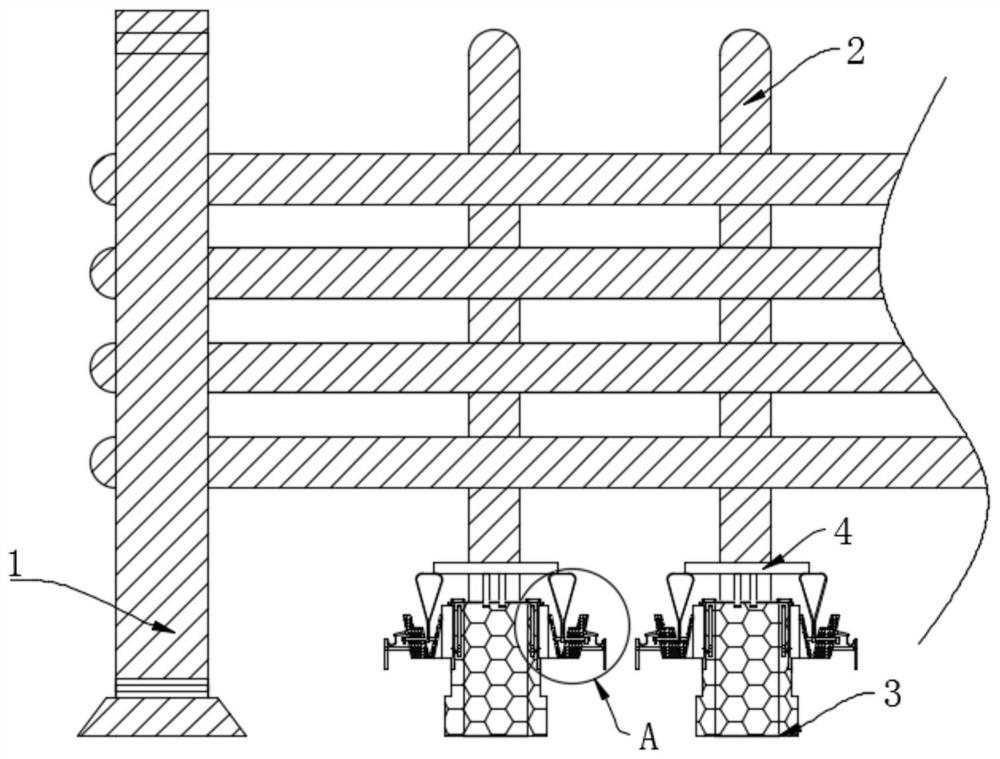

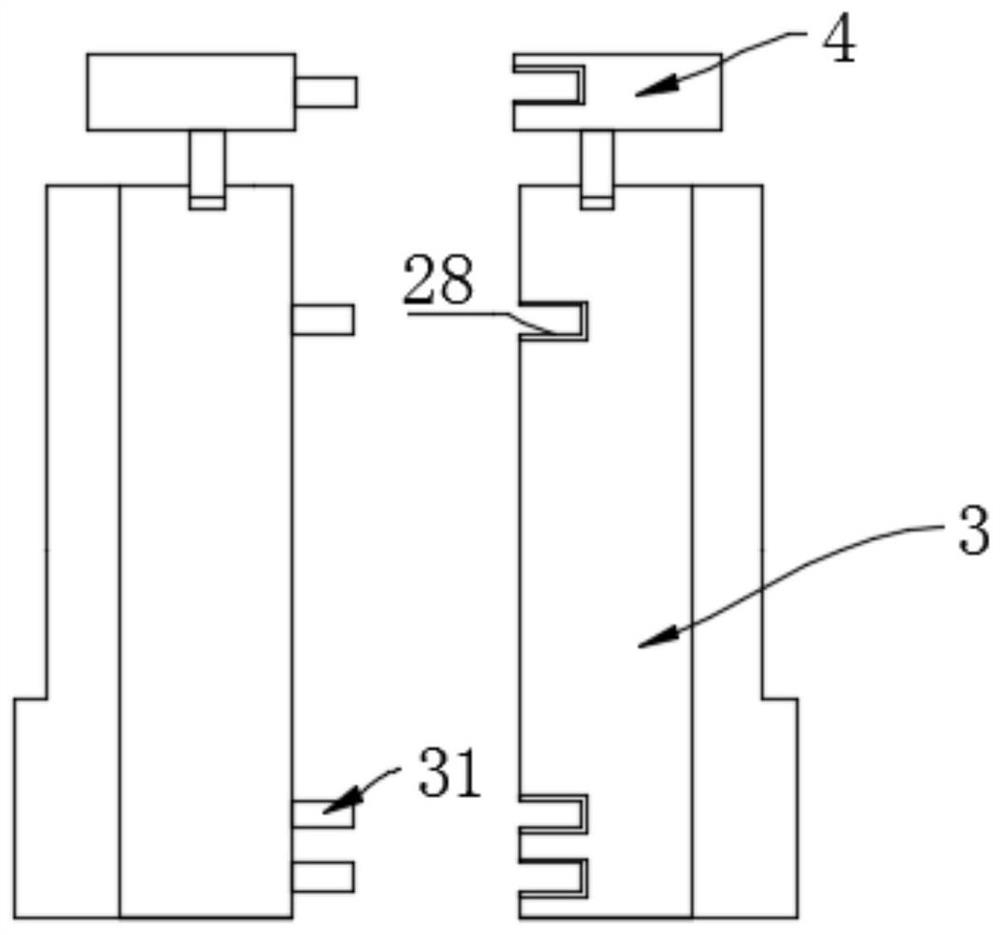

Tower crane standard knot bearing upper air supporting formwork steel platform structure and construction method

InactiveCN103122691APower transmission is clearReasonable forceForms/shuttering/falseworksBuilding material handlingTower cranePipe support

The invention discloses a tower crane standard knot bearing upper air supporting formwork steel platform structure which comprises a tower crane standard knot latticed column foundation and a tower crane standard knot, which is installed on the tower crane standard knot latticed column foundation, of a latticed column structure. A peripheral supporting formwork frame is arranged on the periphery of the tower crane standard knot. The top portion of the tower crane standard knot is provided with a square-shaped or H-shaped top supporting seat. A steel platform is installed on the top supporting seat. A steel pipe supporting frame is installed on the steel platform. A wood beam and a formwork are arranged on the steel pipe supporting frame and used for pouring concrete. The tower crane standard knot bearing upper air supporting formwork steel platform structure has the advantages of being clear in power transmission of a supporting formwork system, reasonable in stress, safe and reliable, capable of meeting requirements that cross section of the structure is large in size and high in erecting height, convenient to construct, workable in construction, stable in sizing and capable of shortening construction period.

Owner:ZHONGTIAN CONSTR GROUP

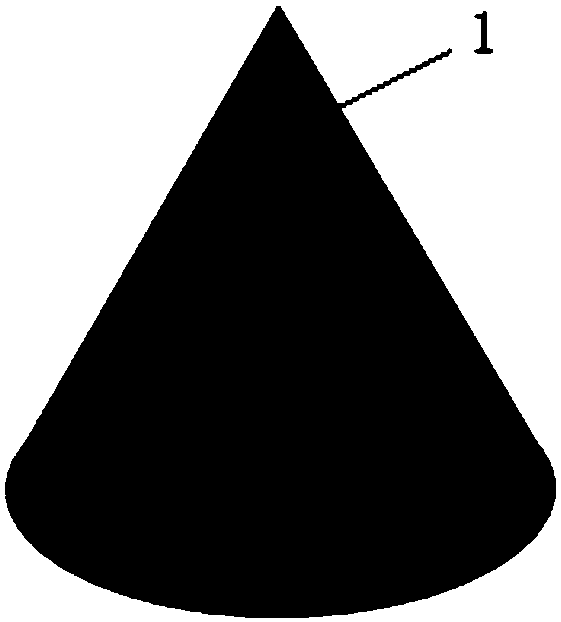

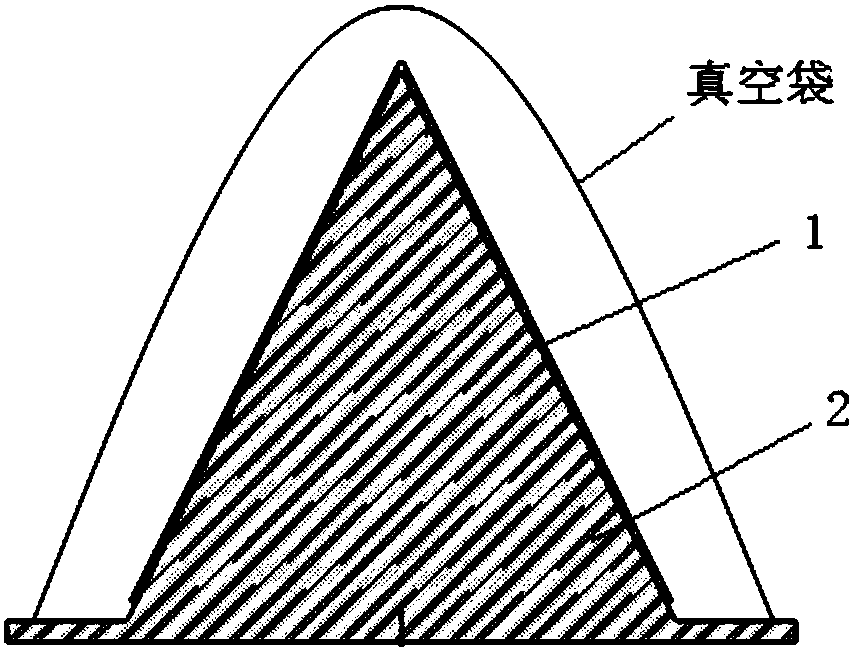

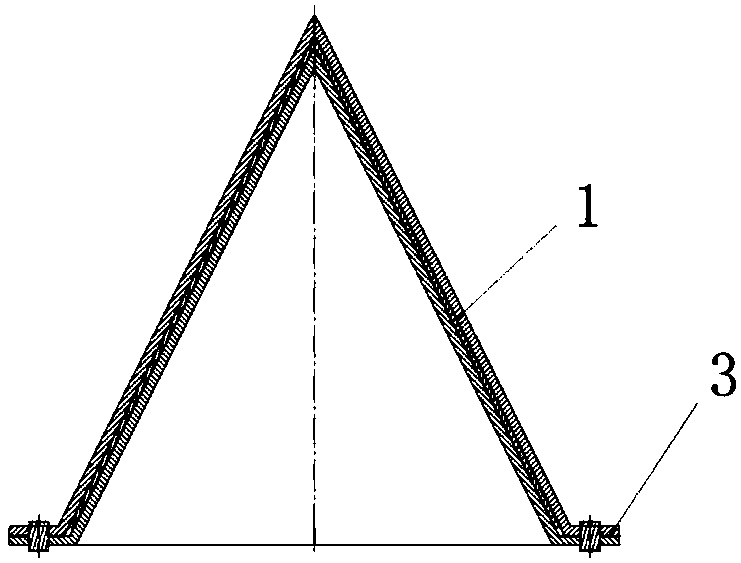

Forming method of thin-walled conical cylinder-shaped ceramic matrix composite component

The invention relates to a forming method of a ceramic matrix composite, in particular to a forming method of a thin-walled conical cylinder-shaped ceramic matrix composite component. According to theforming method, a combined setting mode of autoclave setting and graphite die shape maintenance is adopted; an autoclave technology is more suitable for formation of a resin matrix composite, the pressure in the autoclave is smaller than 1MPa generally, the temperature in the autoclave is smaller than 300 DEG C generally, and formation is completed once for all. The forming method provided by theinvention can solve the problem of large difficulty in formation of the thin-walled conical cylinder-shaped ceramic matrix composite component; and compared with the existing forming method, the forming method can be used for forming the thin-walled conical cylinder-shaped ceramic matrix composite component with uniform volume fraction of fibers and high contour accuracy. The forming method fullyutilizes the advantage of being suitable for forming the thin-walled conical cylinder-shaped component of the autoclave and the advantages of temperature resistance and stabilization in setting of agraphite die, the component is transferred into the graphite die for shape maintenance after being subjected to setting with the autoclave, and the component forming accuracy in a subsequent high-temperature dense technology is ensured.

Owner:AVIC BASIC TECH RES INST

Bamboo vinegar honeycomb type purifying activated carbon and preparation method thereof

ActiveCN103418343AStrong adsorption functionAccelerate the speed of adsorption and desorptionOther chemical processesHoneycombMethyl cellulose

The invention belongs to a bamboo vinegar honeycomb type purifying activated carbon and a preparation method thereof. The bamboo vinegar honeycomb type purifying activated carbon comprises, by weight, 35-40 parts of chemical activated carbon, 25-35 parts of granular activated carbon from coal, 43-49 parts of coconut shell activated carbon, 9-15 parts of bamboo vinegar, 2-3 parts of methyl cellulose and 2-3 parts of talcum powder. The preparation method includes ball grinding, well mixing raw materials, producing product materials, and subjecting the product materials to vacuum pugging, extrusion forming, drying and sintering. The bamboo vinegar honeycomb type purifying activated carbon is good in dirt absorption capability, firm in shaping durable, simple and practical in preparation method, low in sewage treating cost, low-carbon, energy saving, and good in treating effect, and corruption odor generated by toilets, livestock, fish and the like can be purified.

Owner:LISHUI HE ZI PURIFICAT EQUIP CO LTD

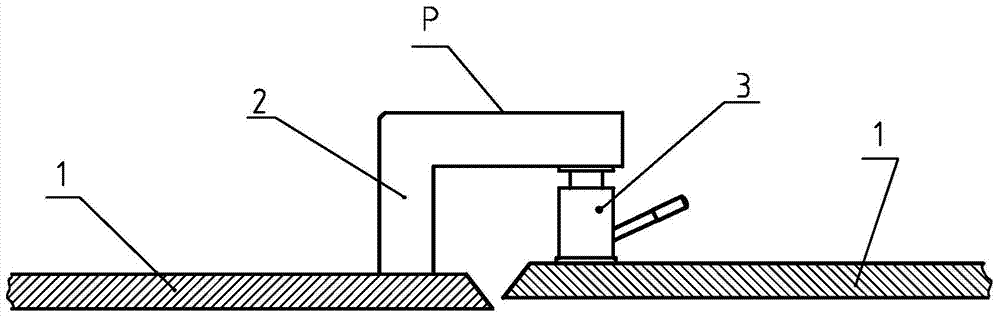

Novel shipbuilding assembly method and steel plate leveling device

InactiveCN104259681AAvoid damageSave human effortWelding/cutting auxillary devicesVessel partsManufacturing technologyWeld seam

The invention discloses a novel hull erection method and belongs to the technical field of shipbuilding. The method includes the steps such as cutting grooves, grinding the grooves, assembling, leveling steel plates, applying pads, welding priming weld seams required for the production of positioning weld seams, welding the positioning weld seams, welding transition weld seams, welding erection weld seams, and polishing the erected whole. The novel hull erection method has the advantages that clamp plates are replaced with the positioning weld seams, the steps of welding the clamp plates and cutting the clamp plates are omitted, manpower and material resources and raw materials are greatly saved, less damage is caused to a hull, cost of polishing before and after welding is saved, and the basis for automated welding is laid.

