Bulb setting machine

A technology of shaping machine and light bulb, which is applied in the direction of electrical components, etc., can solve the problem of unfinished light bulb shaping, etc., and achieve the effect of high-efficiency bulb shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

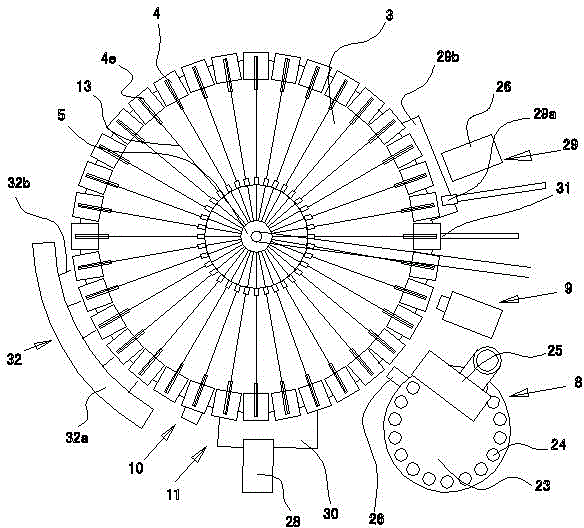

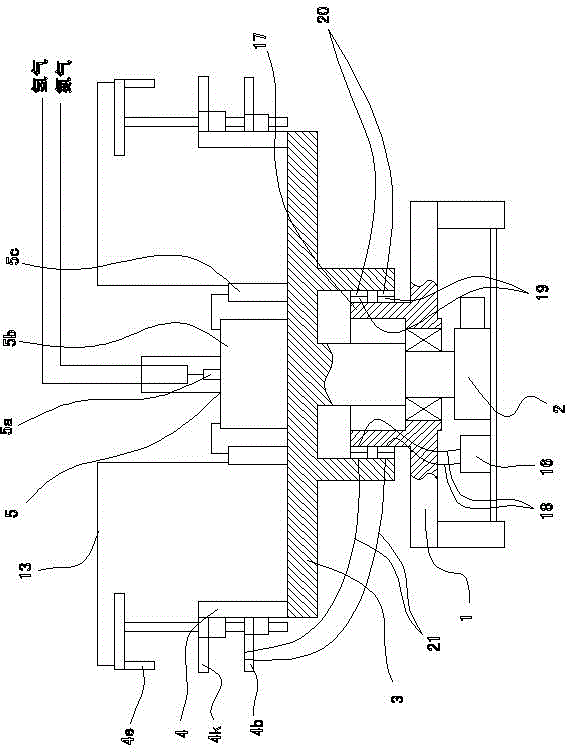

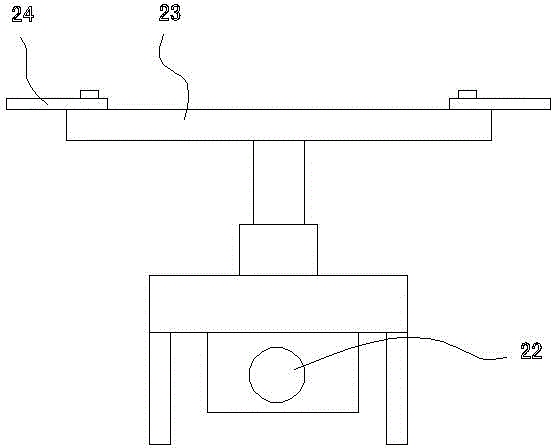

[0024] Such as figure 1 , 2 As shown, the present invention includes a frame 1; a turntable 3 arranged on the frame 1 driven by a power mechanism 2; several light bulb clamping / blowing devices 4 arranged along the periphery of the turntable 3; an air source 5; a power supply device 6 ; microcomputer control device 7; the upper bulb station 8 that is arranged successively along the side of the turntable 3 periphery, the station 9 that connects the inflator, removes the station 10 of the inflator, and takes the bulb station 11 with the finished product container 30, such as Figure 5 , 6 As shown, the bulb clamping / blowing device 4 includes a shelf 4a fixed on the turntable 3; a bulb clip 4d with a power connector 4c inside the chuck 4b arranged on the shelf 4a; Slide the rod 4f arranged on the shelf 4a, the bulb clip 4d is provided with a handle 4g tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com