Door and window outer frame calibration table with water cooling device

A technology for shaping tables and doors and windows, applied in the field of shaping tables for outer frames of doors and windows, can solve problems such as affecting product quality and yield, increasing production costs, and product deformation, and achieving the effects of low processing costs, stable shaping, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

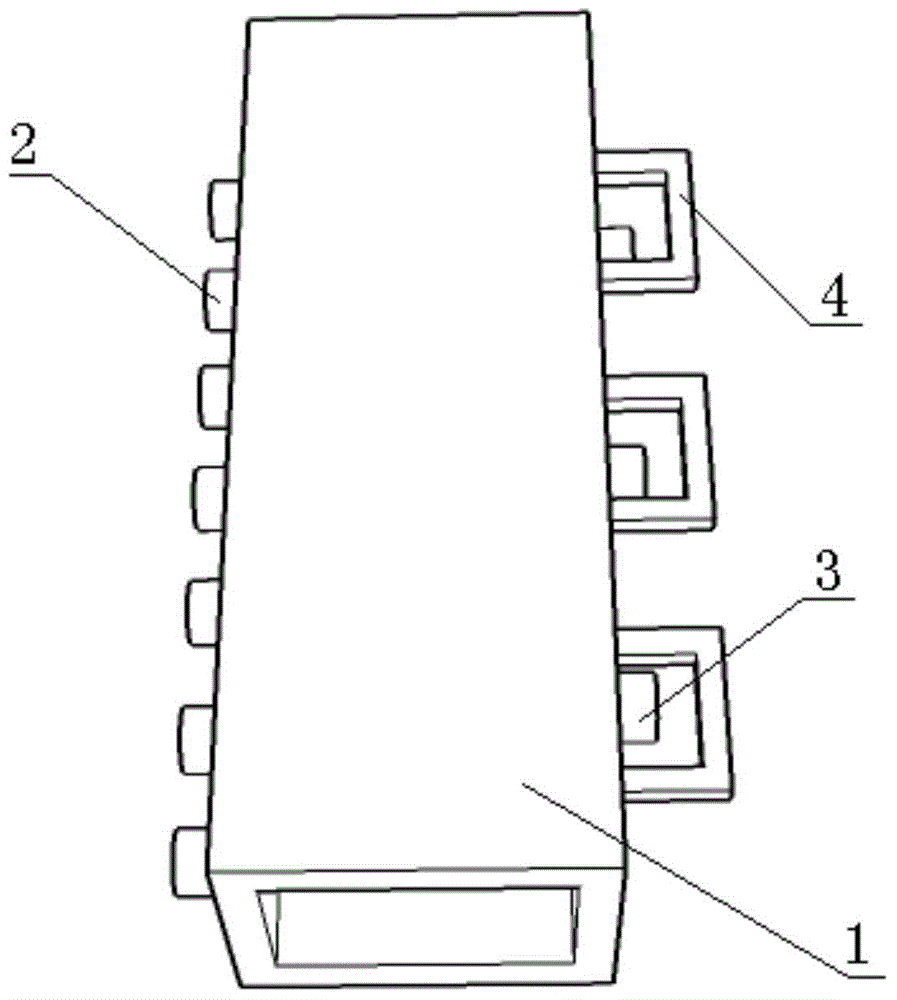

[0014] Such as figure 1 As shown, a water-cooled door and window outer frame shaping table of the present invention includes a circulating water tank 1, a cooling tower and a water pool, and a water pool is arranged below the cooling tower; several water inlets 2 and water outlets 3 are provided on the circulating water tank 1, The water inlet 2 is connected to the pool through the water inlet pipeline, and the water outlet 3 is connected to the cooling tower through the water outlet pipeline. The water inlet end of the water inlet pipeline is provided with a circulating water pump, and the water outlet end of the circulating water pump is provided with a pressure reducing regulating valve; The side of the circulating water tank is provided with a handle 4 for easy adjustment; the inner side of the circulating water tank is provided with a sealing strip, which is well sealed.

[0015] The working process of this example: After extrusion, the intermediate product enters the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com