Adjustable form special for floor construction and construction process thereof

An adjustable and formwork technology, which is applied in the direction of construction and building construction, can solve problems such as fixed elevations that cannot be adjusted flexibly, flatness of side facades that cannot be guaranteed, and support molds that are not firmly fixed, and achieve the installation and disassembly of the operating system, The mold is evenly stressed and does not deform, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

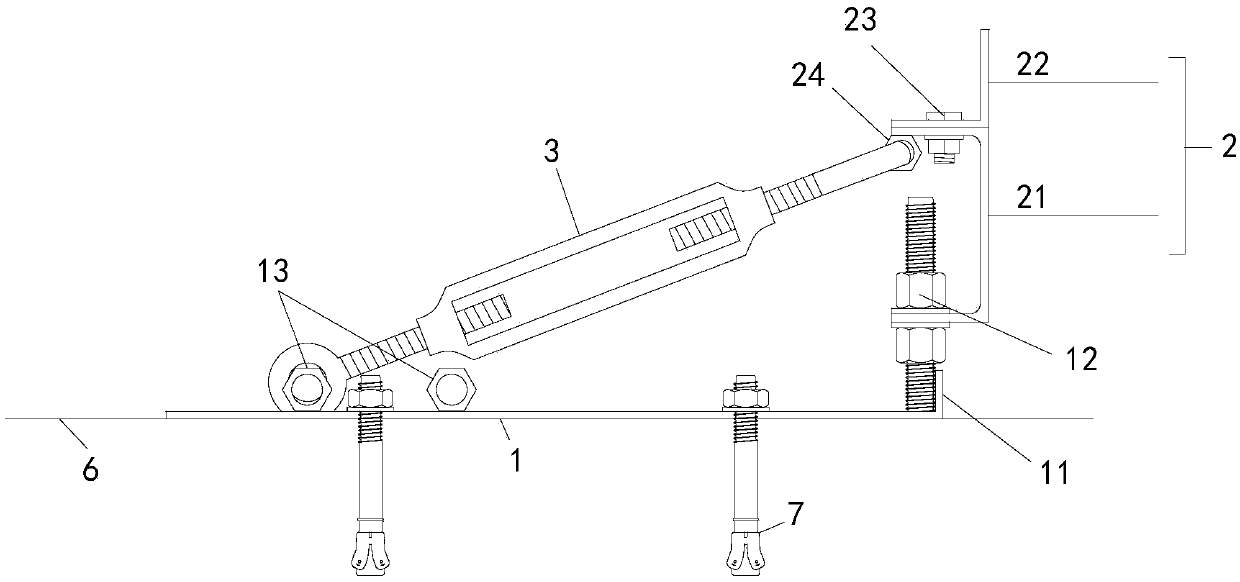

[0031] Embodiment: According to different site conditions, materials of different sizes are used to make this device:

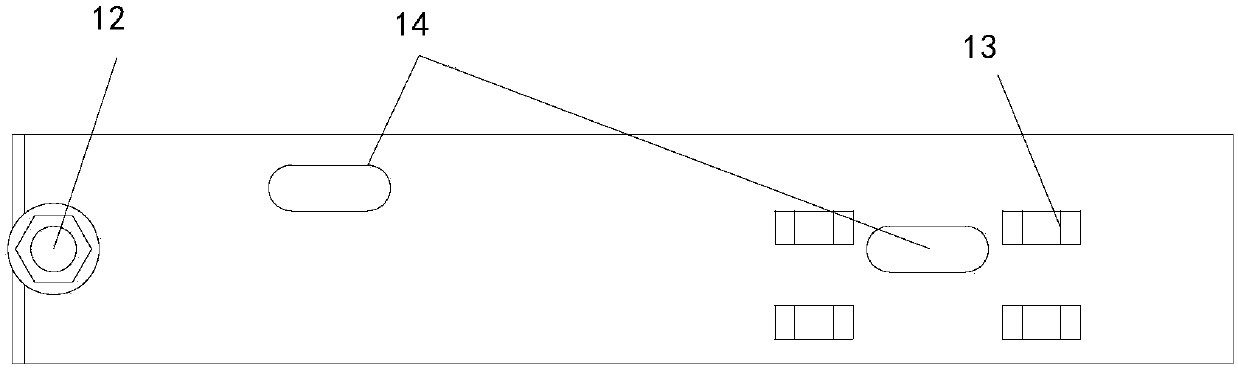

[0032] 1. The steel plate base 1 is 400 mm long, 75 mm wide, and 4 mm thick. One end of the base has a welding plate 11 bent at 90° and 30 mm high to weld and fix the screw. Two expansion bolt holes 14 with a length of 40 mm and a width of 15 mm are provided on the steel plate base 1. , use M10 expansion bolts 7 to fix the steel plate base 1 on the concrete pad 6 . Welding screw 12 is 110 mm high and 15 mm in diameter. The bottom and sides of screw 12 are respectively welded on steel plate base 1 and welding plate 11. Screw 12 is equipped with two fixed adjusting bolts and washers for supporting and adjusting steel formwork 2. The steel plate base 1 is welded with four 4 M10 first nuts 13 to be used as pin holes for the connection of the end of the turnbuckle 3, and the use position can be determined according to the environmental conditions;

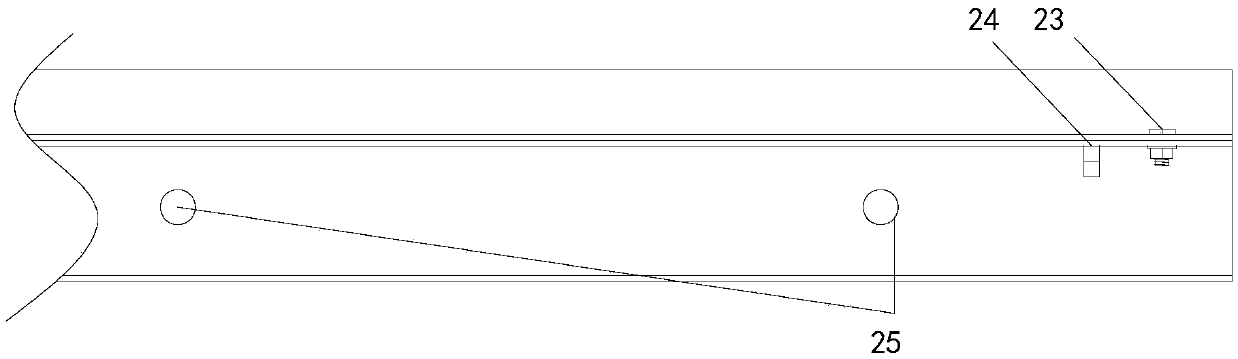

[0033] 2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com