Extrusion shaping equipment and use method thereof for silica gel product preparation

A technology of silica gel and products, applied in the field of extrusion and shaping equipment for the preparation of silicone products, can solve the problems of difficulty in shaping, unstable product quality, low processing efficiency, etc., and achieve the effects of improving processing quality, shaping stability, and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

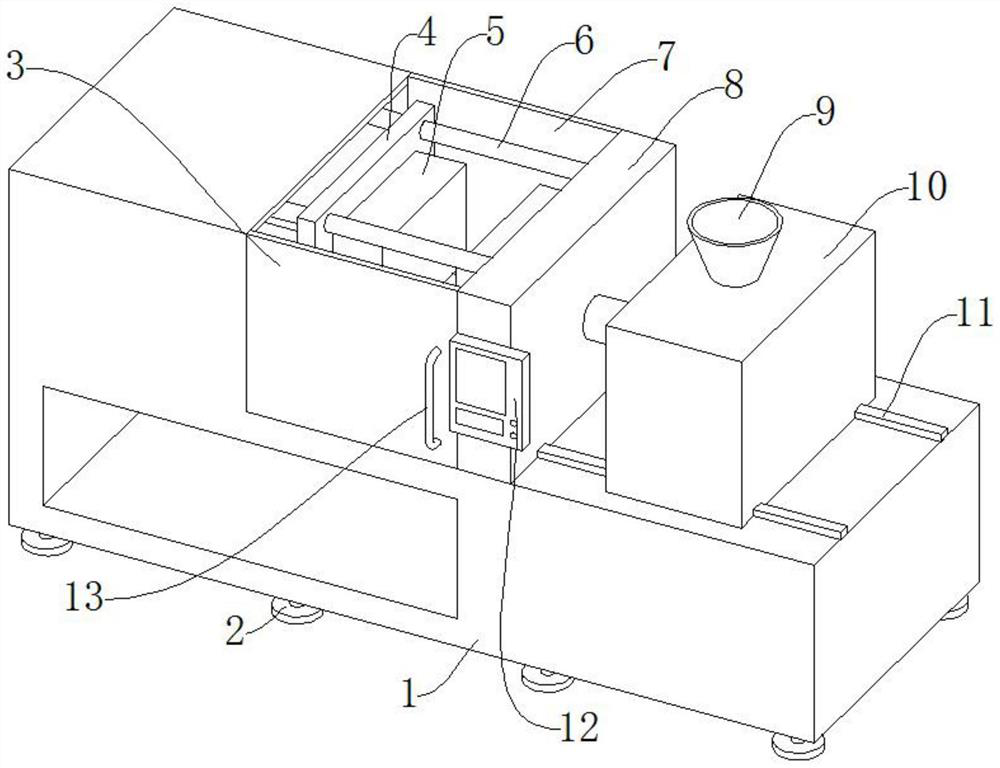

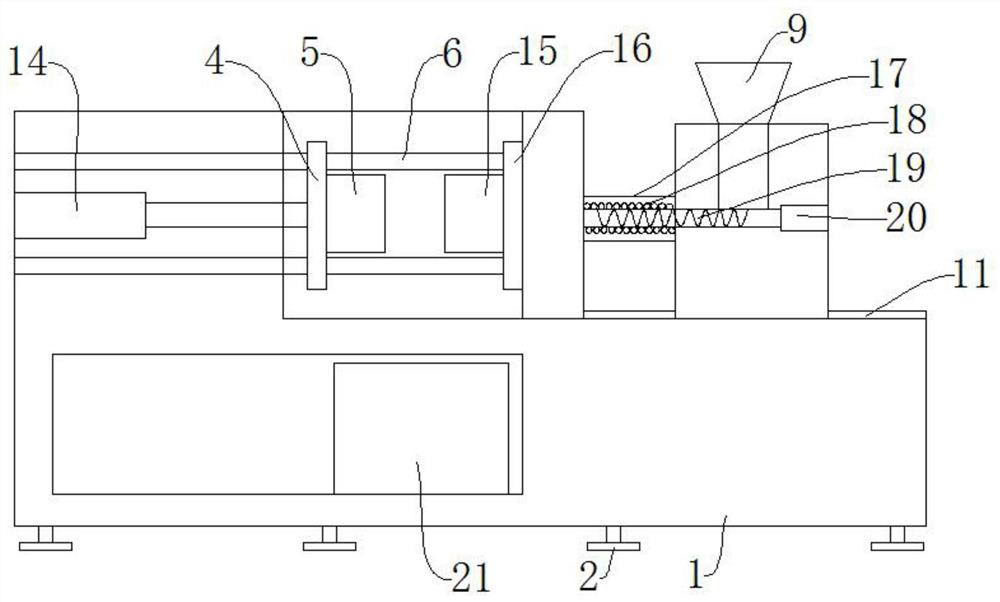

[0037] like Figure 1-Figure 4 As shown, the extrusion and shaping equipment for the preparation of silicone products includes a frame 1, a male mold 5, a female mold 15, and a feed box 10. The lower end of the frame 1 is provided with a support seat 2, and the front side of the frame 1 is equipped with a box door 3. The box door 3 is slidably connected with the frame 1, which is convenient for the door 3 to be opened and operated inside. A handle 13 is fixed on the door 3, and a supporting plate 8 is arranged on one side of the door 3, and a second fixing plate 16 is fixed on the front side of the supporting plate 8. There is an operation panel 12 for setting equipment parameters, a guide column 6 is installed on one side of the support plate 8, the