Patents

Literature

33results about How to "Increase device capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

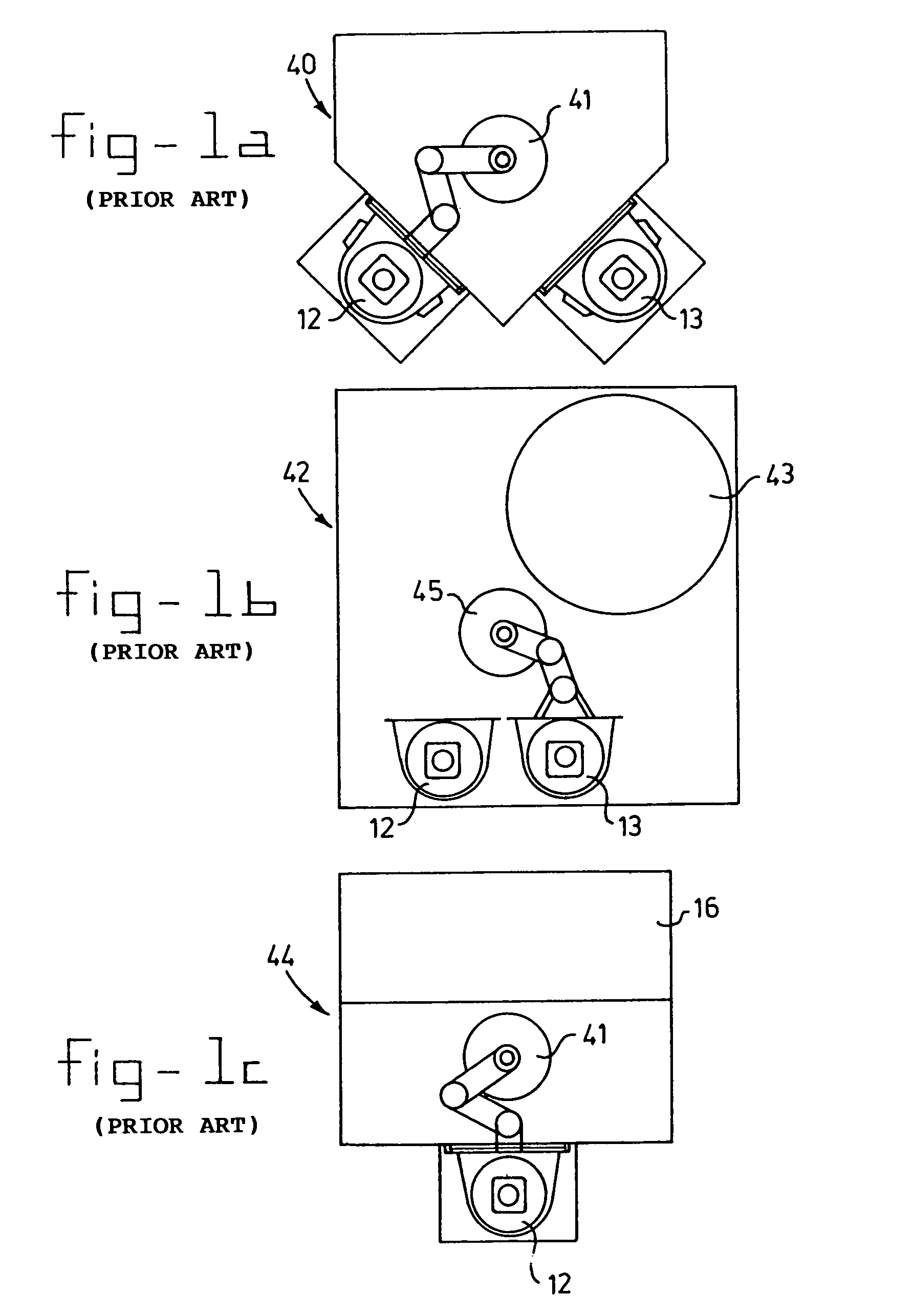

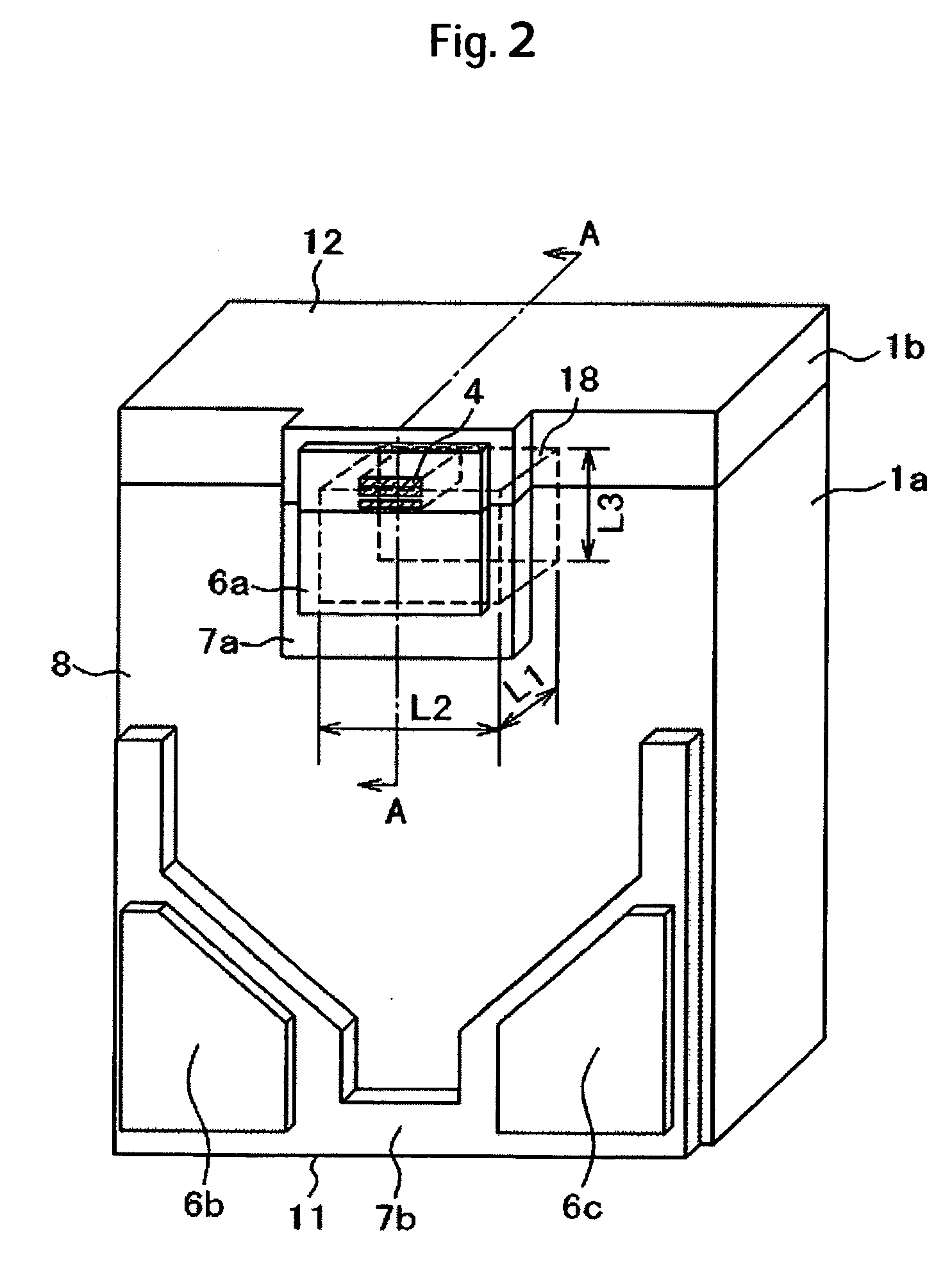

Sorting/storage device for wafers and method for handling thereof

InactiveUS7077614B1Easy and less-expensive to produceReducing throughout capacitySemiconductor/solid-state device manufacturingCharge manipulationMeasurement stationBiomedical engineering

Sorting / storage device for wafers. A sorting device is provided in which at least two cassettes containing wafers may be present and the wafers are moved from one cassette to the other cassette or vice versa. If appropriate, a measuring station may be present in the sorting device. In the immediate vicinity of the sorting device, the cassettes are stored in a magazine which is designed for this purpose and the cassettes are moved using a handling device for cassettes.

Owner:ASM INTERNATIONAL

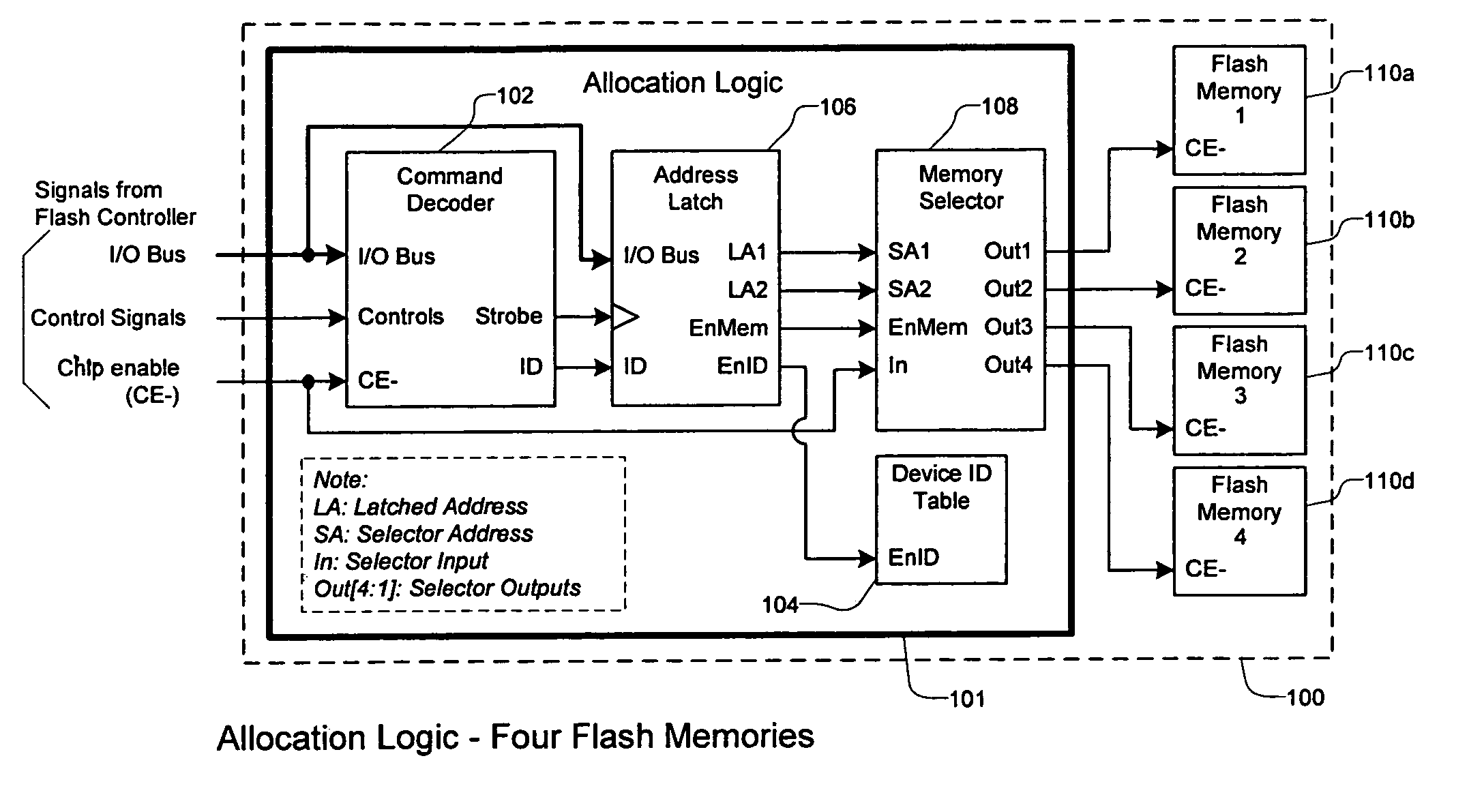

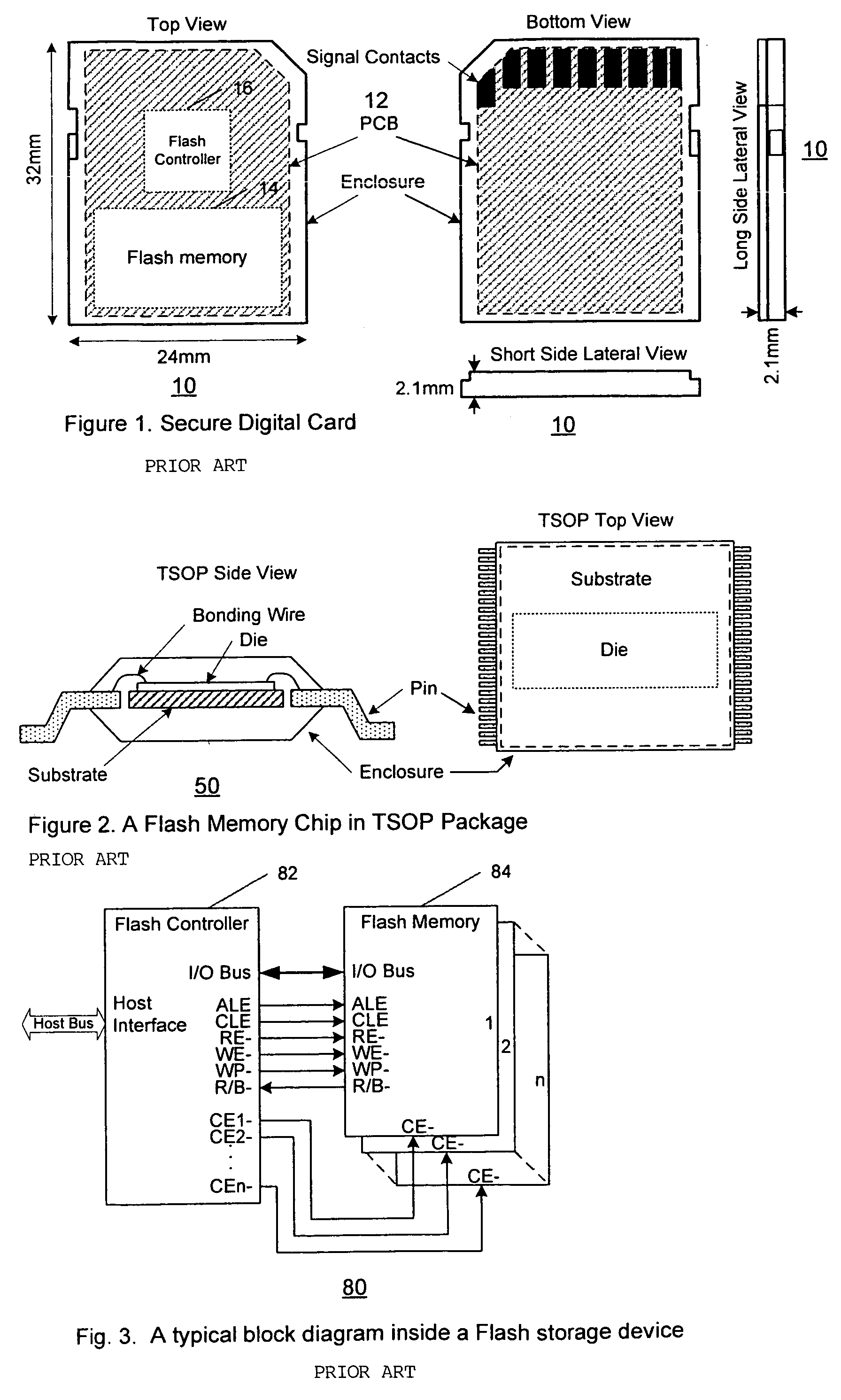

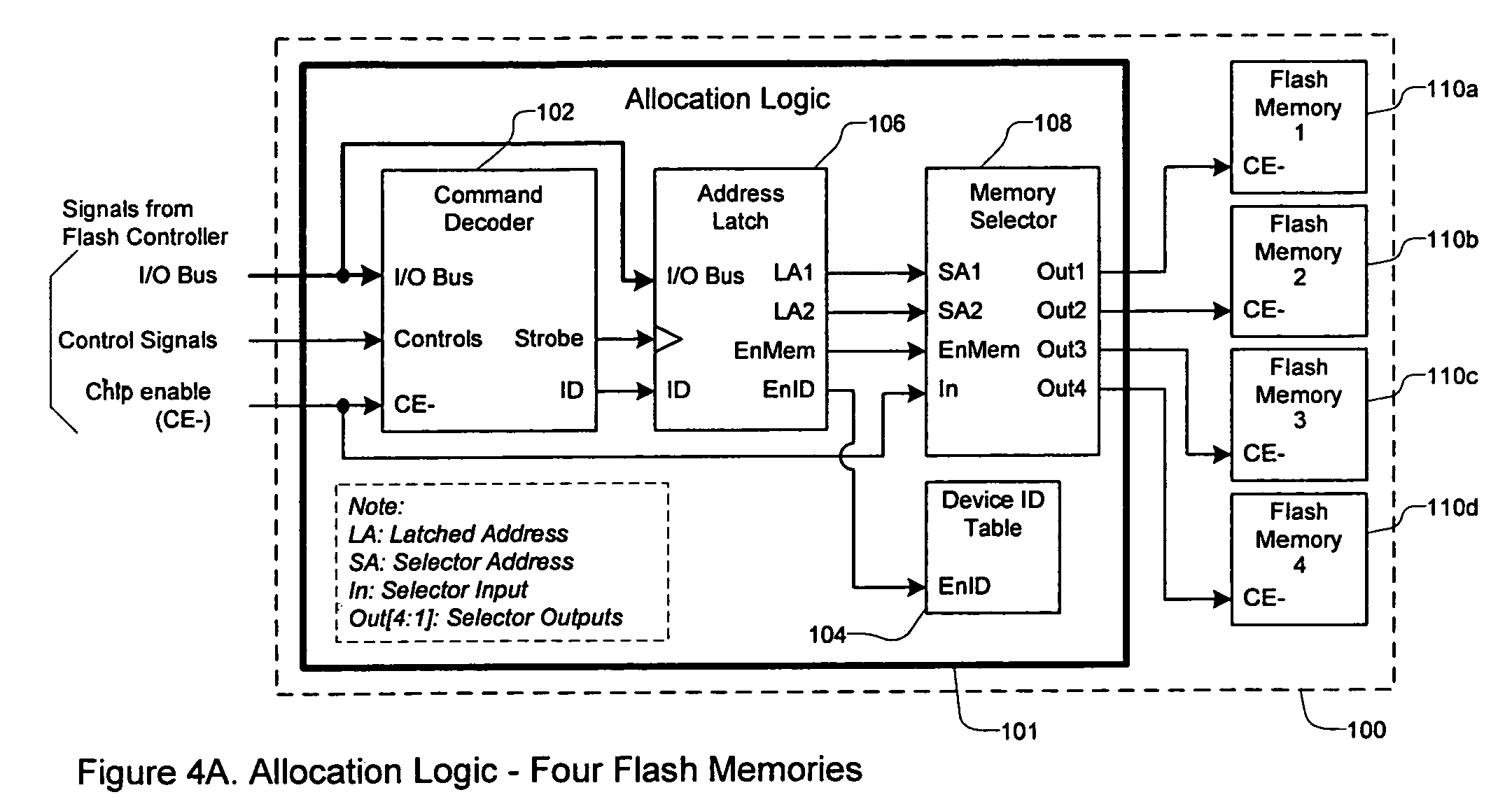

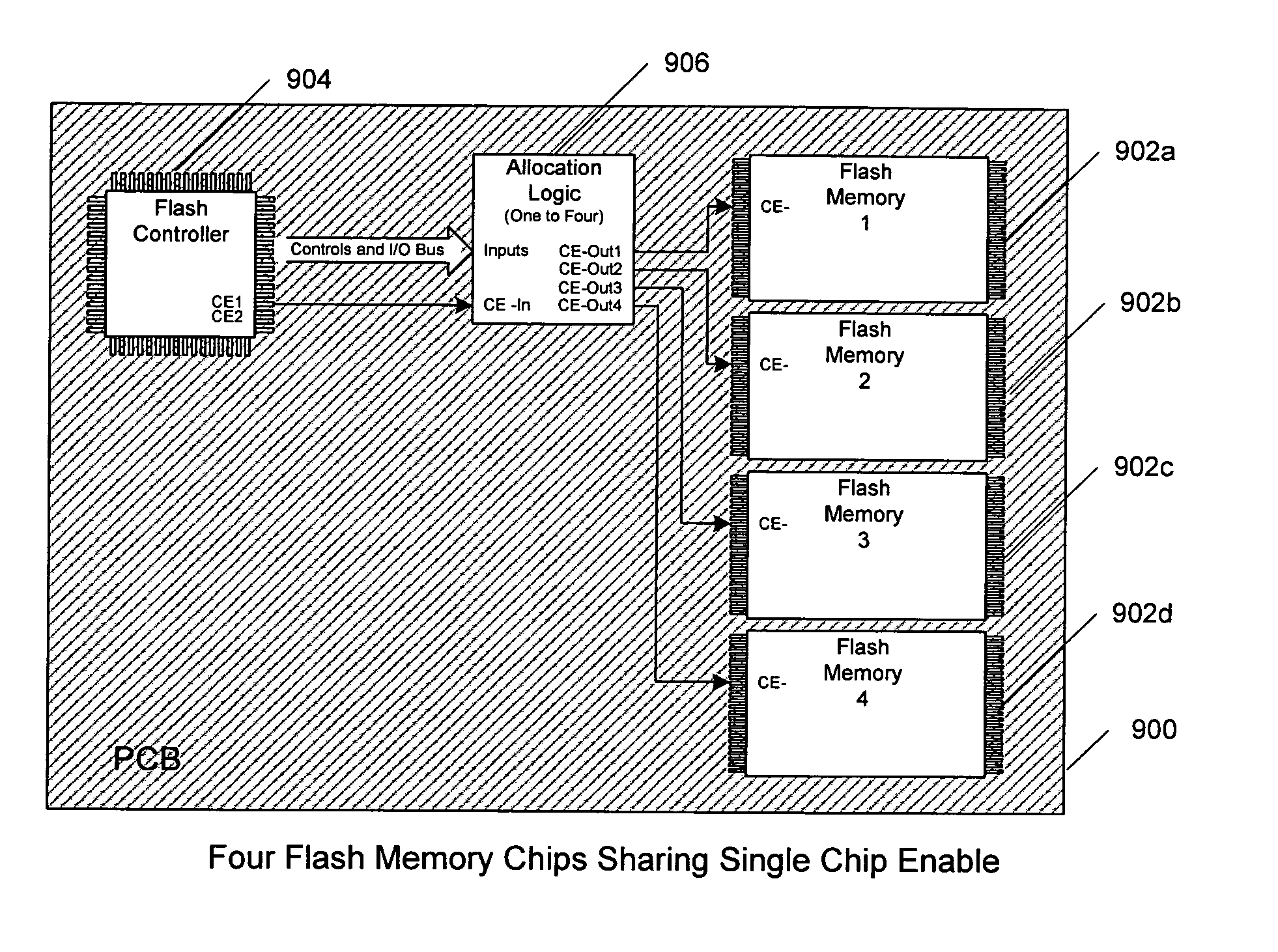

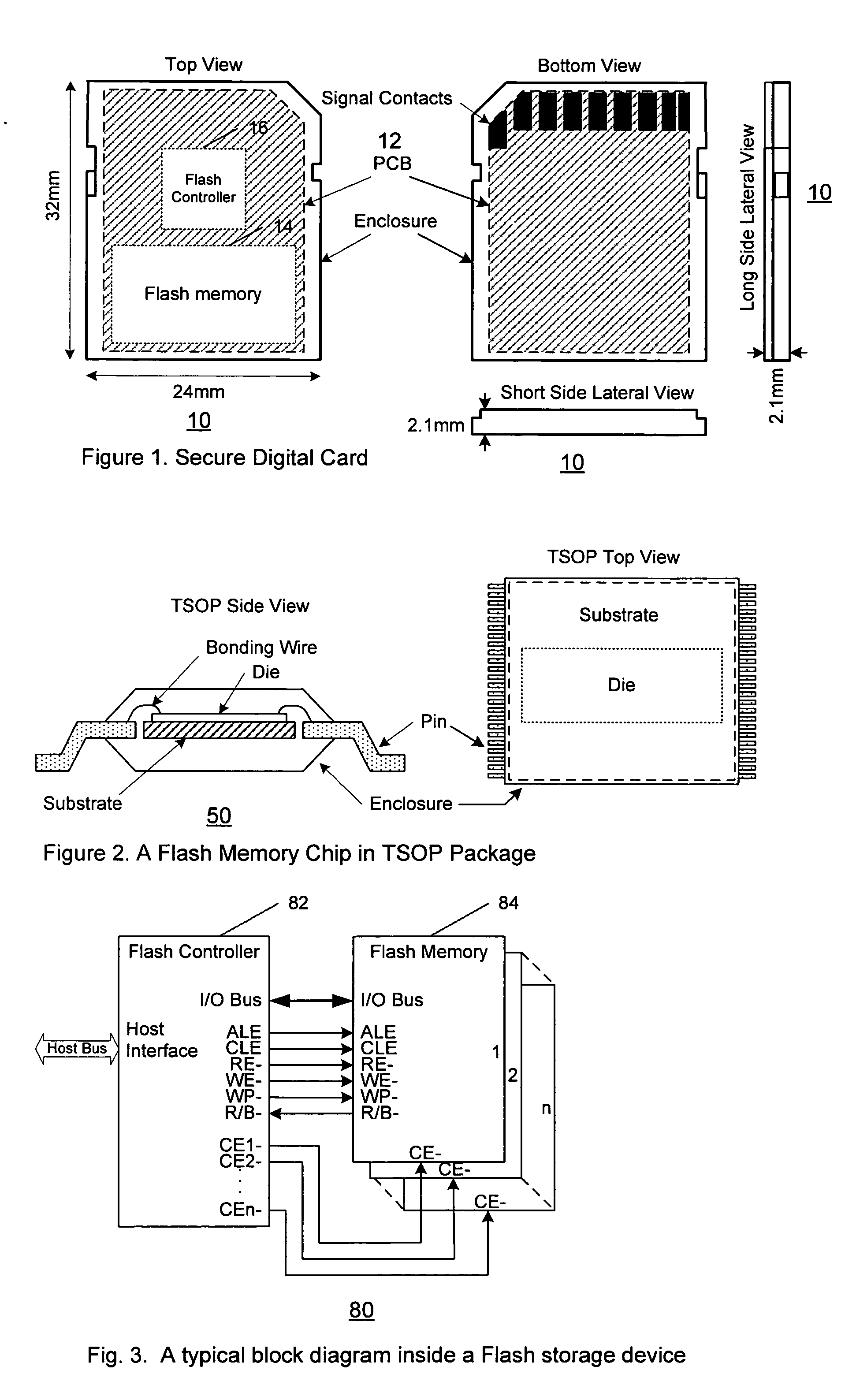

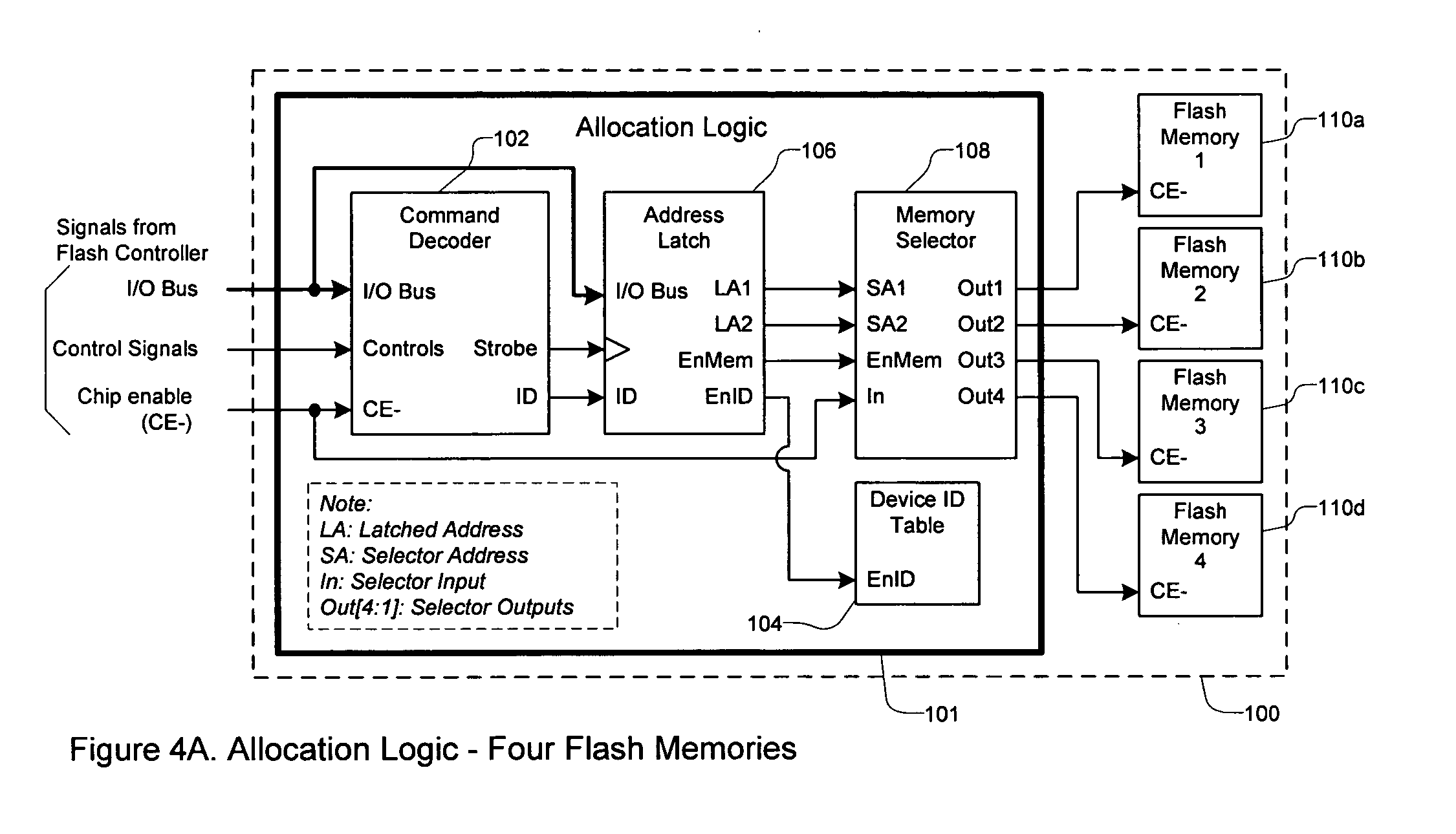

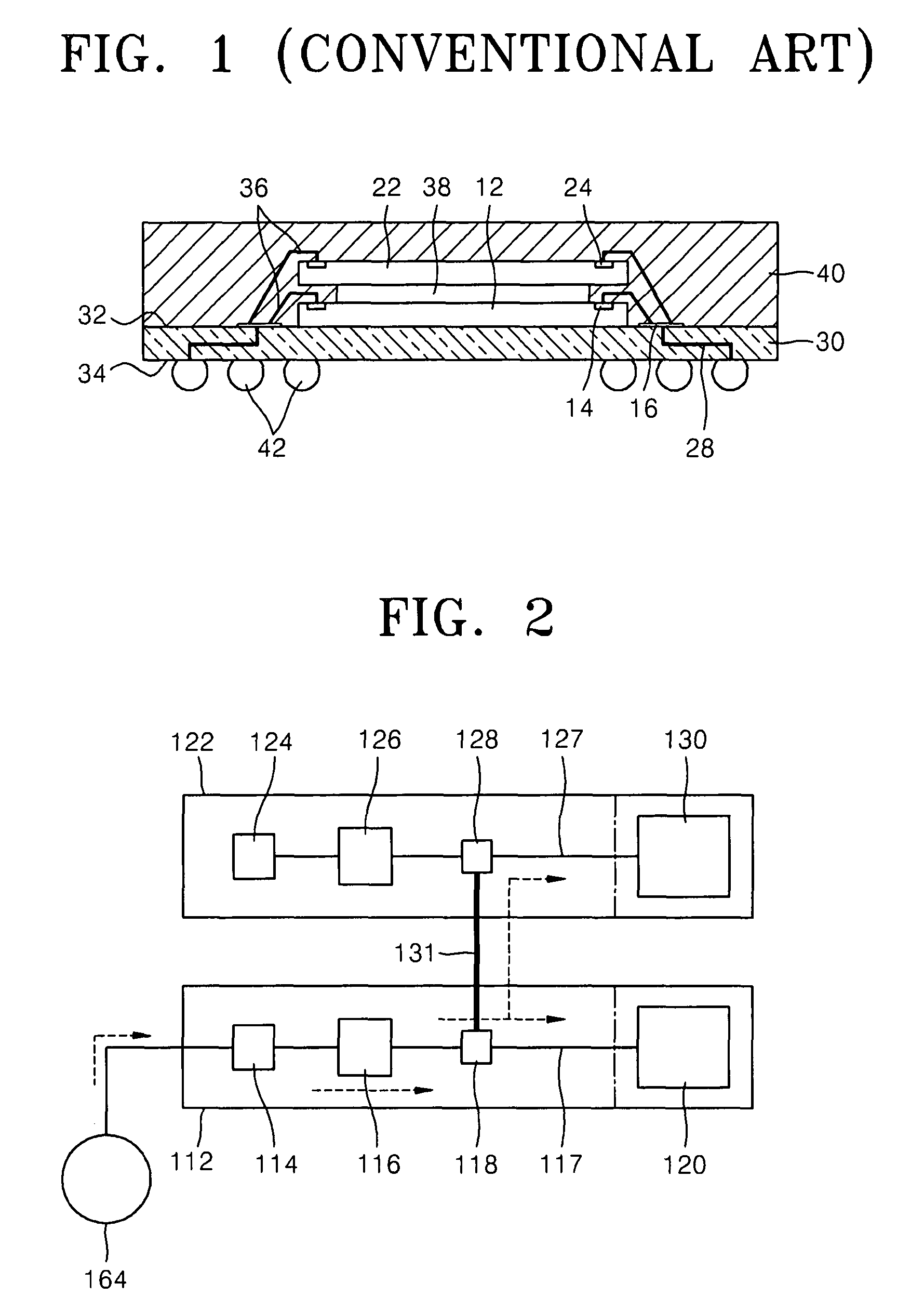

Method and system for expanding flash storage device capacity

InactiveUS7126873B2Increase device capacityIncrease capacityMemory adressing/allocation/relocationRead-only memoriesFlash memory controllerSingle chip

Through the use of an allocation logic unit with a Flash controller, a single primary chip enable is de-multiplexed into a multiple secondary chip enables for multiple Flash memory dies or chips. In so doing, Flash storage device capacity is greatly expanded. In a first aspect, a memory package includes a plurality of memories; and an allocation logic unit coupled to the plurality of memories for receiving a single chip enable signal. The allocation logic unit de-multiplexes the single chip enable signal to a plurality of chip enable signals. Each of the plurality of chip enable signals access to one of the plurality of memories.In a second aspect, a printed circuit board (PCB) includes a Flash controller for providing at least one primary chip enable signal. The PCB also includes a plurality of Flash memory chips and at least one allocation logic unit coupled to at least a portion of the plurality of Flash memory chips and the Flash controller. The allocation logic unit receives the at least one chip enable signal and de-multiplexes the at least one chip enable signal to a plurality of secondary chip enable signals. Each of the plurality of chip enable signals controls access to one of the Flash memory chips.

