Novel shipbuilding assembly method and steel plate leveling device

A technology for steel plate leveling and hull assembly, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of increasing man-hours and labor costs, unable to realize welding automation, and high costs, and achieve the effect of saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

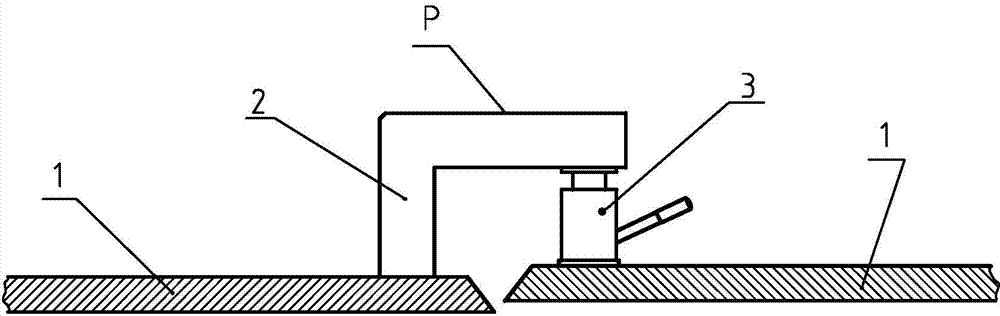

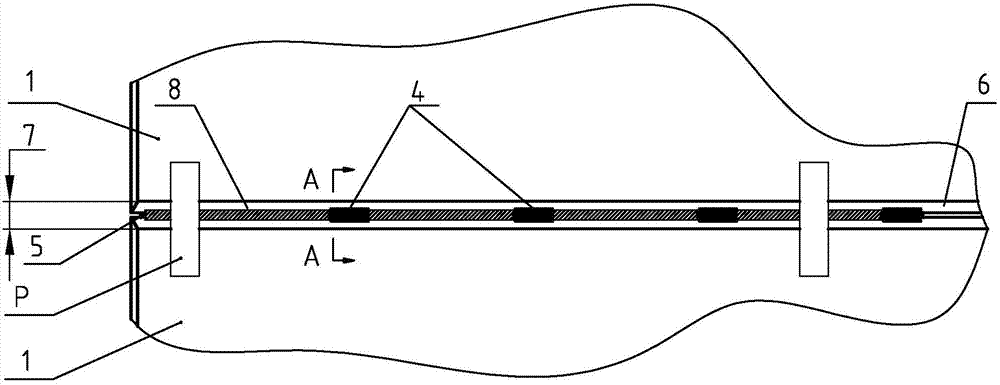

[0077] as attached Figure 1 to Figure 8 A new method of shipbuilding assembly shown, comprising the following steps:

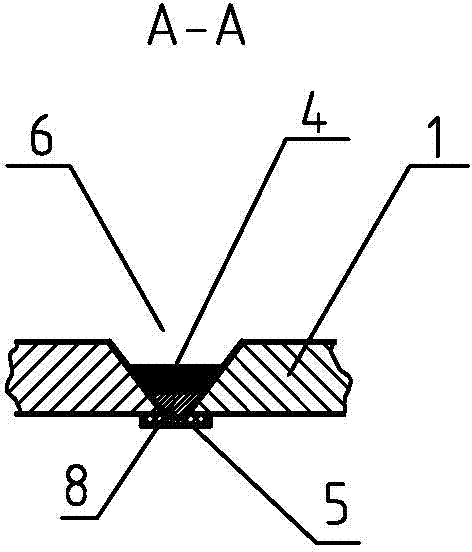

[0078] Step 1, cutting the groove: firstly locate the steel plate 1 that needs to be welded together by the hull, and cut the groove 7 according to the size required by the groove on the two butt joint edges of the steel plate 1 assembled by the hull;

[0079] Step 2. Grinding the groove: use a grinder to smooth the both sides of the groove 7 and the upper and lower sides of the steel plate within 100mm from the groove;

[0080] Step 3. Assemble the flat steel plate: as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the leveling equipment P is installed from the middle or one end of the butt joint 6 of the groove 7. The leveling equipment is a leveling equipment that only contacts with the top of the steel plate. Align and level off to form a leveled area a and maintain this state; the leveling equipment can be an oil top 3 and an oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com