Owner:宋广科

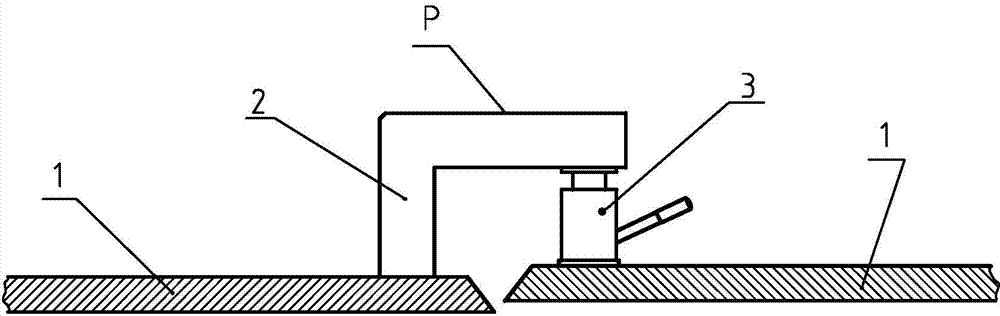

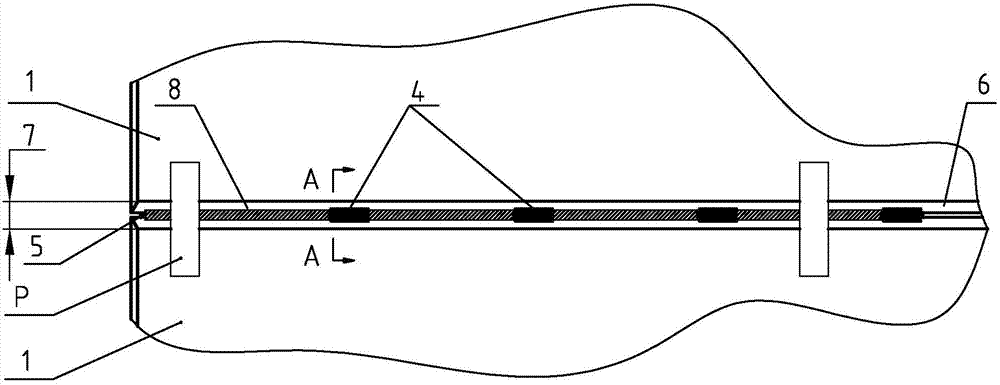

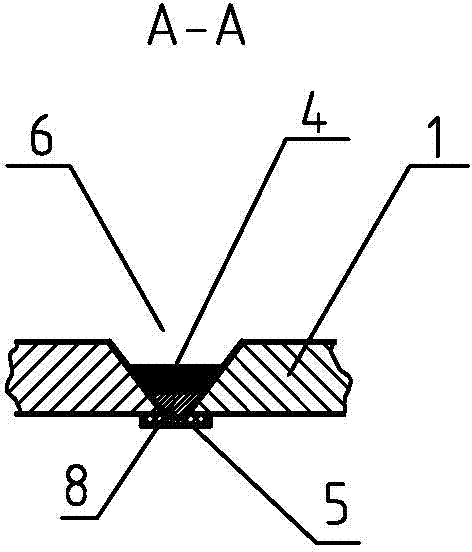

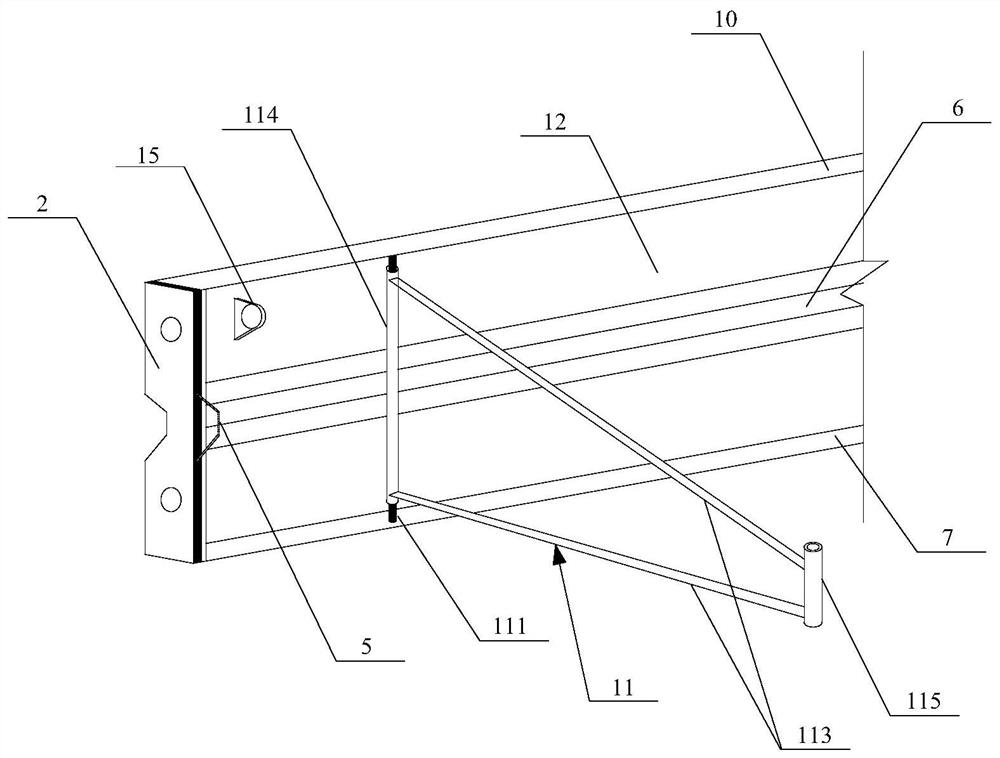

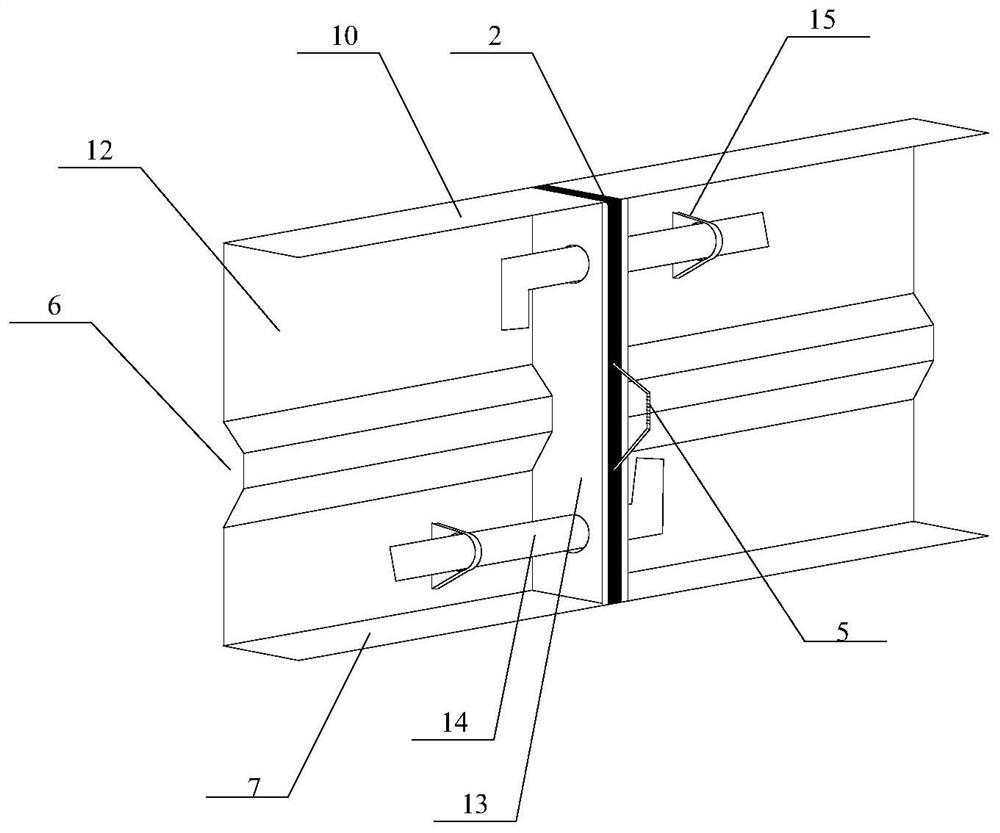

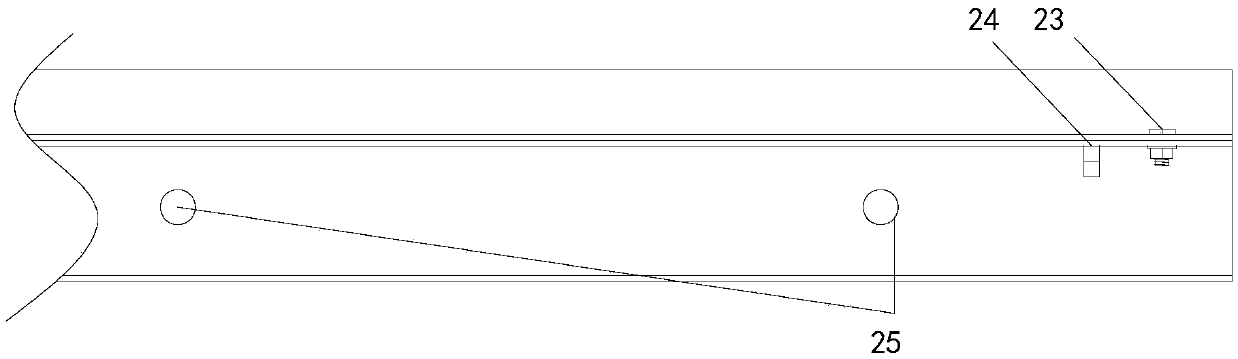

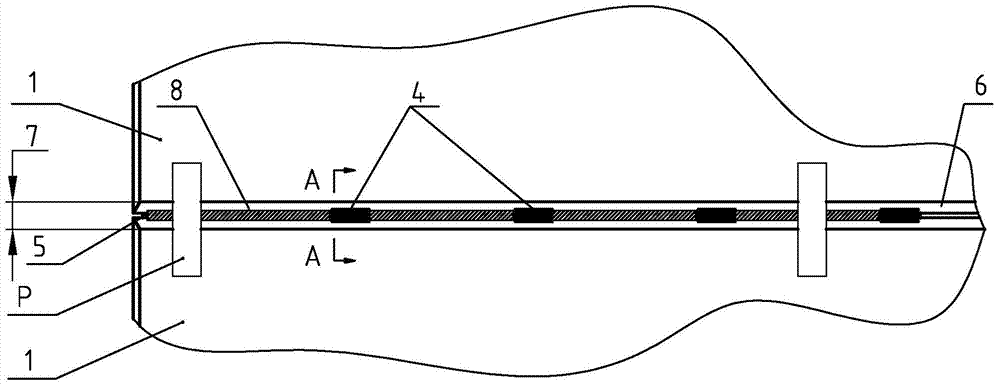

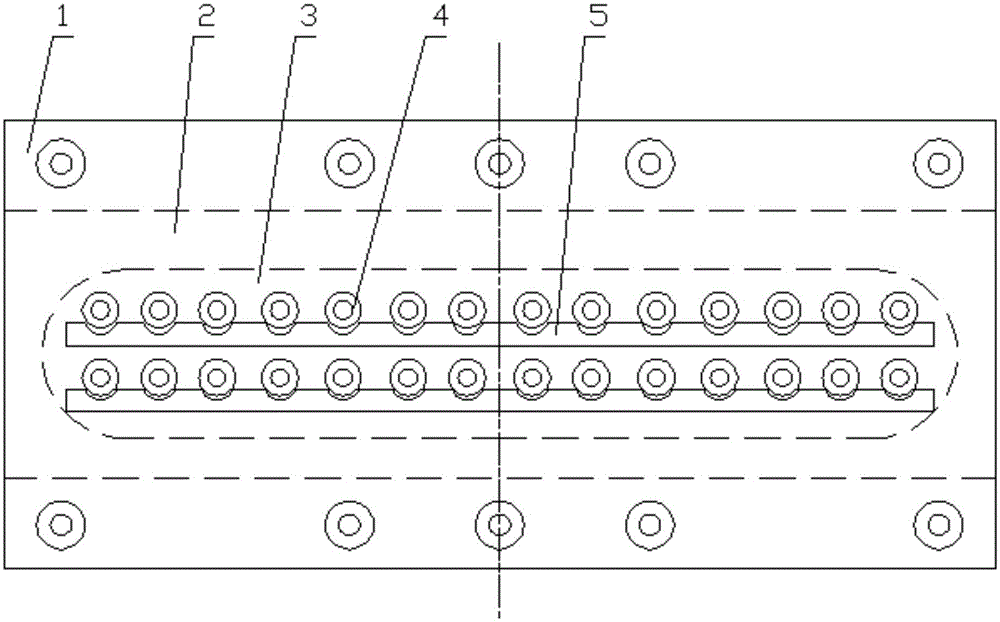

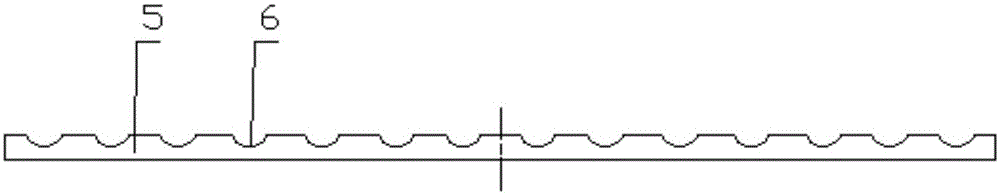

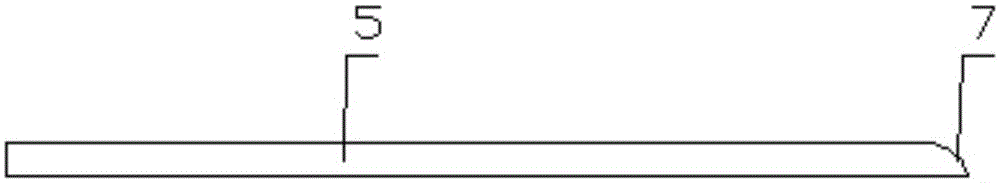

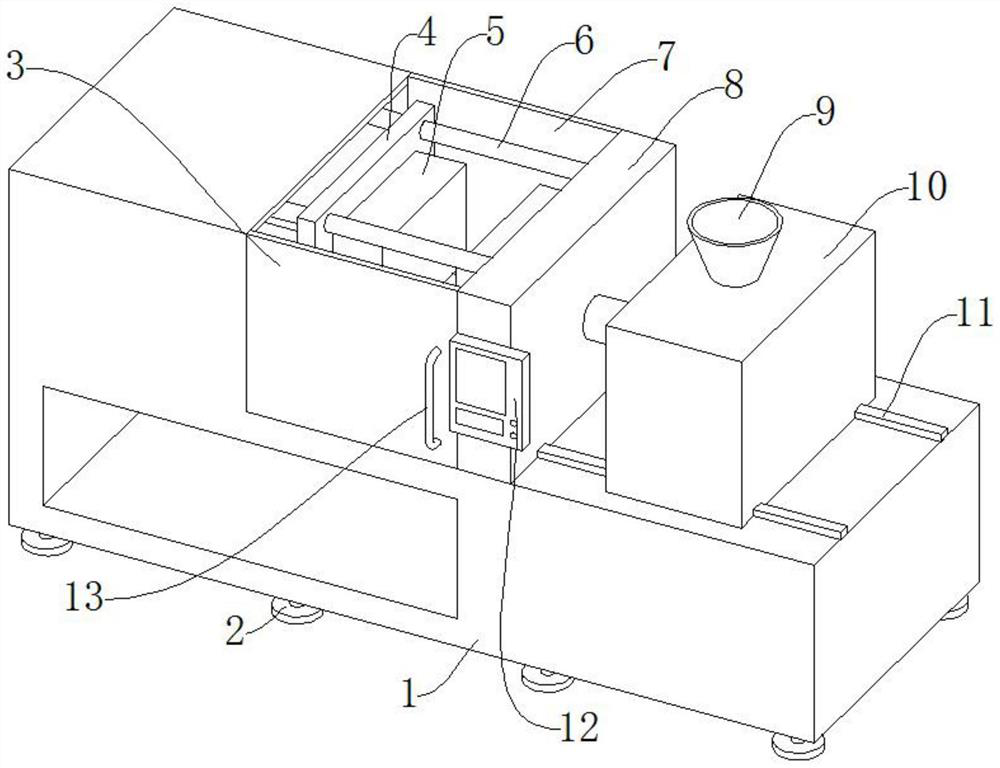

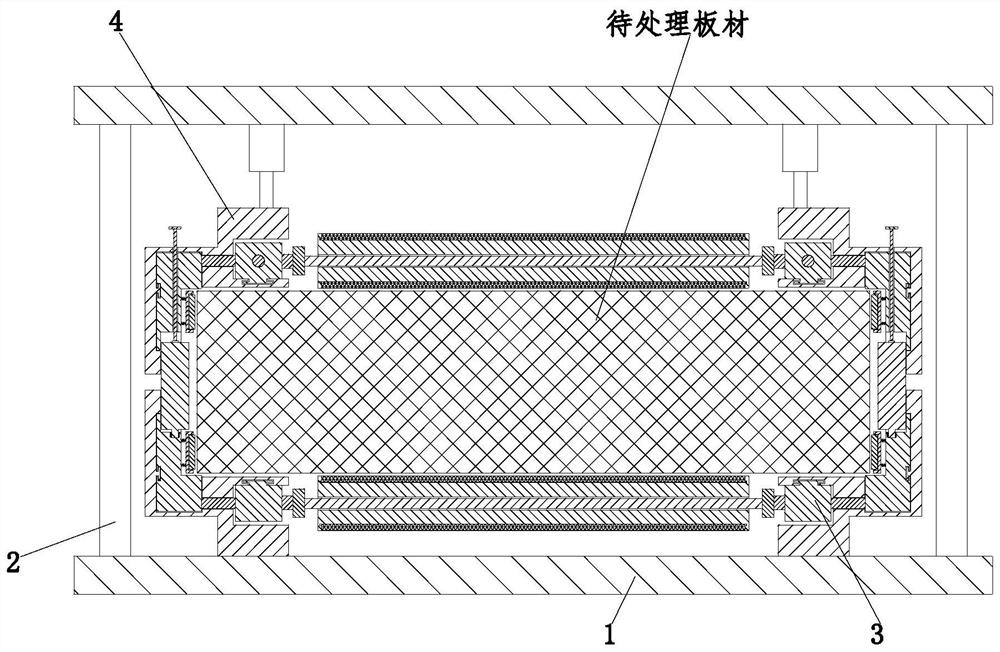

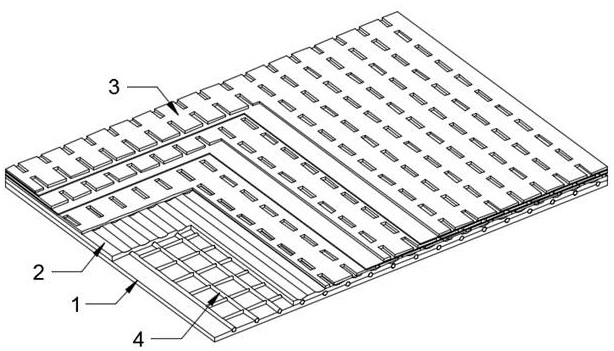

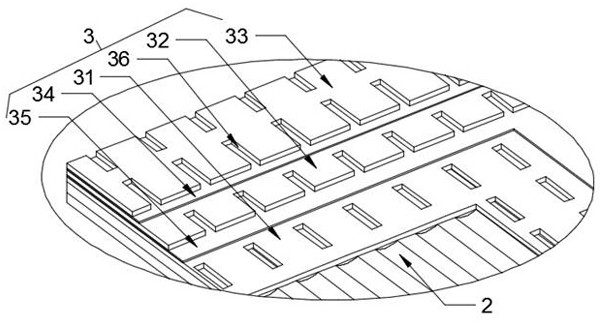

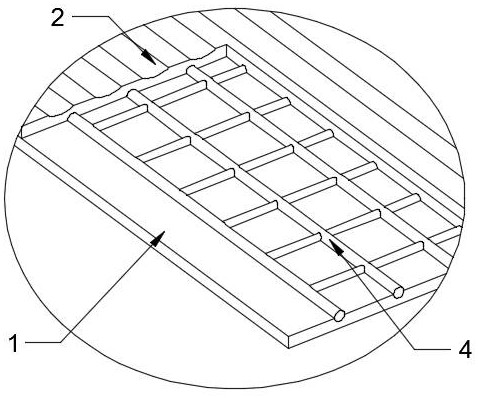

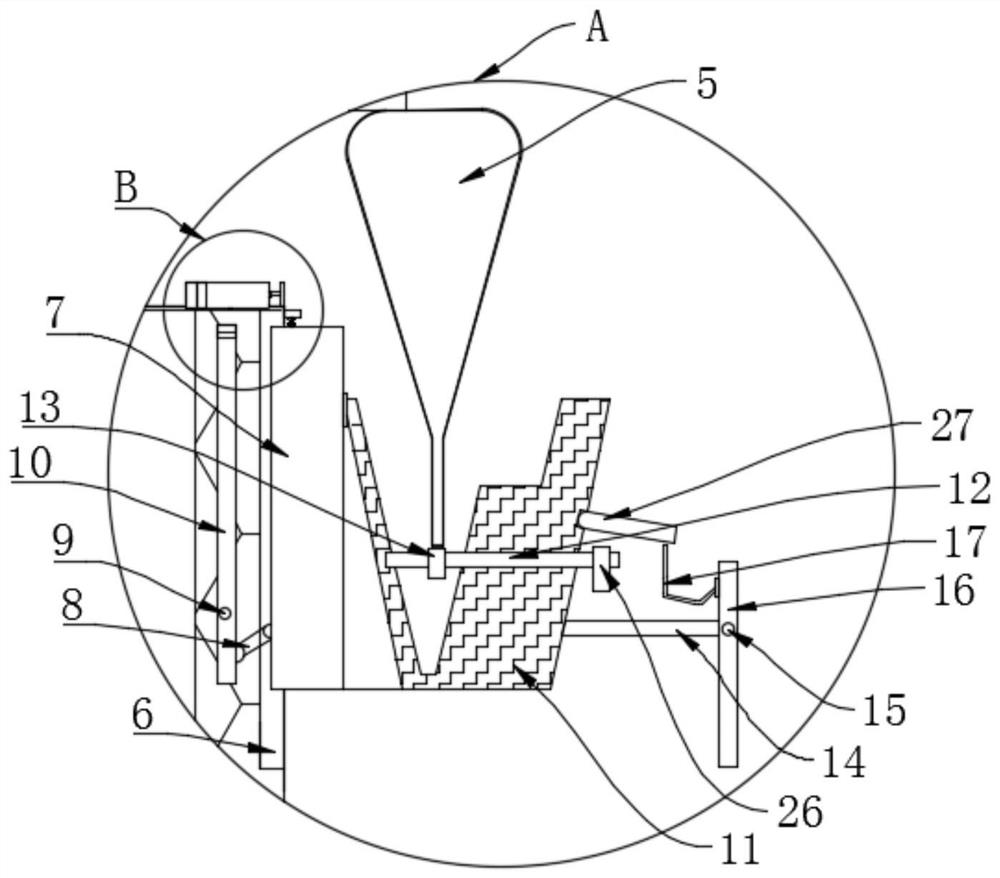

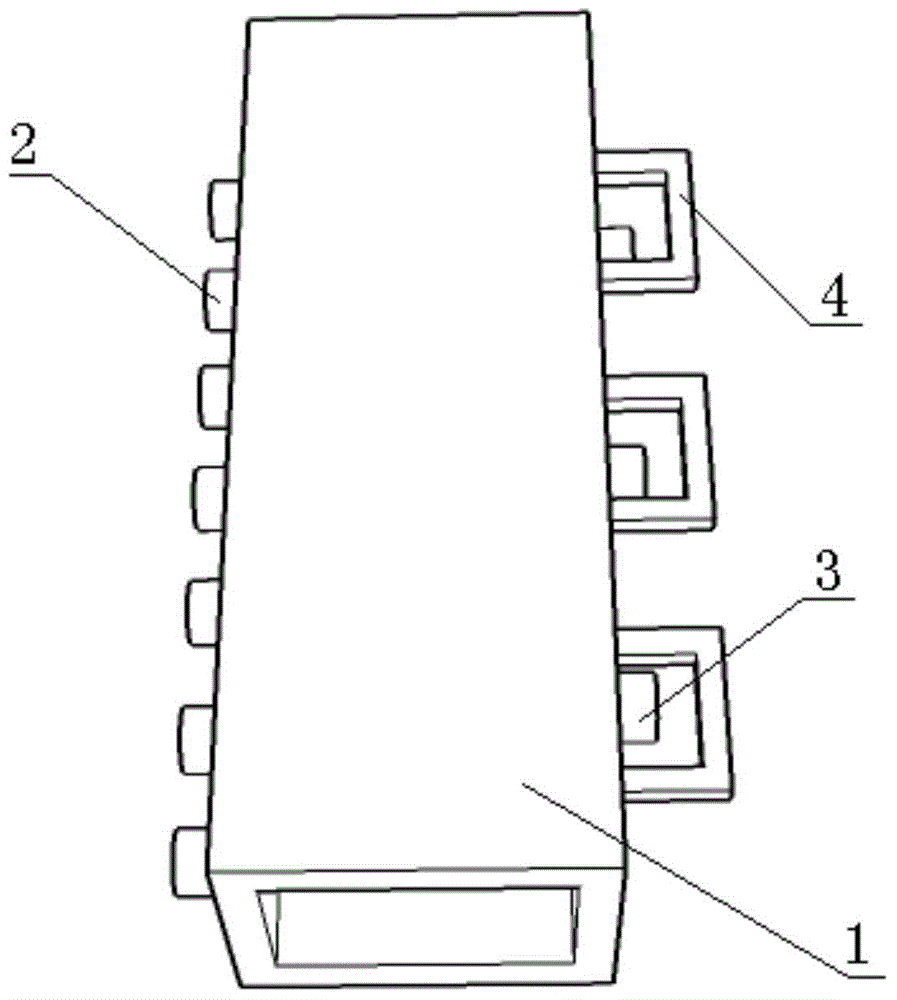

Form device and form system

ActiveCN111979882AStereotype stableQuality assuranceRoads maintainenceArchitectural engineeringRoad surface

The invention provides a form device and a form system. The form device comprises two form structures and a joint cutting plate; the two form structures are oppositely arranged, each form structure isused for shaping poured concrete; and the joint cutting plate is clamped between the two form structures in a drawable manner. According to the form device and the form system, the two form structures support the poured concrete to ensure that the concrete can be stably shaped, when the concrete reaches a preset degree, the joint cutting plate can be pulled out from the space between the two formstructures, and then joint cutting is carried out according to a gap between the two form structures after the joint cutting plate is pulled out, and the two form structures do not need to be dismounted during joint