Owner:ELECTRONICS & TELECOMM RES INST +1

Method and system for expanding flash storage device capacity

InactiveUS20050286284A1Increase device capacityIncrease capacityMemory adressing/allocation/relocationRead-only memoriesLogic cellFlash memory controller

Through the use of an allocation logic unit with a Flash controller, a single primary chip enable is de-multiplexed into a multiple secondary chip enables for multiple Flash memory dies or chips. In so doing, Flash storage device capacity is greatly expanded. In a first aspect, a memory package includes a plurality of memories; and an allocation logic unit coupled to the plurality of memories for receiving a single chip enable signal. The allocation logic unit de-multiplexes the single chip enable signal to a plurality of chip enable signals. Each of the plurality of chip enable signals access to one of the plurality of memories. In a second aspect, a printed circuit board (PCB) includes a Flash controller for providing at least one primary chip enable signal. The PCB also includes a plurality of Flash memory chips and at least one allocation logic unit coupled to at least a portion of the plurality of Flash memory chips and the Flash controller. The allocation logic unit receives the at least one chip enable signal and de-multiplexes the at least one chip enable signal to a plurality of secondary chip enable signals. Each of the plurality of chip enable signals controls access to one of the Flash memory chips.

Owner:ELECTRONICS & TELECOMM RES INST +1

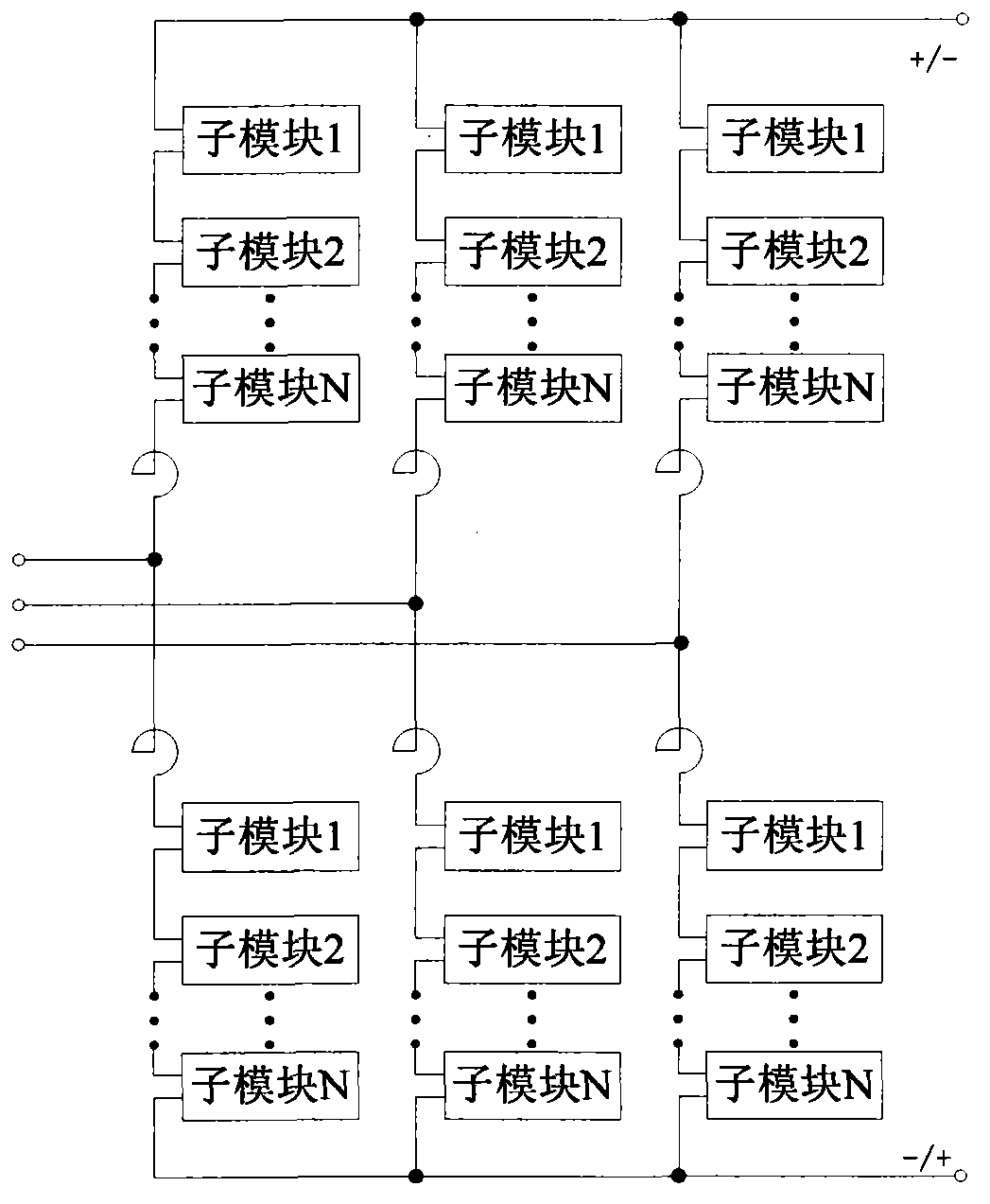

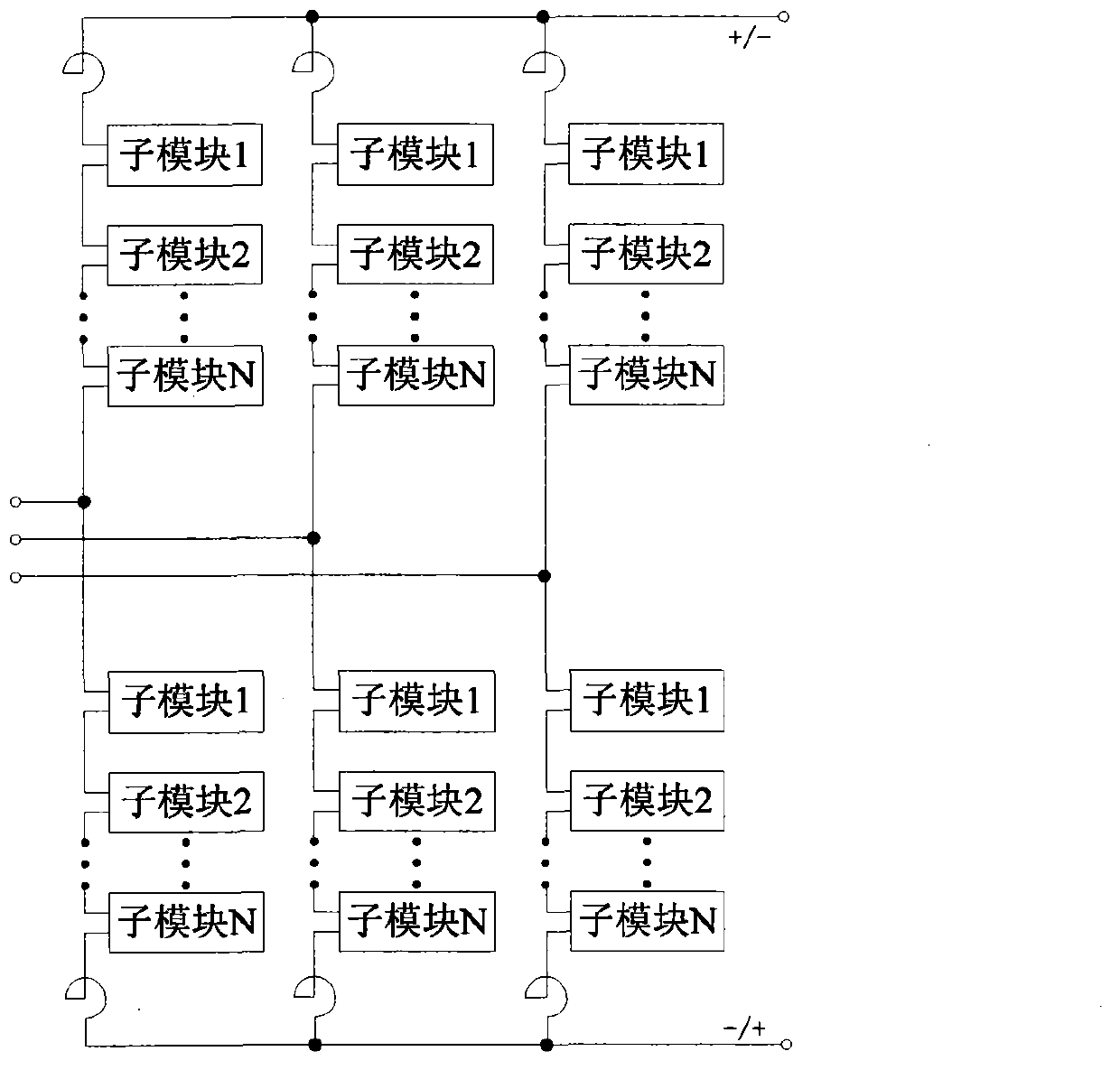

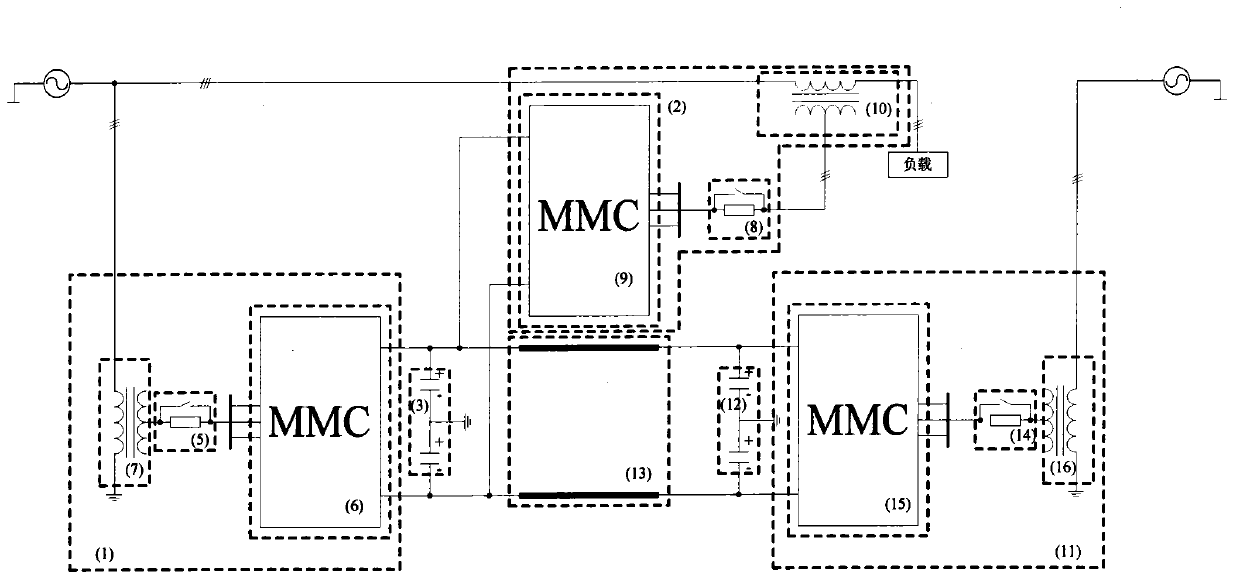

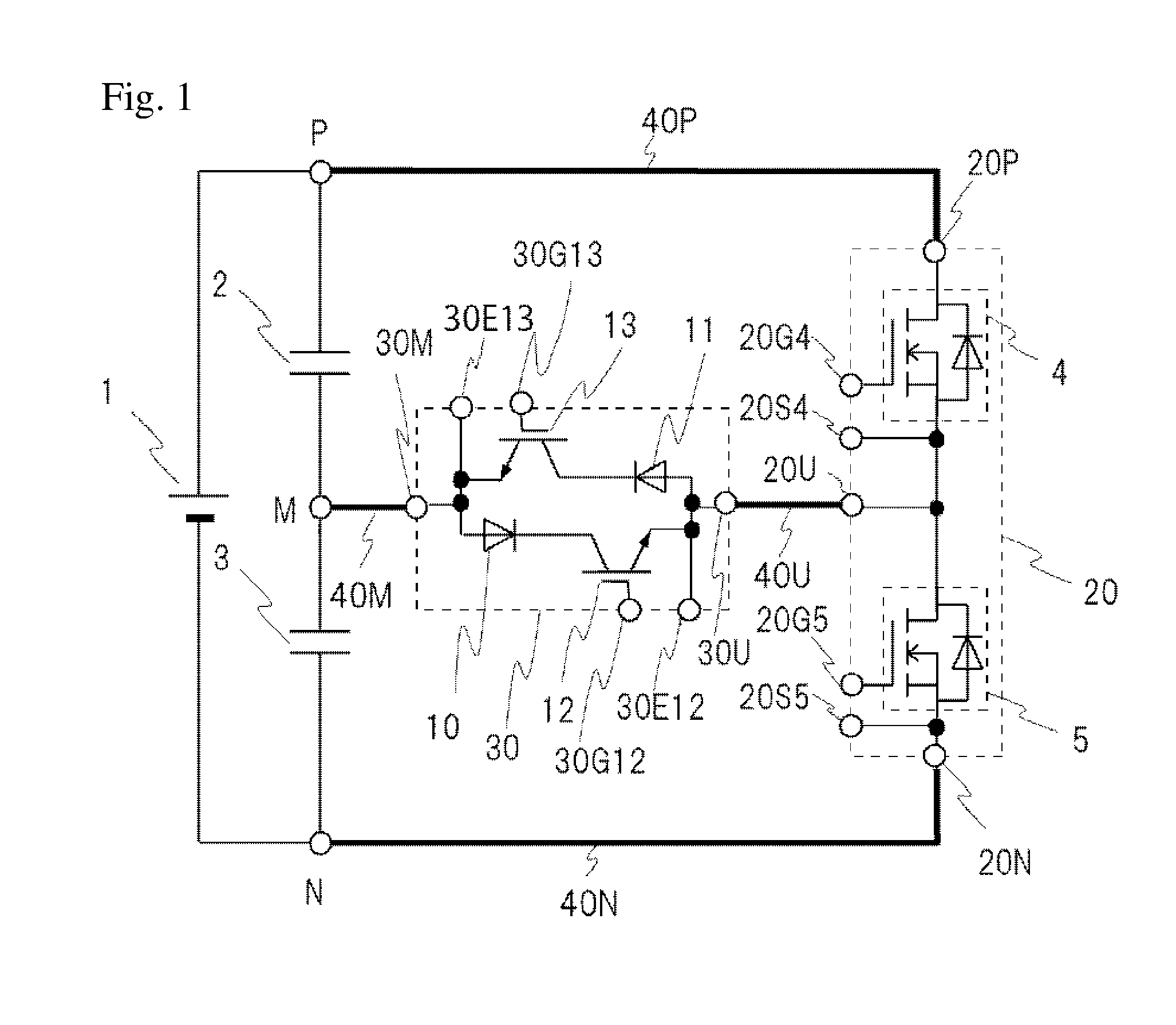

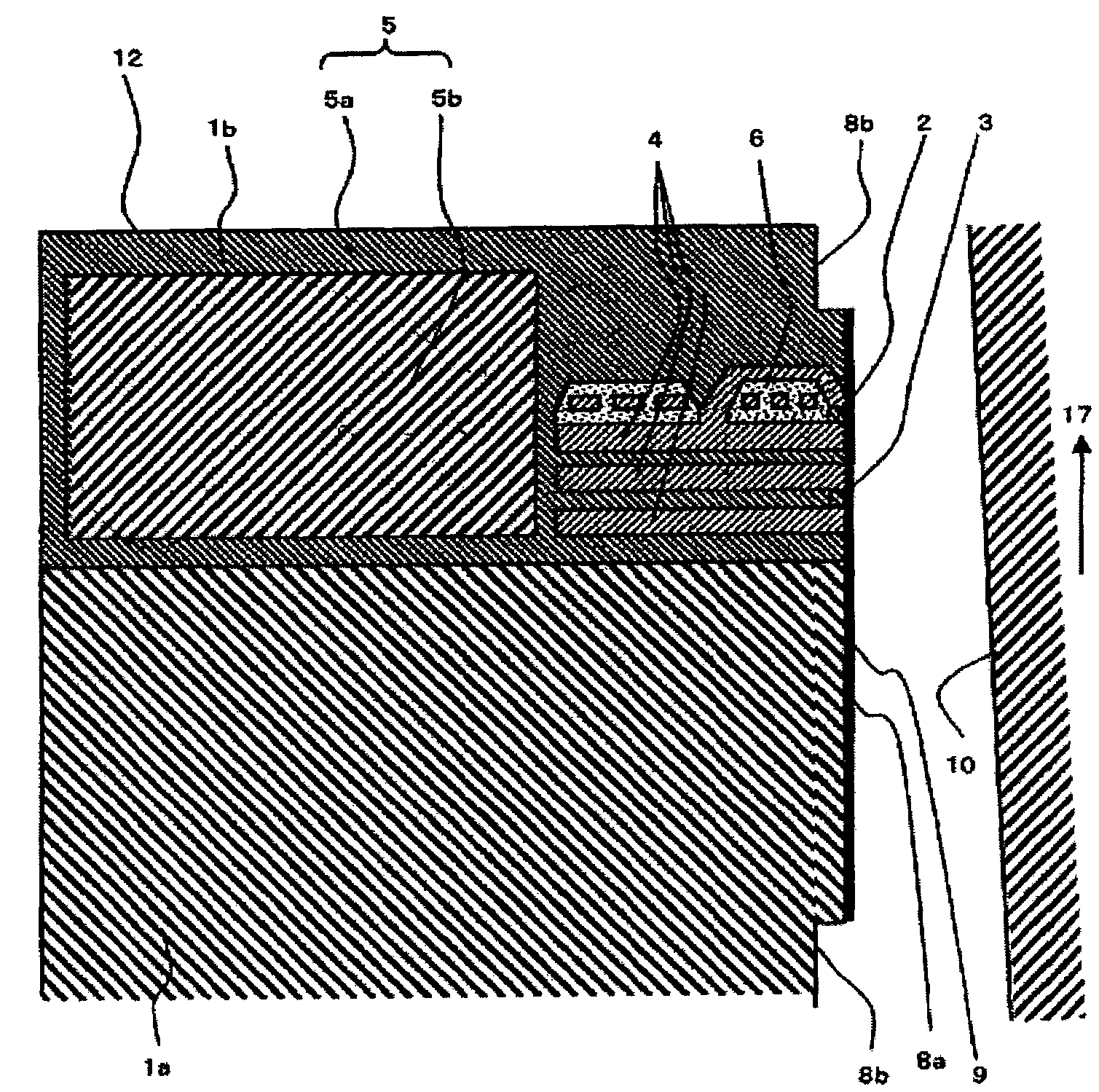

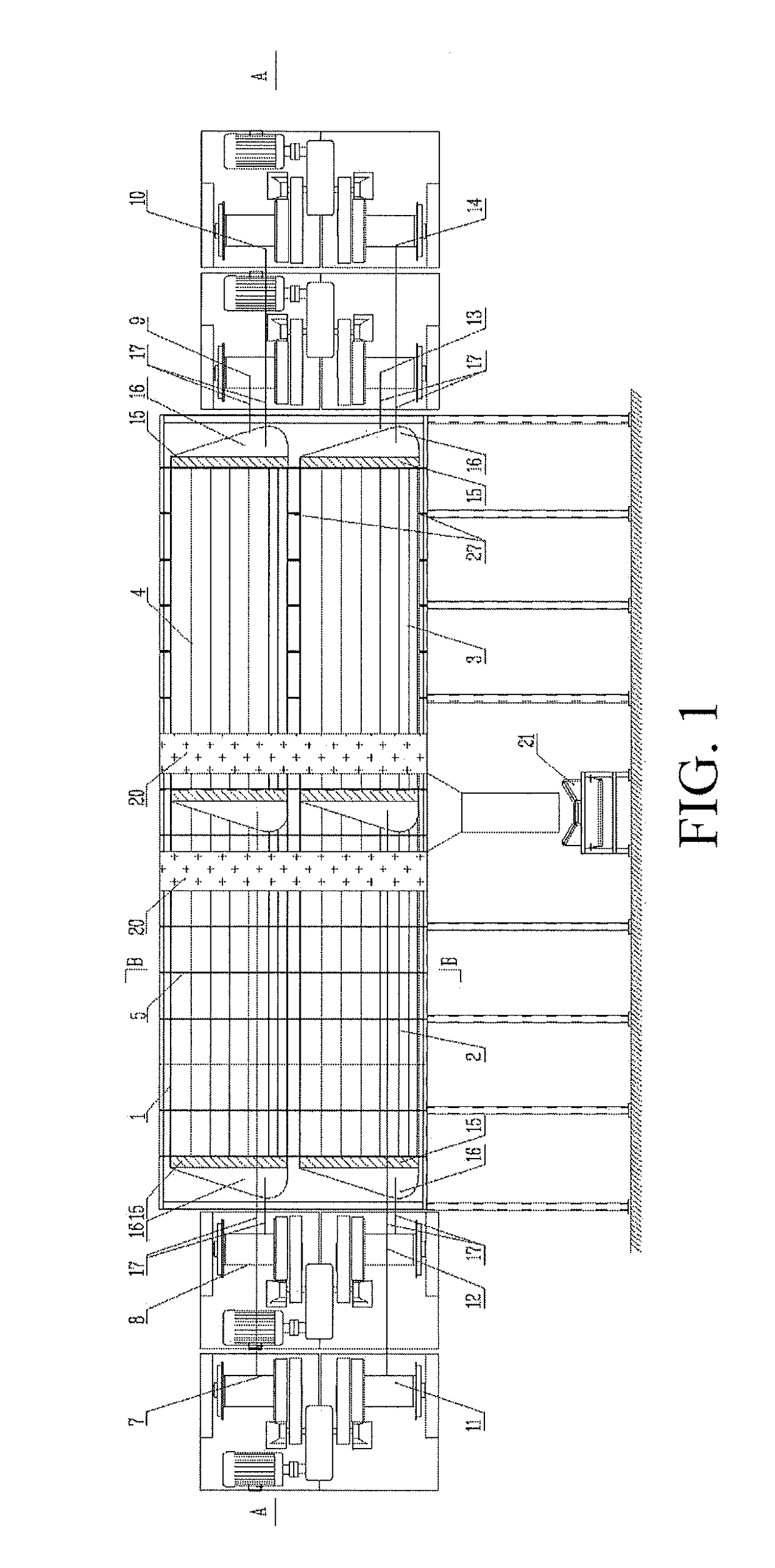

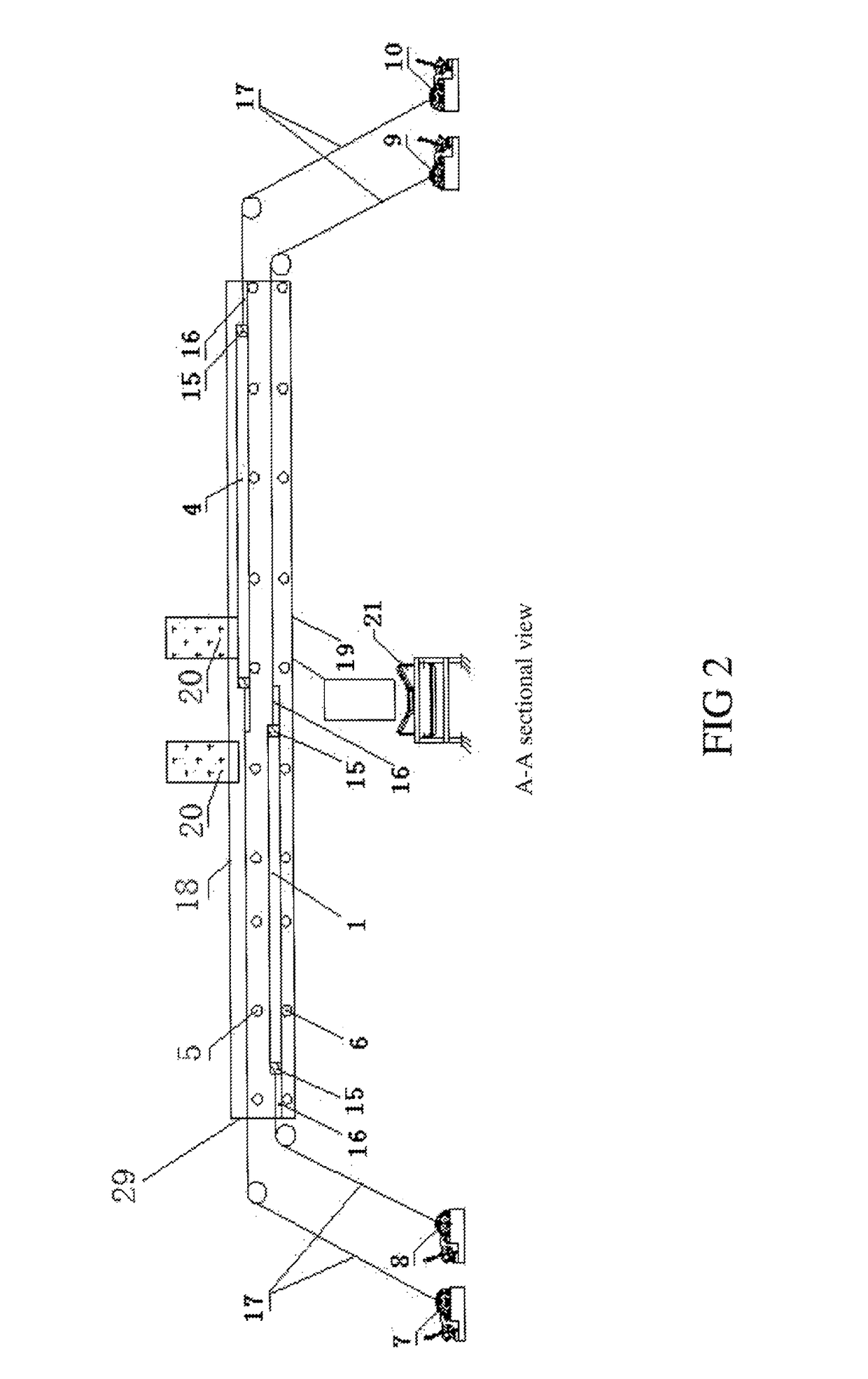

HVDC (high voltage direct current controller) and UPFC (unified power flow controller) system based on modularized multi-level converter

ActiveCN103001242AIncrease device capacitySave engineering construction cost and investmentAc-dc conversionElectric power transfer ac networkTransmission lineEngineering

The invention provides an HVDC (high voltage direct current controller) and UPFC (unified power flow controller) system based on a modularized multi-level converter. The HVDC and UPFC system comprises converting devices (1, 2 and 11), grounding circuits (3 and 12) and a direct current transmission line (13). The UPFC is formed by the converting device (1) and the converting device (2). The HVDC is formed by the converting device (1) and converting device (11). The HVDC and the UPFC shares one converting device, so that cost and investment for engineering construction are saved, equipment utilization rate is improved, concentrated management and control are facilitated. The converting devices use the topological structure of the modularized multi-level converter, so that technical difficulty in component serial connection is avoided, split-phase control and modularization are facilitated, fault units can be bypassed through redundancy, operation stability of the devices is improved, on and off frequency of components is low, and device operation loss is low.

