Method for eliminating distortion of lap joint area of fender stamping part front bumper

A technology for front bumpers and fenders, which is applied to vehicle parts, instruments, transportation and packaging, etc., to achieve the effects of compressing the debugging cycle, eliminating distortion in the overlapping area, and ensuring assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

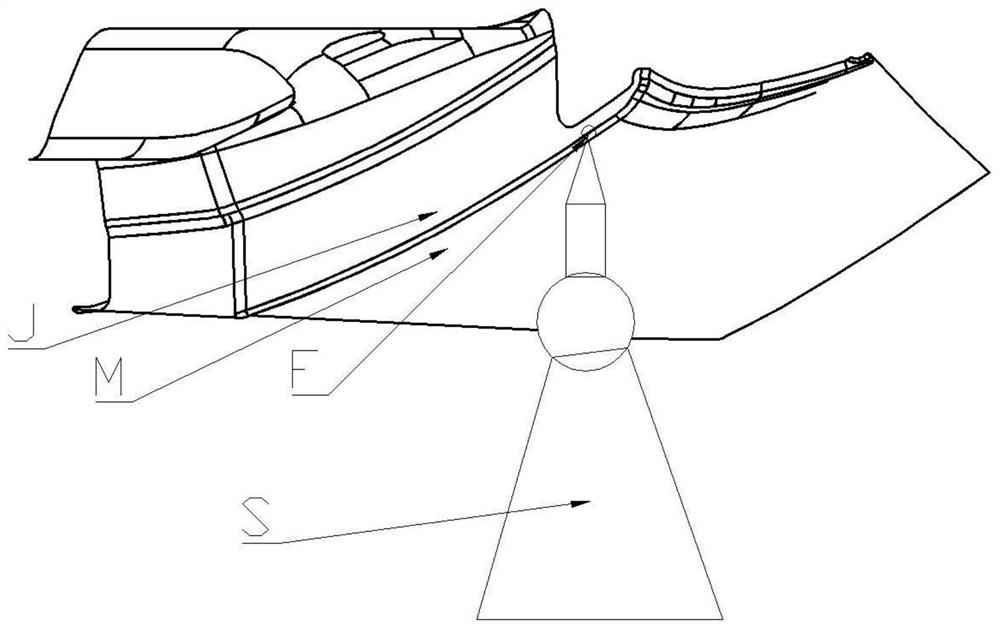

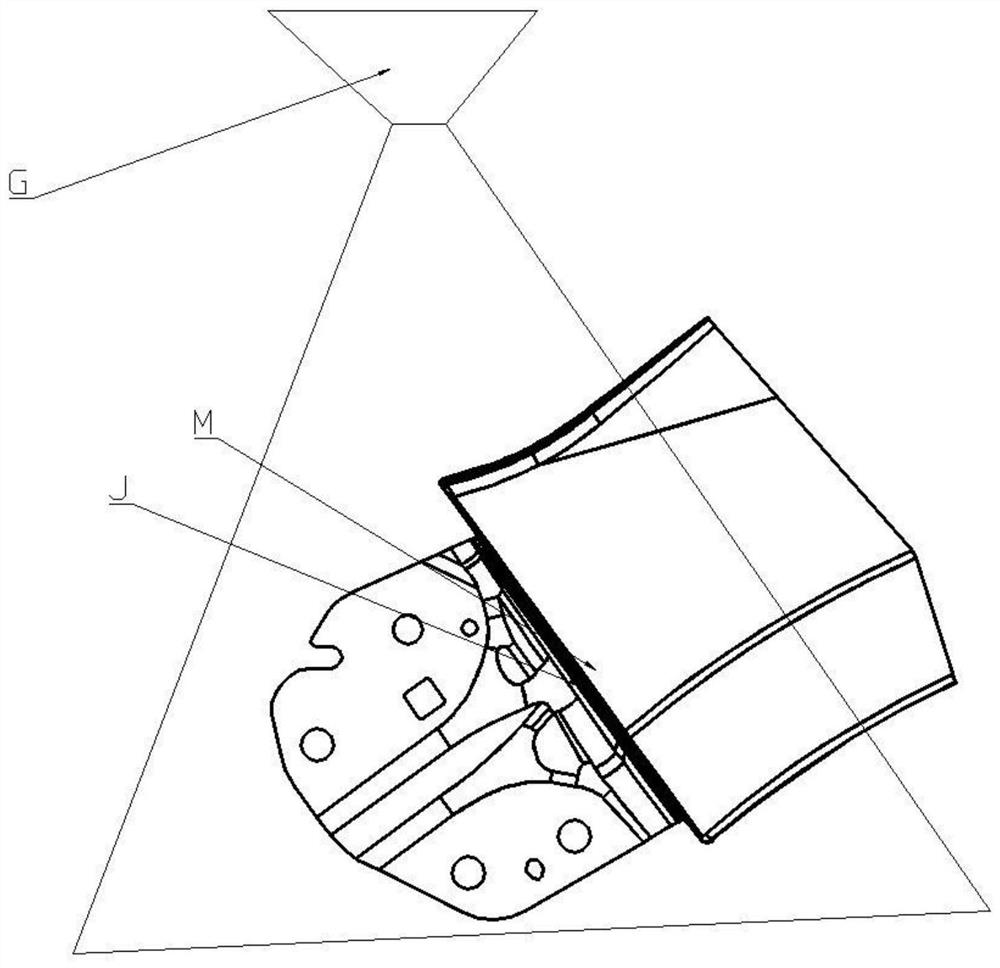

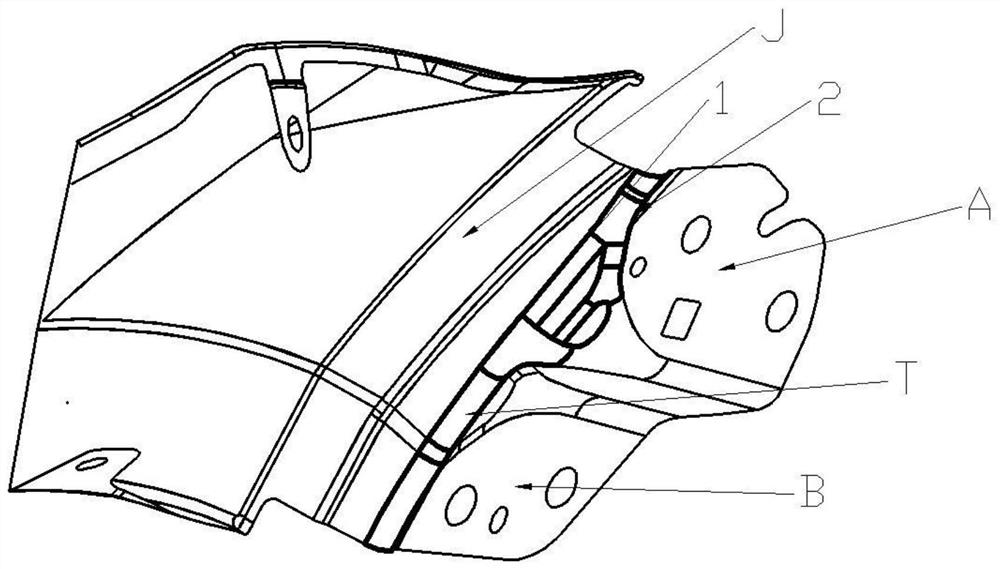

[0044]Seefigure 1 ,figure 2 ,image 3 ,Figure 4 ,Figure 5,Image 6 As shown, the data measurement of the overlap area of the front bumper of the fender is carried out by precision measuring equipment (figure 1 withfigure 2 Middle icon M / J), after obtaining the data, analyze the data directionality of all the profile data in the front bumper overlap area of the fender, and confirm each profile in the front bumper overlap area of the fender according to the analyzed data directionality Relevance. Complement the craftsmanship in the overlap area of the front bumper of the fender (image 3 Middle icon T) Carry out fillet compensation to correct the mounting surface of the front bumper overlap area of the fender (image 3 The middle icon A / B) rebounds to a twisted state. After the springback and distortion of the mounting surface of the front bumper overlap area of the fender plate are eliminated, the product is confirmed and the data of the front bumper overlap area of the fen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com