Process for preparing plied yarn by one-step process using textured yarn and highly retractable yarn

A technology of high shrinkage yarn and textured yarn, used in textiles and papermaking, etc., can solve the problems of process and product quality defects, large intermolecular stress of textured yarn, affecting the style and effect of cloth surface, etc., and achieve good product style. , the effect of reducing energy consumption and increasing the production capacity of the device

Inactive Publication Date: 2005-03-16

中国石化仪征化纤股份有限公司

View PDF0 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the textured yarn in this production method has not undergone high-temperature heat setting, resulting in defects in the process and product quality, mainly as follows:

[0007] First, the internal stress between the molecules of the textured yarn is relatively large, and the molecular structure is unstable, resulting in uneven dyeing;

[0008] Second, the internal residual torque of the textured yarn is relatively large, and the phenomenon that the high-shrinkage yarn floats on the surface of the textured yarn when it is plied with the high-shrinkage yarn makes the high-shrinkage yarn float on the surface of the cloth surface during fabric finishing, which affects the fabric surface. styles and effects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0030] 〖Example 1〗Sea-island yarn and high-shrinkage yarn are combined in one step

[0031] Process conditions

Embodiment 2

[0032] 〖Example 2〗Sea-island yarn and high-shrinkage yarn are combined in one step

[0033] Process conditions

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

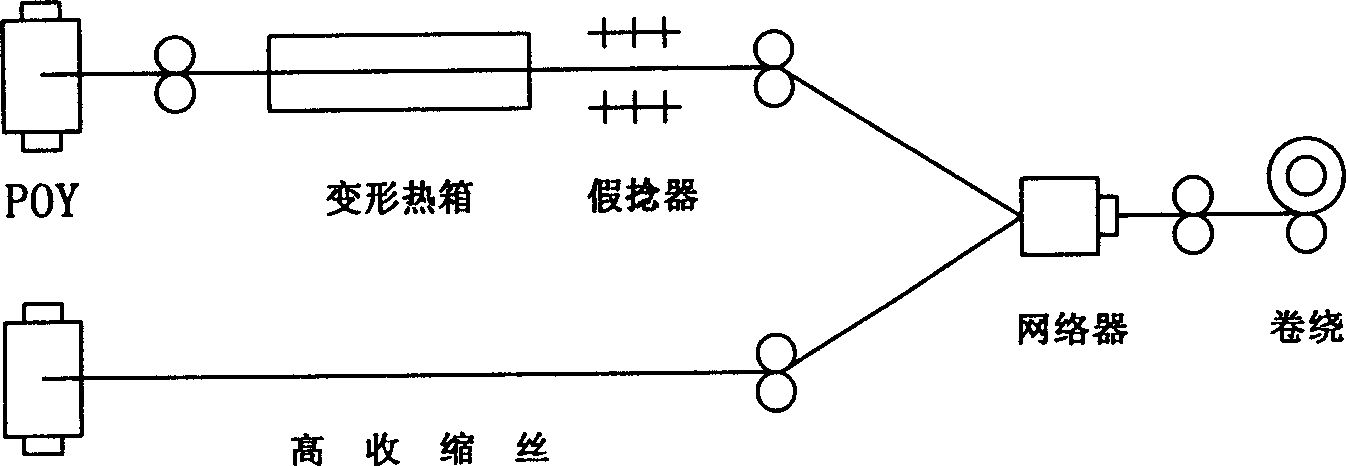

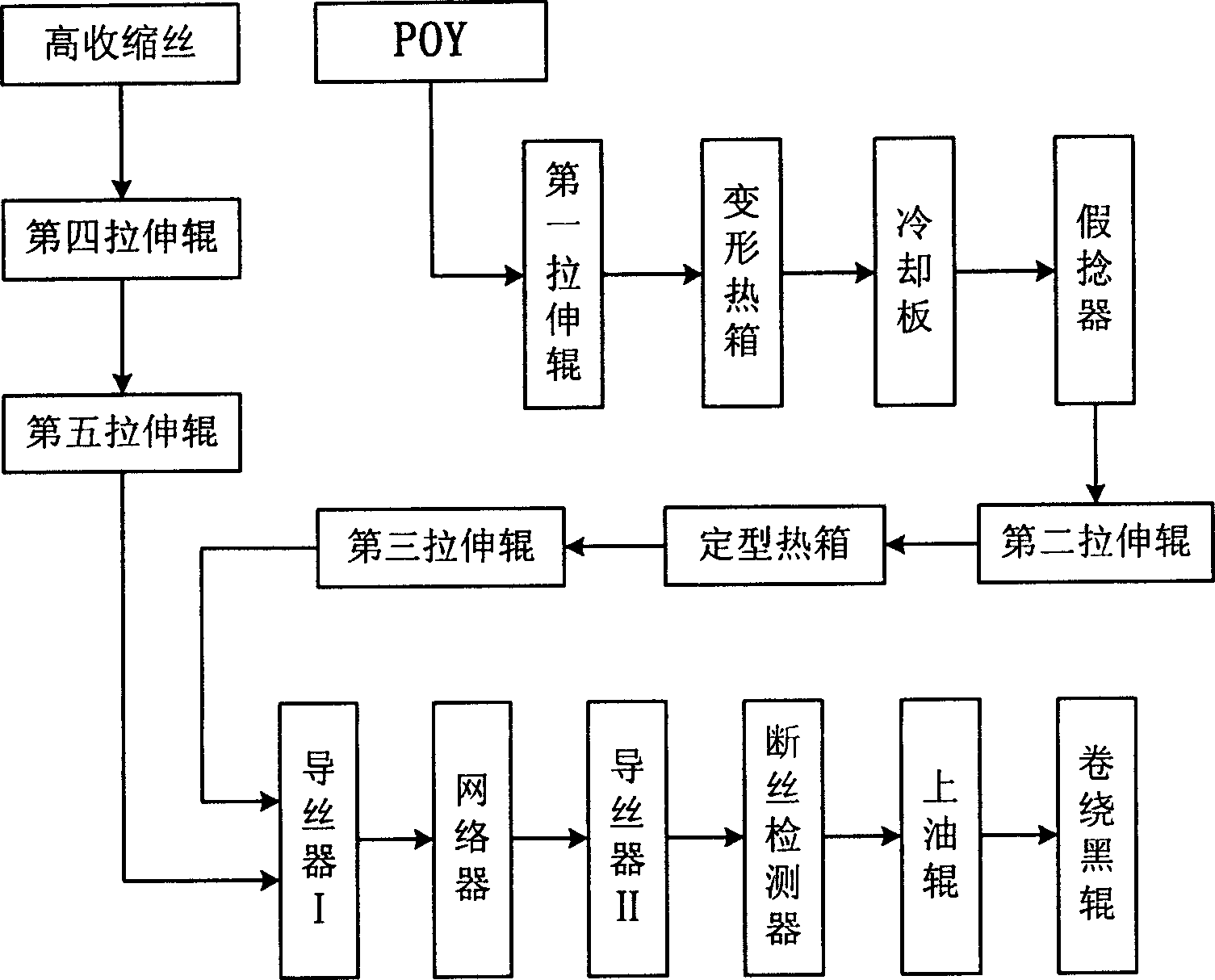