Owner:CHINA EPRI SCIENCE & TECHNOLOGY CO LTD +2

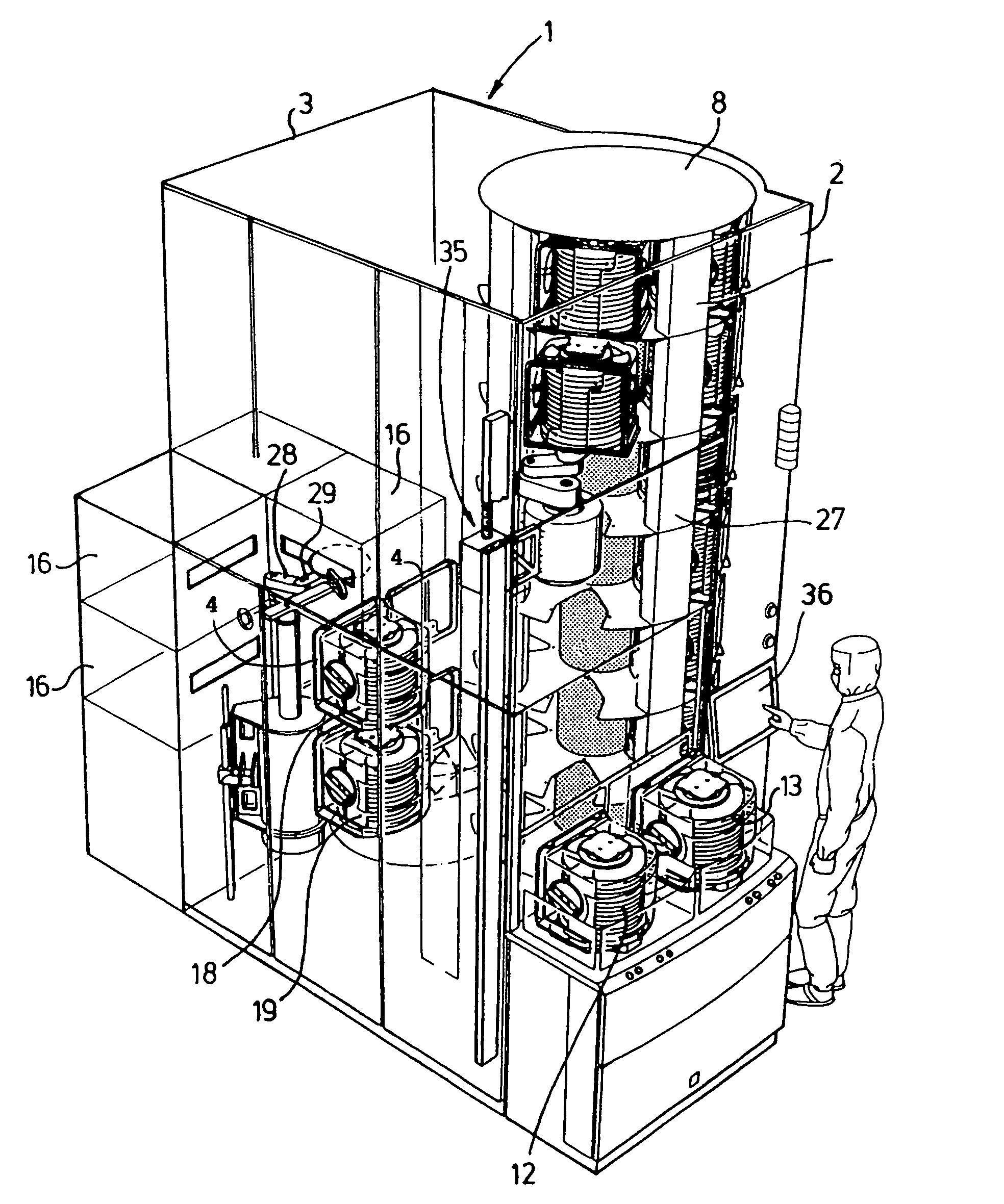

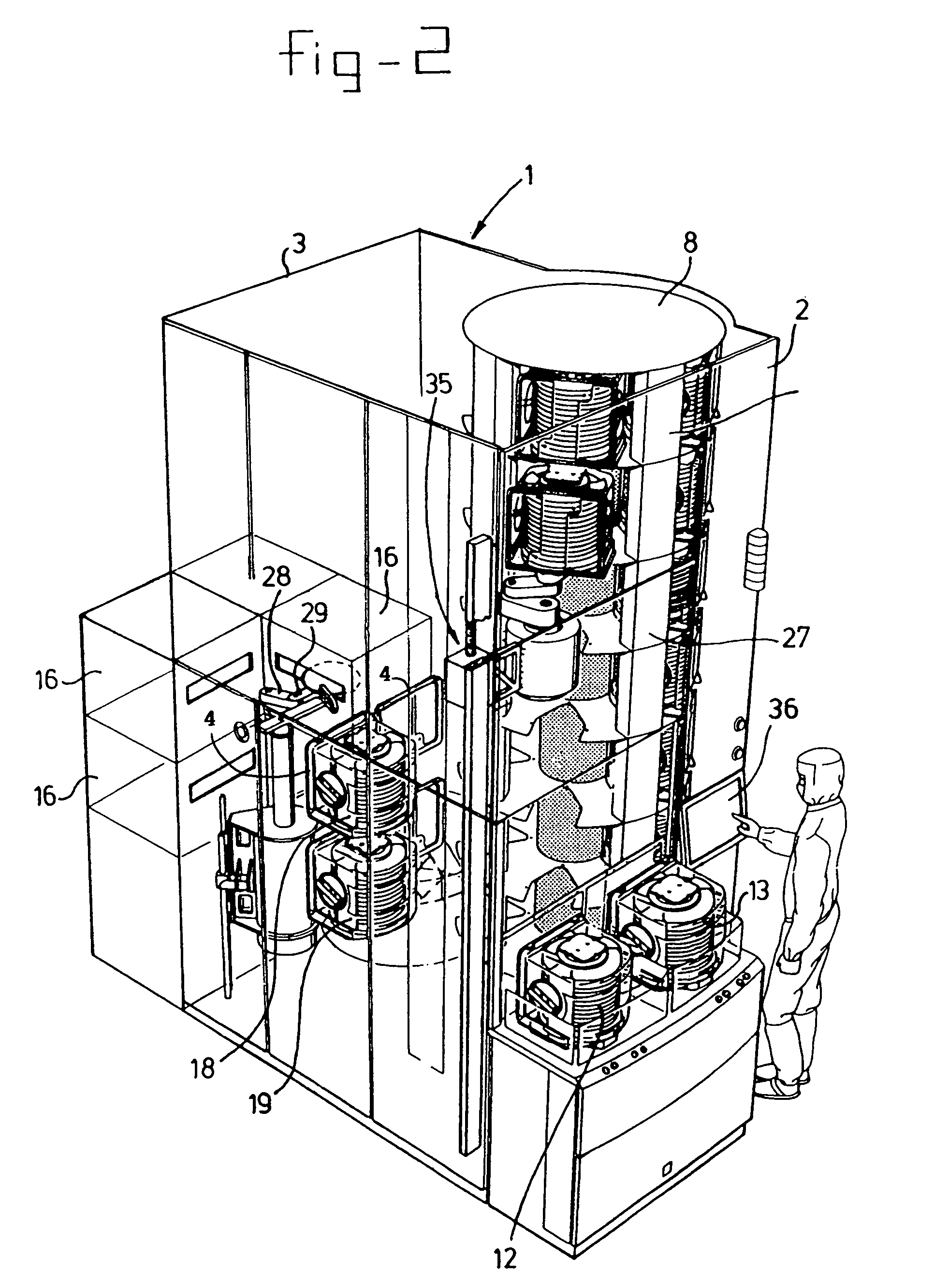

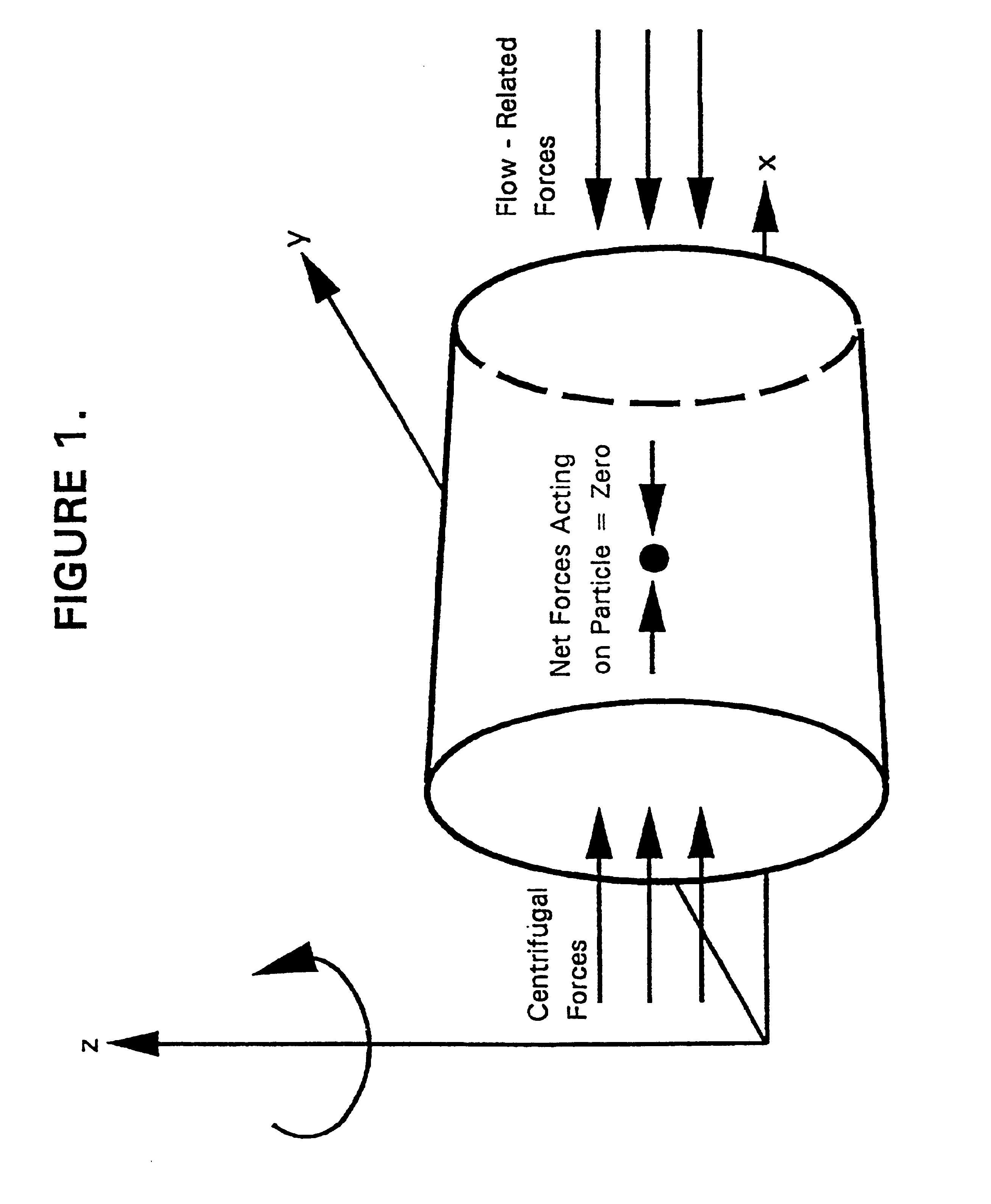

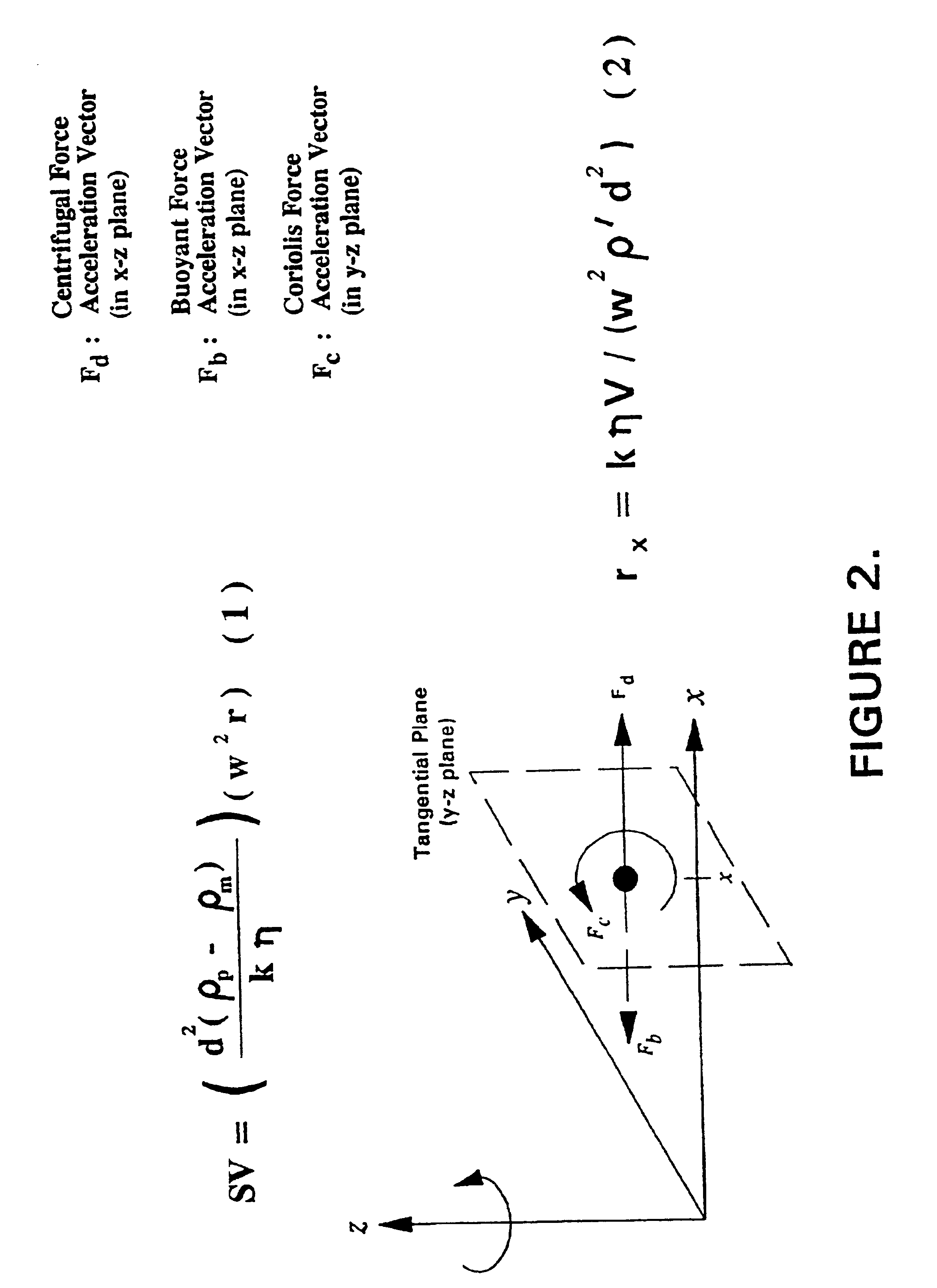

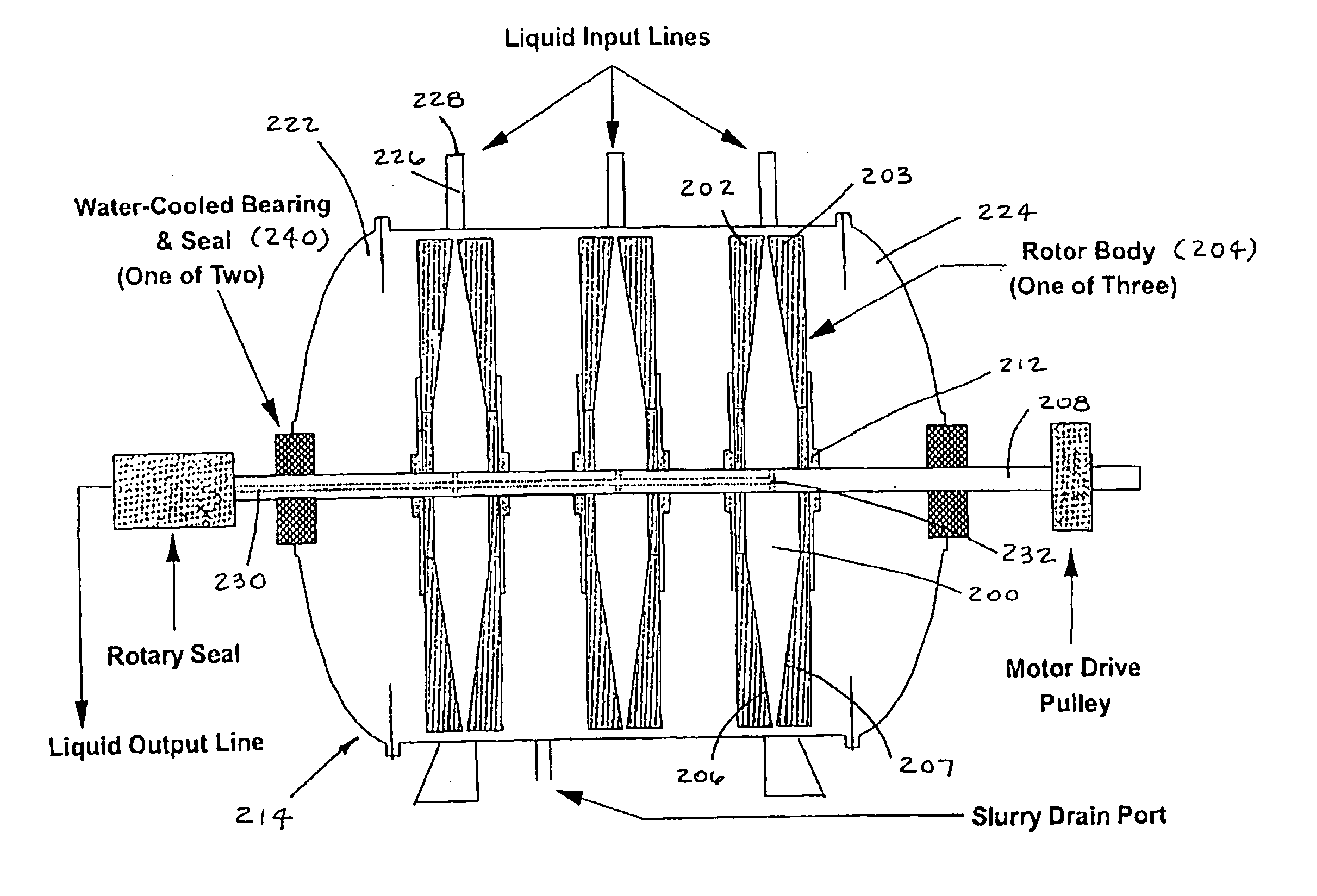

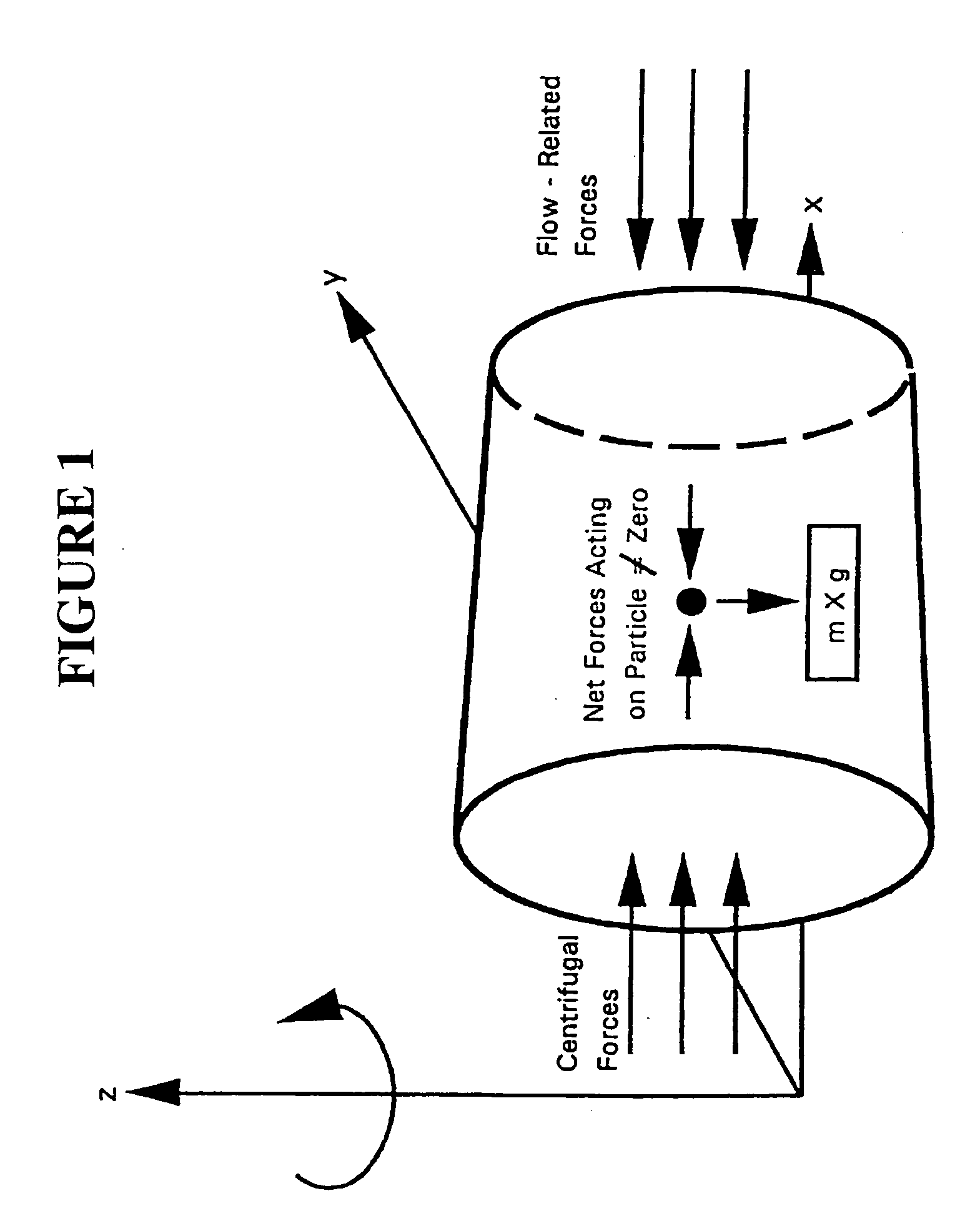

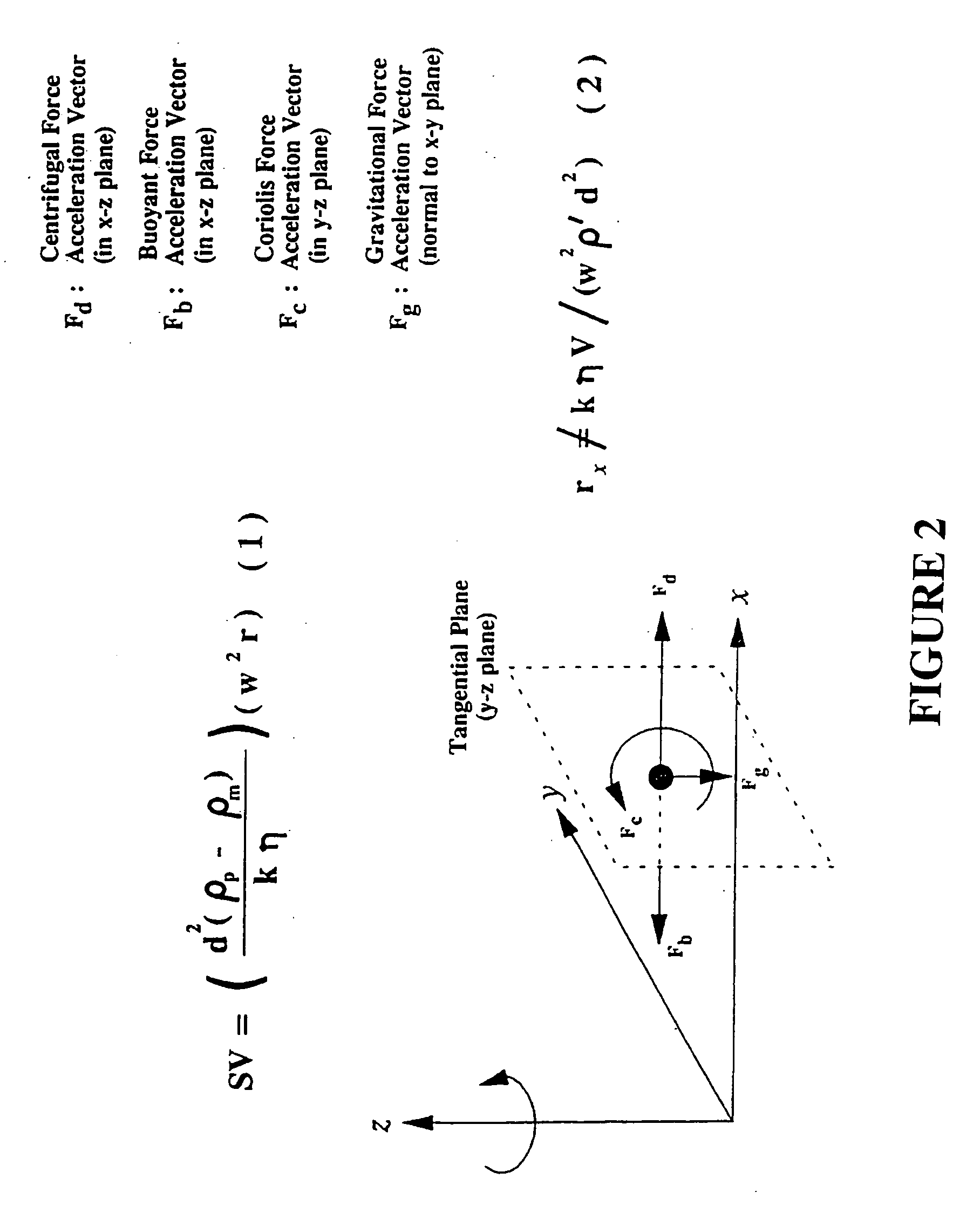

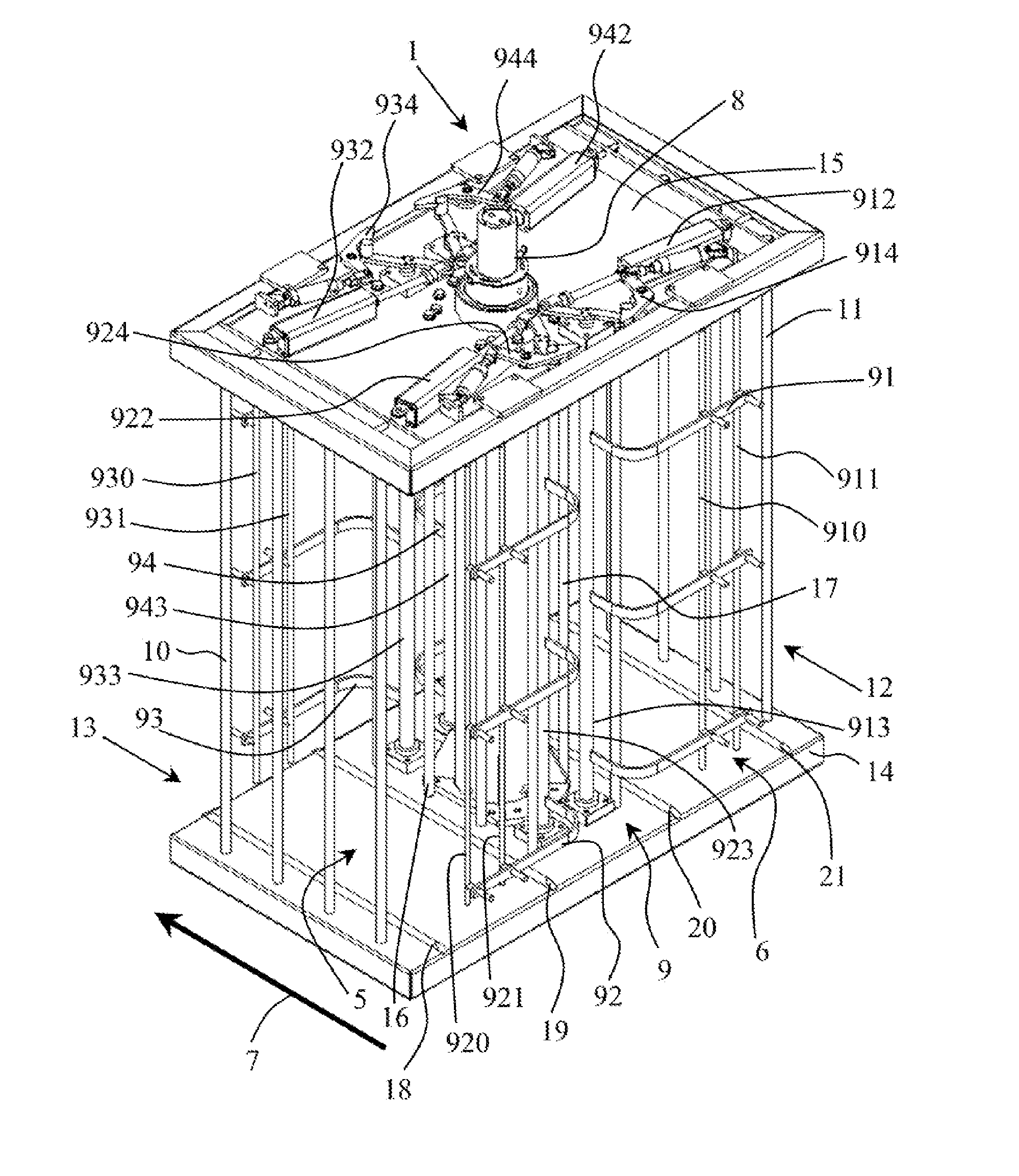

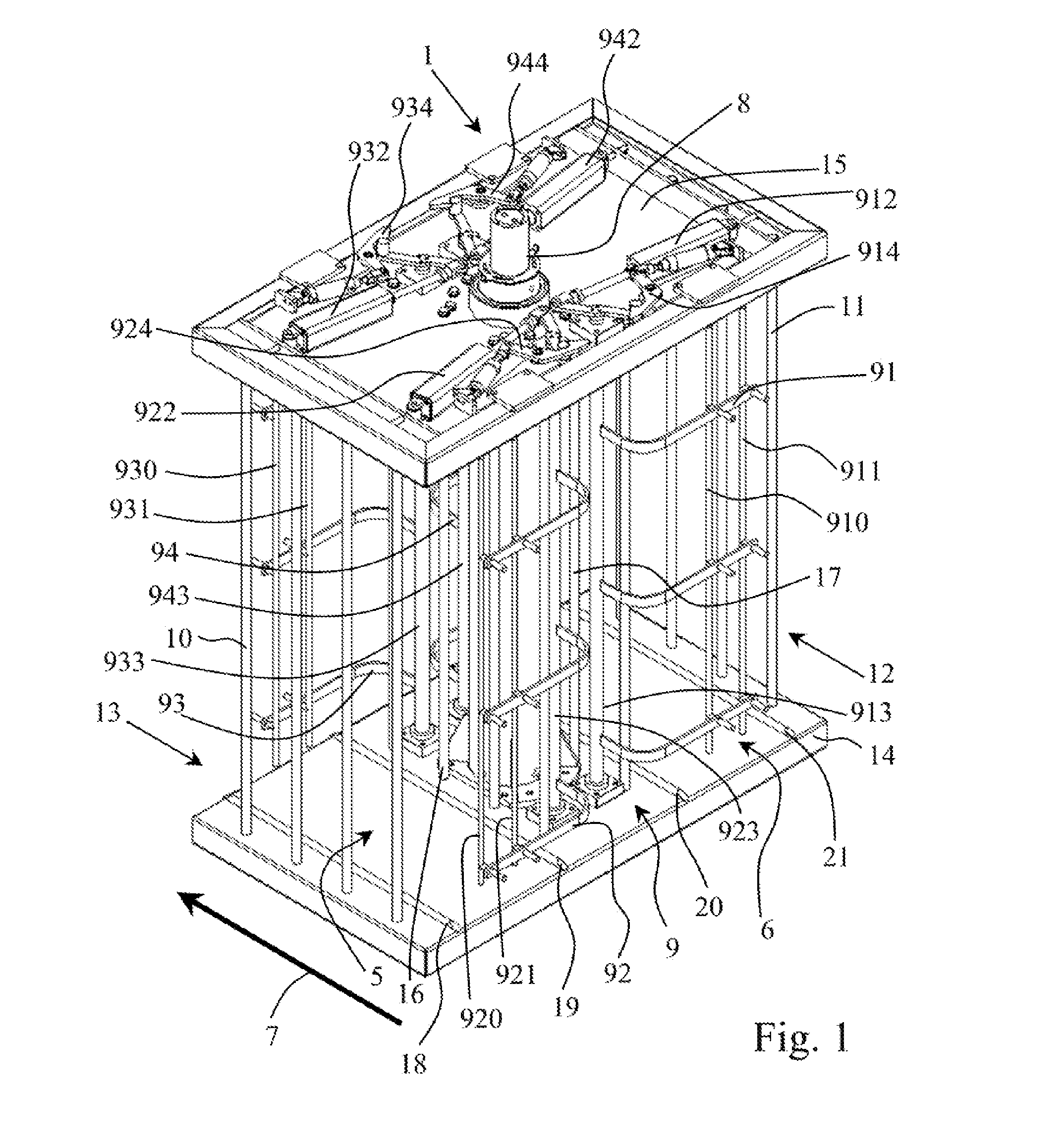

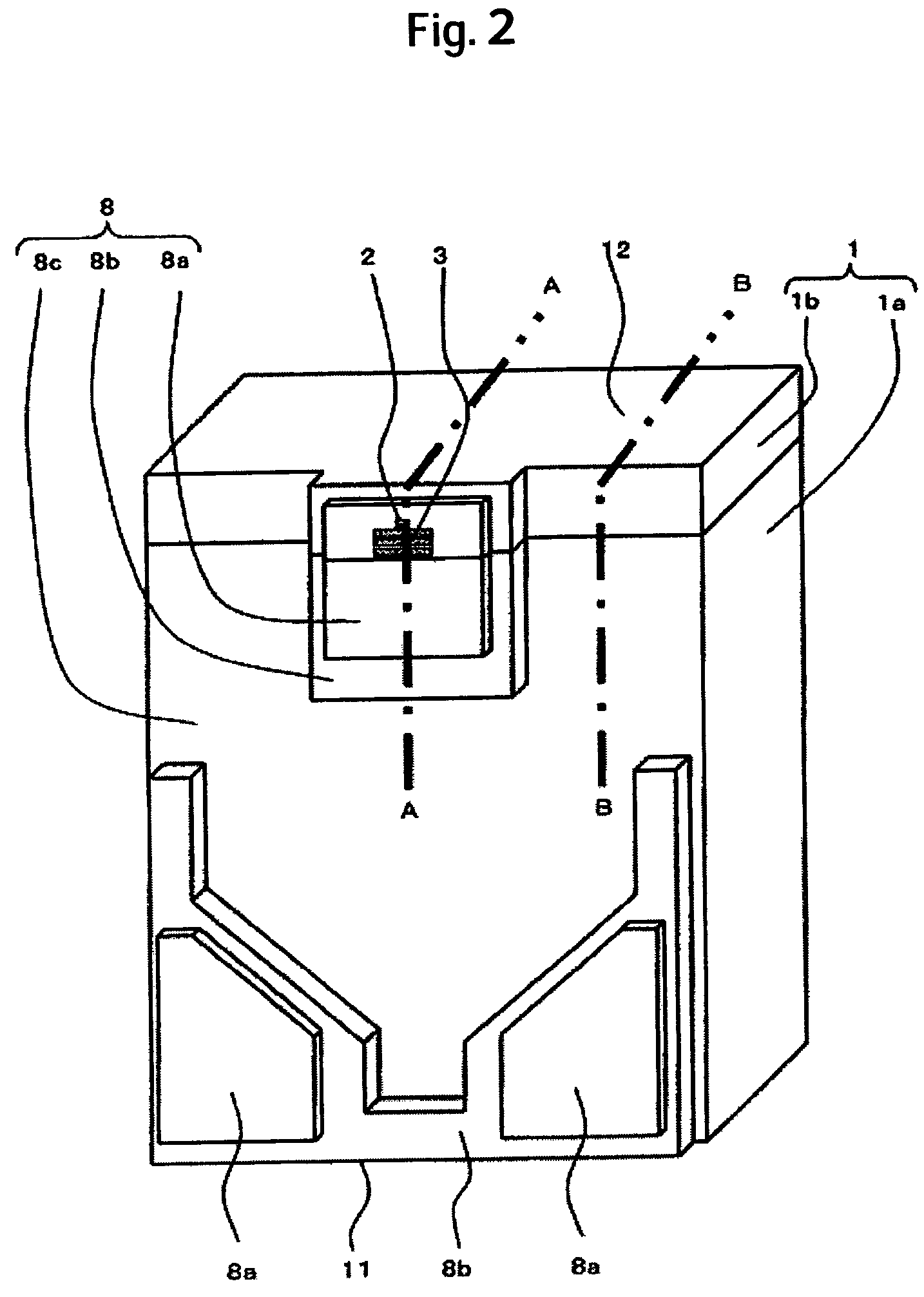

Biocatalyst chamber encapsulation system for bioremediation and fermentation

InactiveUS6916652B2Improve production yieldHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringCell growth

The invention comprises novel culture methods and devices in which biocatalysts are substantially immobilized contained, suspended and or incubated in a chamber. At least one injection element provides a fluid flow to a perimeter of the chamber and the fluid force of the fluids flowing into the chamber works with the centripetal force created by rotation of the device to suspend the cells within the chamber, promote cell growth and / or clean the fluid as it passes thru the suspended biocatalyst.

Owner:SARTORIUS STEDIM NORTH AMERICA INC

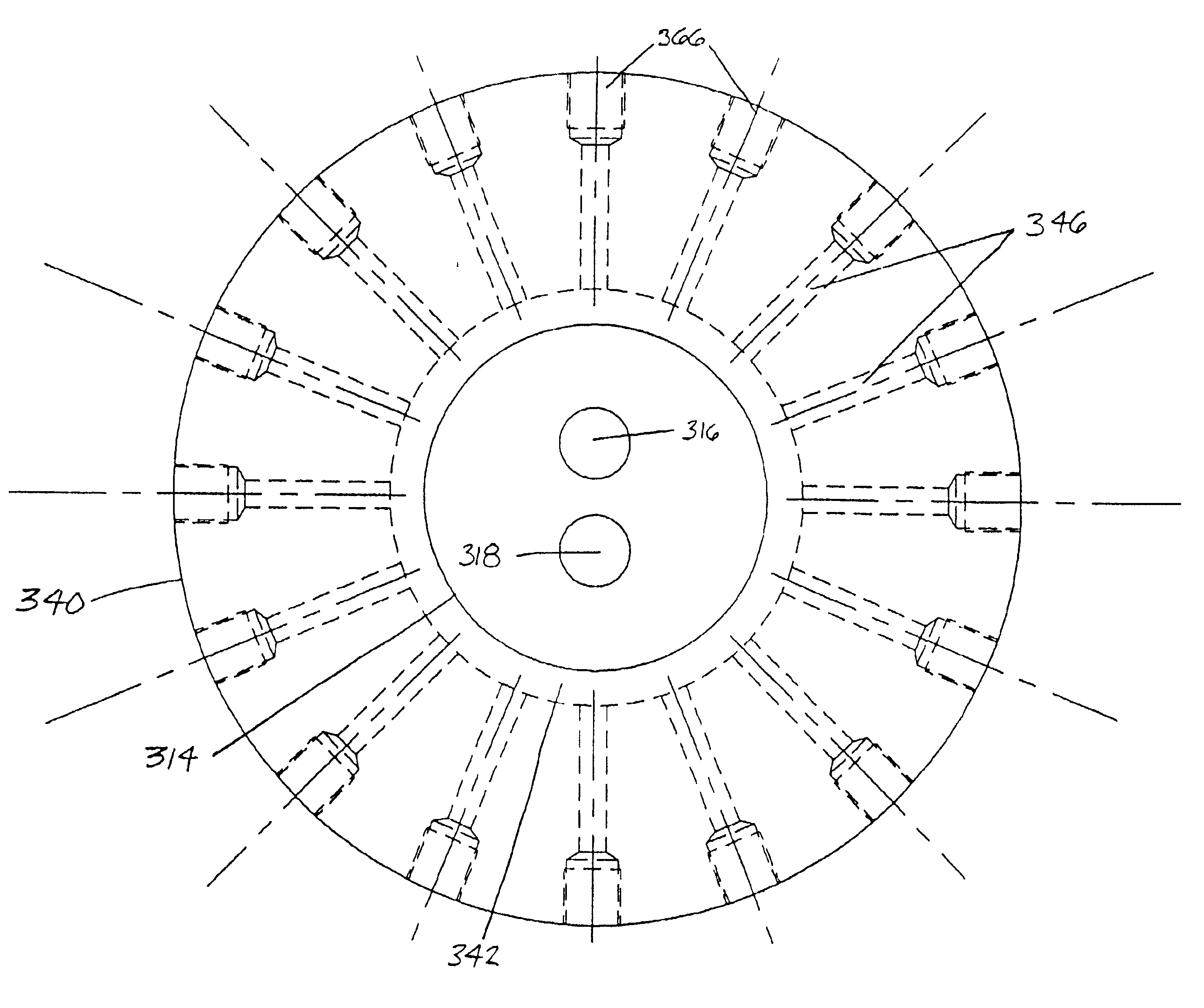

Biocatalyst chamber encapsulation system for bioremediation and fermentation with improved rotor

InactiveUS20050266548A1Increase device capacityHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBioremediation

The invention comprises novel culture methods and devices in which biocatalysts are substantially immobilized contained, suspended and / or incubated in a chamber. At least one injection element provides a fluid flow to a perimeter of the chamber and the fluid force of the fluids flowing into the chamber works with the centripetal force created by rotation of the device to suspend the cells within the chamber, promote cell growth and / or clean the fluid as it passes thru the suspended biocatalyst. Other embodiments are also claimed and described.