cutting, so that joint cutting and form dismounting are carried out in sequence according to the standard process, joint cutting is carried out in time, the pavement quality is guaranteed, pavement cracks caused by untimely joint cutting are avoided, the strength of all parts of the concrete is guaranteed, and the overall quality of the poured concrete is improved.

Owner:CHINA FIRST METALLURGICAL GROUP

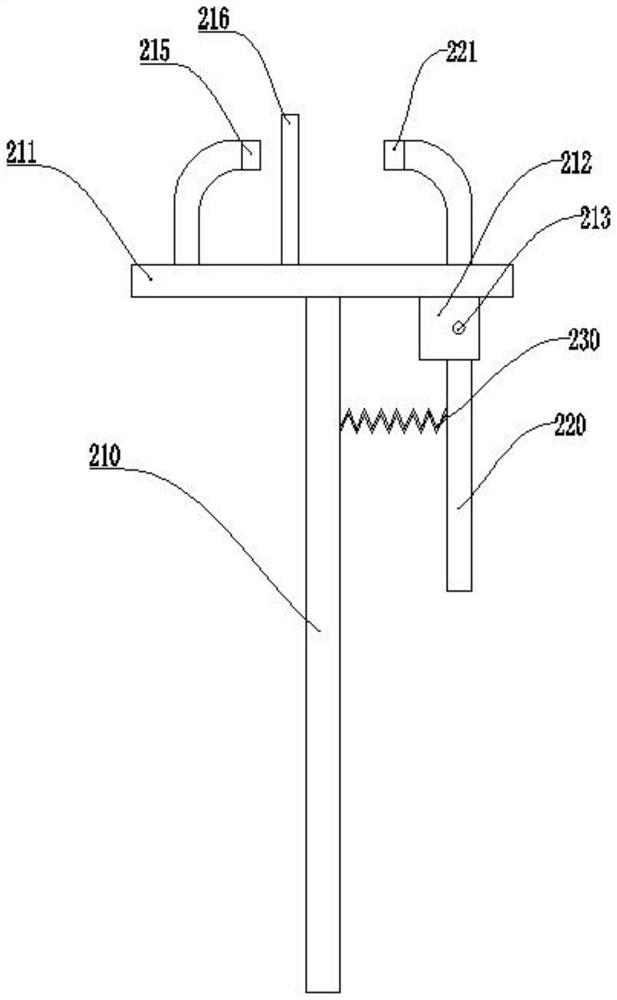

Plant modeling method

InactiveCN108934899ALive fastQuick transplanting and shapingMagnesium fertilisersAlkali orthophosphate fertiliserWound healingPlant models

The invention belongs to the technical field of plant modeling, and discloses a plant modeling method. The plant modeling method includes the five steps of digging a tree pit, installing a support, selecting a seedling for planting, cutting branches for culturing and conducting auxiliary modeling. Plant modeling is completed under the leeward shade condition, the final plant model is more attractive through the support and the cut-for-culture mode, modeling can be realized in the current year, the formed plant model can be moved, and the plant is rapid in after-transplanting survival, high insurvival rate, rapid in transplanting and modeling, stable in modeling and rapid in setting effect; plant selecting is conducted during planting, plant wound healing cream is smeared after cutting, fracture surface healing and rapid germinating are promoted, the damage of harmful substances to sections is relieved, and the success rate is increased; the modeling time is shortened, the ornamental value is good, and the method is suitable for use and popularization.