The invention relates to a process for preparing plied yarn by one-step process using textured yarn and highly retractable yarn, comprising: having the draw texturising machine as main processing device, drawing and deforming the pre-oriented yarn POY, heating moulding the produced deforming yarn by the heat moulding box and the third drawing roll; meanwhile, setting the fourth and fifth drawing roll on the draw texturising machine, feeding and drawing the highly retractable yarn, sending into network device for combining with the deformation yarn, detecting and oiling by guide, detector and oiling roll, finally winding to obtain the resultant yarn. The invention increases the moulding procedure of the deformation yarn, solves the problem the moulding the yarn combining in a single step. The resultant yarn has a good fastness and uniformity of the network degree, little yarn breakage which can be used to produce the material like wool fabrics, polyester peach skin, suede nap.

Description

technical field [0001] The invention belongs to the production process of synthetic fibers, and relates to a preparation method of ply yarn, in particular to making ply yarn from textured yarn and high-shrinkage yarn through a one-step process route. Background technique [0002] When developing wool-like fabrics, jeanette, and suede fabrics, some varieties need to combine various forms of textured yarns such as fine denier yarns, ultra-fine denier yarns, and sea-island yarns with high-shrinkage yarns to obtain plied yarns. During dyeing and finishing, due to the different thermal shrinkage rates of the two fibers, the high-shrinkage fiber produces a large shrinkage and forms a skeleton; while the textured yarn has a relatively small shrinkage rate and floats on the surface to maximize the superfine fiber effect on the surface and form a skeleton. Better wool and velvet feeling, or better display of artificial leather effect. Therefore, the excellent properties of this kind...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D02G1/18

Inventor 季平王芳李刚朱福和王子彬

Owner 中国石化仪征化纤股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com