Owner:SARTORIUS STEDIM NORTH AMERICA INC

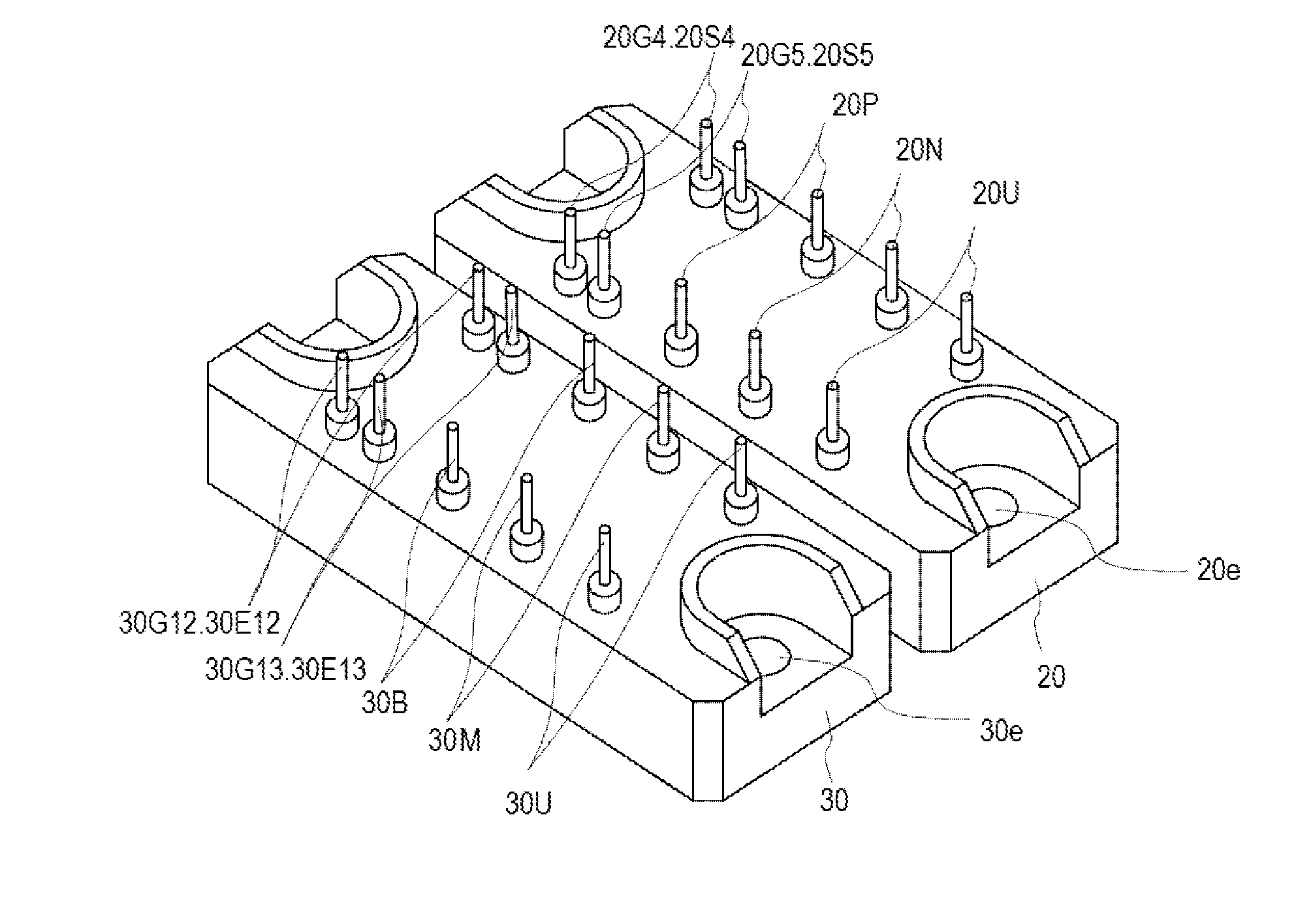

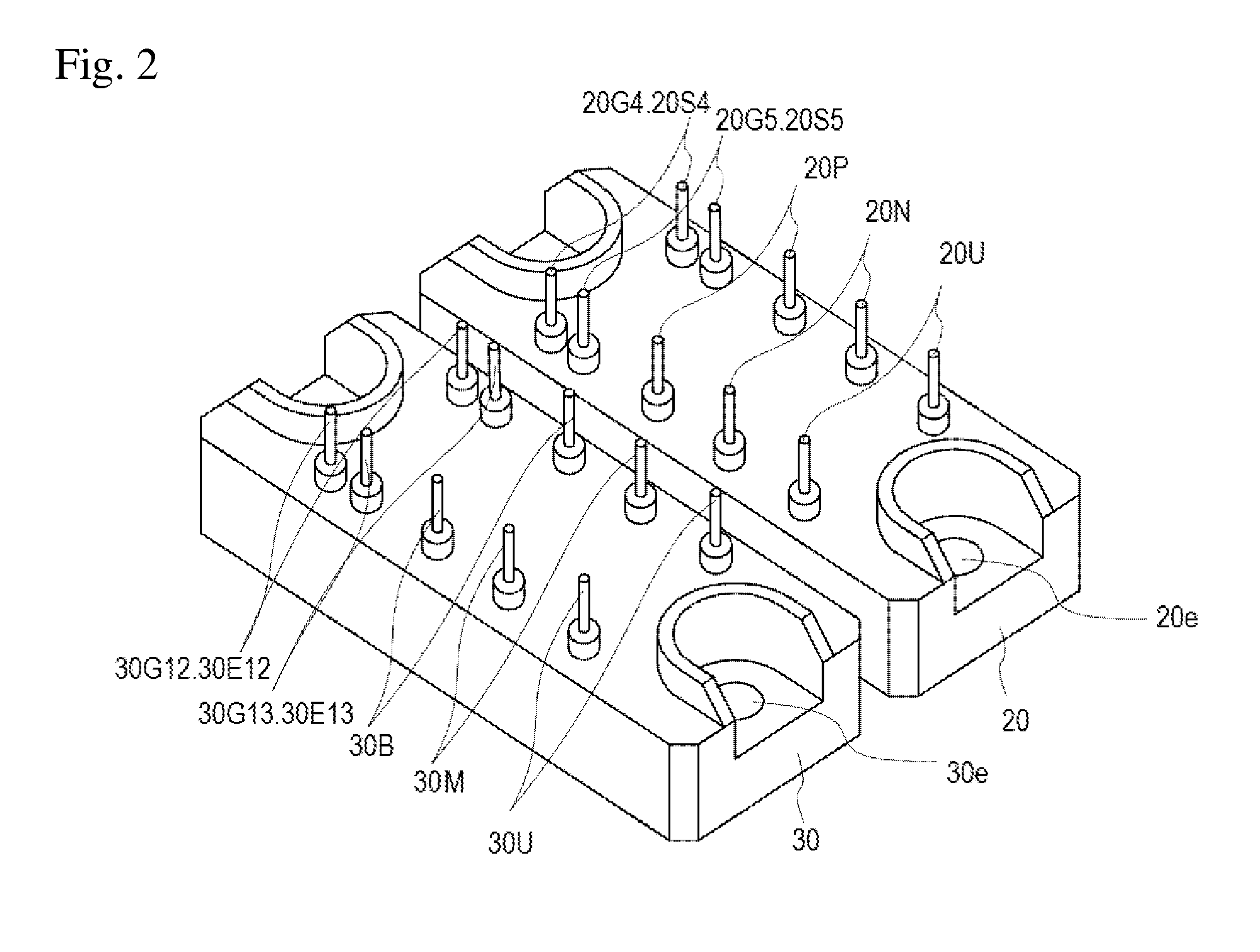

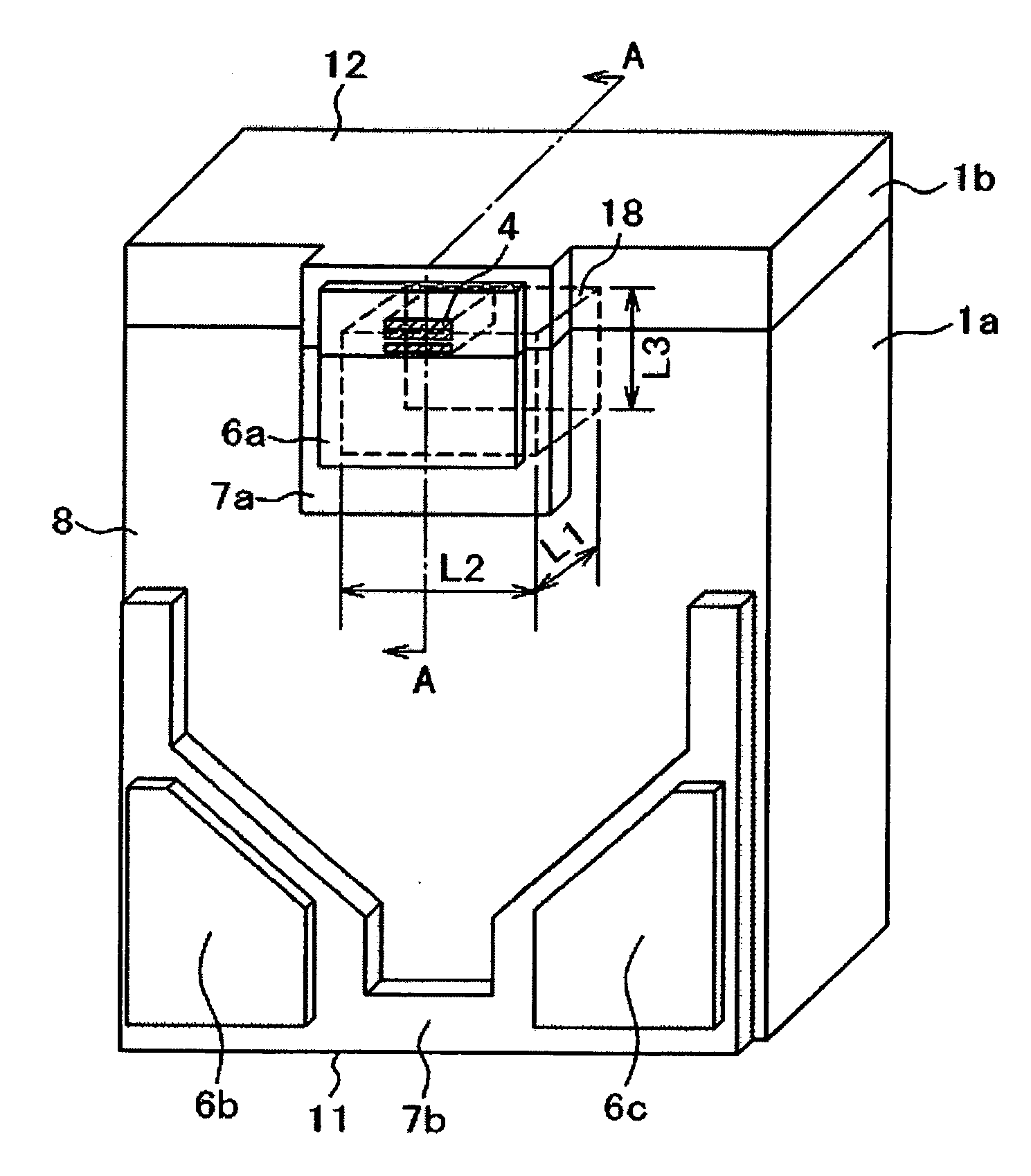

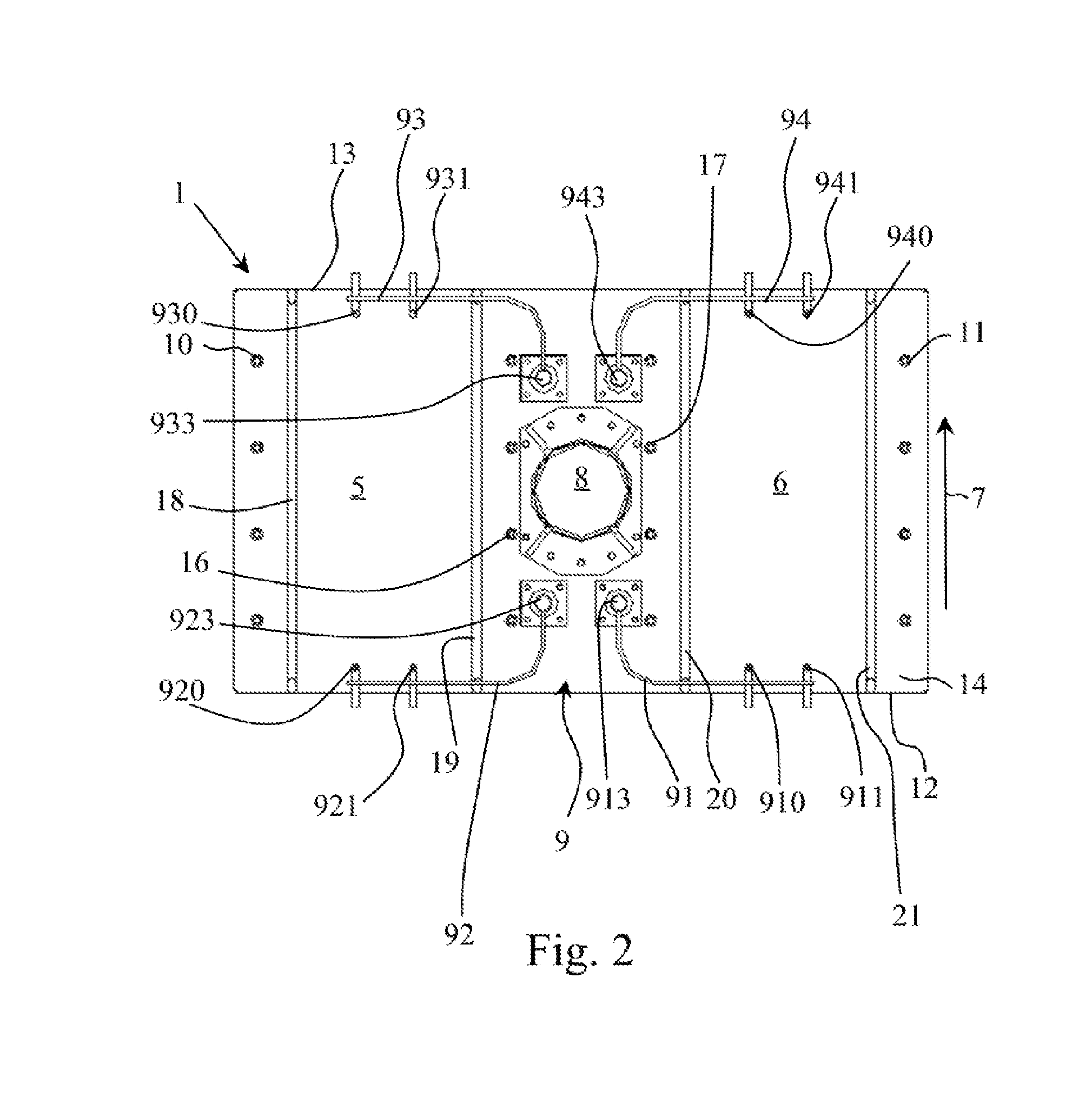

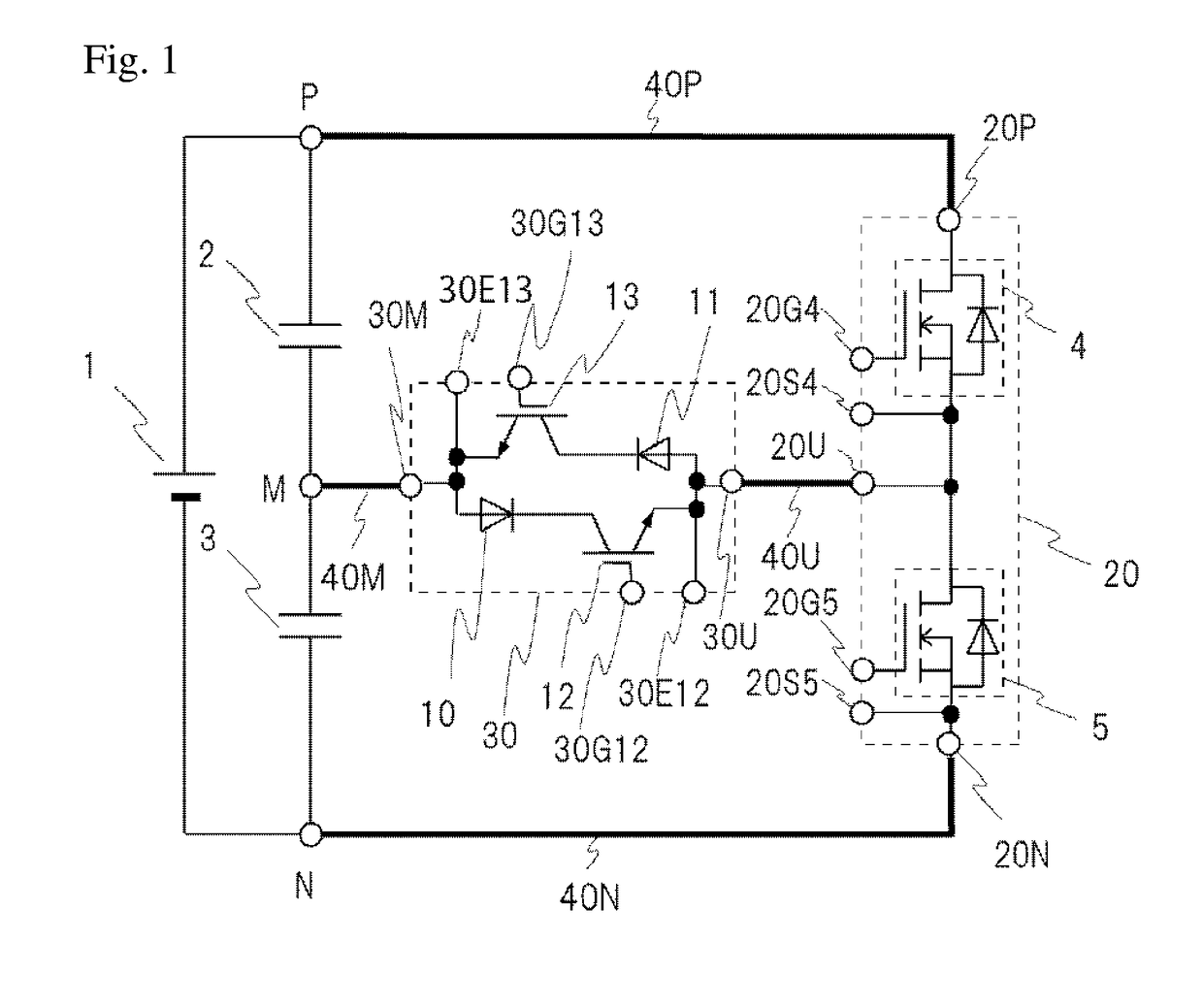

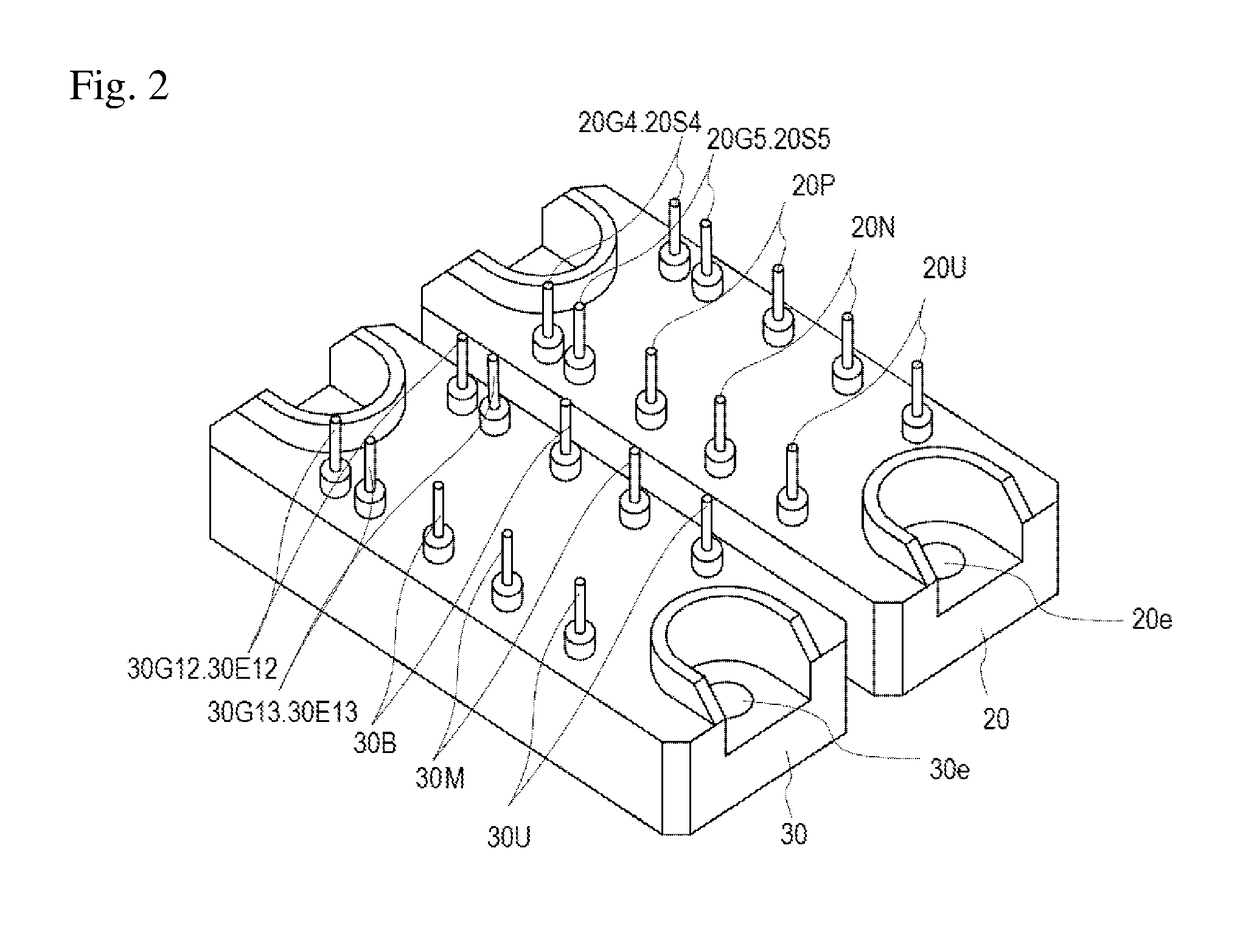

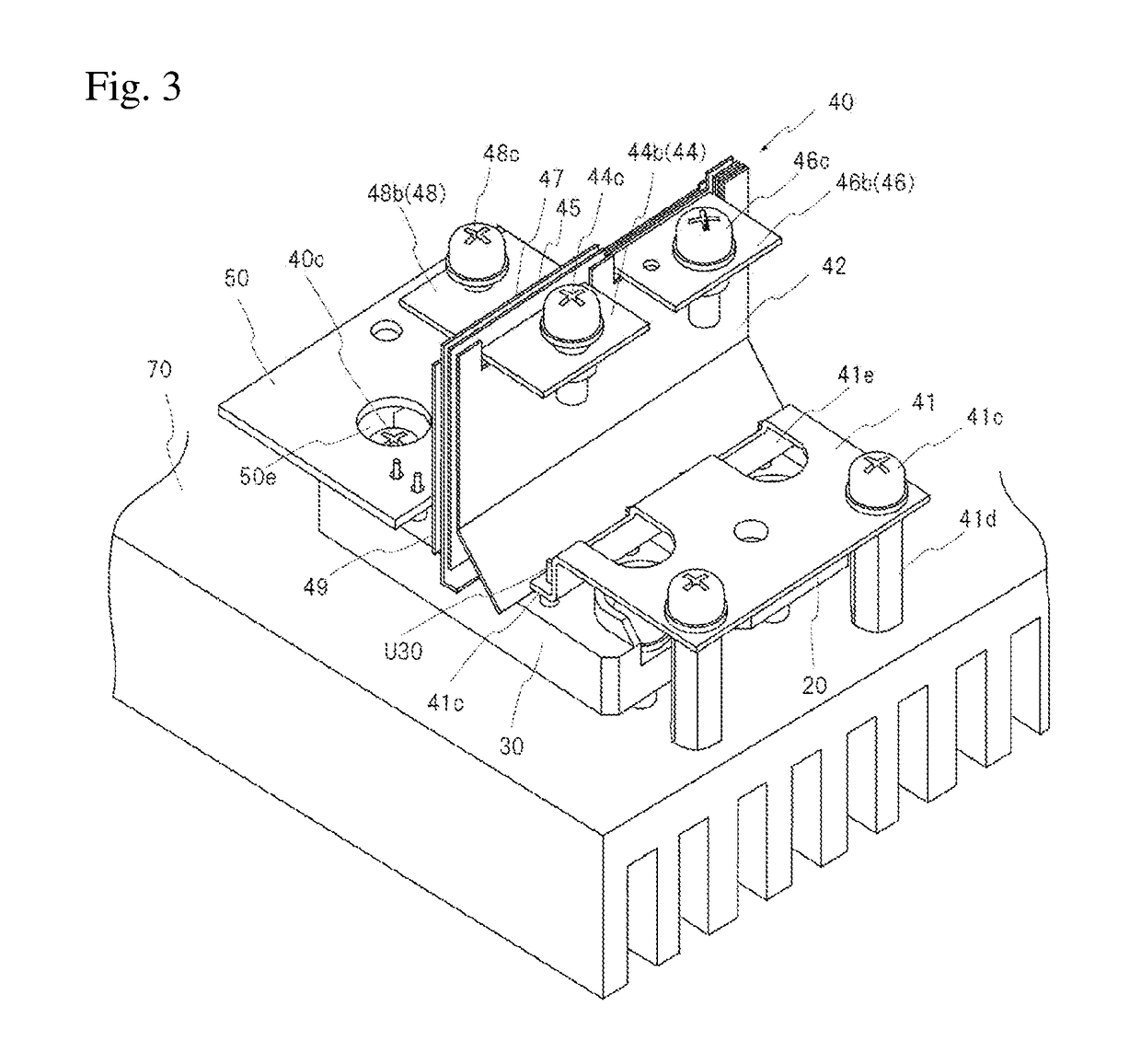

Three-level power converter

ActiveUS20160344301A1Increase device capacityReduce wiring inductanceConversion constructional detailsSolid-state devicesThree levelDc capacitor

A three-level power converter includes a first module housing a vertical arm forming a three-level power conversion circuit; a second module disposed adjacent to the first module and housing an intermediate arm forming the three-level power conversion circuit; high-potential and low-potential connecting terminal boards each extending vertically, and having a lower end connected to connecting terminals on an upper surface of the first module, and an upper end provided with an external connecting end; and a flat intermediate-potential connecting terminal board extending vertically, and having a lower end connected to connecting terminals on an upper surface of the second module, and an upper end provided with an external connecting end. The high-potential, low-potential, and intermediate-potential connecting terminal boards are stacked close to and parallel to one another. Each of the external connecting ends is connected to a corresponding terminal of a DC capacitor.

Owner:FUJI ELECTRIC CO LTD

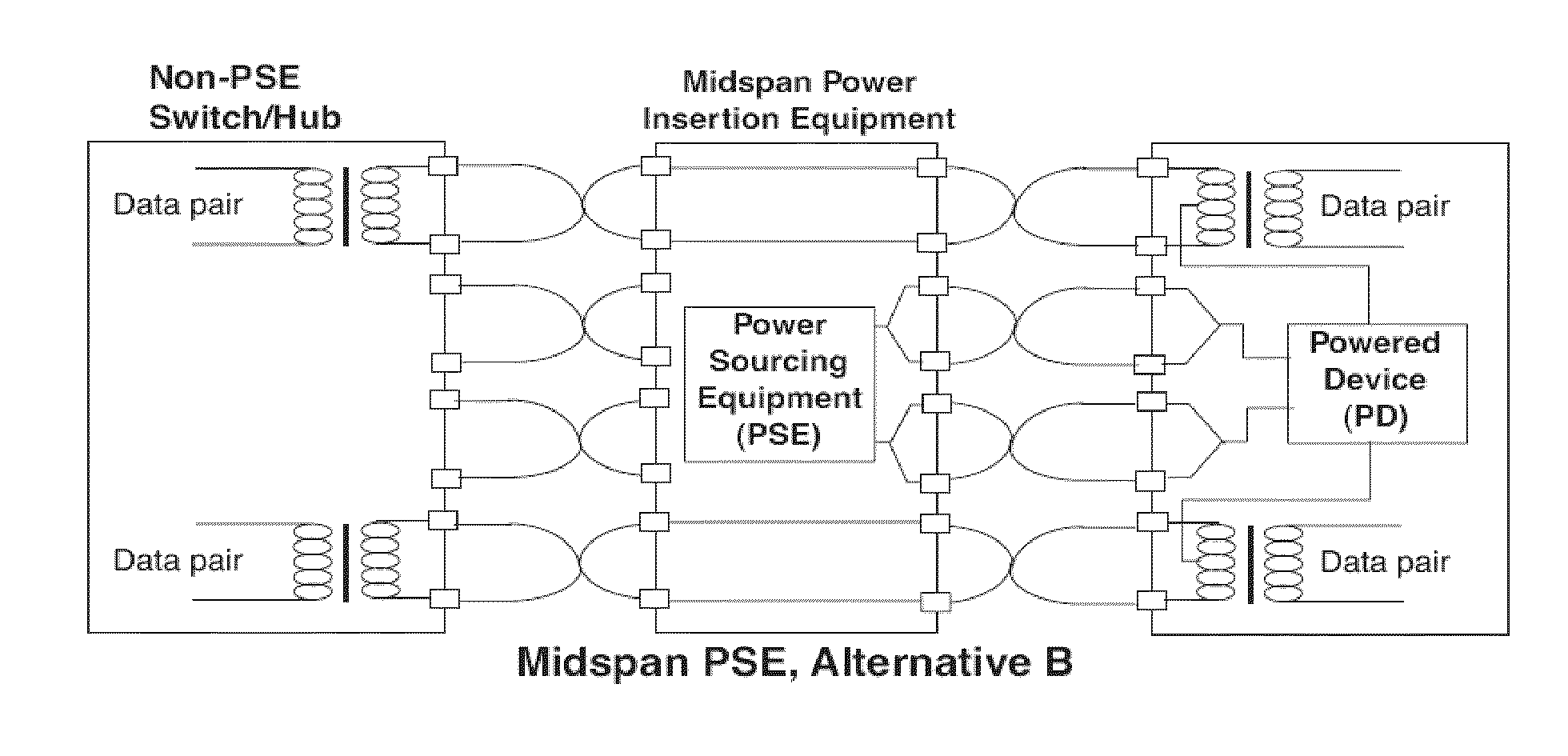

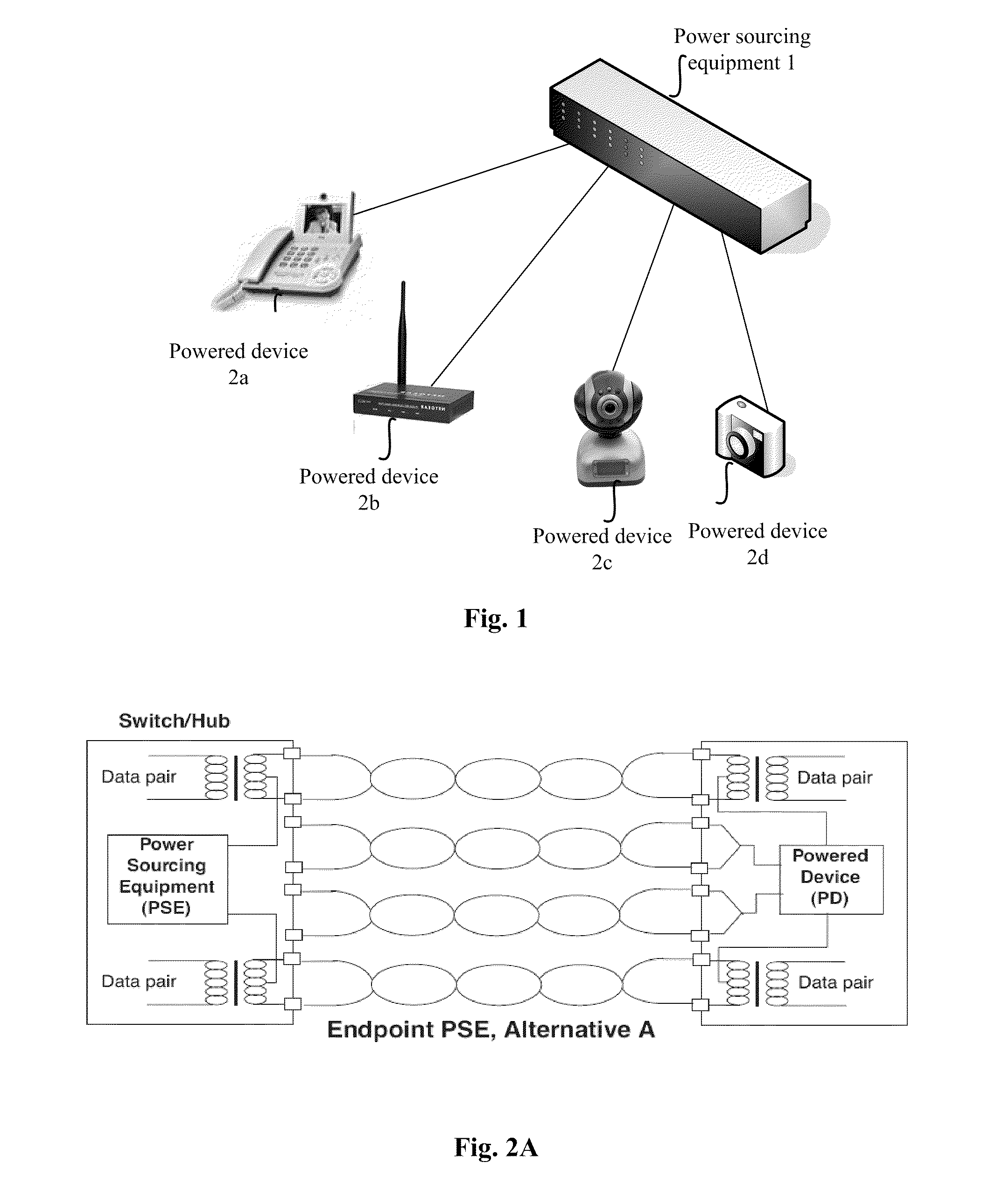

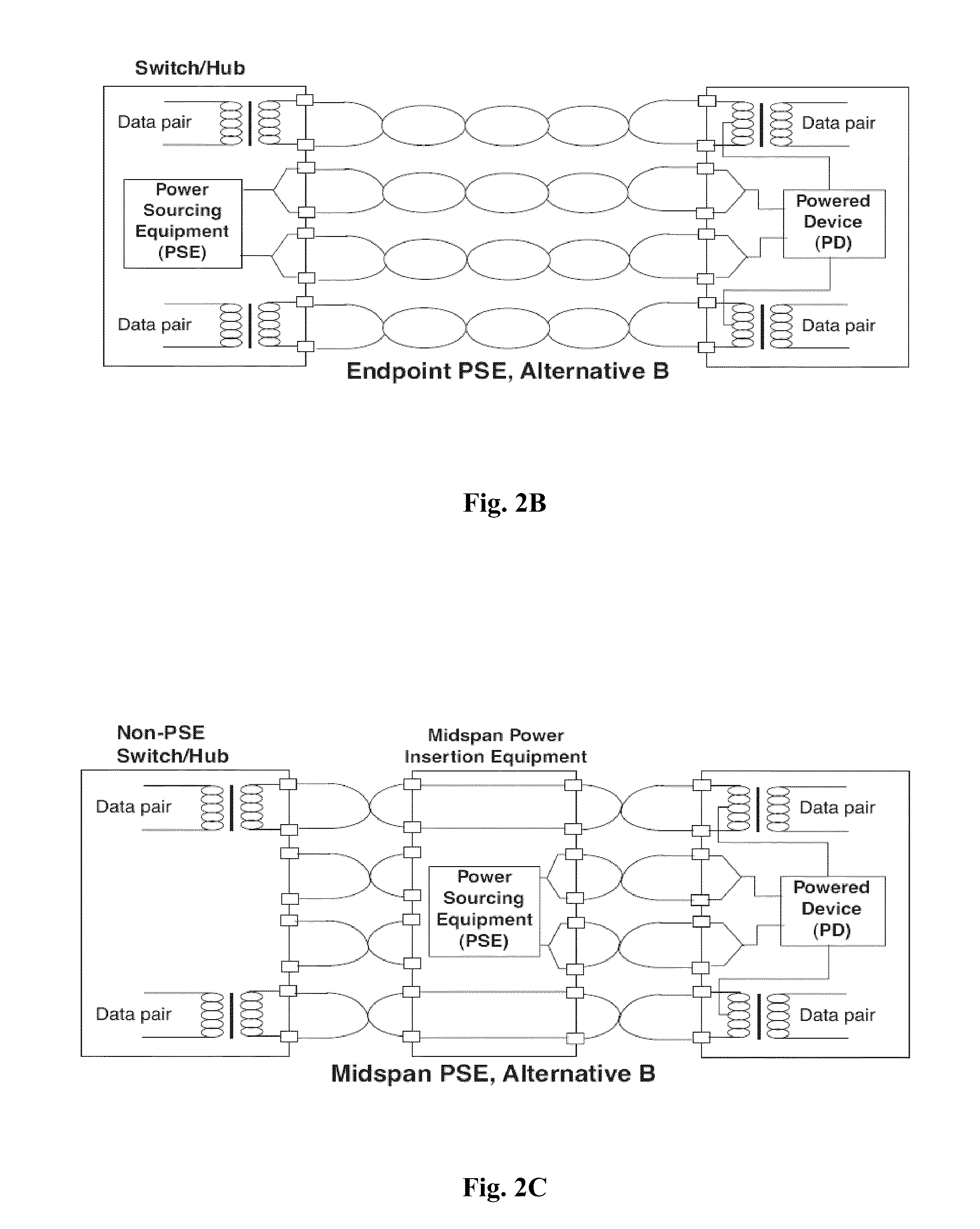

Method and apparatus for increasing the number of the powered devices supported by the poe system

InactiveUS20110298428A1Increase the number ofShift the power supplying capability of the power sourcing equipmentBatteries circuit arrangementsVolume/mass flow measurementElectricityEmbedded system

In order to increase the number of the powered devices that can be supported by the Ethernet power supply system, the present invention proposed to equip the powered device with an electrical energy storage device, namely shift the power timely shift the power supplying capability of the power sourcing equipment. The power sourcing equipment charges the electrical energy storage device, and then the powered device is supplied by the electrical energy storage device under usual situations. Thus the number of the powered devices that can be supported by the Ethernet power supply system is increased without increasing the supplying capability of the electrical quantity of the power sourcing equipment. Using the solution in the present invention, the capacity of the powered devices in the POE system is increased without having to change the hardware of the power sourcing equipment, and without having to change the wiring.