first fixed plate 4 moves on the track, a second fixed plate 16 is arranged on the guide column 6 near the support plate 8, and the second fixed plate 16 is fixed with a female mold 15, the guide post 6 is provided with a first fi...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is:

[0040] The support seat 2 is made of cast steel material, and the support seat 2 is evenly distributed on the lower end of the frame 1, and there are eight places to improve the stability of the support seat 2 supporting the overall structure, so that the working process is stable and the working performance is stable.

[0041] The present invention also provides a method for using the extrusion and shaping equipment for the preparation of silica gel products, which is applied to the above extrusion and shaping equipment for the preparation of silica gel products. The specific method of use is as follows:

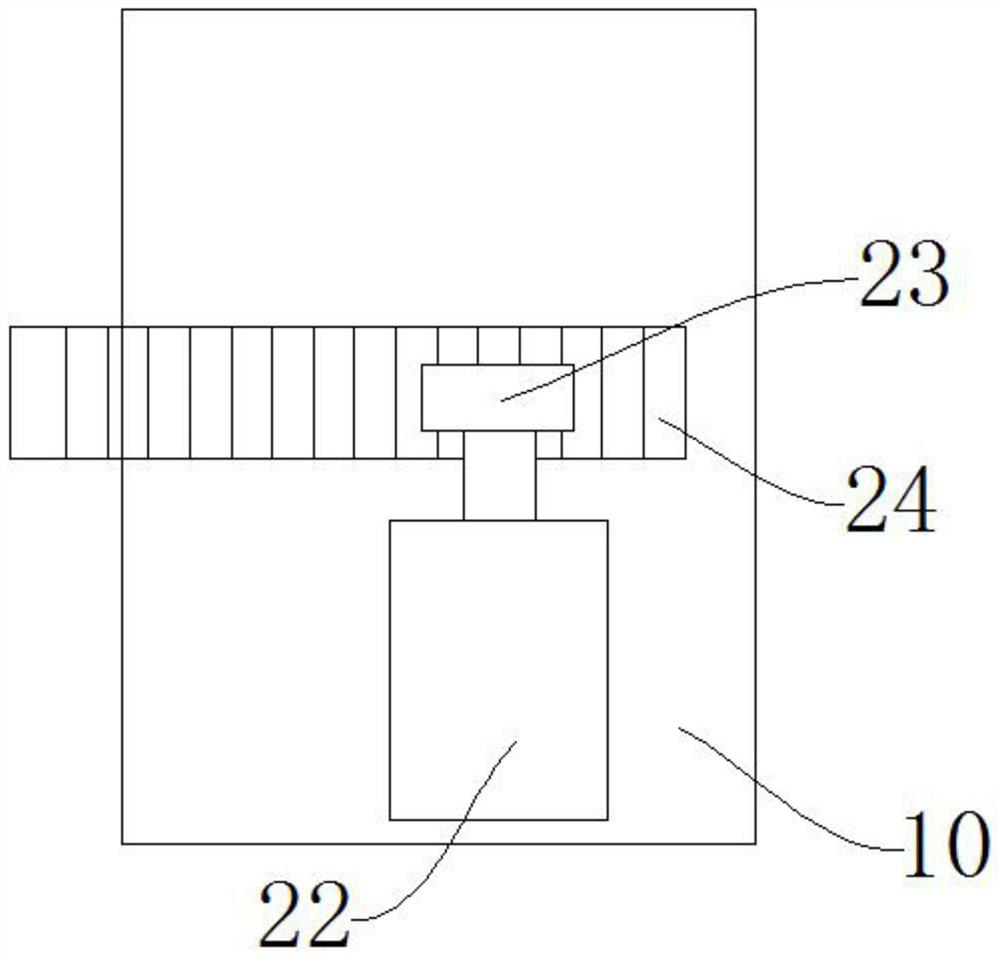

[0042]a. Drive the gear 23 to rotate through the rotation of the motor 22, and mesh with the rack 24, so that the feed box 10 approaches the support plate 8 until the feed cylinder 17 contacts the support plate 8;

[0043] b. Put the silica gel raw material into the feeding hopper 9, the servo motor 20 dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com