Owner:成都千蜀农业发展有限公司

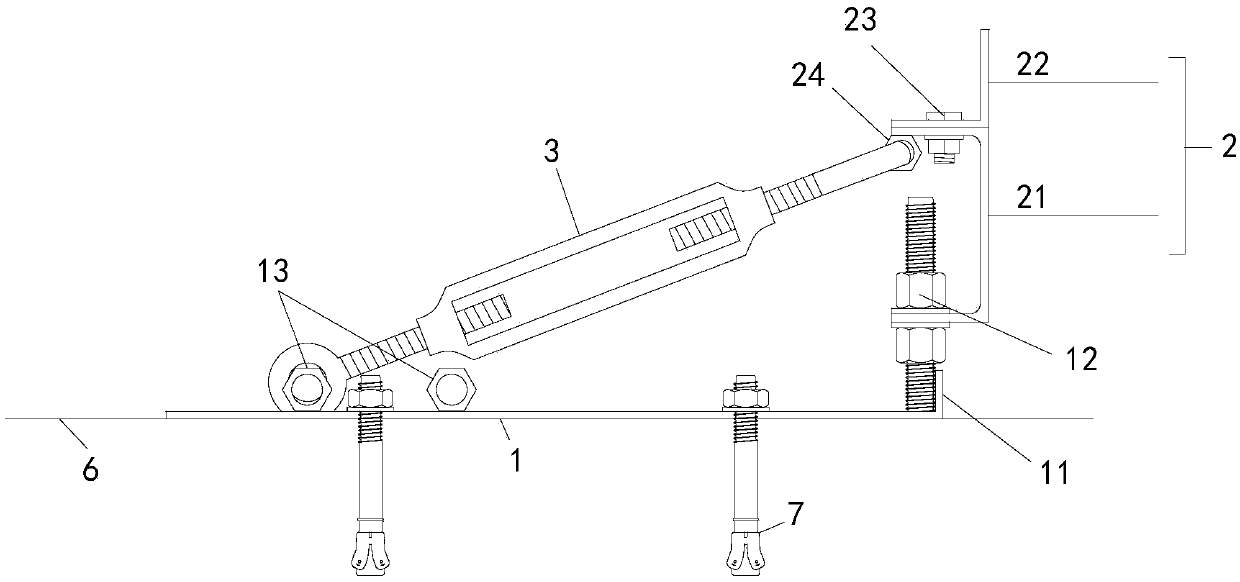

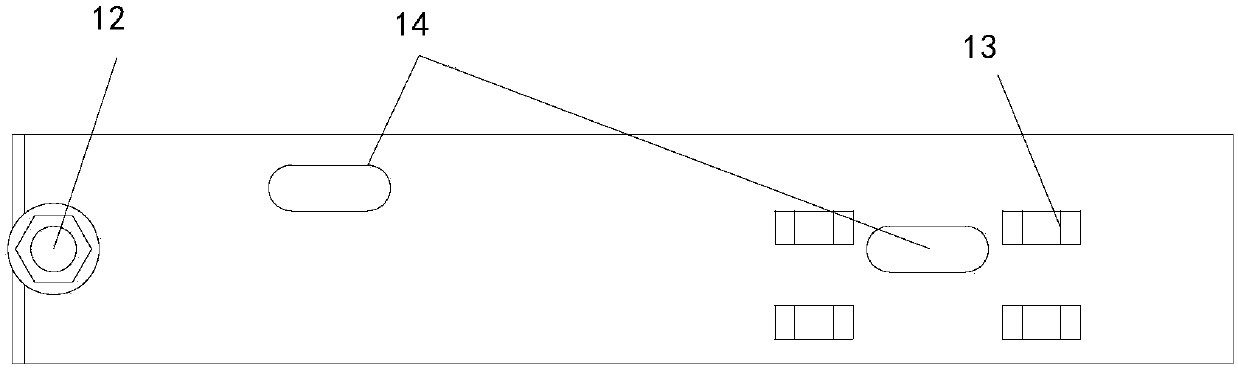

Adjustable form special for floor construction and construction process thereof

PendingCN109098418AStereotype stableWill not deformBuilding constructionsFinal product manufactureArchitectural engineeringSteel plates

An adjustable form special for floor construction and a construction process thereof are provided. The adjustable form special for floor construction comprises a steel plate base, a steel form and a turnbuckle. The bottom face of the steel plate base is straight. Multiple of the steel plate bases are fixed to a concrete cushion layer at designed intervals through expansion bolts. Screws perpendicular to the steel plate base are welded onto the steel plate base. The steel form is perpendicular to the steel plate base. The bottom of the steel form is fixed to the screws of the steel plate base via adjusting nuts so that multiple steel plate bases can be connected together. The turnbuckle for stabilizing the connection of the steel plate base and the steel form and adjusting evenness of a side face of the steel form is connected between the steel form and the steel plate base. The adjustable form special for floor construction is suitable for all floor construction projects having high evenness requirement, has good shaping firmness, simple structure and high adjusting precision, is convenient to mount and demount and transport, and is suitable for reuse.

Owner:中建五局第三建设有限公司

A process for mixing activated carbon with hemp stalks and roots

InactiveCN106608625BLarge specific surface areaStrong adsorption functionCarbon compoundsSolid waste disposalActivation methodTree root

The invention aims to provide a preparation method for mixed active carbon. The mixed active carbon is prepared from China hemp stems and tree roots through activation, kneading and extrusion by using a one-step phosphoric acid activation method. Selection of active carbon made of corresponding materials according different adsorption objects has not been reported in current single active carbon application technology. Normally, active carbon is prepared from a single material in the prior art, which leads to low adsorption rate and poor adsorption effect of the active carbon. The active carbon prepared in the invention has a high specific surface area, a good dirt adsorption function and the advantages of firm shaping, usage of the waste, low pollution treatment cost, low carbon, energy conservation and good treatment effect.

Owner:BEIJING FORESTRY UNIVERSITY

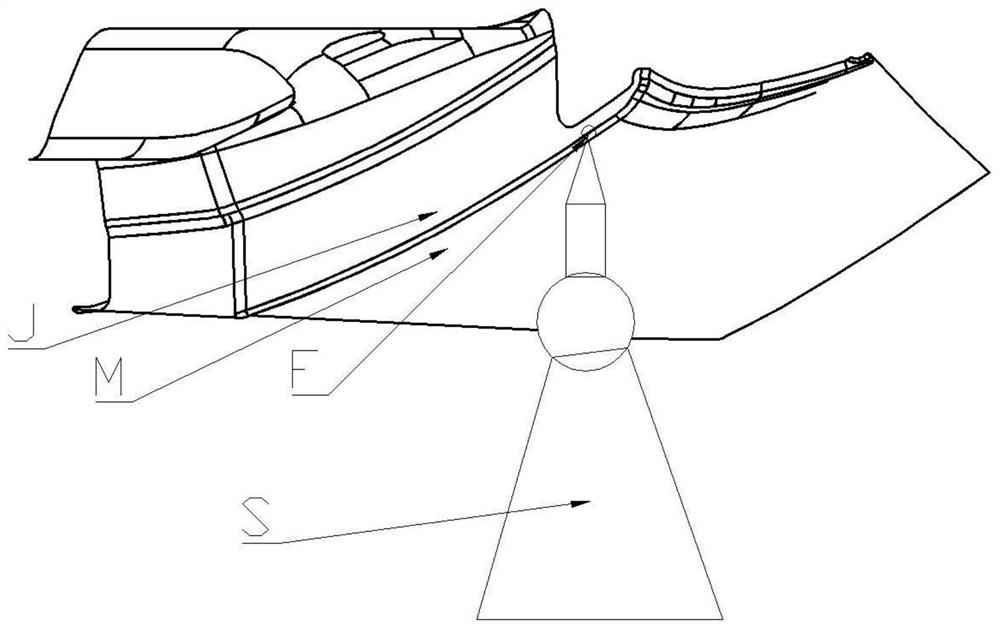

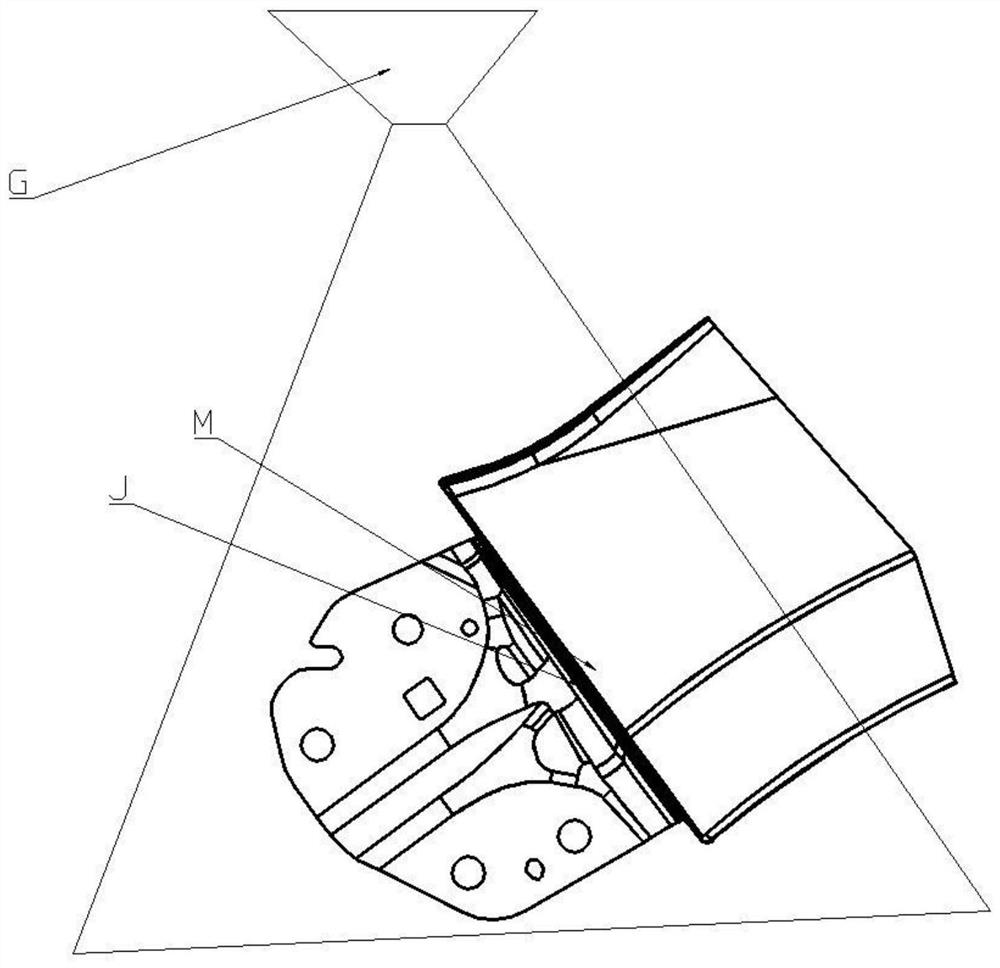

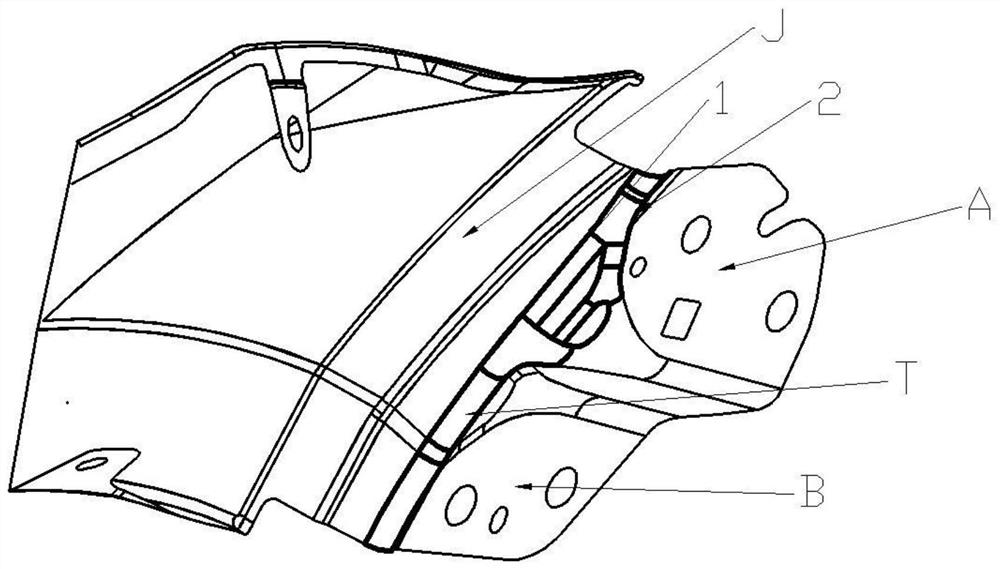

Method for eliminating distortion of lap joint area of fender stamping part front bumper

ActiveCN112338092AWarp worksImprove stabilityUsing optical meansVehicle componentsFenderMeasuring equipment

The invention discloses a method for eliminating distortion of a lap joint area of a fender stamping part front bumper. The method comprises the following steps of application of a forming compensation process, development of a debugging process and the like. According to the method, precision measurement equipment is used in cooperation to confirm the fender stamping part front bumper torsion resilience value; by supplementing fillet compensation to a shaping process and utilizing the principle of fillet plastic deformation shaping stability, the fender stamping part front bumper torsion resilience is effectively corrected; the compliance grinding direction is standardized to ensure that the corrected fender stamping part front bumper torsion resilience is stable; and through reasonable use of a multi-dimensional installing point compensation means, the comprehensive debugging method for eliminating the fender stamping part front bumper torsion resilience effectively correct the fender stamping part front bumper torsion resilience, the debugging period is shortened, the data stability is improved, and the overall assembly quality of a vehicle body is guaranteed.