Owner:ALCATEL LUCENT SAS

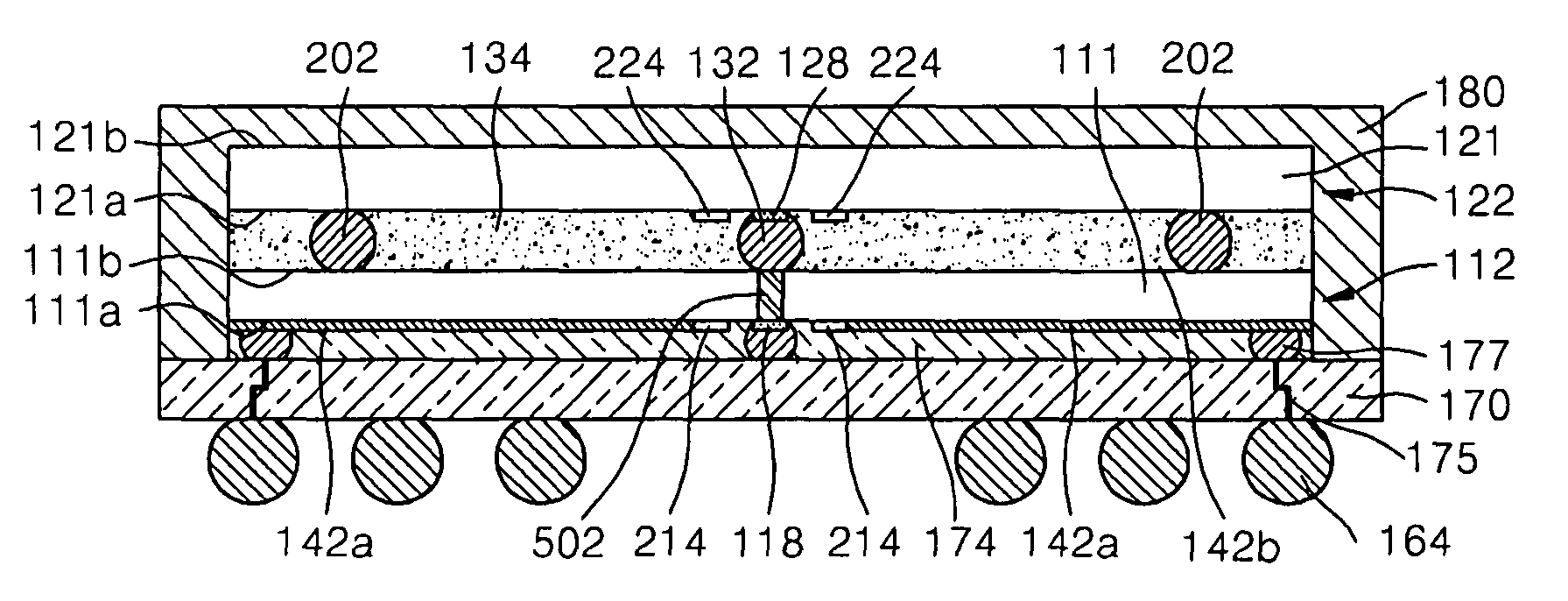

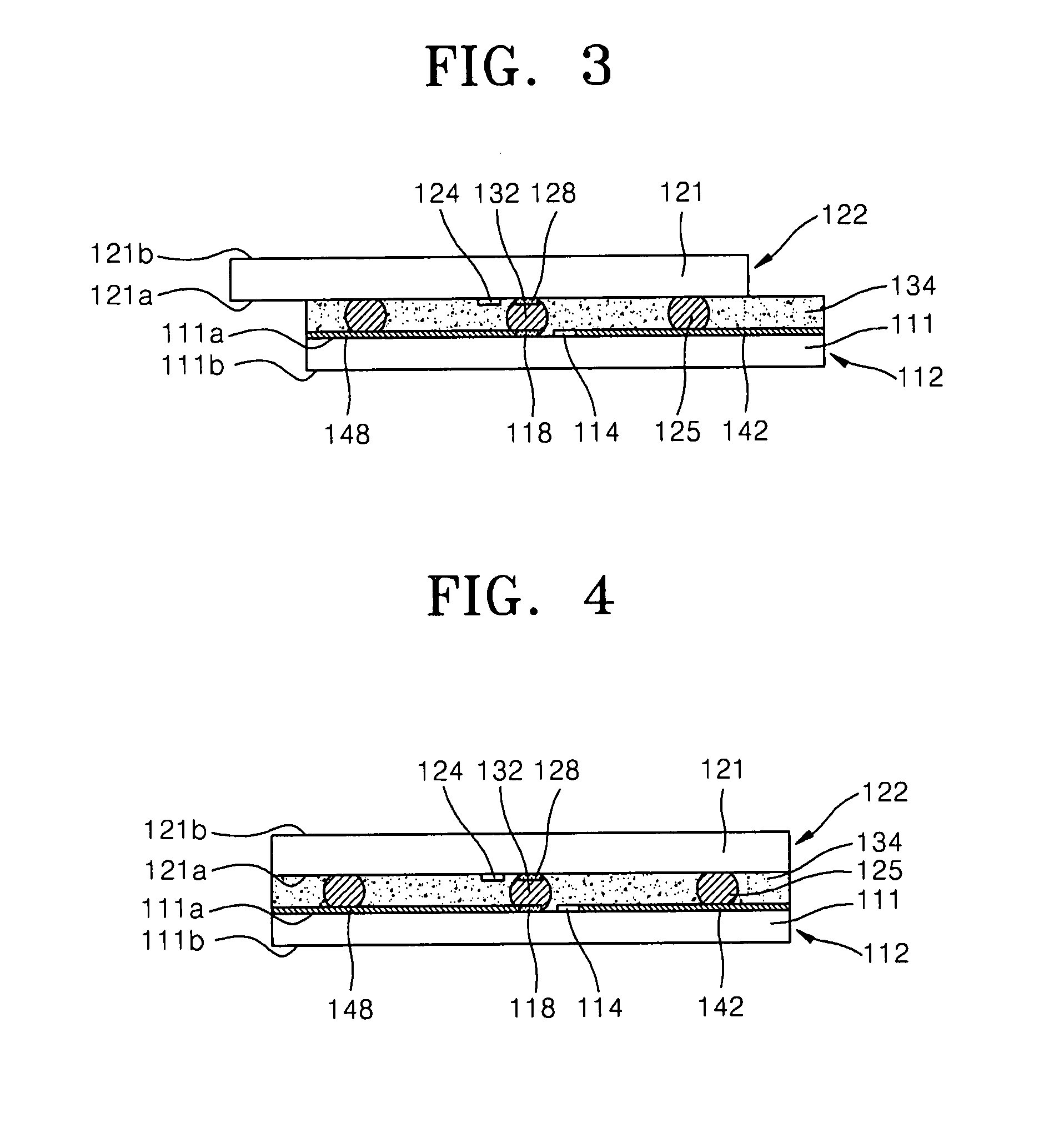

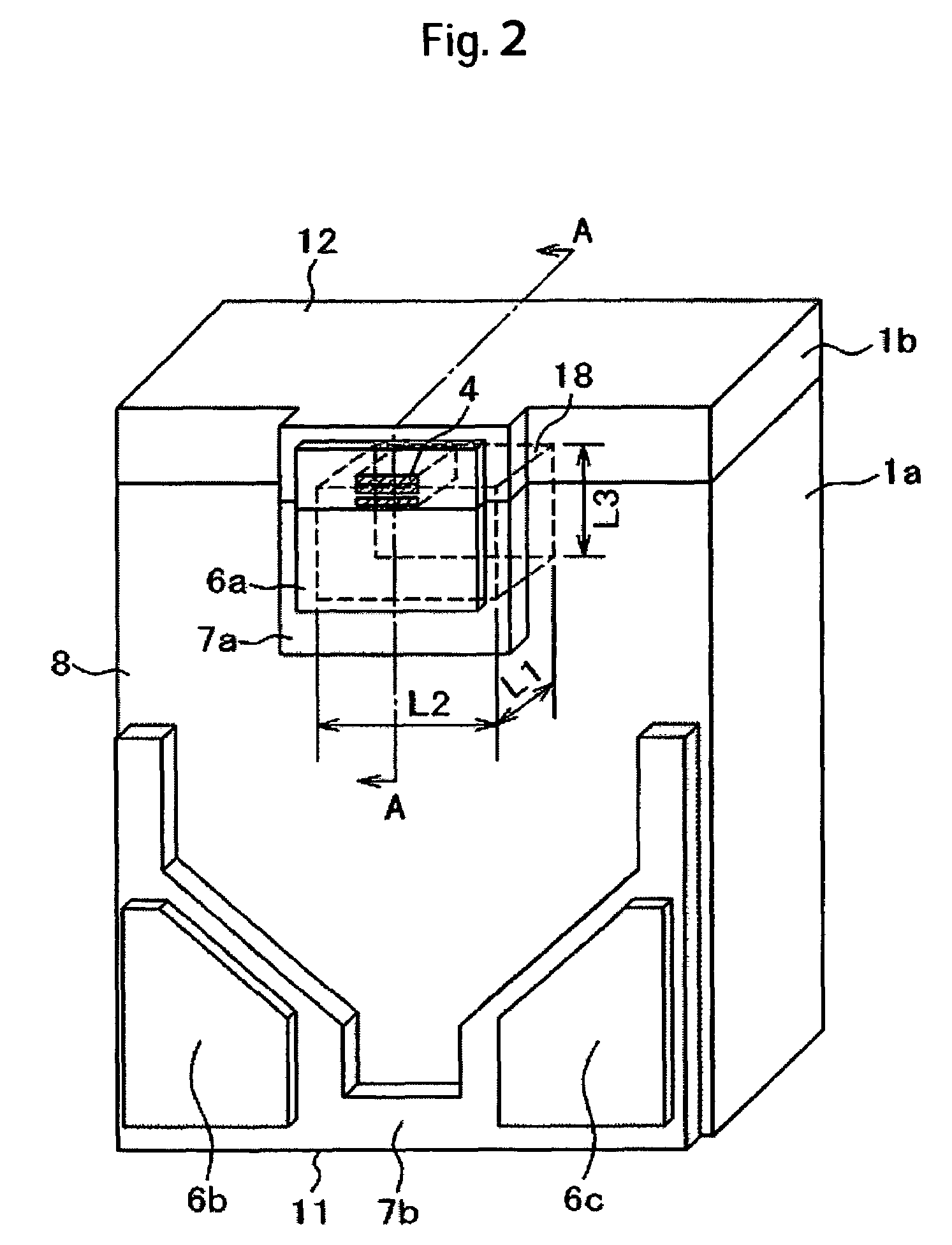

Chip stack, chip stack package, and method of forming chip stack and chip stack package

ActiveUS7964948B2Increase device capacityKeep runningSemiconductor/solid-state device detailsSolid-state devicesEngineeringChip stacking

A chip stack may include a first chip and a second chip stacked on the first chip. Each of the first and second chips may include a substrate having an active surface and an inactive surface opposite to the active surface; an internal circuit in the active surface; an I / O chip pad on the active surface and connected to the internal circuit through an I / O buffer; and a I / O connection pad connected to the I / O chip pad through the I / O buffer by a circuit wiring. A redistributed I / O chip pad layer may be on the active surface of the first chip, the redistributed I / O chip pad layer redistributing the I / O chip pad. The I / O connection pads of the first chip and the second chip may be electrically connected to each other by an electrical connecting part.

Owner:SAMSUNG ELECTRONICS CO LTD

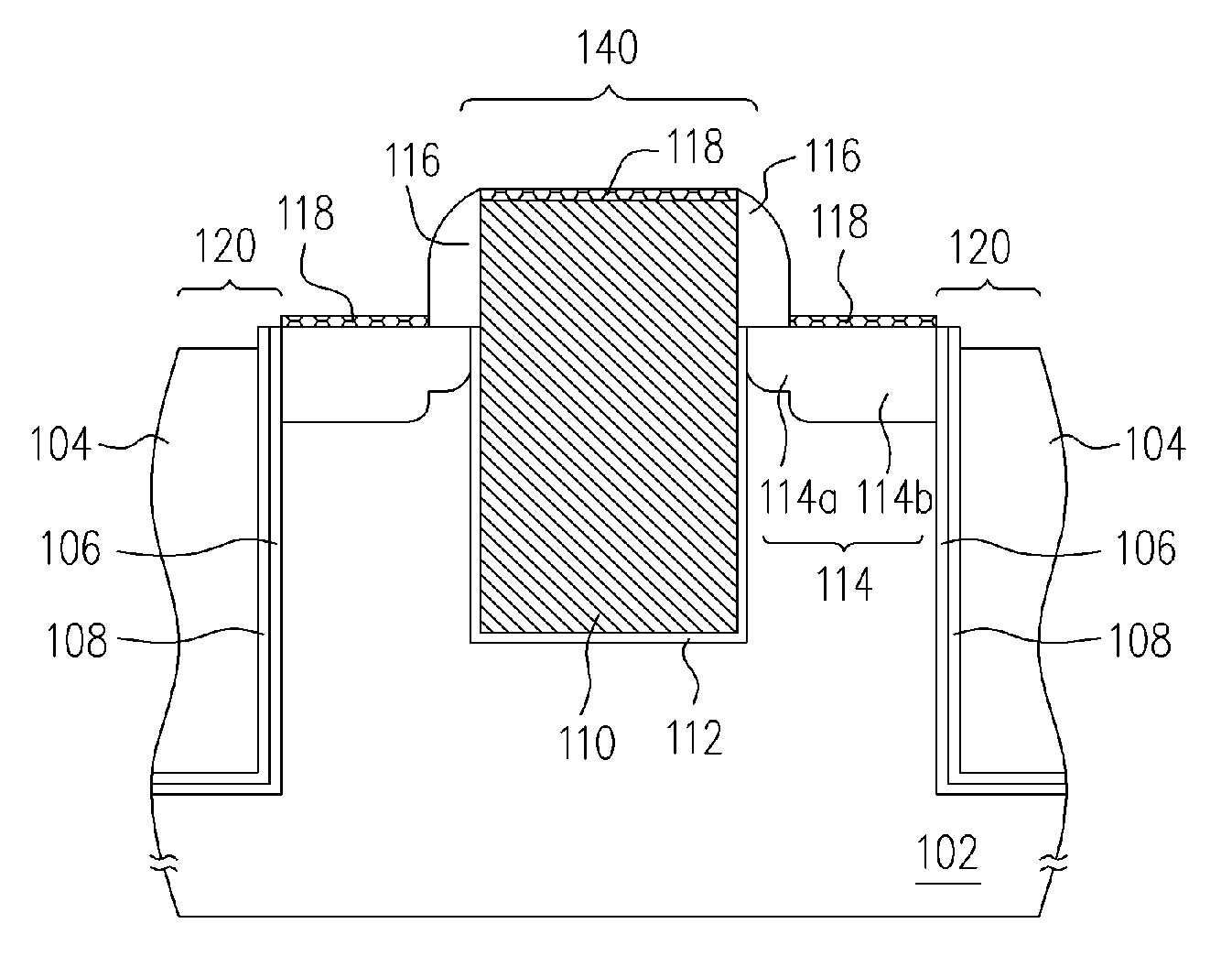

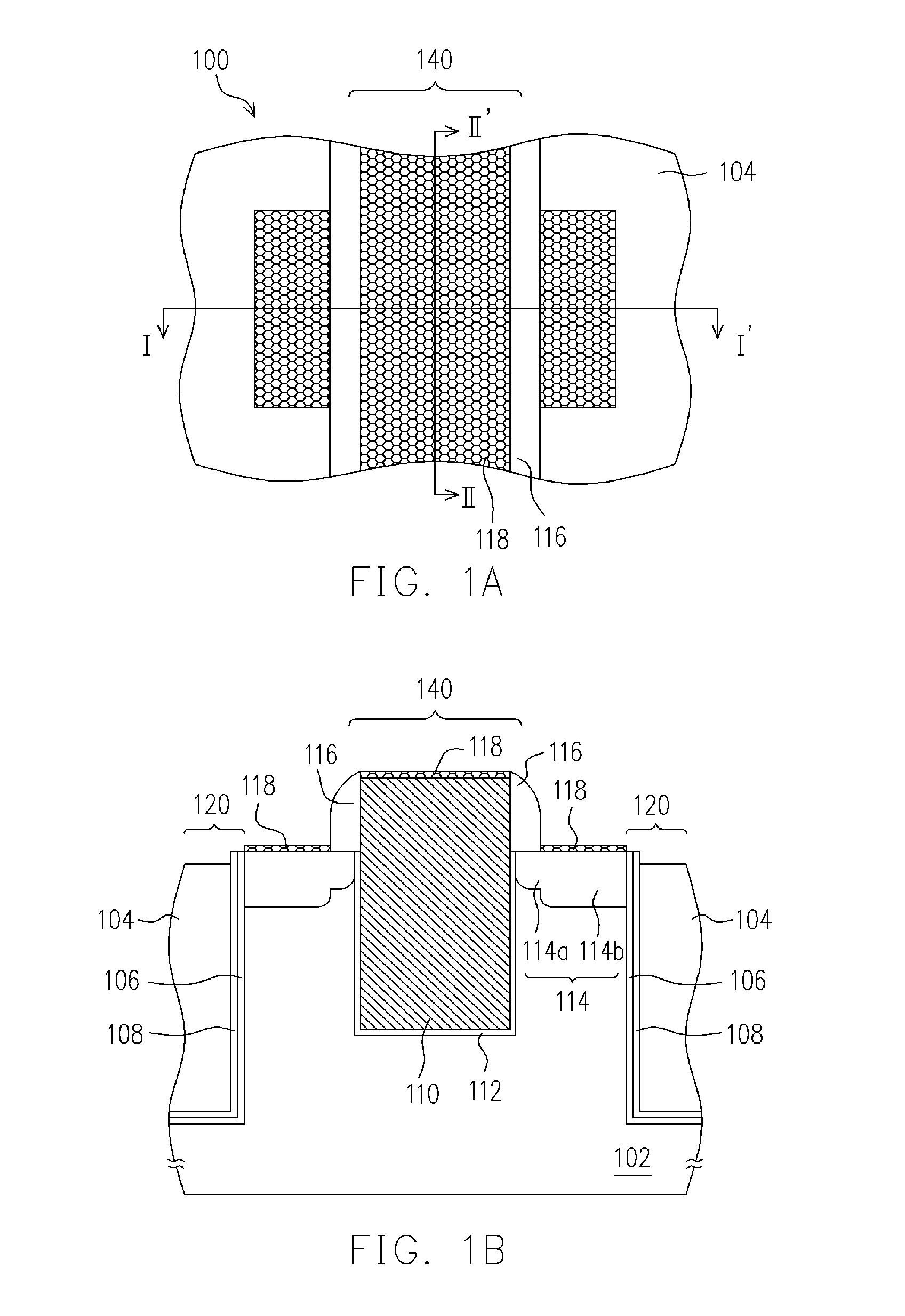

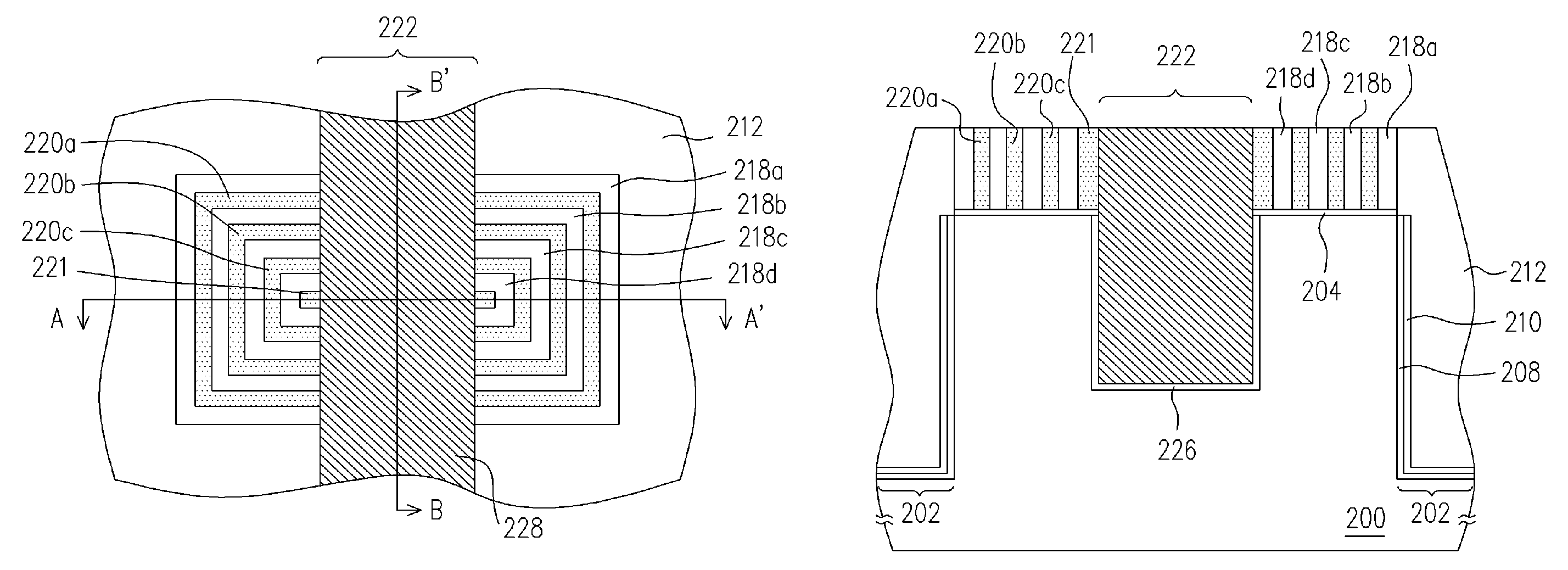

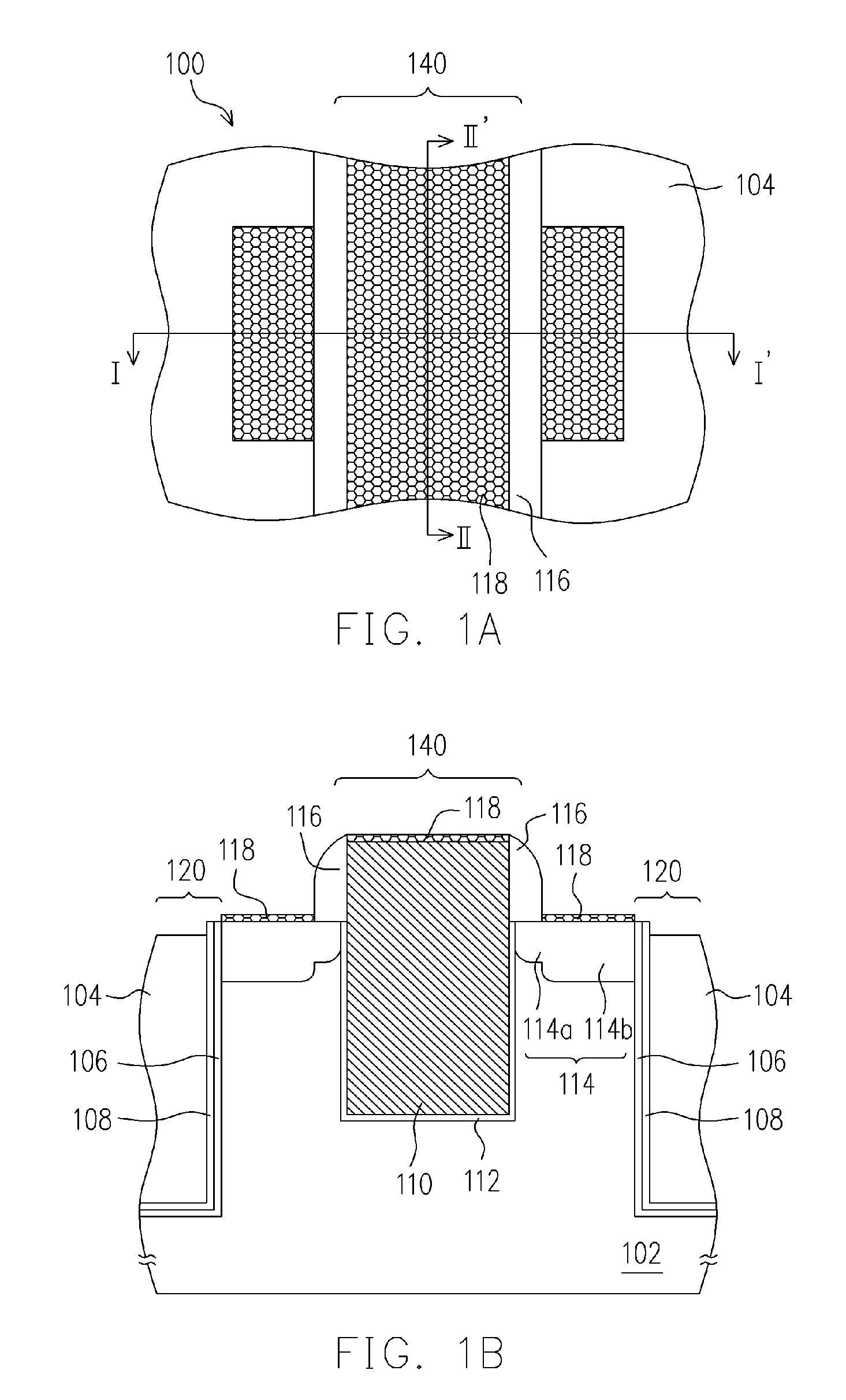

Multi-fin field effect transistor and fabricating method thereof

ActiveUS20070278595A1Avoid influenceImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesField-effect transistorGate oxide

A multi-fin field effect transistor includes a substrate, an oxide layer, a conductive layer, a gate oxide layer, and a doped region is provided. The substrate is surrounded by a trench, and there are at least two fin-type silicon layers formed in the substrate in a region prepared to form a gate thereon. The oxide layer is disposed in the trench and the top surface of the oxide layer is lower than that of the fin-type silicon layers. The conductive layer is disposed in the region prepared to form a gate. The top surface of the conductive layer is higher than that of the fin-type silicon layers. The gate oxide layer is disposed between the conductive layer and the fin-type silicon layers and disposed between the conductive layer and the substrate. The doped region is disposed in the substrate on both sides of the conductive layer.

Owner:PROMOS TECH INC

Thin film battery charge control and method

InactiveUS20140055085A1Maximizing initial capacityExtend lifetime of battery packBatteries circuit arrangementsFinal product manufactureBattery chargeElectrical battery

A thin film battery and charging system is provided comprising a cathode material, a cathode current collector, an anode current collector, and an electrolyte layer separating the cathode material from the anode current collector configured to form a battery having at least one intercalating electrode. The system additionally comprises an integrated-circuit battery-charging and managing circuit and a user controlled input having selection capability for the user to choose from a plurality of levels of state of charge of the battery. A method of charging a thin film battery is also described.