Owner:CHINA FIRST AUTOMOBILE

High-elasticity foamed polyethylene material

The invention discloses a high-elasticity foamed polyethylene material. The material is characterized by comprising the following substances by weight: 80 to 98 parts of high density polyethylene, 2 to 5 parts of hydro-quinoline, 15 to 21 parts of polyol ester of benzoic acid, 10 to 17 parts of acetylated monoglyceride, 10 to 18 parts of polytetrafluoroethylene, 3.5 to 11 parts of red phosphorus, 5 to 9 parts of zirconium oxide, 3 to 6 parts of vanadium phosphate, 1 to 3 parts of polyolefin, 3 to 5 parts of expanded pearl powder, 25 to 31 parts of graphite, 5 to 12 parts of redispersible latex powder, 10 to 16 parts of gypsum powder, 3.5 to 7 parts of perlite, 12 to 26 parts of chlorinated paraffin and 7 to 12 parts of silicone oil. According to the invention, a formula for the foamed polyethylene material is simple; raw materials can be thoroughly decomposed; the prepared foamed polyethylene material has no odor and good elasticity; a pressed product has good shapebility and a stable shape; and the material has the advantages of flame resistance, small density, light weight, heat insulation, etc.

Owner:QINGDAO HUA CHENG TIAN MACHINERY MFG

Novel hull erection method

InactiveCN103753040AAvoid damageSave human effortWaterborne vesselsWelding/cutting auxillary devicesMaterial resourcesEngineering

The invention discloses a novel hull erection method and belongs to the technical field of shipbuilding. The method includes the steps such as cutting grooves, grinding the grooves, assembling, leveling steel plates, applying pads, welding priming weld seams required for the production of positioning weld seams, welding the positioning weld seams, welding transition weld seams, welding erection weld seams, and polishing the erected whole. The novel hull erection method has the advantages that clamp plates are replaced with the positioning weld seams, the steps of welding the clamp plates and cutting the clamp plates are omitted, manpower and material resources and raw materials are greatly saved, less damage is caused to a hull, cost of polishing before and after welding is saved, and the basis for automated welding is laid.

Owner:宋广科

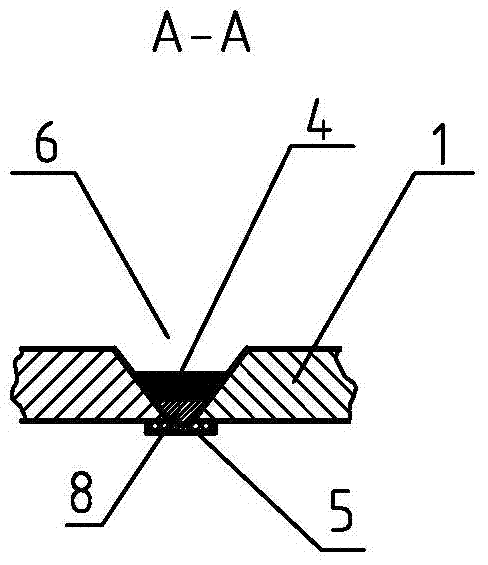

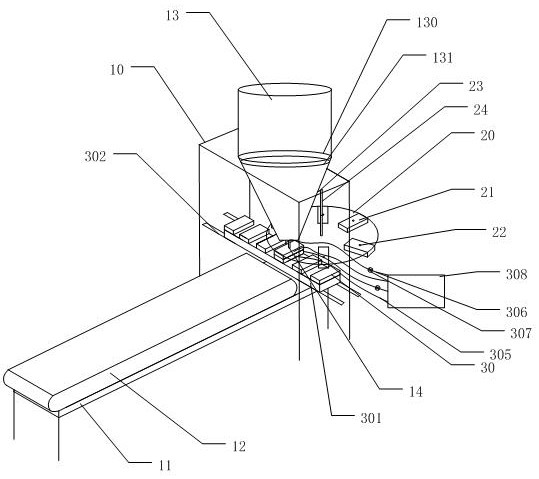

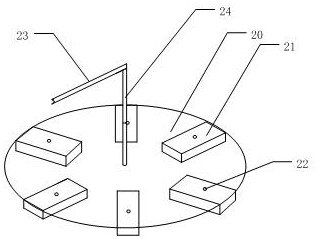

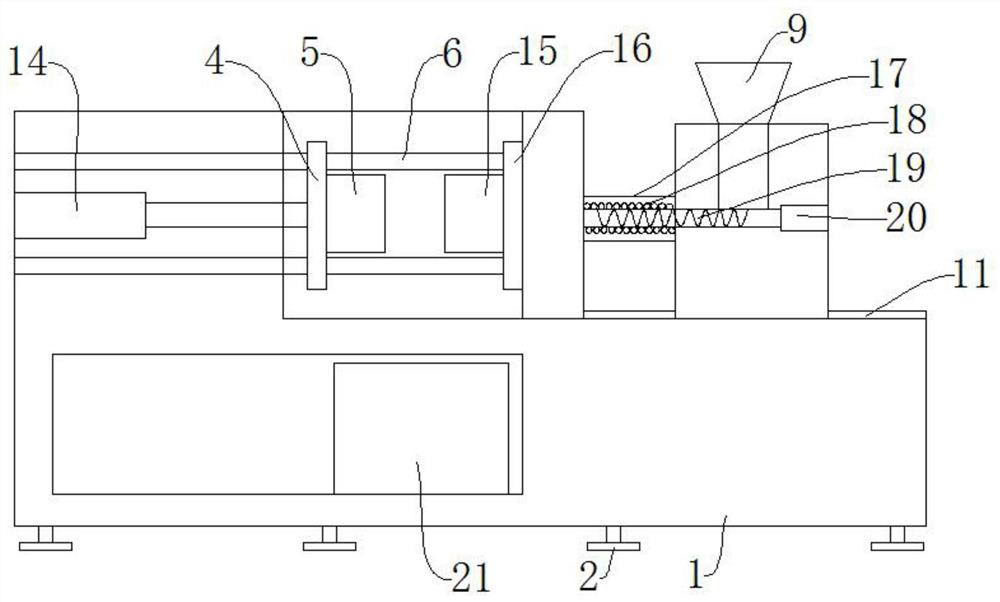

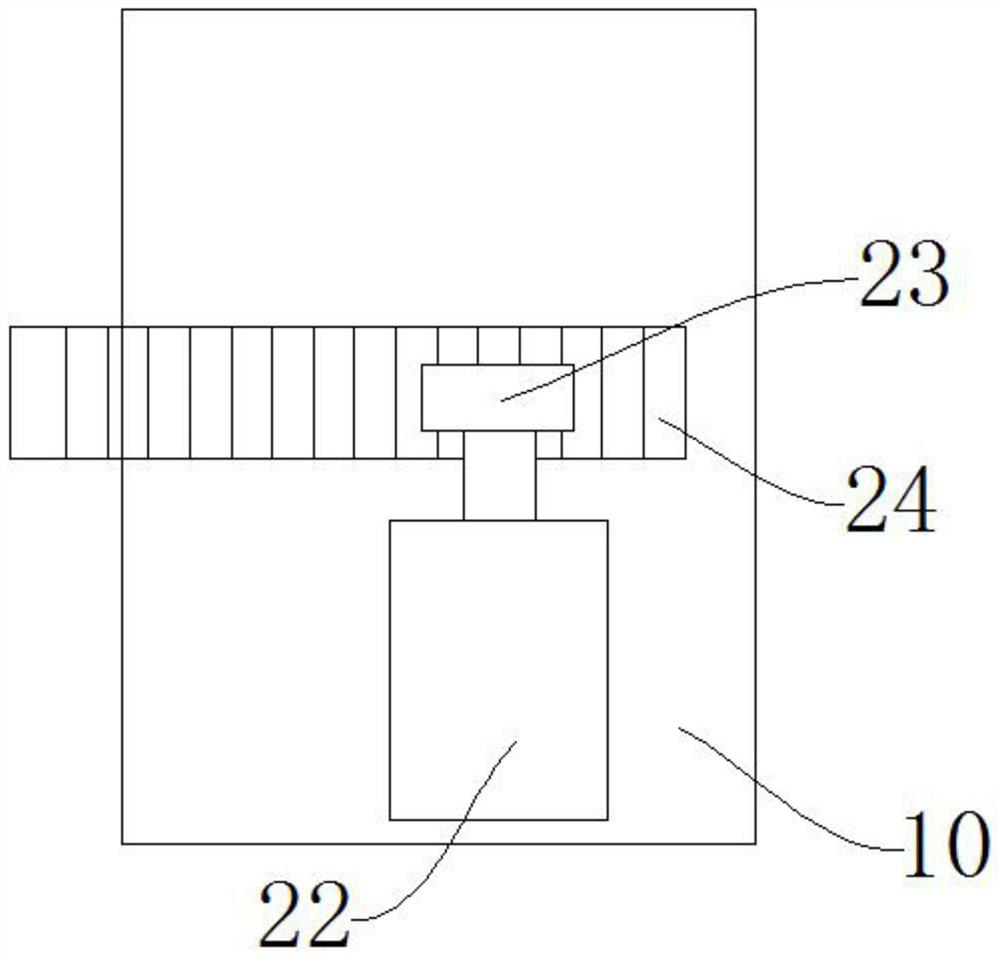

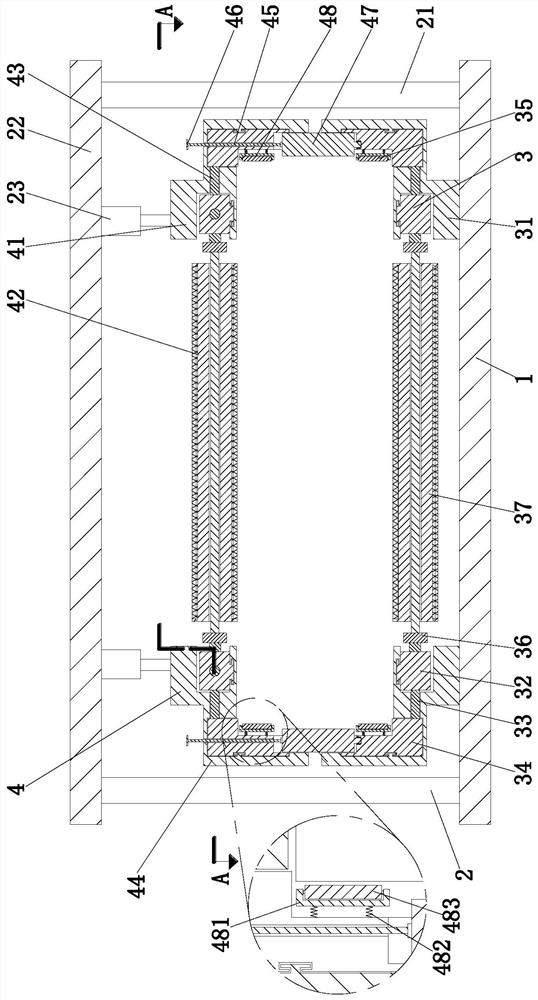

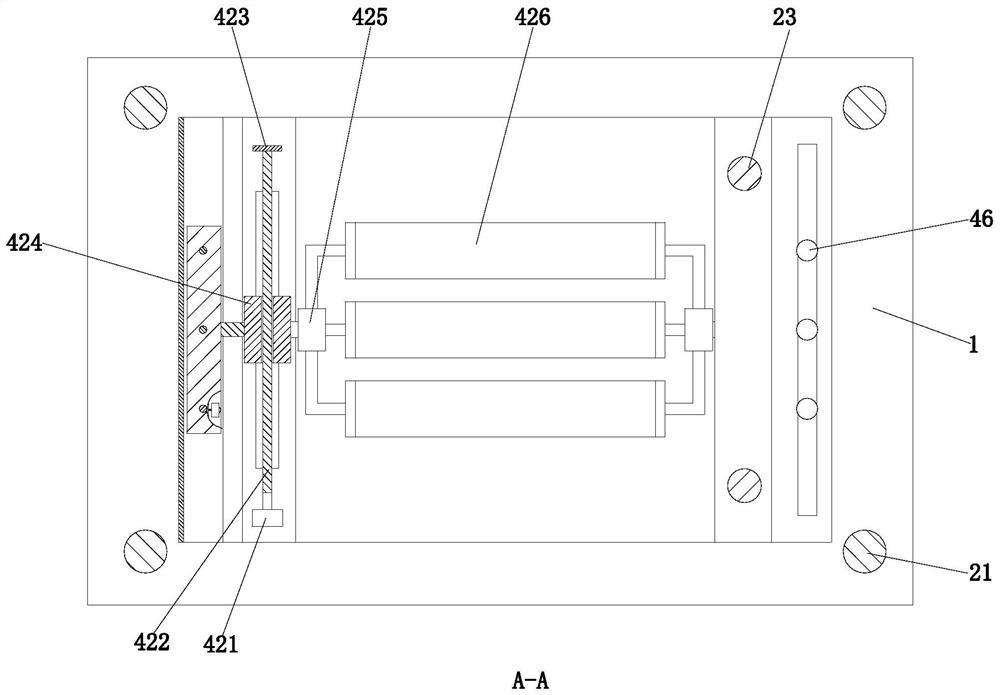

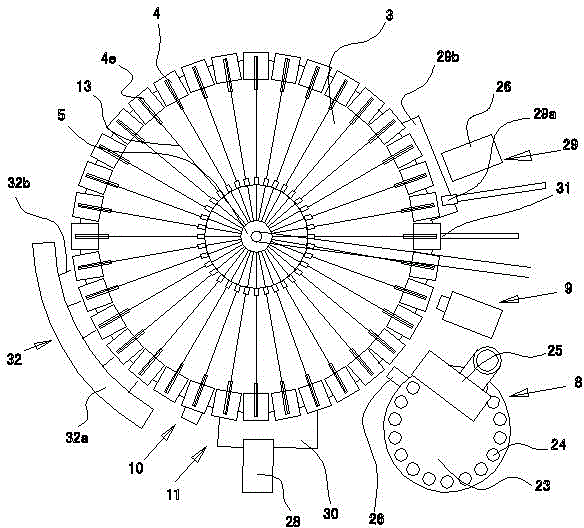

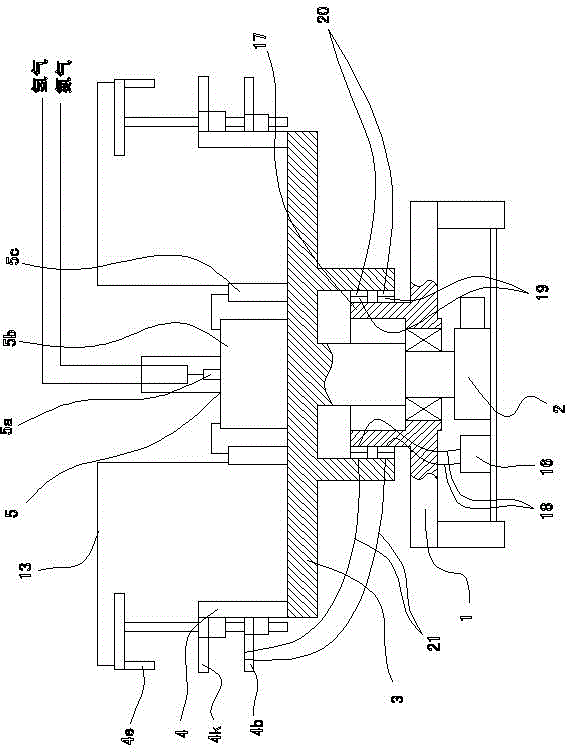

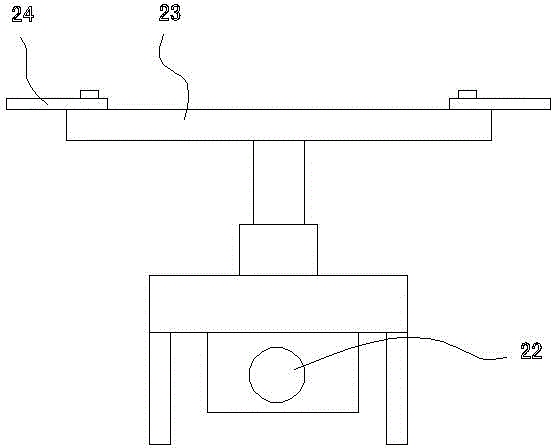

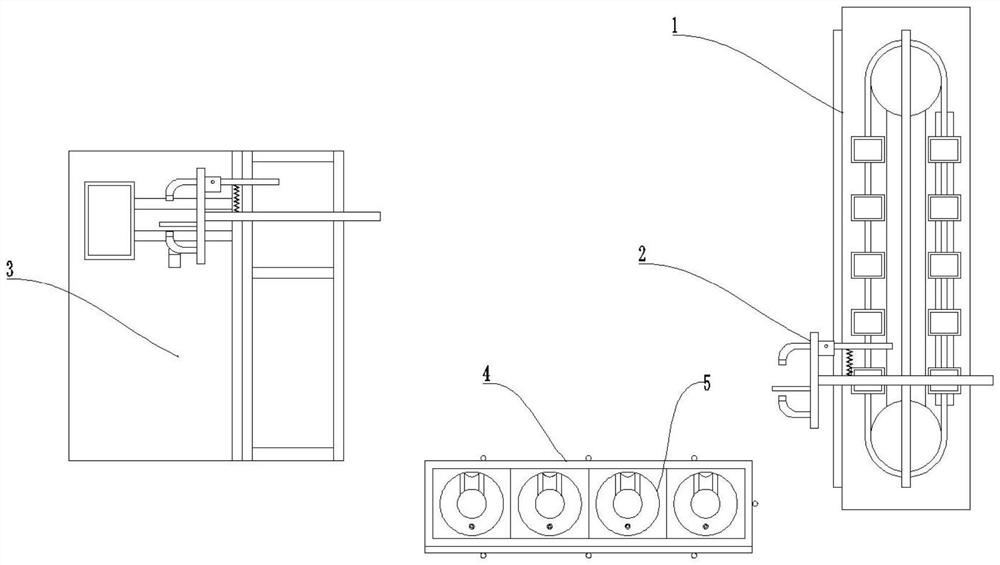

Compression molding device for dog chew processing

PendingCN113276335APress-molded structure is simple and compactReduce manufacturing costFeeding-stuffMoulding deviceEngineering

The invention discloses a compression molding device for dog chew processing. The compression molding device comprises a workbench, a material extruding device and a compression device; the workbench comprises a conveying device and a supporting frame body, and the supporting frame body is erected at the front end of the conveying device; the material extruding device comprises a material storage barrel, a material extruding opening is formed in the lower portion of the material storage barrel, a first valve body is arranged at the material extruding opening, and the material storage barrel is arranged on the supporting frame body; the compression device comprises an upper pressing mold frame and a lower pressing mold frame; the upper pressing mold frame comprises a circular frame body and a plurality of upper pressing molds; the circular frame body is transversely connected to one side of the material extruding opening in a manner of rotating and moving up and down, so that when the circular frame body rotates, the material extruding opening is respectively opposite to each upper pressing mold below in the forward direction and is respectively matched and clamped and fixed to each upper pressing mold below the material extruding opening; a through hole matched with the material extruding opening is formed in each upper pressing mold; and the lower pressing mold frame can transversely move along a conveying structure and is arranged under the material extruding opening in an up-down lifting mode, and the lower pressing mold frame comprises a plurality of lower pressing molds matched with the upper pressing molds in a one-to-one correspondence mode. According to the compression molding device, the structure is simpler and more compact, one machine with multiple types is realized, the production cost is greatly saved, and the applicability is wider.