Owner:CYMBET CORP

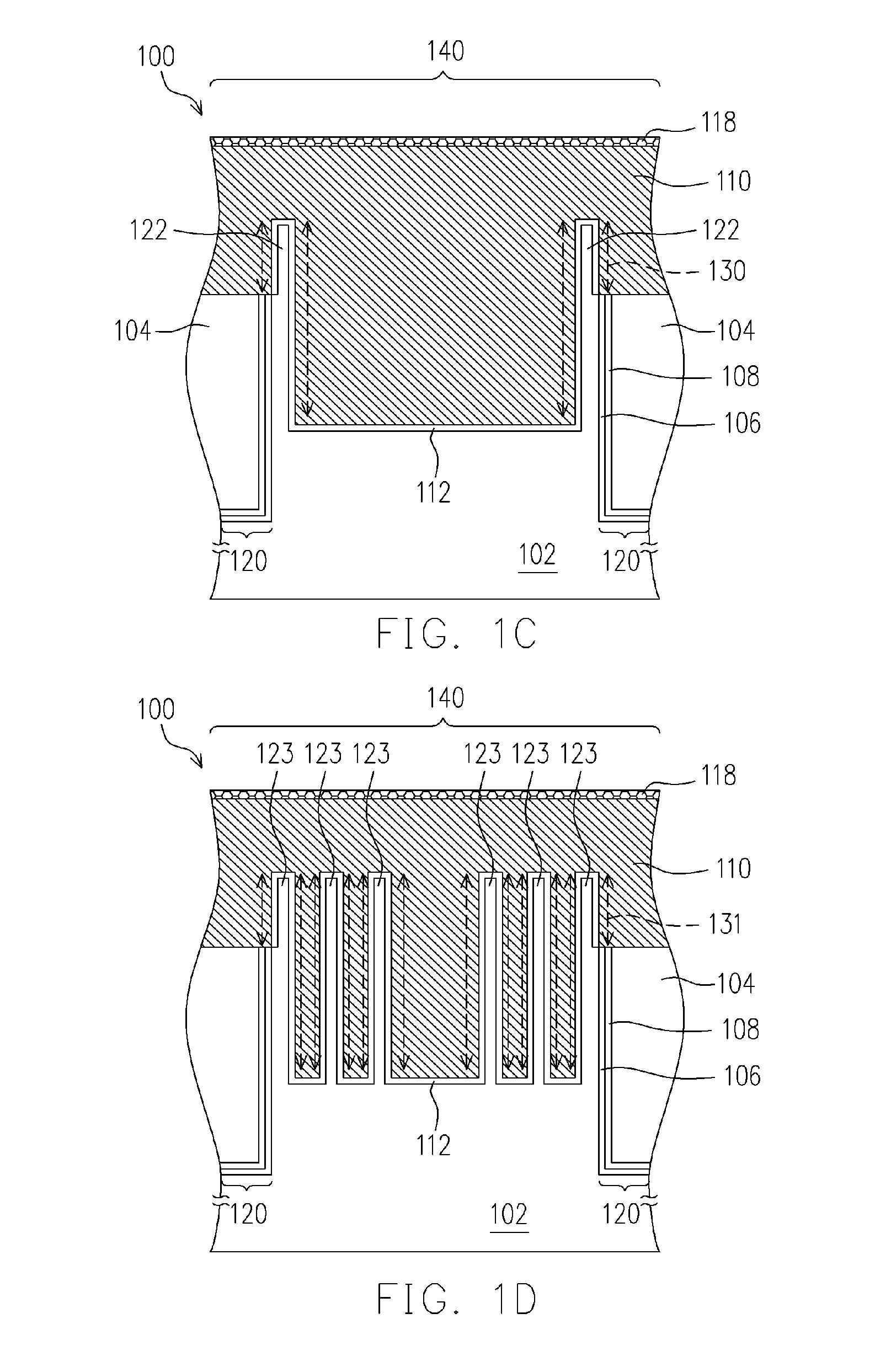

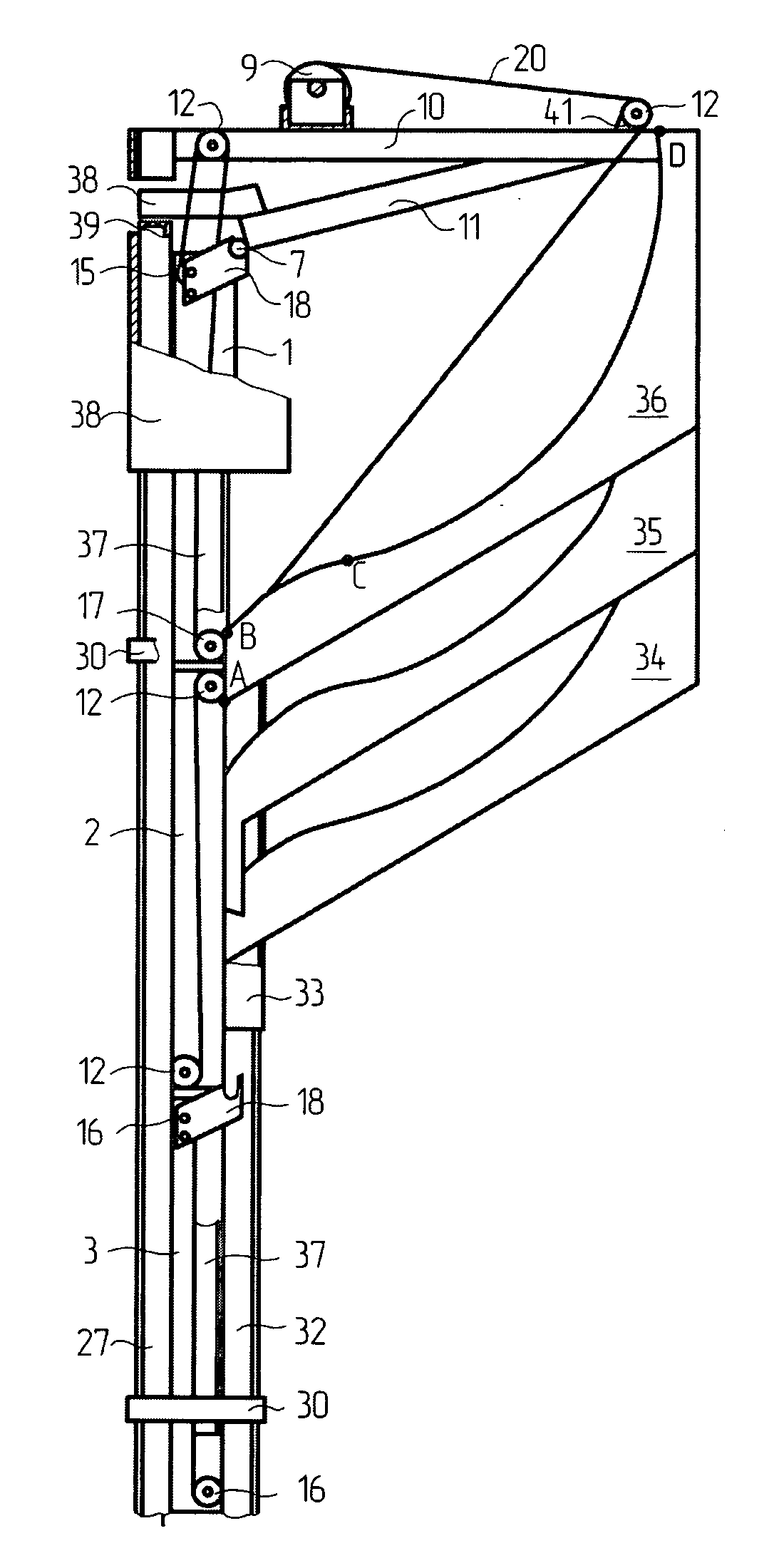

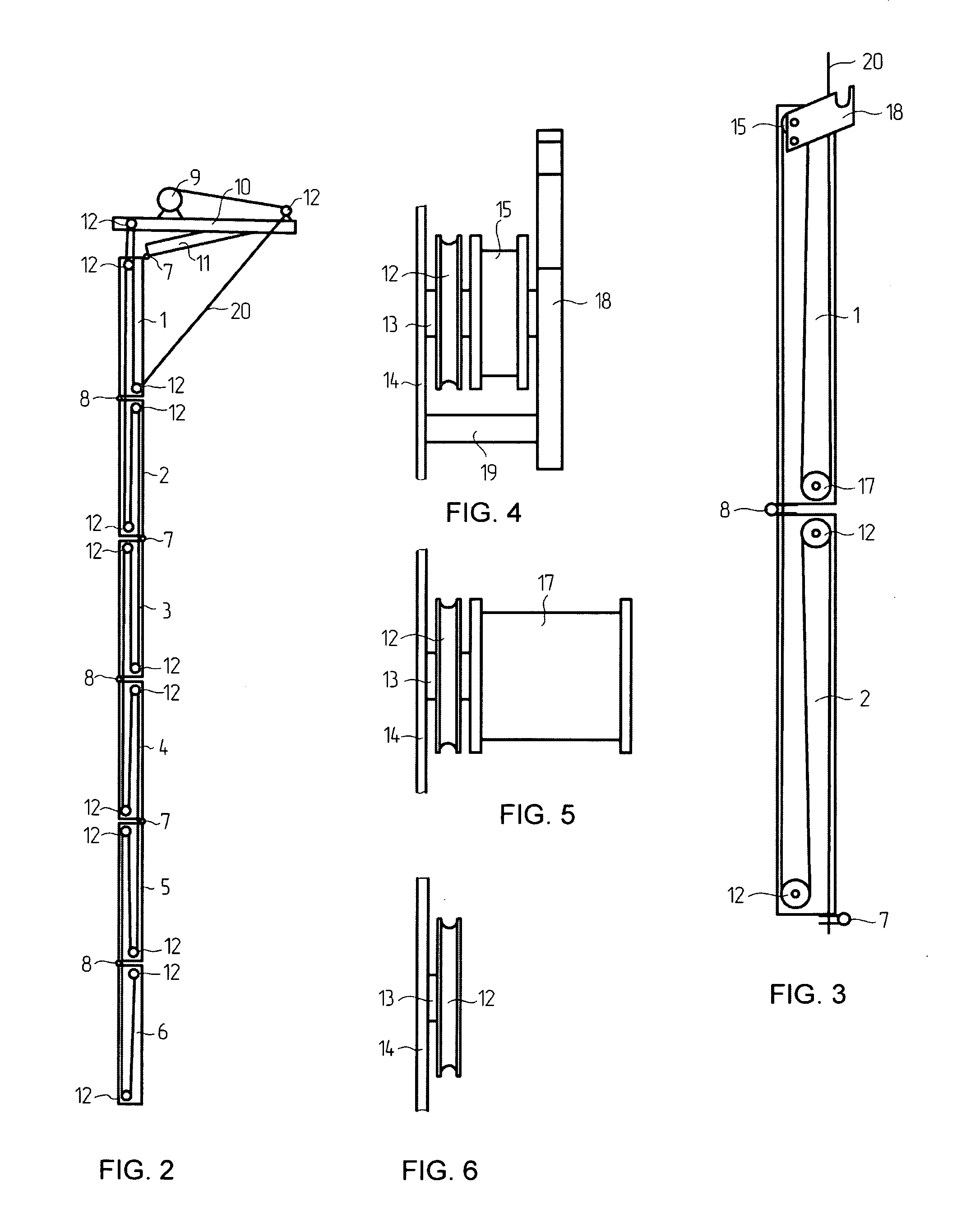

Sectional folding up garage door

ActiveUS20100287840A1Increase device capacityIncrease the areaSunshadesMan-operated mechanismVertical planeOperating energy

A sectional folding up garage door refers to constructions with moving sectional elements intended for closing apertures in buildings and edifices. The area of invention's application is its use as automatically operated door both for private and commercial use. A sectional folding up garage door provides the sectional panel lifting up in vertical plane, folding such panel in consecutive order by two sections inside a premise as the door is being lifting, and piling compactly inside in the top part of an aperture. The door includes a panel of sections joint one by one like an accordion, a frame and sections power mechanism.

Owner:GODOVALOV VLADIMIR

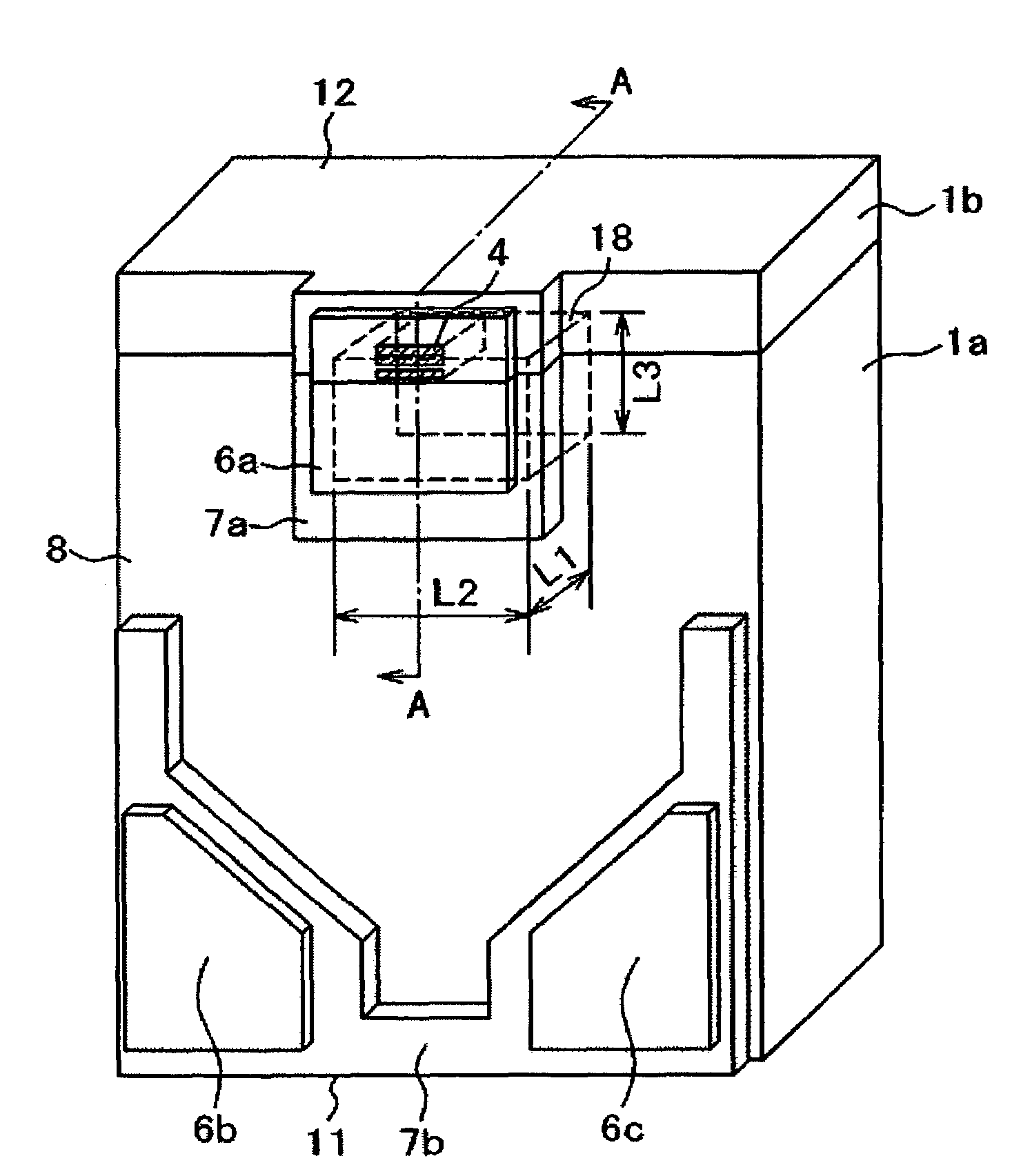

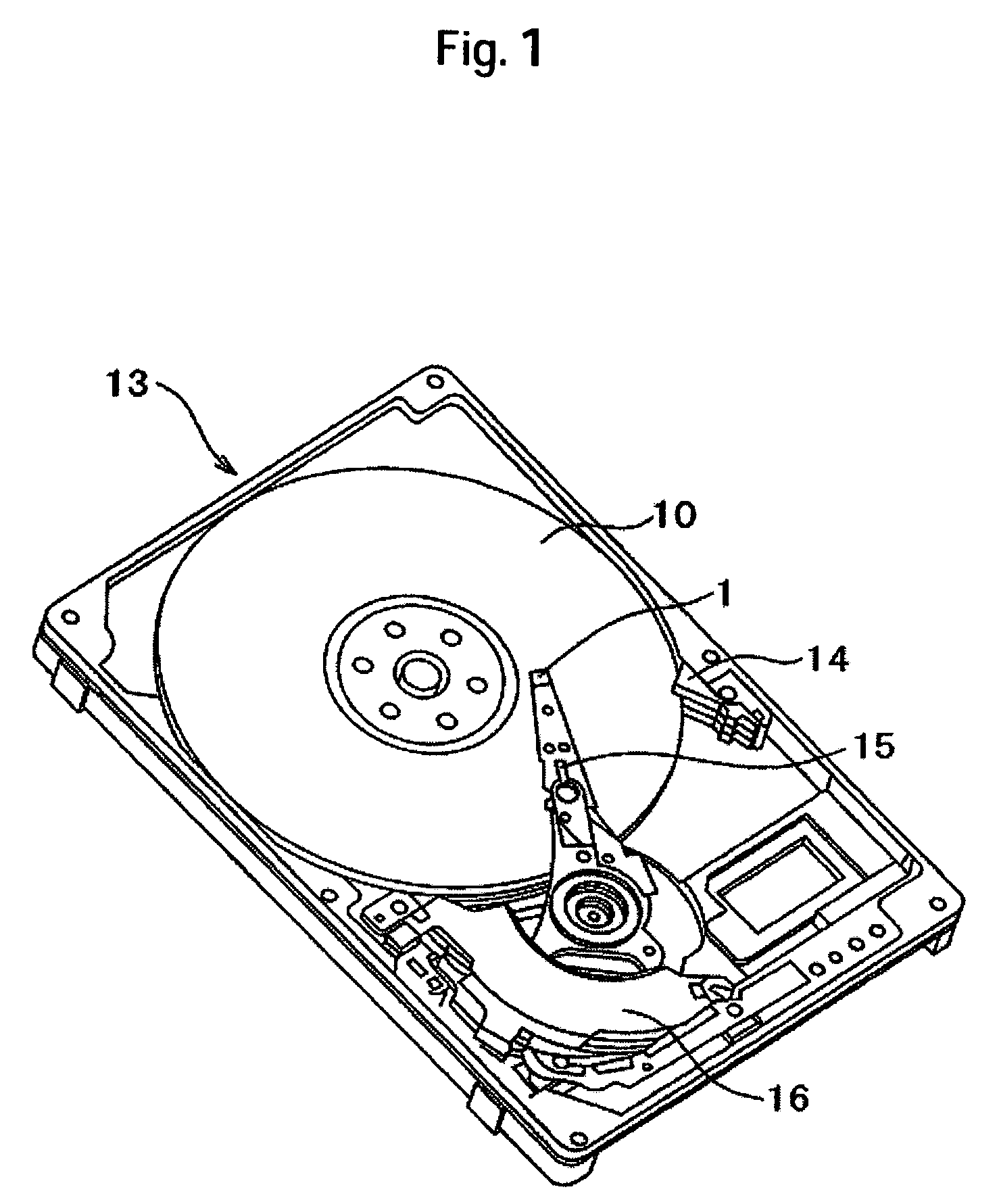

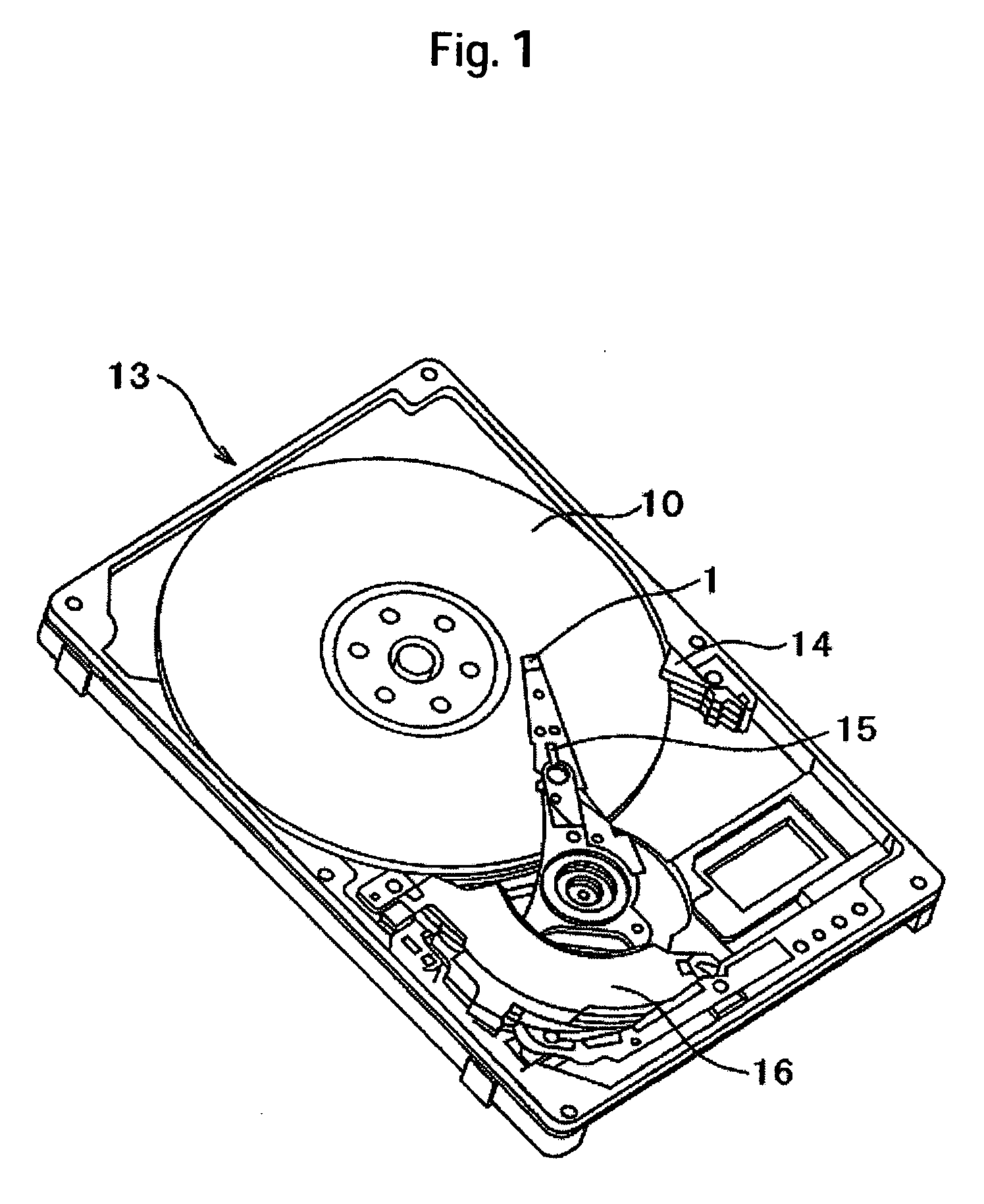

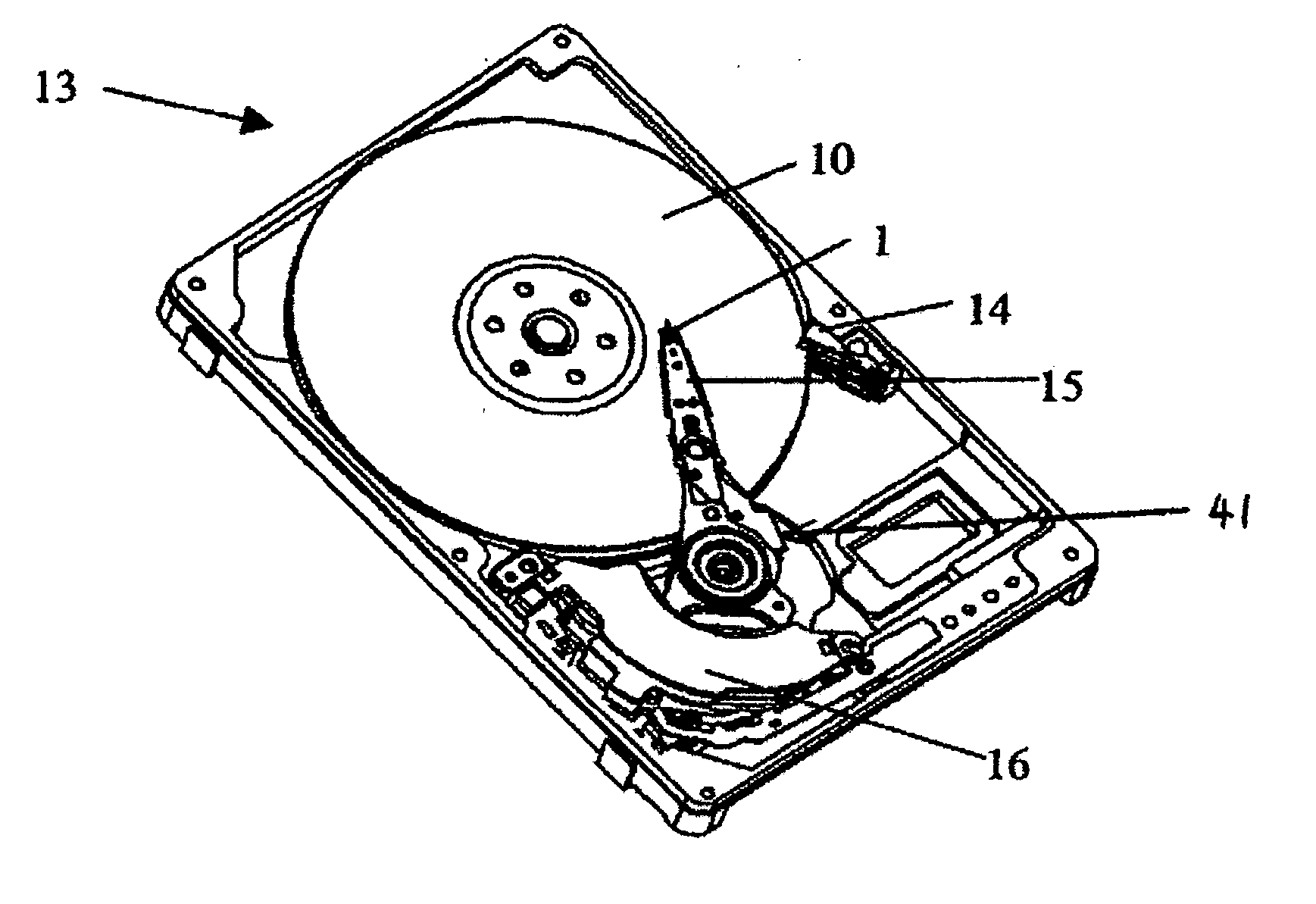

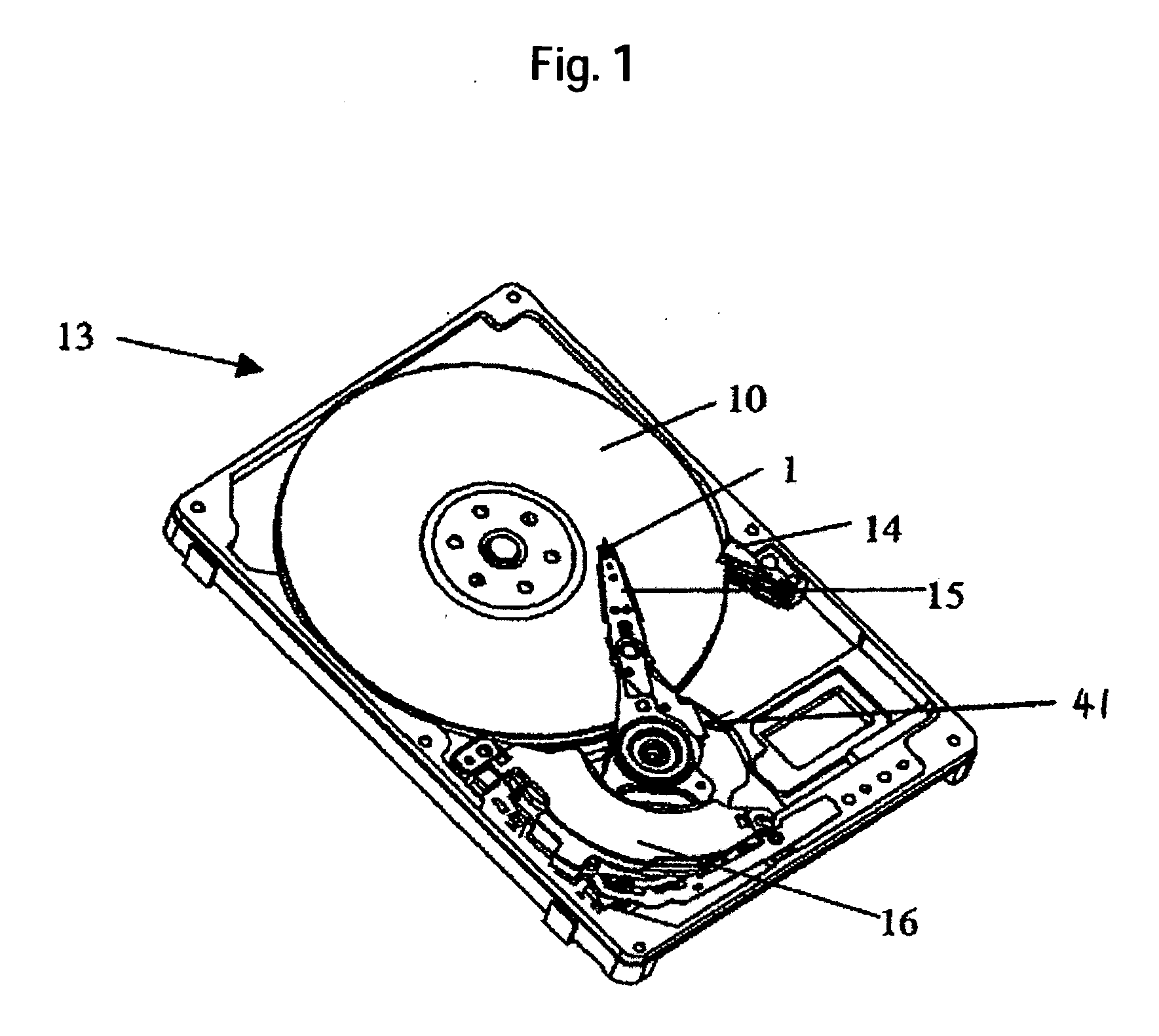

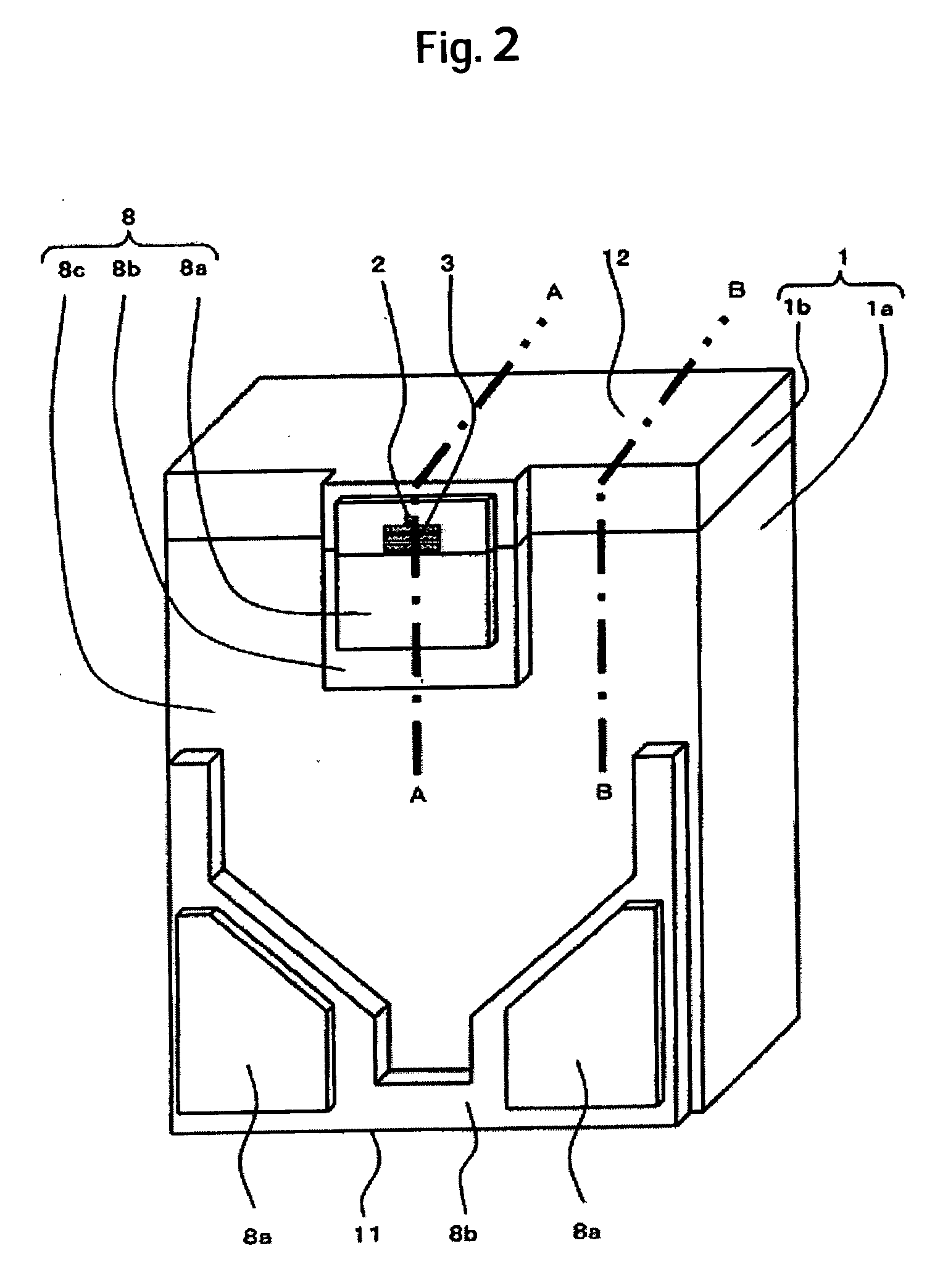

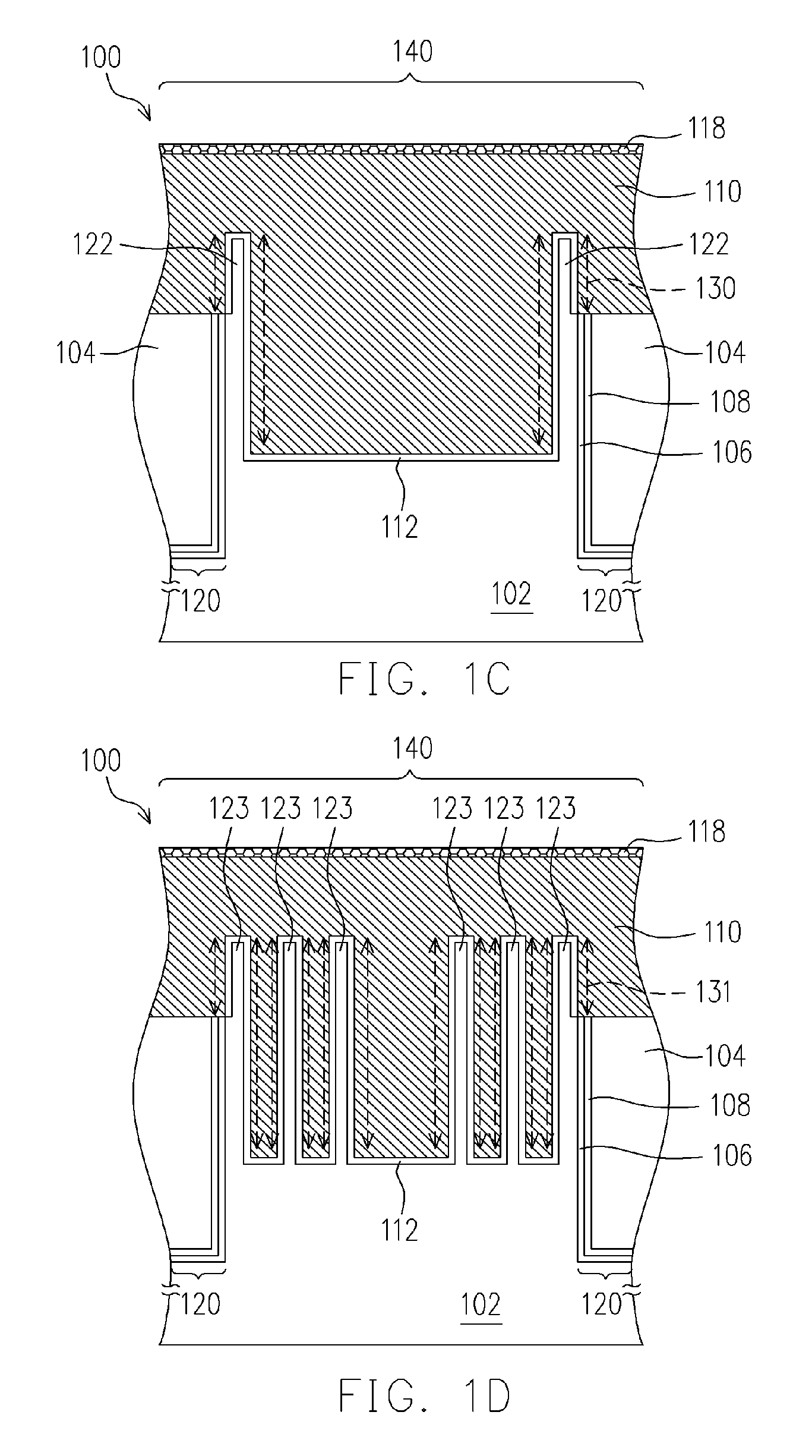

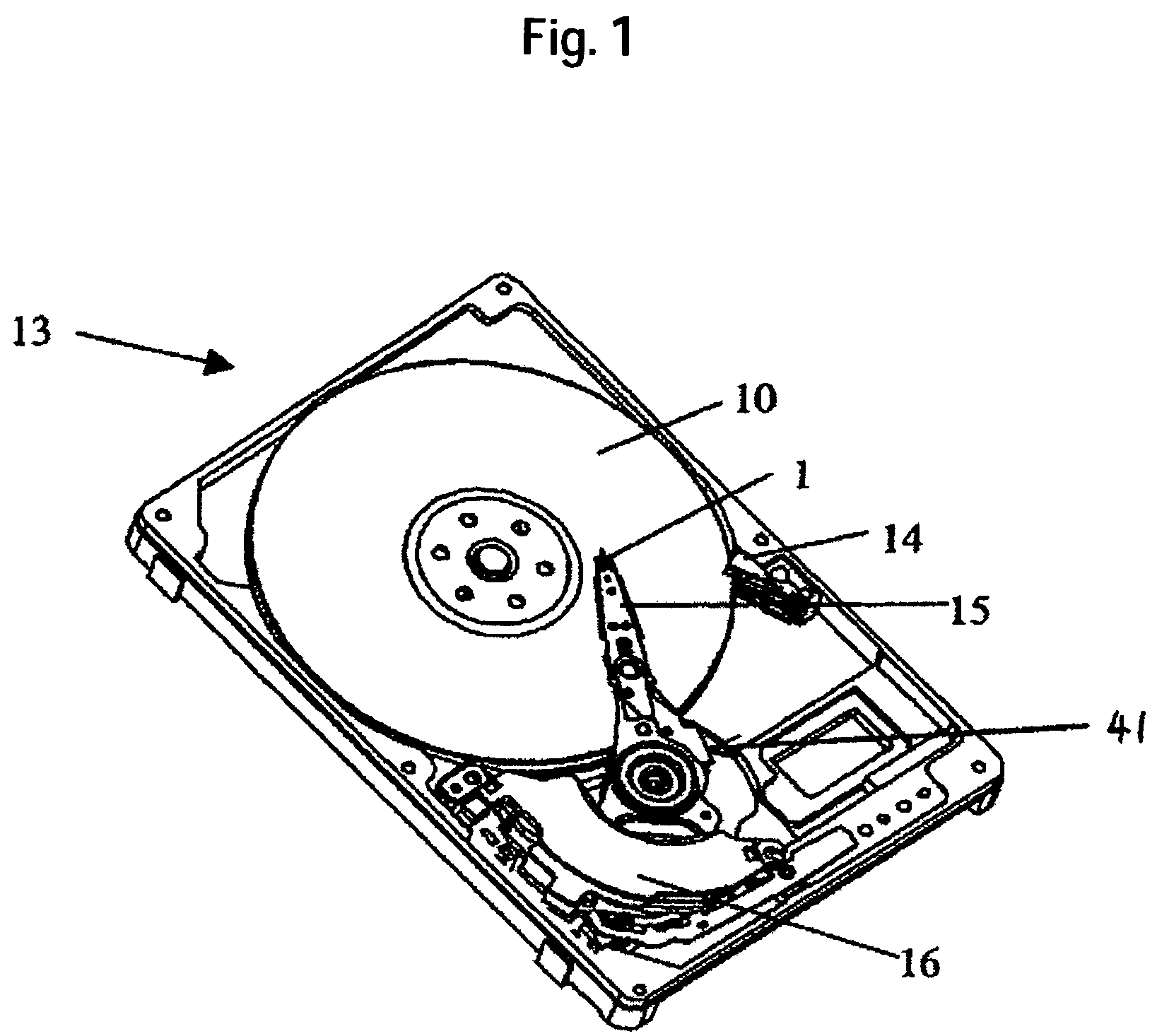

Silicon-made magnetic head slider and method of producing the same

InactiveUS7619857B2Improve productivityReduce the amount requiredFluid-dynamic spacing of headsRecord information storageEngineeringRecording density

Embodiments of the invention provide a magnetic disk device which lowers the cost, maintains reliability by compensating the thermal dent or protuberance caused by a change in the environmental temperature, makes it possible to increase the recording density by decreasing the floating amount of the slider, to increase the capacity of the device or to decrease the size thereof. In one embodiment, a magnetic disk device comprises a magnetic disk, a magnetic head slider, and a drive unit for moving the magnetic head slider, wherein an air stream is generated between the magnetic disk that rotates and the magnetic head slider to effect the recording or the reproduction in a state where the magnetic head slider is floating. The magnetic head slider includes a slider substrate portion and a thin-film head portion that has recording and reproducing elements, a metal film, and an insulating film formed on the slider substrate portion and constituting a slider-floating plane along with the slider substrate portion. The slider substrate portion includes a silicon substrate with a recessed portion, and a metal member buried in the recessed portion.