Owner:WENZHOU JINHENG PET PROD CO LTD

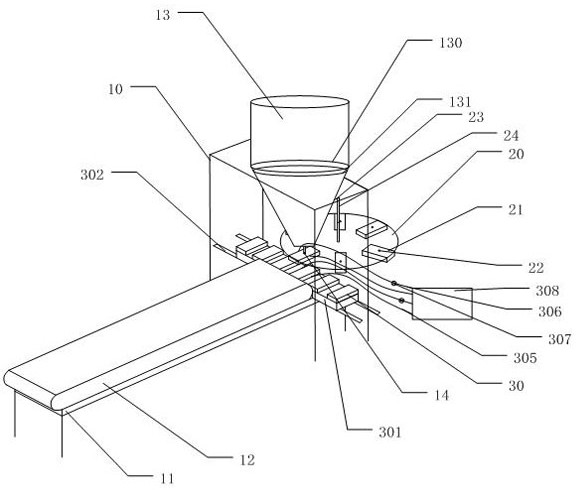

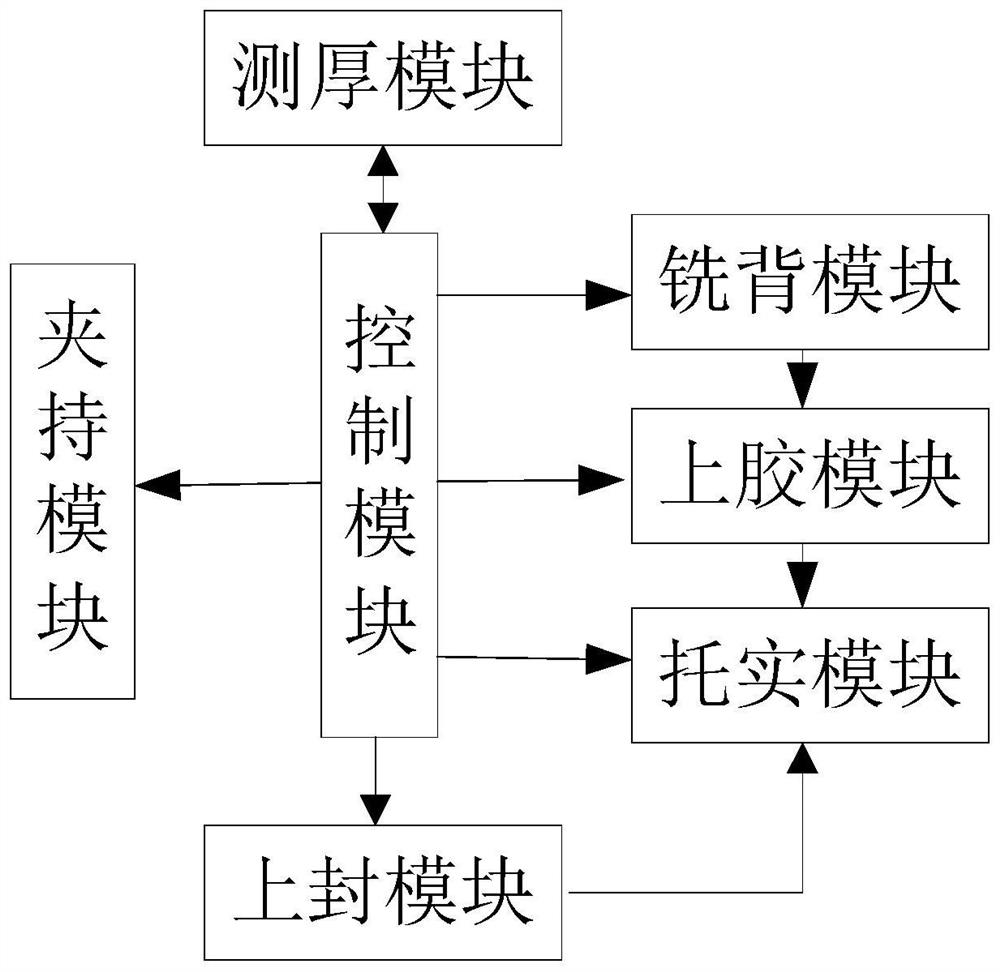

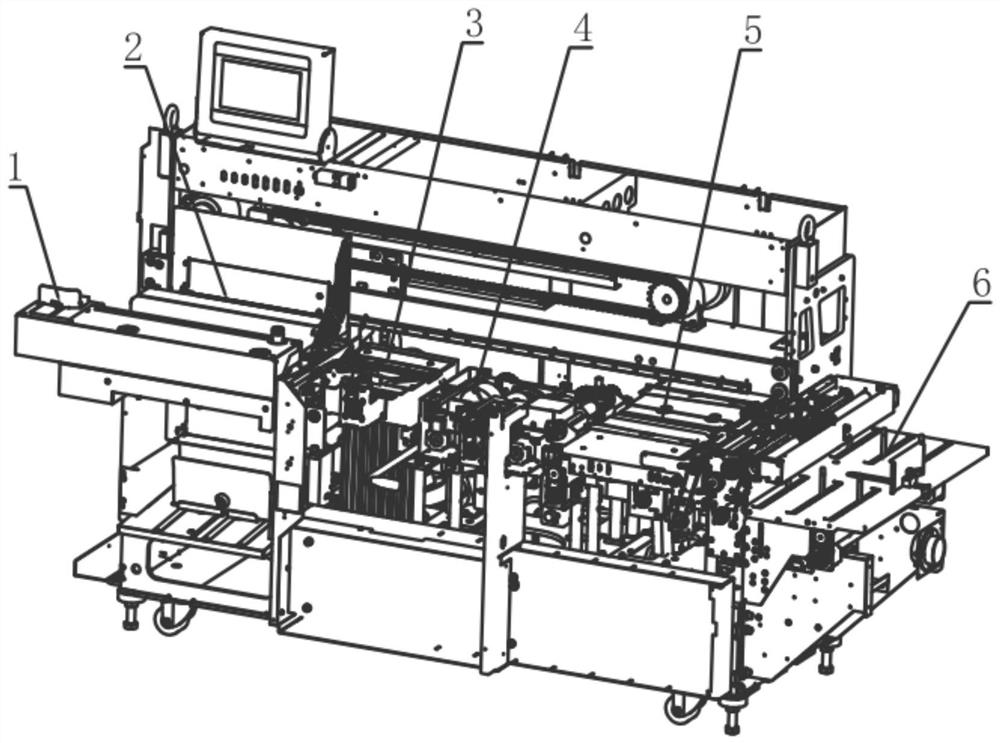

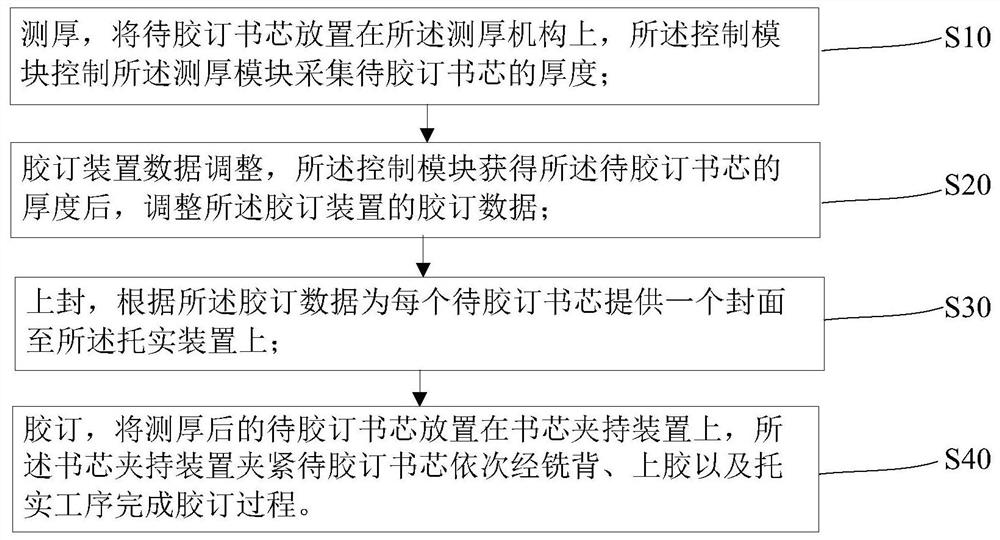

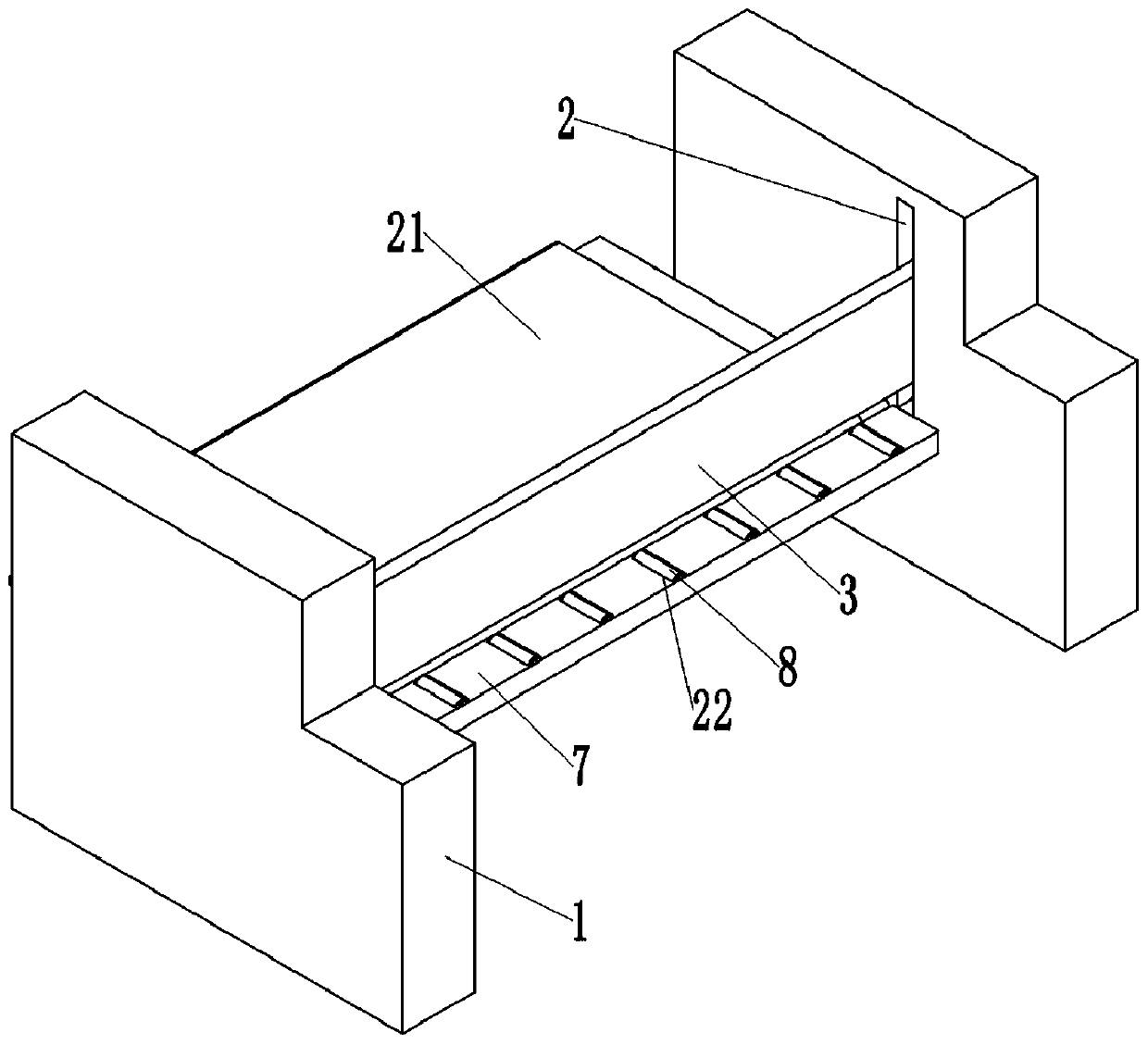

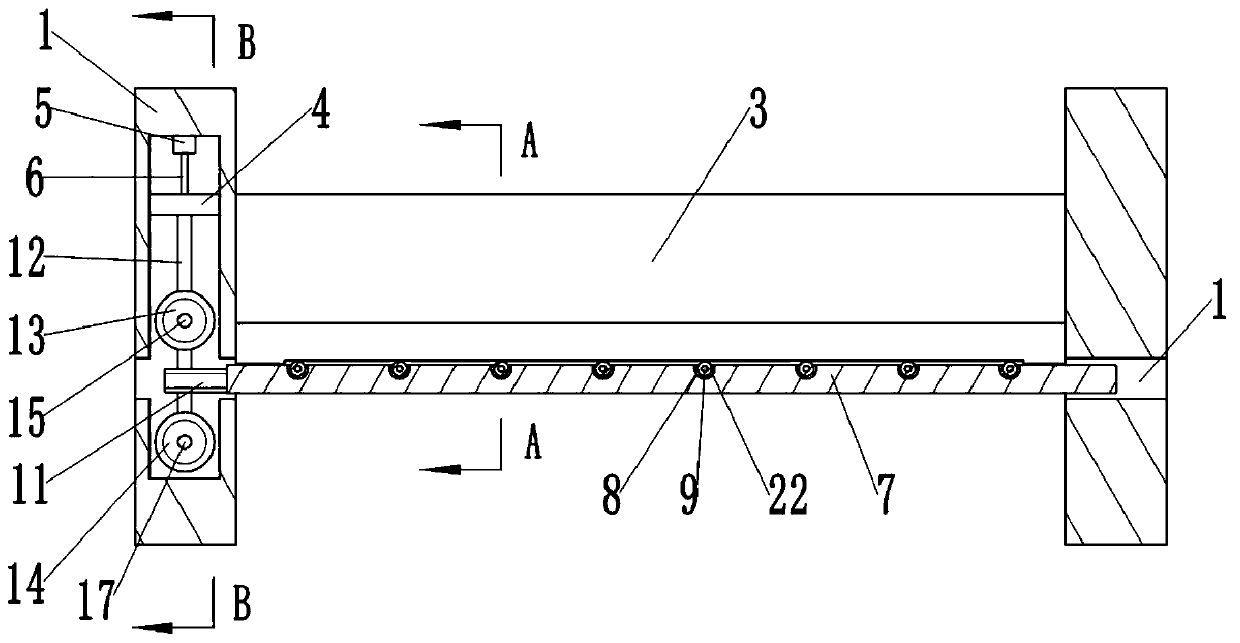

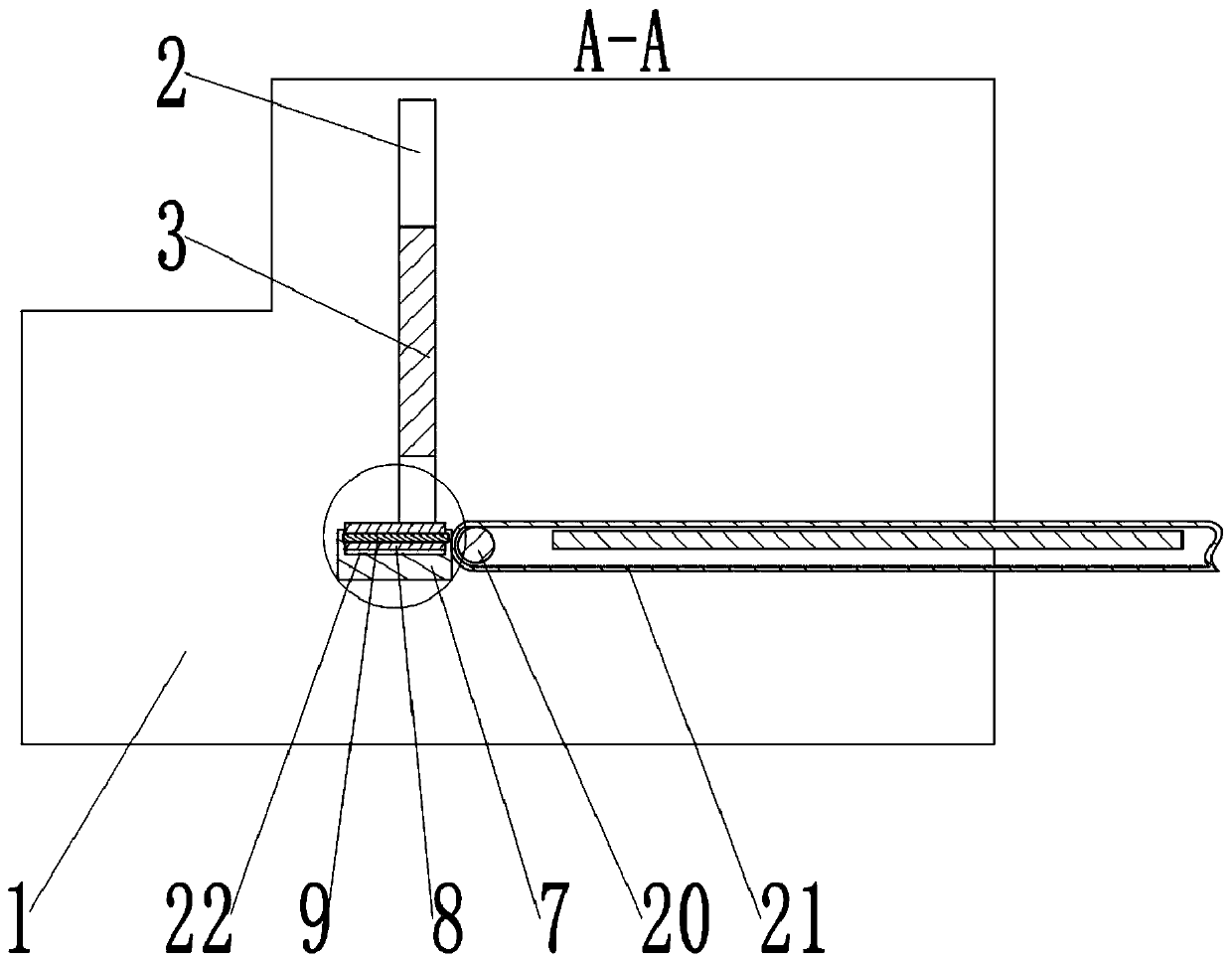

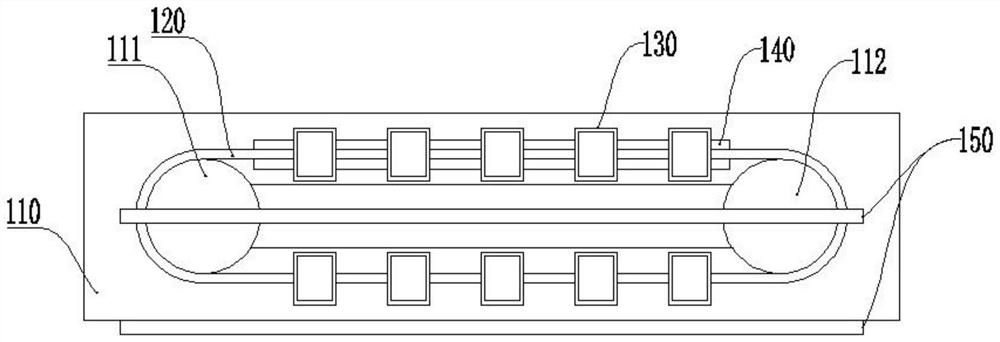

Intelligent book adhesive binding system and using method thereof

InactiveCN112339468AQuality improvementStereotype stableBook making processesBookbinding adhesiveAdhesiveSoftware engineering

The invention provides an intelligent book adhesive binding system and a using method thereof. The intelligent book adhesive binding system comprises a control module, a thickness measuring module connected with the control module and for controlling the thickness measuring mechanism to acquire the thickness of to-be-adhesive-binded bookblock, a back milling module for controlling a back milling device to mill a book back for the to-be-adhesive-binded bookblock, an adhesive applying module for controlling an adhesive applying device to apply an adhesive to the book backs of the to-be-adhesive-binded bookblock after back milling and a supporting and compacting module, and the back milling module outputs to the adhesive applying module; and the supporting and compacting module is used for controlling a supporting and compacting device to adhesive-bind the adhesive-applied to-be-adhesive-binded bookblock with the cover together in a supporting and compacting manner, and the adhesive applying module outputs to the supporting and compacting module. According to the intelligent book adhesive binding system and the using method thereof, before adhesive binding, the thickness measuring module is used for measuring the thickness of the to-be-adhesive-binded bookblock, then adhesive binding data is adjusted according to the measured thickness of the to-be-adhesive-binded bookblock, and compared with a traditional adhesive binding method, sizing is stable, the book adhesive binding quality is improved, and a book after adhesive binding is more attractive.

Owner:HAIMEN PURPLE PRINTING MACHINERY

Flattening device for production of nearsightedness preventing homework book

PendingCN110406174AImprove the extrusion effectStereotype stableMechanical working/deformationEngineeringMechanical engineering

The invention relates to the technical field of production devices of homework books and particularly discloses a flattening device for production of a nearsightedness preventing homework book. The flattening device for production of the nearsightedness preventing homework book comprises a machine frame and a lower flattening mechanism. The lower flattening mechanism comprises a moving plate and squeezing rollers. The squeezing rollers are rotationally connected to the moving plate. The upper surfaces of the squeezing rollers are higher than the upper surface of the moving plate. The moving plate is horizontally connected to the machine frame in a sliding manner. The flattening device for production of the nearsightedness preventing homework book can solve the technical problem that in theprior art, since the squeezing action on the crease portion on the homework book is not enough, the crease portion is difficult to shape.

Owner:重庆市开州区三中印务有限公司

Manufacturing method of honeycomb type purification activated carbon

InactiveCN101972630BStrong adsorption functionFully adsorbedOther chemical processesFiltration separationAdhesiveTherapeutic effect

The invention belongs to a manufacturing method of honeycomb type purification activated carbon. The type purification activated carbon is prepared from 20-30 parts by weight of chemical activated carbon, 11.7-21.7 parts by weight of coal-based granular activated carbon and 55.3-63.3 parts by weight of coconut shell activated carbon. The manufacturing method comprises the following steps of: ball-milling, and selecting 65-75 parts by weight of activated carbon powder granules, 1-2 parts by weight of liquidity auxiliary agent, 2-4 parts by weight of adhesive and 20.5-30.5 parts by weight of clay as the raw materials of the honeycomb type purification activated carbon; mixing the raw materials, and uniformly stirring to prepare a product material; pug-milling in vacuum, molding by extrusion, airing and sintering to obtain the honeycomb type purification activated carbon. The interior of the honeycomb type purification activated carbon prepared by using the method can fully absorb air to form low wind resistance cross-ventilation; the activated carbon made of corresponding materials can be selected according to absorbed objects, the good absorption function of the activated carbon is ensured, and the activated carbon has firm shaping and durability. The invention has the advantages of simple and feasible method, low pollution treatment cost, low carbon, energy saving and good treatment effect.

Owner:LISHUI HE ZI PURIFICAT EQUIP CO LTD

Twin-screw extruder die head for plastic particle production

The invention relates to a twin-screw extruder die head for plastic particle production. The extruder head comprises a die head body capable of being fixedly connected with the twin-screw extruder head, a positioning guide groove, a groove-type flow channel, die holes and forming strip-shaped plastic supporting plates. The middle of the inner side of the die head body is provided with the positioning guide groove connected with the extruder head in the radial direction. The middle of the bottom of the positioning guide groove is provided with the groove-type flow channel for balancing the die head pressure. A plurality of rows of the die holes are formed in the groove-type flow channel in the vertical direction side by side in parallel. Each forming strip-shaped plastic supporting plate is outwards arranged at the position, below each row of die holes, on the die head body in the radial direction, and a plurality of forming strip-shaped plastic output grooves are formed in the forming strip-shaped plastic supporting plates corresponding to the die holes of each row of die holes. The twin-screw extruder die head is scientific in design, convenient to use and simple in structure, the extrusion efficiency of an extruder is improved, manpower and material resources are saved, and quality of finished products of plastic particles is guaranteed and improved.