Owner:WESTERN DIGITAL TECH INC

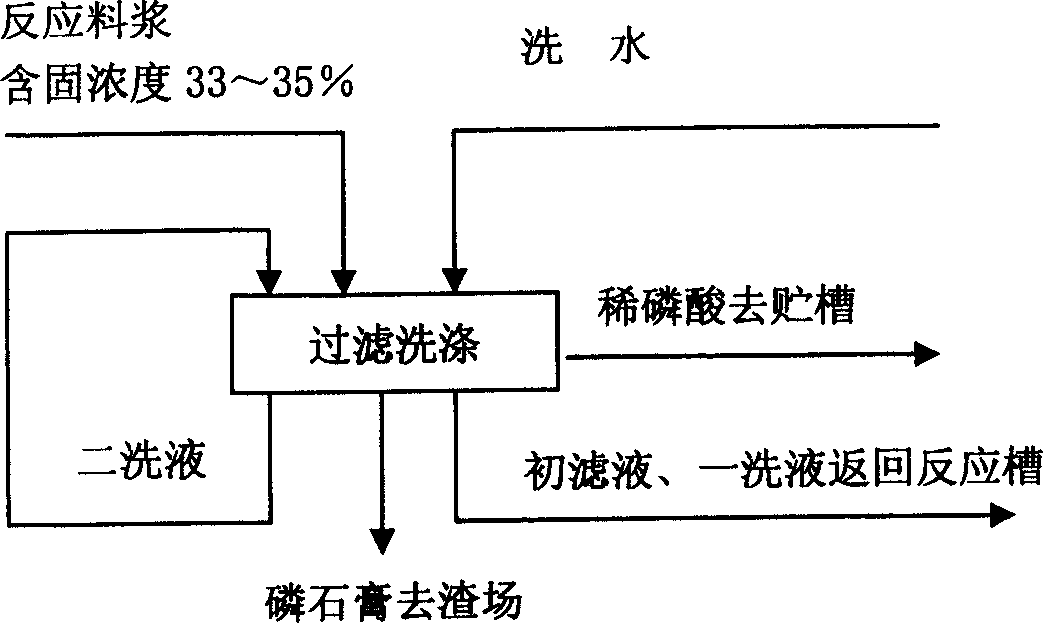

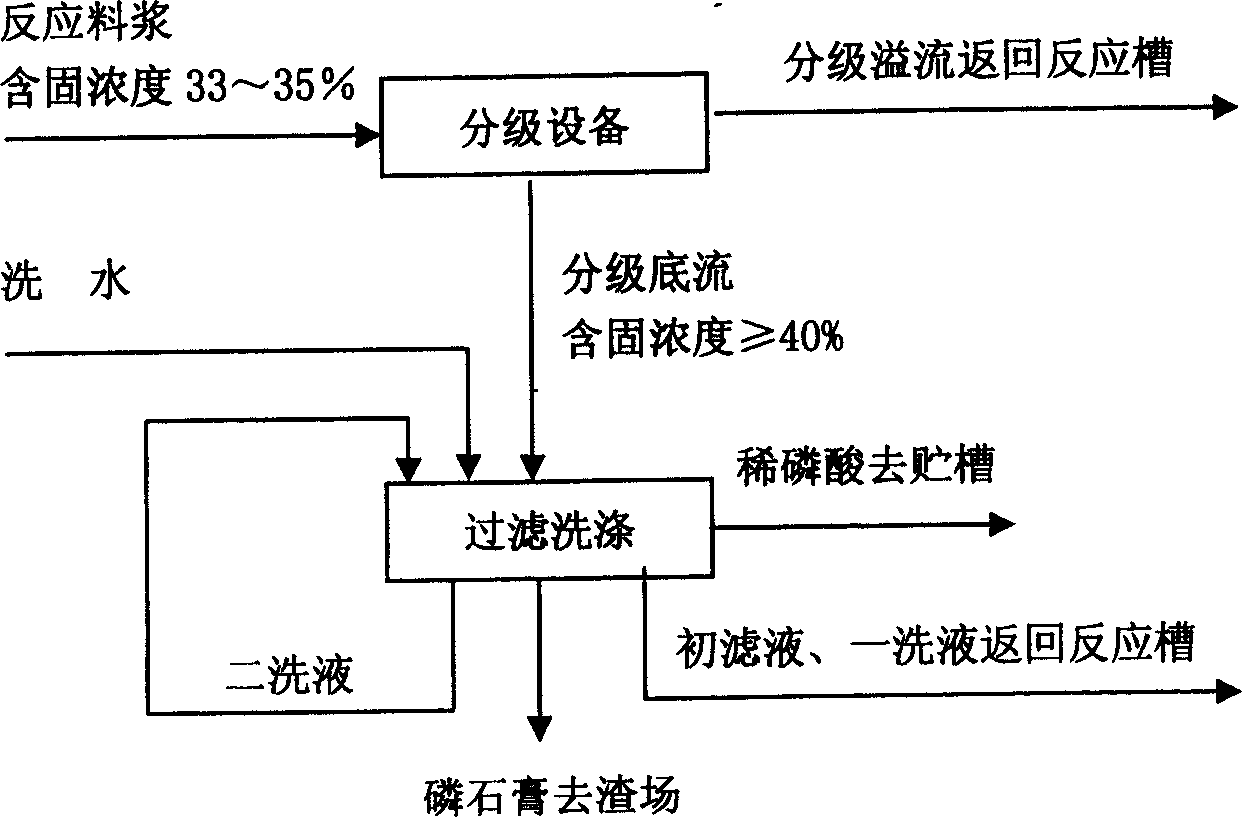

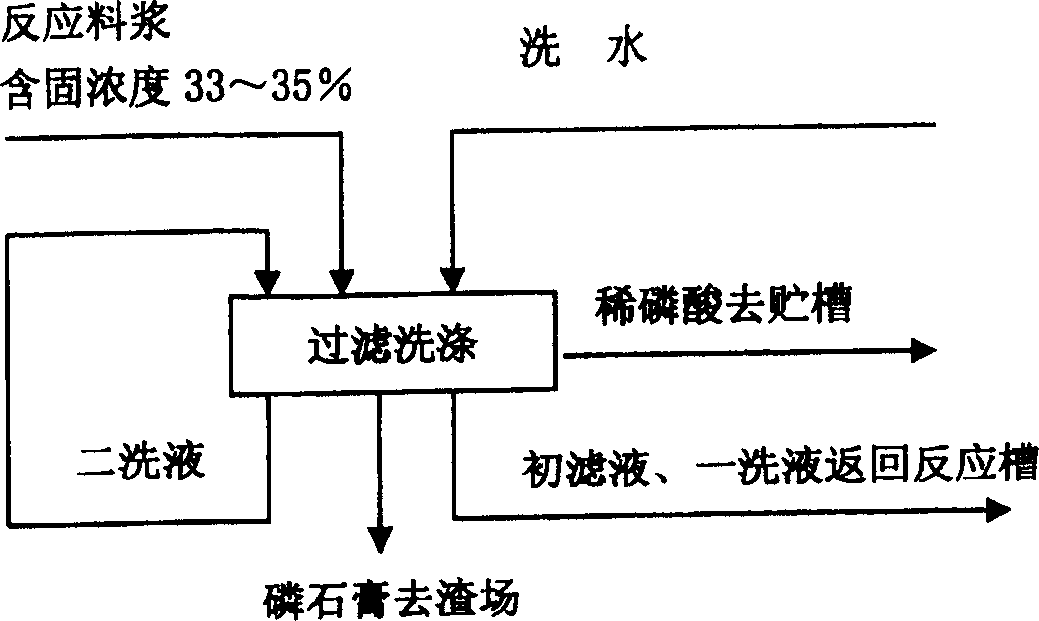

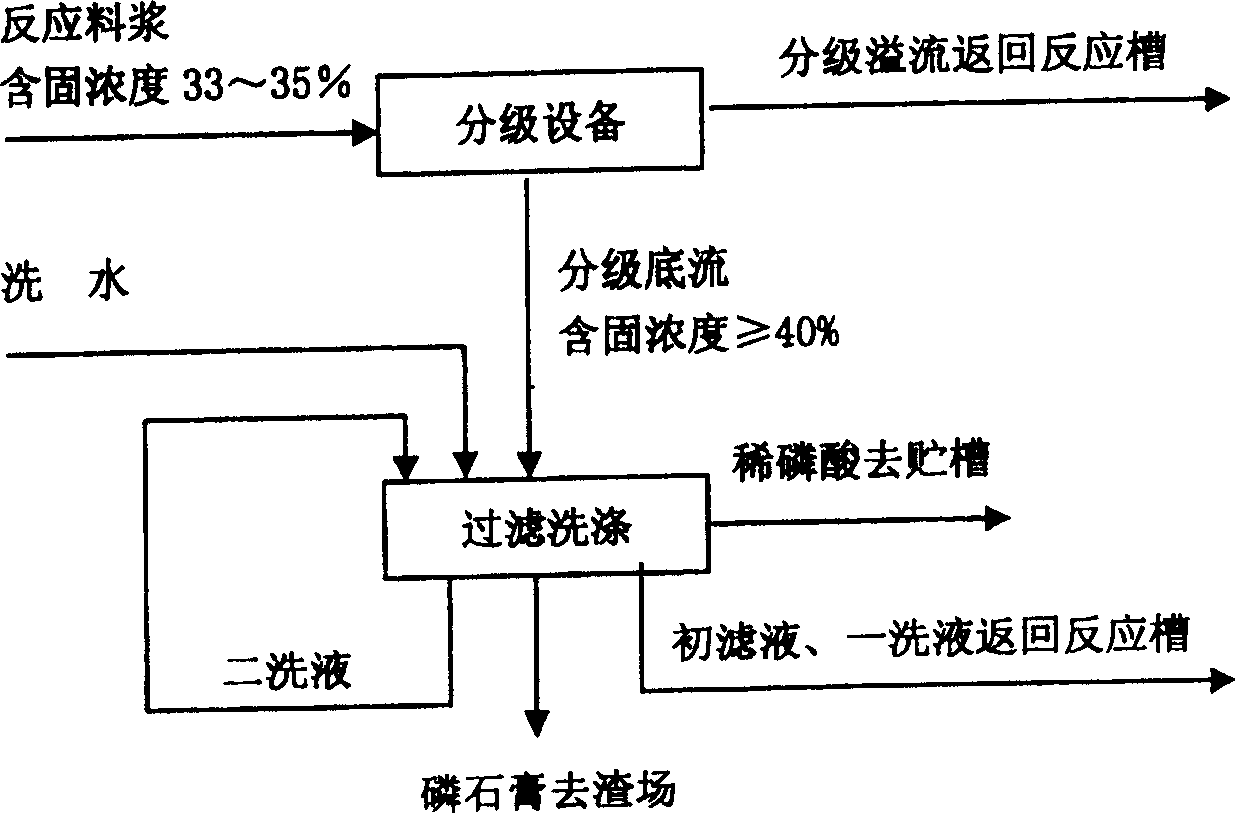

Method for improving property of dihydrate wet-process phosphoric acid reaction slurry

The invention discloses a method for improving the performance of dihydrate wet methods phosphoric acid reaction stuff, which comprises the following steps: Classify treating the stuffs by a classifier, the ardealite crystal size of classification bottom current is: the proportion of particles of +40 um size is 90%-95%, 100 um size is 50%-65%, +150 um size is 20%-35%. Filtering and washing the classification bottom current in a filter. The ardealite crystal size of classification overflow is: the proportion of particles of -40 um size is 80%-85%, -100 um size is 100%. Growing and increasing further have the classification overflow in a seed crystal reaction tank and entering the next classified cycle. Taking the ardealite filtrated and washed to the slag ground, and taking the diluted phosphoric acid to the storage tank, returning the preliminary filter liquid and 1st cleaning solution to the reaction tank, and quadratic countercurrent washing the 2nd cleaning solution in the filter.

Owner:云南云天化国际化工有限公司

Silicon-made magnetic head slider and method of producing the same

InactiveUS20060209464A1Increase productivityLower costRecord information storageFluid-dynamic spacing of headsMagnetic disksRecording density

Embodiments of the invention provide a magnetic disk device which lowers the cost, maintains reliability by compensating the thermal dent or protuberance caused by a change in the environmental temperature, makes it possible to increase the recording density by decreasing the floating amount of the slider, to increase the capacity of the device or to decrease the size thereof. In one embodiment, a magnetic disk device comprises a magnetic disk, a magnetic head slider, and a drive unit for moving the magnetic head slider, wherein an air stream is generated between the magnetic disk that rotates and the magnetic head slider to effect the recording or the reproduction in a state where the magnetic head slider is floating. The magnetic head slider includes a slider substrate portion and a thin-film head portion that has recording and reproducing elements, a metal film, and an insulating film formed on the slider substrate portion and constituting a slider-floating plane along with the slider substrate portion. The slider substrate portion includes a silicon substrate with a recessed portion, and a metal member buried in the recessed portion.

Owner:WESTERN DIGITAL TECH INC

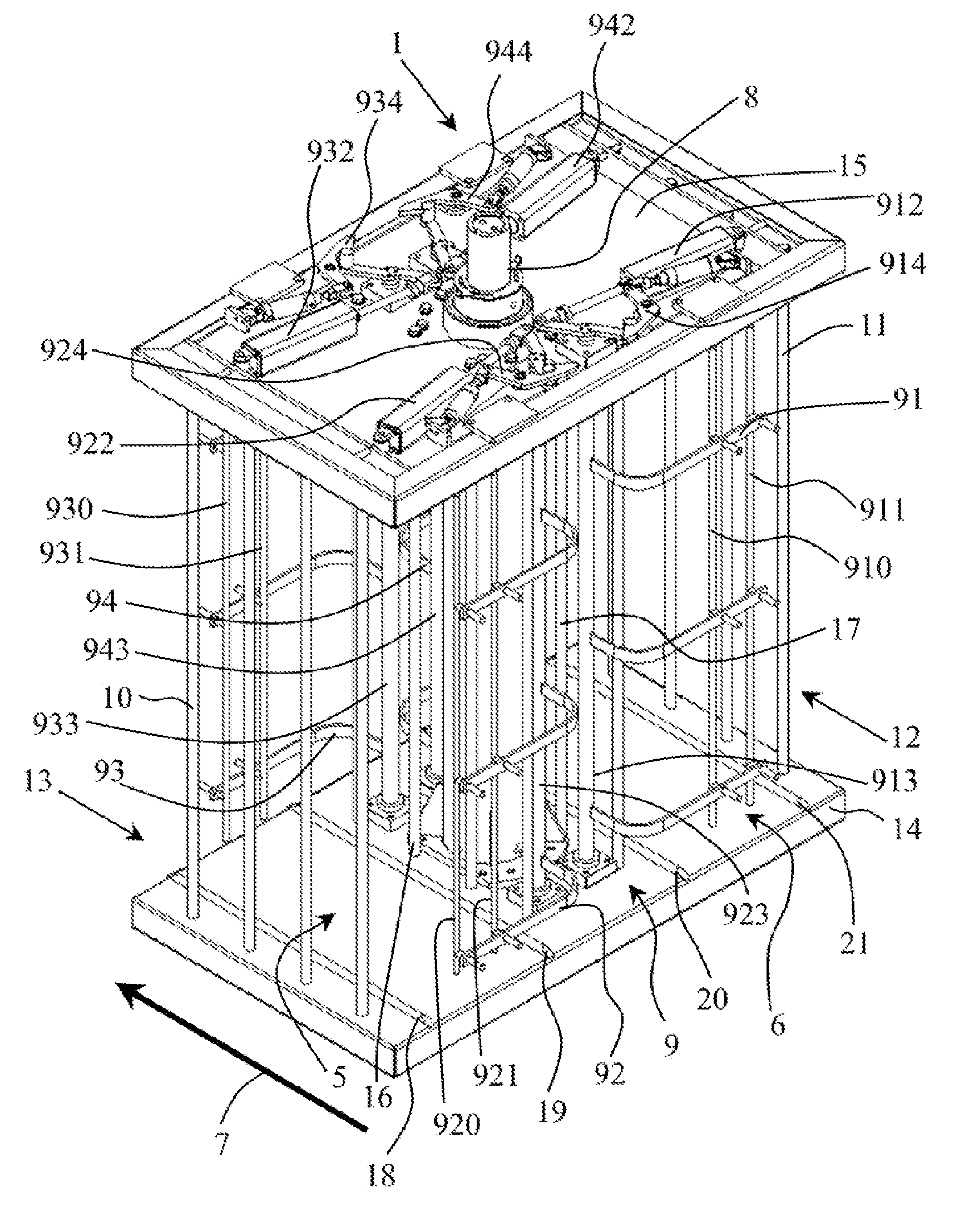

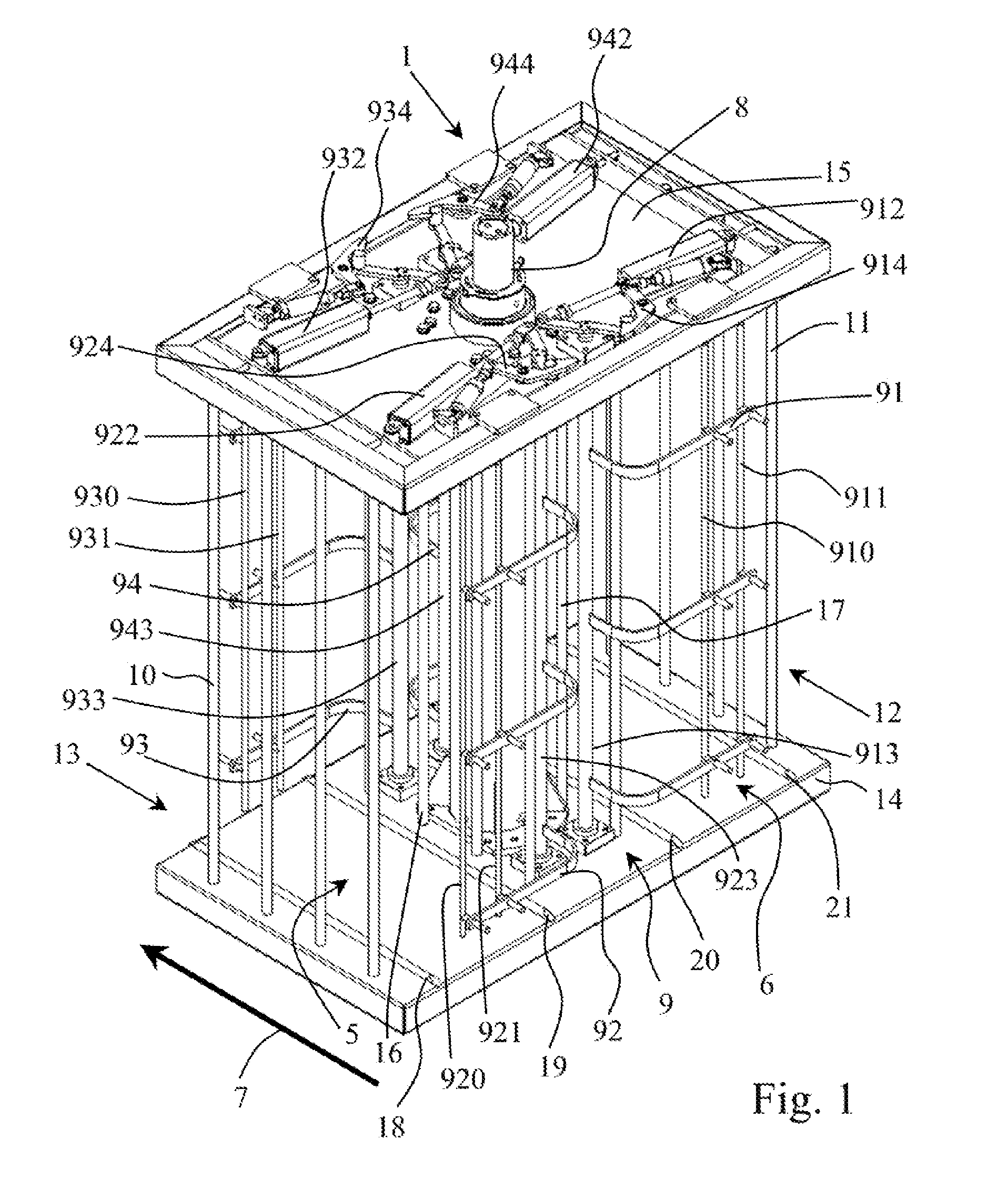

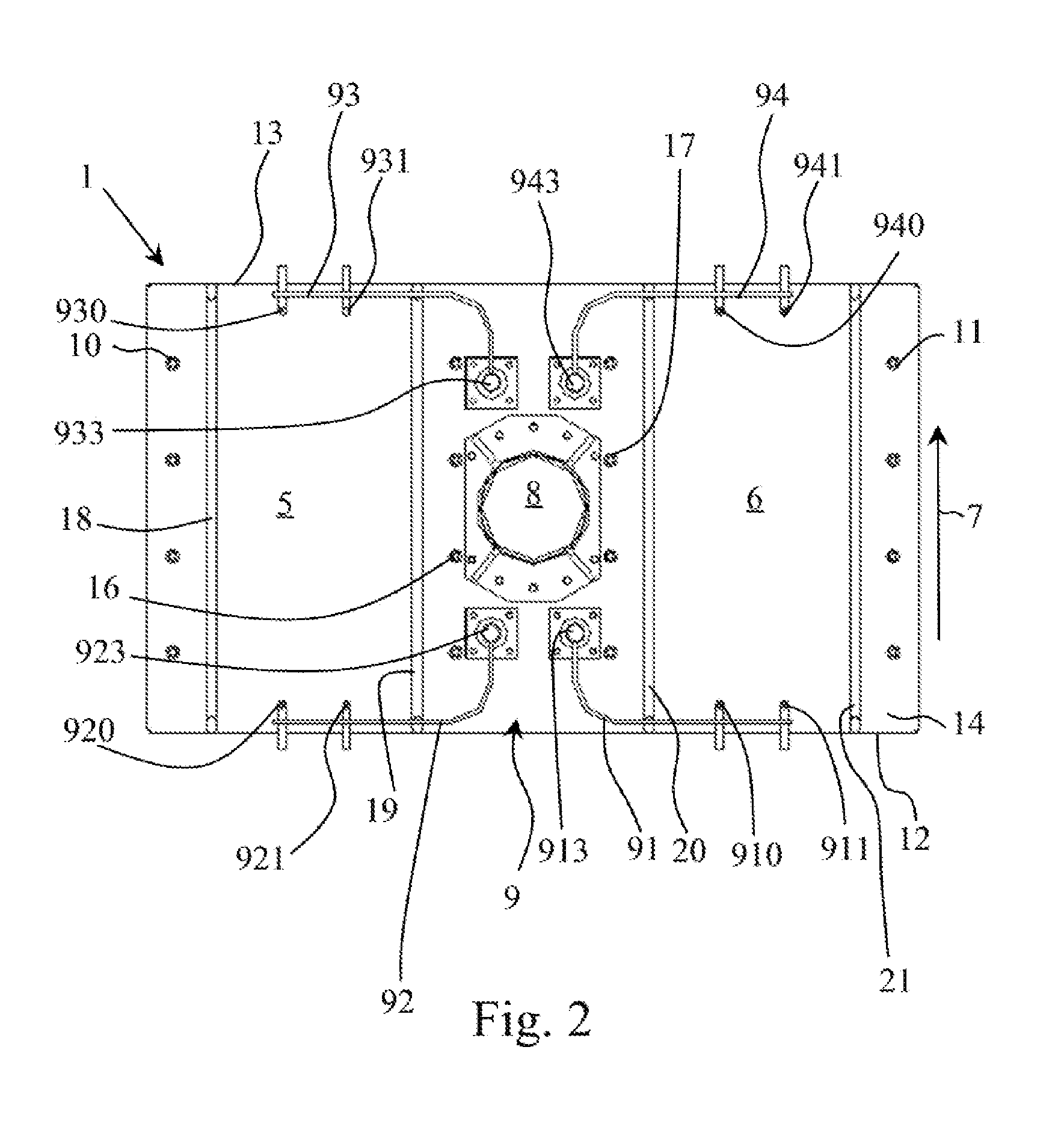

Container drying device

InactiveUS20140317947A1Increase centrifugal forceIncrease device capacityDrying solid materials without heatDrying chambers/containersMechanical engineering

Container drying device of the spin-dryer type includes at least two booths, each being adapted to accommodate at least one stack of containers, the at least one stack of containers being loaded into the at least two booths in a loading direction, an axis of rotation about which the container drying device being rotatable, extending in a direction substantially perpendicular to the loading direction, and being arranged centrally in the container drying device; and a closing device being movable between a closed position in which the closing device closes the at least two booths at least partially and an open position in which the at least one stack of containers may be loaded into and / or removed from each of the at least two booths, the at least two booths being arranged excentrically, symmetrically on opposite sides of the axis of rotation and substantially in parallel with each other.

Owner:SEMI STAAL

Silicon-made magnetic head slider

InactiveUS20060077592A1Improve productivityCost reductionRecord information storageFluid-dynamic spacing of headsMagnetic disksRecording density

In a magnetic disk device, cost reduction is designed by improving productivity, and increase in recording density and increase in capacity of the device or size reduction are designed with reliability being ensured. In one embodiment, a magnetic disk device has a magnetic disk arranged rotatably, a magnetic head slider arranged in a manner of facing a surface of the magnetic disk, and a driving device for moving the magnetic head slider in a radial direction of the surface of the magnetic disk. The magnetic head slider has a silicon slider-substrate-portion and a thin-film head portion which is formed on the slider substrate portion using a thin-film process and forms an air-bearing surface along with the slider substrate portion. The thin-film head portion has recording / reproduction elements facing the surface of the magnetic disk, and a ceramic insulation film has alumina and silicon-based ceramics in order to have a coefficient of linear expansion approximately equal to that of the silicon slider-substrate-portion.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Method of fabricating multi-fin field effect transistor

ActiveUS7510955B2Improve reliabilityImprove stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesField-effect transistorGate oxide

A multi-fin field effect transistor includes a substrate, an oxide layer, a conductive layer, a gate oxide layer, and a doped region is provided. The substrate is surrounded by a trench, and there are at least two fin-type silicon layers formed in the substrate in a region prepared to form a gate thereon. The oxide layer is disposed in the trench and the top surface of the oxide layer is lower than that of the fin-type silicon layers. The conductive layer is disposed in the region prepared to form a gate. The top surface of the conductive layer is higher than that of the fin-type silicon layers. The gate oxide layer is disposed between the conductive layer and the fin-type silicon layers and disposed between the conductive layer and the substrate. The doped region is disposed in the substrate on both sides of the conductive layer.

Owner:PROMOS TECH INC

Silicon-made magnetic head slider

InactiveUS7508631B2Improve recording densityImprove productivityRecord information storageFluid-dynamic spacing of headsProduction rateEngineering

In a magnetic disk device, cost reduction is designed by improving productivity, and increase in recording density and increase in capacity of the device or size reduction are designed with reliability being ensured. In one embodiment, a magnetic disk device has a magnetic disk arranged rotatably, a magnetic head slider arranged in a manner of facing a surface of the magnetic disk, and a driving device for moving the magnetic head slider in a radial direction of the surface of the magnetic disk. The magnetic head slider has a silicon slider-substrate-portion and a thin-film head portion which is formed on the slider substrate portion using a thin-film process and forms an air-bearing surface along with the slider substrate portion. The thin-film head portion has recording / reproduction elements facing the surface of the magnetic disk, and a ceramic insulation film has alumina and silicon-based ceramics in order to have a coefficient of linear expansion approximately equal to that of the silicon slider-substrate-portion.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Three-level power converter

ActiveUS10153708B2Increase device capacityReduce wiring inductanceConversion constructional detailsCasings/cabinets/drawers detailsThree levelDc capacitor

A three-level power converter includes a first module housing a vertical arm forming a three-level power conversion circuit; a second module disposed adjacent to the first module and housing an intermediate arm forming the three-level power conversion circuit; high-potential and low-potential connecting terminal boards each extending vertically, and having a lower end connected to connecting terminals on an upper surface of the first module, and an upper end provided with an external connecting end; and a flat intermediate-potential connecting terminal board extending vertically, and having a lower end connected to connecting terminals on an upper surface of the second module, and an upper end provided with an external connecting end. The high-potential, low-potential, and intermediate-potential connecting terminal boards are stacked close to and parallel to one another. Each of the external connecting ends is connected to a corresponding terminal of a DC capacitor.

Owner:FUJI ELECTRIC CO LTD

Method for improving property of dihydrate wet-process phosphoric acid reaction slurry