Owner:天津思迈德高分子科技股份有限公司

Extrusion shaping equipment and use method thereof for silica gel product preparation

The invention discloses extrusion shaping equipment and a use method thereof for silica gel product preparation. The extrusion shaping equipment comprises a frame, a male mold, a female mold and a material feeding box, wherein the lower end of the frame is provided with supporting seats, the front side of the frame is provided with a box door, the box door is slidably connected with the frame andis fixedly provided with a handle, one side of the box door is provided with a supporting plate, the front side of the supporting plate is provided with an operation panel, one side of the supportingplate is provided with guide columns, the positions, close to the supporting plate, on the guide columns are provided with a second fixed plate, the second fixed plate is fixedly provided with the female mold, and the positions, away from the second fixed plate, on the guide columns are provided with a first fixed plate. According to the extrusion shaping equipment and the use method thereof for the silica gel product preparation, the male mold is stably made to move under driving of a hydraulic column through the guide columns and is made to be stable in position relative to the female mold,the molding process is made to be stable, and the processing quality is improved; and by means of the manner that a silica gel product enters into a finished-product box again to be subjected to cooling shaping by utilizing cooling water after being shaped stably inside the male mold and the female mold, the processing efficiency is improved, and shaping is made to be stable.

Owner:浙江硅创科技股份有限公司

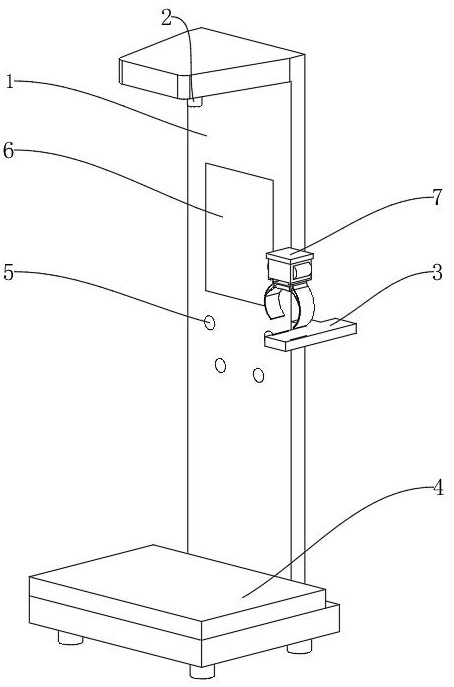

A furniture manufacturing wooden board surface shaping treatment system

ActiveCN110466027BGuaranteed flatnessImprove the efficiency of styling processingWood compressionFixed frameFurniture manufacturing

The invention provides a surface sizing treatment system for wooden boards in furniture manufacturing, which includes a bottom plate, a fixed frame, a lower sizing module and an upper sizing module; a fixing frame is arranged above the bottom plate, and a lower sizing module is arranged at the upper middle of the bottom plate, and The lower sizing module is located inside the fixed frame, and the upper sizing module is connected to the fixed frame, and it is located directly above the lower sizing module; the present invention can solve the problem that the existing equipment is mostly used to sizing the surface of the board through wooden boards Or heavy objects locally squeeze the surface of the board, which is likely to cause wrinkles on the surface of the board, bubbles or edge warping, and the shaping effect is not good; and in the process of shaping the surface of the board, the force on the surface of the board is uneven, resulting in The surface is damaged, and it cannot be adjusted when processing the side walls of plates of different thicknesses, resulting in incomplete shaping of the side walls of the plates and affecting normal use.

Owner:HANGZHOU CHENGYUE FURNITURE CO LTD

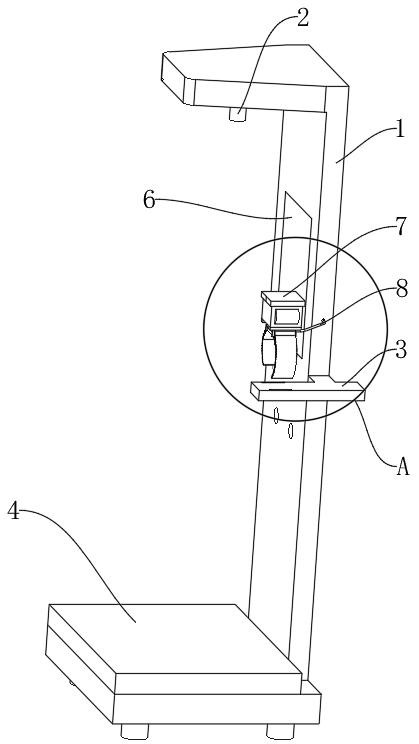

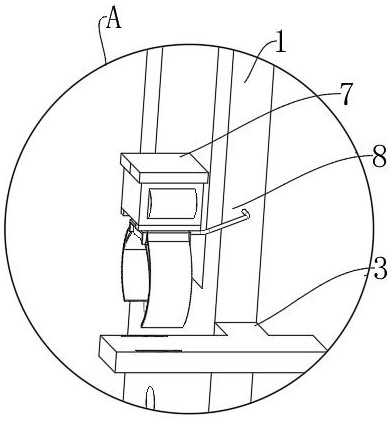

Intelligent health management all-in-one machine

ActiveCN114569095AStereotype stableHigh sensitivityEvaluation of blood vesselsSensorsPhysical medicine and rehabilitationWhole body

Owner:深圳市森葆实业有限公司

Bulb setting machine

InactiveCN102768939BStereotype stableEfficient stylingElectrical apparatusMicrocomputer controlElectrical and Electronics engineering

Owner:李家凌

Bamboo vinegar honeycomb type purification activated carbon and preparation method thereof

ActiveCN103418343BStrong adsorption functionAccelerate the speed of adsorption and desorptionOther chemical processesCelluloseMethyl cellulose

The invention belongs to a bamboo vinegar honeycomb type purifying activated carbon and a preparation method thereof. The bamboo vinegar honeycomb type purifying activated carbon comprises, by weight, 35-40 parts of chemical activated carbon, 25-35 parts of granular activated carbon from coal, 43-49 parts of coconut shell activated carbon, 9-15 parts of bamboo vinegar, 2-3 parts of methyl cellulose and 2-3 parts of talcum powder. The preparation method includes ball grinding, well mixing raw materials, producing product materials, and subjecting the product materials to vacuum pugging, extrusion forming, drying and sintering. The bamboo vinegar honeycomb type purifying activated carbon is good in dirt absorption capability, firm in shaping durable, simple and practical in preparation method, low in sewage treating cost, low-carbon, energy saving, and good in treating effect, and corruption odor generated by toilets, livestock, fish and the like can be purified.

Owner:LISHUI HE ZI PURIFICAT EQUIP CO LTD

Efficient production system for glass containers

PendingCN114835386AStereotype stableStereotypes are reliableGlass transportation apparatusGlass reforming apparatusMechanical engineeringIndustrial engineering

The invention relates to the field of glass container production, and discloses a glass container efficient production system which comprises a middle material conveyor used for transferring cup bodies or forming wine distributors. The transfer clamp is used for transferring the cup body; the handle bonding table is used for carrying out handle bonding operation; the forming tool and the forming die are used for shaping the handle; the formed cup body is clamped by the transfer clamp and then placed on the middle material conveyor, and when the handle is bonded, the transfer clamp with the cup body is taken down from the middle material conveyor and moved to the handle bonding table to manually bond the handle on the cup body. And then the cup body bonded with the handle is placed in a forming die on a forming tool through the transfer clamp, and the bonded handle is shaped through the forming die. The problems that in the prior art, the wine distributor production efficiency is low, and joint seam defects exist in a handle can be solved.

Owner:CHONGQING JIANLI GLASS PROD CO LTD

Soft polyurethane synthetic leather with skin-touch mercerizing 3D effect

InactiveCN113696587AStereotype stableAdd deformation reset effectSynthetic resin layered productsTextiles and paperFiberPolymer science

The invention provides soft polyurethane synthetic leather with a skin-touch mercerizing 3D effect, and relates to the field of polyurethane synthetic leather. The polyurethane synthetic leather comprises a polyurethane resin layer, a fiber layer is arranged on the surface of the polyurethane resin layer, a base layer for shaping the polyurethane resin layer is arranged above the fiber layer, and a bonding layer is bonded between the polyurethane resin layer and the base layer. According to the invention, the first cloth layer, the second cloth layer and the third cloth layer are bonded into a whole through the outer bonding layer and the inner bonding layer, so that the polyurethane resin layer is relatively stably shaped. Due to the arrangement of the fiber holes, the basic layer has sufficient deformation space in the bending deformation process, so that unrecoverable wrinkles generated on the surfaces of the base layer and the polyurethane resin layer due to overlarge deformation stress are avoided. In addition, due to the arrangement of the first cloth layer, the second cloth layer and the third cloth layer, when a plurality of main bodies are spliced, the first cloth layer, the second cloth layer and the third cloth layer at adjacent positions can be correspondingly sheared and inserted, so that the strength of connecting parts is high, the joint is not easy to slit, and the aesthetic degree is high.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

Environmentally-friendly coal specially used for barbecue and preparation method of coal

InactiveCN107557090AStereotype stableEasy to transportBiofuelsSolid fuelsEconomic benefitsAnthracite

The invention relates to the field of fuels, and specially relates to environmentally-friendly coal specially used for barbecue and a preparation method of the coal. The environmentally-friendly coalspecially used for the barbecue is characterized by comprising the following raw materials: by weight: 20-80 parts of coke powder, 10-40 parts of charcoal powder, 10-60 parts of anthracite culm, and 2-20 parts of a binding agent. The environmentally-friendly coal is shaped and steady, convenient for transportation, cannot cause dust pollution in transportation process, and does not generate smokeand dust in barbecue process, a heat producing value of the environmentally-friendly coal is much higher than that of charcoal, and the environmentally-friendly coal has huge economic benefits, savesenergy and protects environments, has a simple preparation process, and is suitable for industrialized production.

Owner:SHANDONG NORMAL UNIV

Degradable polyethylene foamed material

The invention discloses a degradable polyethylene foamed material which is characterized by comprising the following substances in parts by weight: 25-31 parts of chlorinated paraffin, 10-13 parts of hydrogen quinoline, 20-31 parts of polyol benzoate, 5.5-13 parts of gypsum powder, 5-8 parts of carbon, 10-14 parts of silicon, 15-19 parts of a coupling agent, 3-12 parts of polyimino group, 8-14 parts of color master batch, 11-17 parts of redispersible powder, 3.5-7 parts of perlite, 75-86 parts of high density polyethylene and 5-13 parts of silicon oil. Not only is the degradable polyethylene foamed material simple in formula, can raw materials be thoroughly decomposed and is a product free of odor, but also the product is good in elasticity, a pressed product is good in forming property and very stable in forming property, and moreover the degradable polyethylene foamed material has the advantages of flame retardancy, small density, light weight, heat preservation and the like.

Owner:QINGDAO HUA CHENG TIAN MACHINERY MFG

Degradable high-flame-retardancy foamed material

The invention discloses a degradable high-flame-retardancy foamed material which comprises the following components in parts by weight: 33-56 parts of ethylene bis(stearamide), 15-29 parts of glass fiber, 5-11 parts of ethyl acrylate, 3-14 parts of diphenyl phosphate, 5-8 parts of chlorinated paraffin, 9-17 parts of redispersible latex powder, 10-17 parts of fatty acid amide, 3.5-7 parts of polymethylhydrosiloxane, 55-68 parts of high-density polyethylene, 2-6 parts of diammonium phosphate and 25-30 parts of silicon oil. The degradable high-flame-retardancy foamed material has the advantages of simple formula, completely decomposable raw materials, no peculiar smell, high elasticity, favorable forming property of the compaction product, high forming stability, flame retardancy, low density, light weight, thermal insulation and the like.

Owner:QINGDAO JINXIU SHUIYUAN COMMERCE & TRADE

A thin carrier tape cover tape base paper and its manufacturing method

ActiveCN107858855BProperly cut offNot easy to tangleWater-repelling agents additionReinforcing agents additionFiberAdhesive

The invention relates to the technical field of electronic element packaging, in particular to covering paper used through being matched with a thin type carry tape. The fixed quantity of the coveringtape raw paper is 25g / m<2> to 40g / m<2>; the longitudinal tensile strength is 2.5 KN / m to 4.5 KN / m; the ratio of the longitudinal tension to the transverse tension is (5:1) to (6:1), the D65 brightness is 78 to 85 percent; the transparency is 65 to 80 percent; the surface intensity is 22A; the water absorptivity is 13g / <2> to 18g / <2>; the moisture content is 5.0 to 7.0 percent. Through light-facing inspection, the paper fiber tissue arrangement is uniform; no cloud pattern fiber groups exist. The raw paper tensile strength is high; the transparency is high; the fiber shaping is firm; the surface intensity is high; during the cutting and end surface friction, hair falling and powder falling cannot occur; the raw paper is used as a substrate instead of a PET film; a hot sealing glue film isdirectly covered on the raw paper substrate; then, splitting processing is performed to obtain the thin type carry tape covering tape raw paper. The coating of adhesives, PE films, anti-static agentsand the like is not needed.

Owner:浙江洁美电子信息材料有限公司

Bridge guardrail base shaping combined template

PendingCN112482230AAvoid enteringAvoid dilutionBridge structural detailsBridge erection/assemblySlide plateSlurry

The invention discloses a bridge guardrail base shaping combined template which comprises a fixing support, a plurality of guardrails are fixedly connected to the fixing support, two combined templateframes are fixedly connected to the side faces of the bottom ends of the guardrails in a sleeving mode, and baffles are fixedly connected to the two combined template frames respectively; wherein bolts are arranged on one combined template frame and one baffle, clamping grooves are formed in the other combined template frame and the other baffle, the clamping grooves are connected with the boltsin a clamped mode, a plurality of first water collecting tanks are fixedly connected to the two baffles, and feeding ports are formed in the two combined template frames. According to the bridge guardrail base shaping combined template, in rainy days, the gravity of rainwater is used for controlling a sliding plate to close the feeding ports, water can be prevented from entering the combined template frames through the feeding ports, the problem that slurry in the combined template frames is scoured by rainwater is solved, the slurry is prevented from being diluted by rainwater, and the shaping effect of the combined template frames is improved.

Owner:河南省第一公路工程有限公司 +1

Door and window outer frame calibration table with water cooling device

The invention relates to the technical field of plastic calibration equipment, and provides a door and window outer frame calibration table with a water cooling device. The door and window outer frame calibration table comprises a circulating water tank, a cooling tower and a pond, wherein the pond is arranged below the cooling tower; a plurality of water inlets and water outlets are formed in the circulating water tank; the water inlets are communicated with the pond through water inlet pipes; the water outlets are communicated with the cooling tower through water outlet pipes; and circulating water pumps are arranged at the water inlet ends of the water inlet pipes. The door and window outer frame calibration table has the advantages and beneficial effects that due to adoption of the technical scheme, the calibration table is good in cooling effect, stable to calibrate, simple in structure, convenient to maintain and low in processing cost; and the quality of the product is ensured.

Owner:TIANJIN KUNHAO PLASTIC PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com