Owner:云南云天化国际化工有限公司

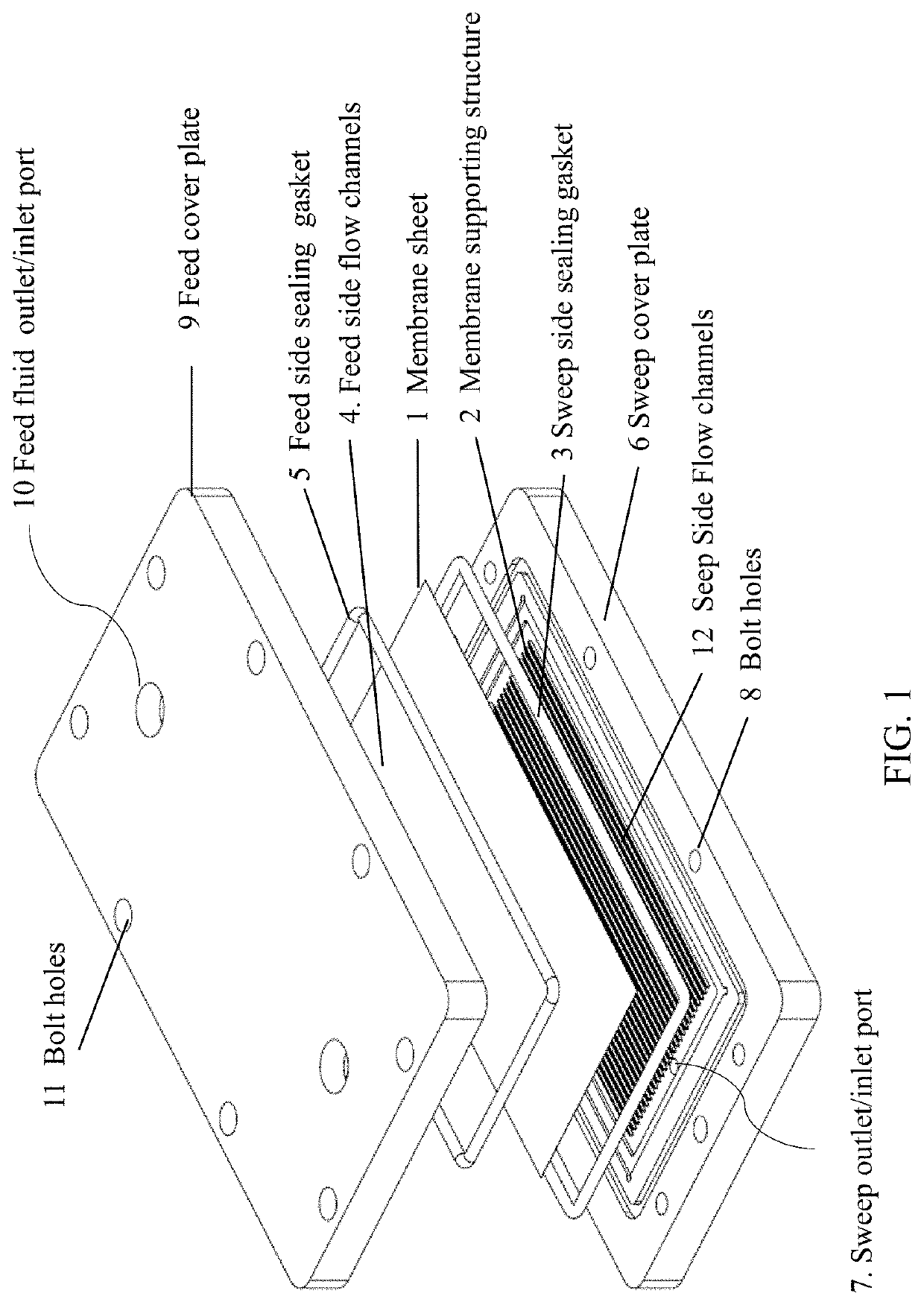

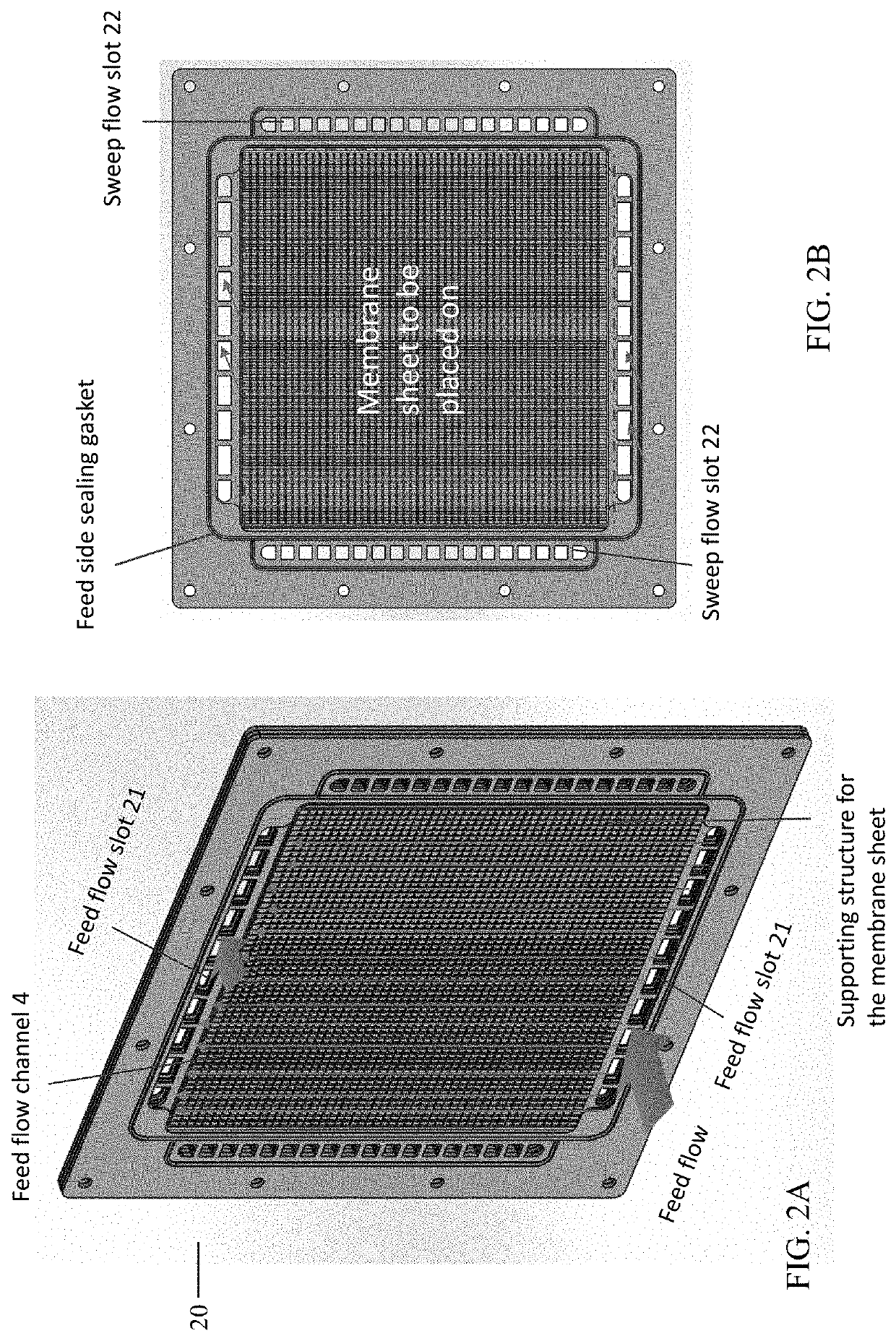

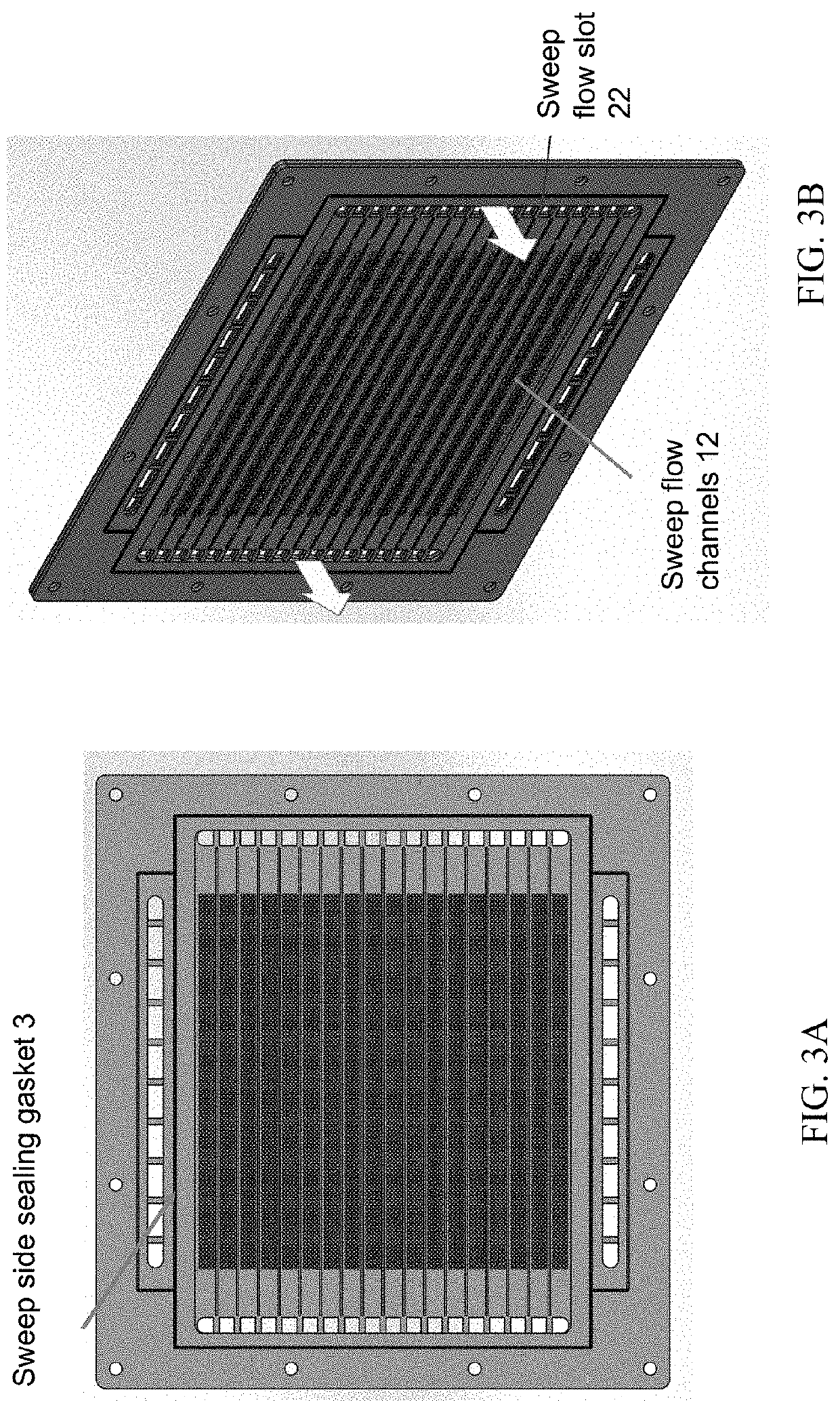

Universal Planar Membrane Device for Mass Transfer

ActiveUS20210069651A1Easy to processEasy to assembleMembranesDispersed particle separationChemical physicsCross-flow filtration

A membrane device is presented that can used for a wide range of applications from once-through filtration, crossflow filtration, molecular separation, gas / liquid absorption or reaction, gas dispersion into liquid, and degassing of liquid. The device comprises a thin flat sheet membrane that allows certain fluid or molecules go through while blocking others. The membrane sheet is fixed on a supporting structure with mini channel on two sides of the membrane for respective feed and sweep flows. The membrane sheet is sealed with gaskets with two cover plates that the membrane sheet can be replaced or cleaned. The cover plate provides connection ports to connect the feed fluid to the feed channels on one membrane surface and to connect the sweep fluid to the sweep channels on the other surface of the membrane.

Owner:MOLECULE WORKS INC

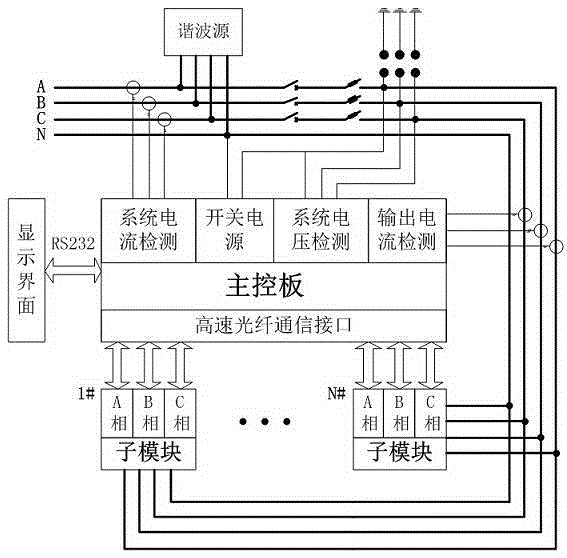

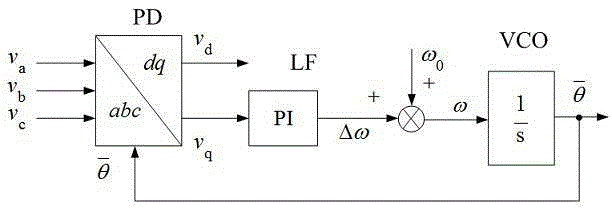

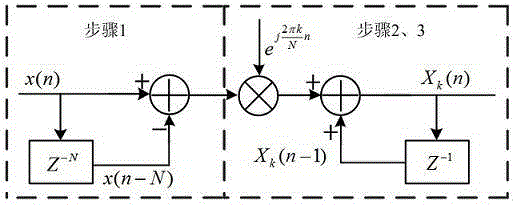

Active power filter control system and method based on FPGA

InactiveCN105337280AIncrease device capacityLow latencyActive power filteringAc network to reduce harmonics/ripplesActive power filterFpga chip

The invention provides an active power filter control system based on FPGA. The active power filter control system based on FPGA comprises a control unit, a logic protection unit, a display unit and a PWM unit, wherein the control unit, the logic protection unit, the display unit and the PWM unit are highly integrated on an FPGA chip. The active power filter control system based on FPGA can improve the installed capacity and reduce the delay of a control system, and is high in compensation precision and is favorable in compensation effect.

Owner:NANJING APAITEK TECH

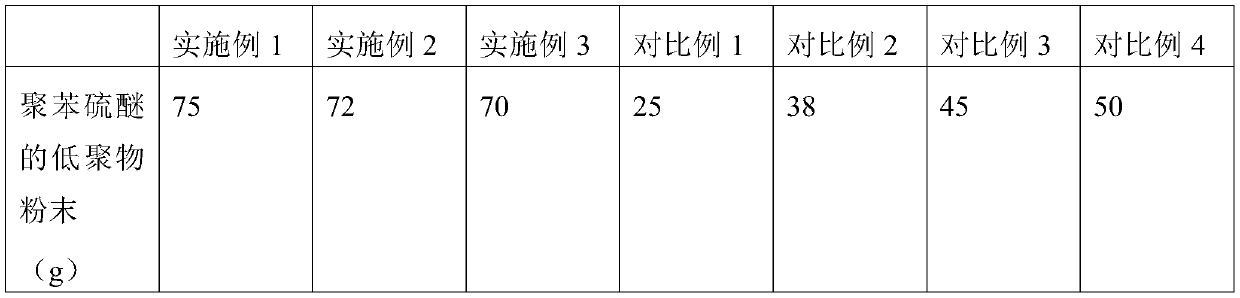

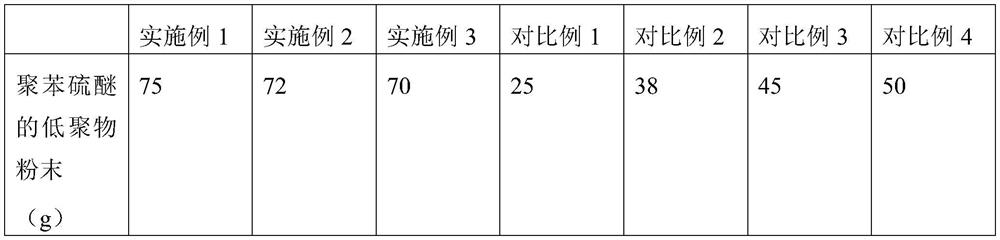

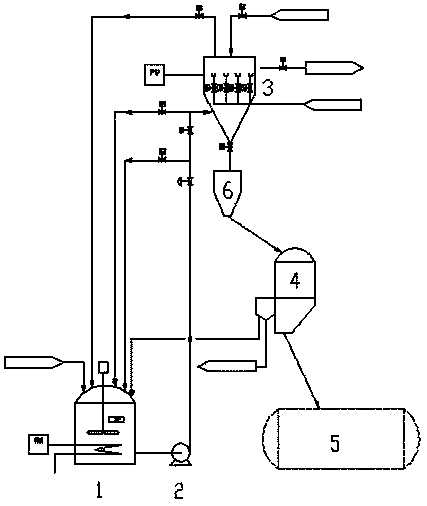

Process for separating and purifying polyphenylene sulfide

The invention discloses a process for separating and purifying polyphenylene sulfide. The process includes (1), separating the granular polyphenylene sulfide from mixtures with the polyphenylene sulfide by centrifugal machines, and mixing the remaining mixtures and diatomaceous earth with one another in mixing kettles to obtain mixtures A; (2), connecting outlets of the mixing kettles with pumps,connecting outlets of the pumps with regulating valves, connecting the regulating valves with plate hermetic filters, conveying the mixtures A to the plate hermetic filters by the pumps and filteringthe mixtures A to obtain solid materials and filter liquor B; (3), delivering the filter liquor B into rectification systems and rectifying the filter liquor B. The process has the advantages that theself-operated regulating valves and the plate hermetic filters are used with one another, the diatomaceous earth is applied to procedures for separating and purifying the polyphenylene sulfide, accordingly, the problems of pump and rectification tower blockage due to materials, the requirement on detaching tower equipment for clearing or washing the tower equipment and material leakage can be effectively solved by the aid of the process, product loss further can be reduced, environmental pollution can be abated, and the productivity can be improved.

Owner:ZHUHAI CHANGXIAN CHEM TECH

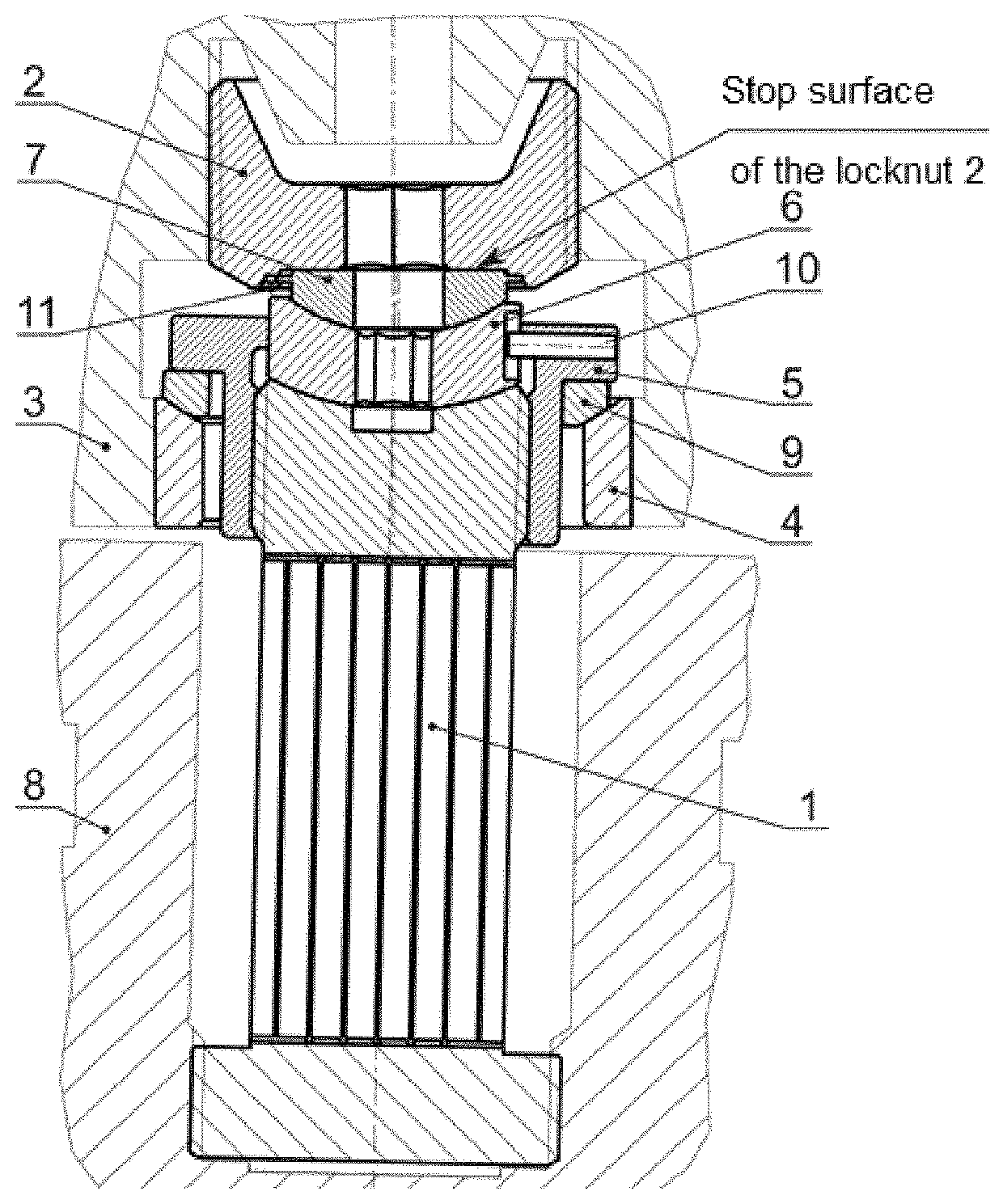

Device for securing a blanket module to a fusion reactor vacuum vessel

ActiveUS10593433B2Increase in permitted torque valuePrevents possible weakeningNuclear energy generationThermonuclear fusion reactorEngineeringMechanical engineering

The invention relates to the field of thermonuclear fusion and can be used for securing a blanket module to a vacuum vessel of a fusion reactor. The connecting device comprises a flexible support in the form of rods mounted between an upper flange having a concave spherical surface and a lower flange; a displacement compensator mounted on the upper flange; and a male-threaded locknut. The displacement compensator is fixedly connected to the blanket module and comprises a locking screw and a supporting sleeve, which are pivotally interconnected, a spacer sleeve, and a coupling sleeve with a spherical protuberance. The spacer sleeve is movably connected to the locking screw and pivotally connected to the upper flange of the flexible support and to the spherical protuberance of the coupling sleeve. The coupling sleeve is fixedly connected to a stop surface of the locknut.

Owner:ROSSIJSKAJA FEDERATSIJA OT IMENI KOTOROJ VYSTUPAET GOSUDARSTVENNAJA KORPORATSIJA PO ATOMNOJ EHNERGII ROSATOM

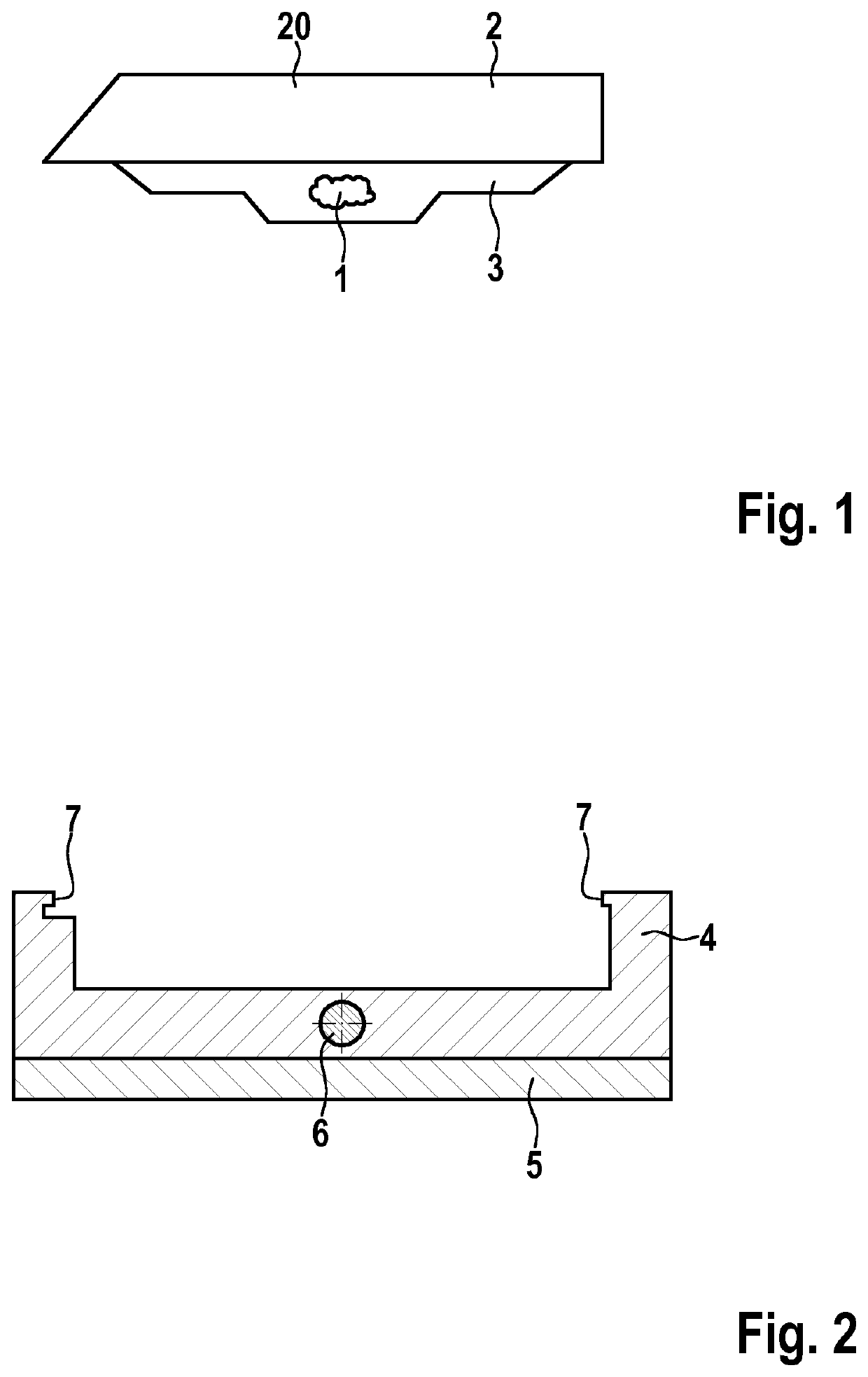

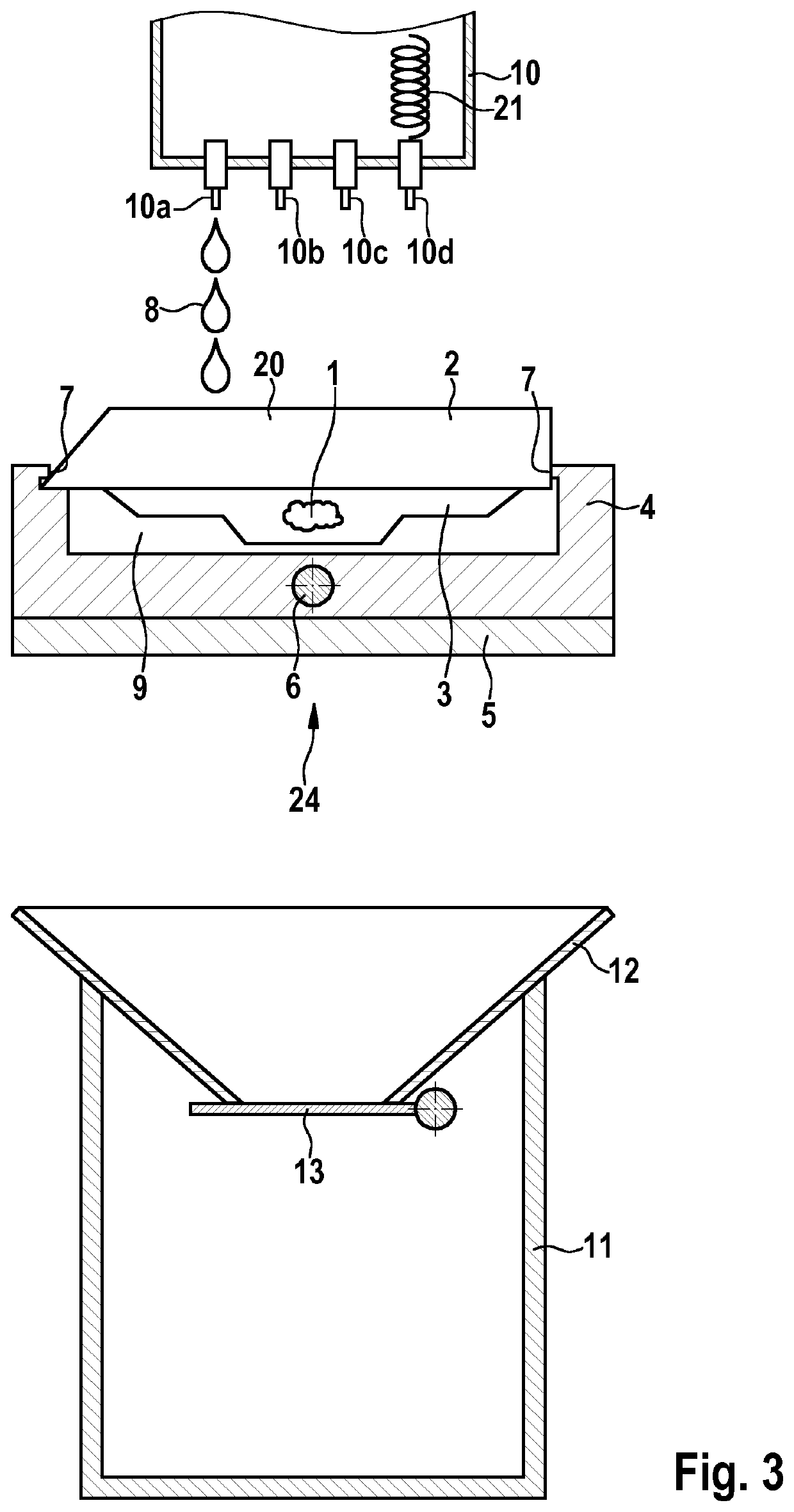

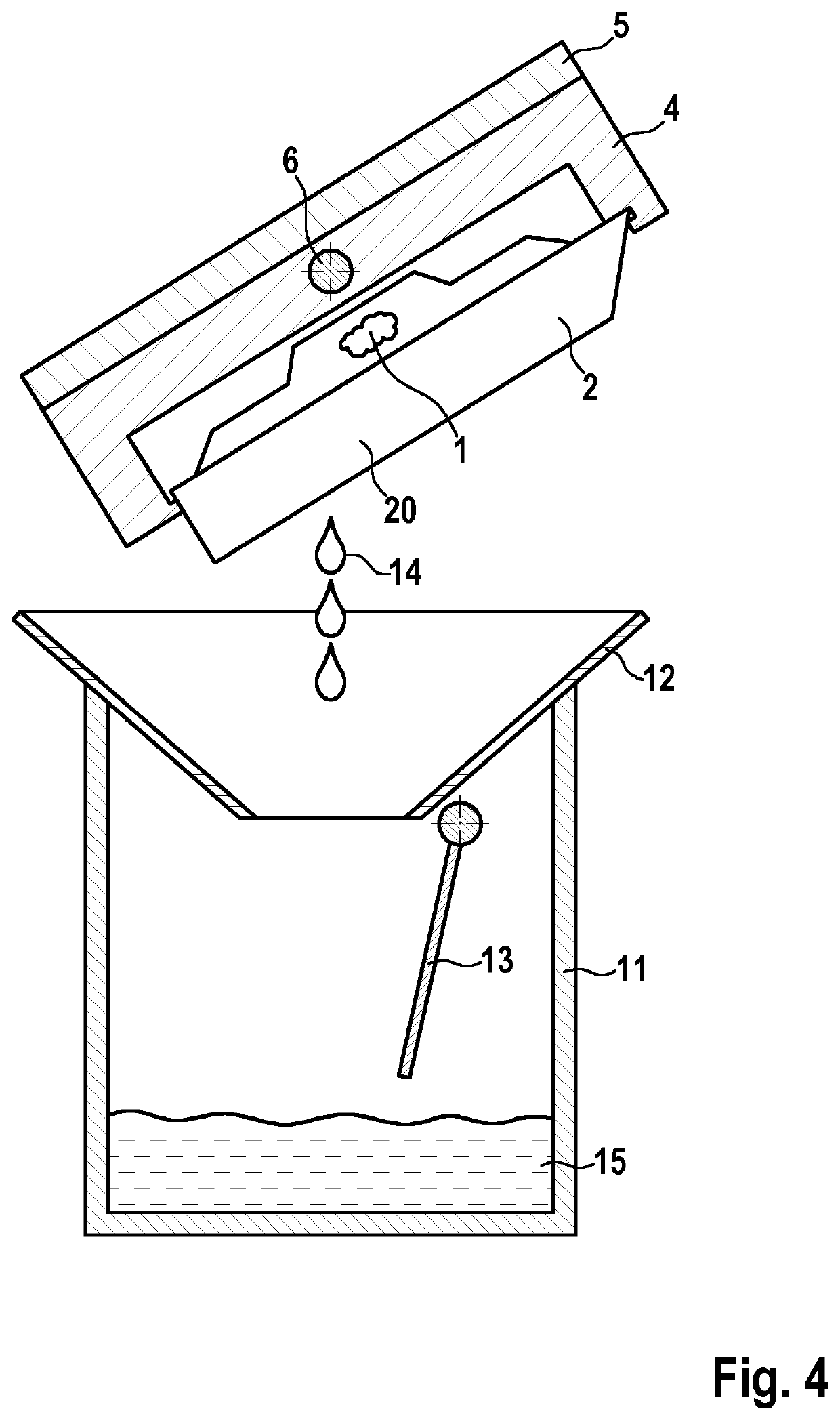

Device for preparing a tissue sample and particularly for producing a wax block containing a tissue sample

PendingUS20200166439A1Simple and reliable fashionIncrease device capacityPreparing sample for investigationMedicineTissue sample

The invention relates to an apparatus (1) for producing a wax block containing a tissue sample (1), comprising: a container (4) into which the tissue sample (1) is placed; and a dispensing apparatus (10) for dispensing different substances (8) into the container (4). The apparatus (1) according to the present invention is notable for the fact that it comprises an emptying device (23) for emptying the container (4); and a control unit (22) is provided, which is designed to apply control to the dispensing apparatus (10) and to the emptying device (23) in such a way that in several successive cycles, at least one of the substances is respectively dispensed into the container (4) and the container (4) is emptied again after a specific time period.

Owner:LEICA BIOSYST NUSSLOCH

A kind of separation and purification process of polyphenylene sulfide

ActiveCN109734912BCorrosiveness is not consideredReduce fermentation costsProcess engineeringPhenyl sulfide

The invention discloses a process for separating and purifying polyphenylene sulfide. The process includes (1), separating the granular polyphenylene sulfide from mixtures with the polyphenylene sulfide by centrifugal machines, and mixing the remaining mixtures and diatomaceous earth with one another in mixing kettles to obtain mixtures A; (2), connecting outlets of the mixing kettles with pumps,connecting outlets of the pumps with regulating valves, connecting the regulating valves with plate hermetic filters, conveying the mixtures A to the plate hermetic filters by the pumps and filteringthe mixtures A to obtain solid materials and filter liquor B; (3), delivering the filter liquor B into rectification systems and rectifying the filter liquor B. The process has the advantages that theself-operated regulating valves and the plate hermetic filters are used with one another, the diatomaceous earth is applied to procedures for separating and purifying the polyphenylene sulfide, accordingly, the problems of pump and rectification tower blockage due to materials, the requirement on detaching tower equipment for clearing or washing the tower equipment and material leakage can be effectively solved by the aid of the process, product loss further can be reduced, environmental pollution can be abated, and the productivity can be improved.

Owner:ZHUHAI CHANGXIAN CHEM TECH

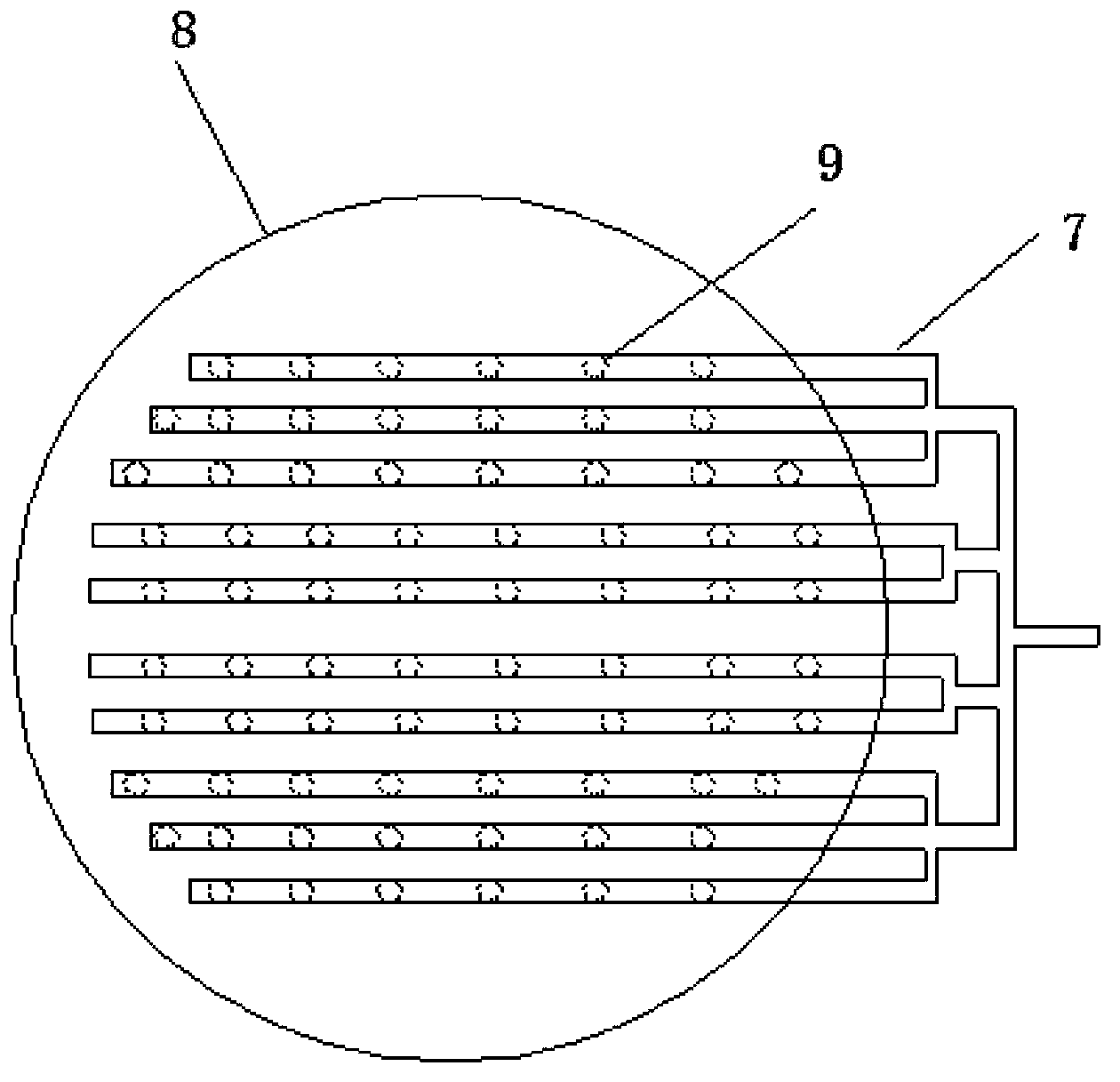

Thickening process of coarse adipic acid

ActiveCN102731289BShort filter cycleEasy to operateStationary filtering element filtersCarboxylic compound separation/purificationAutomatic controlAdipic acid

The invention provides a thickening process of coarse adipic acid. In the thickening process, a static bundling-type thickener is used. The thickener consists of a thickener shell side and a thickener tube side; a candlewick-type filter element is used; and a filter tube of the thickener tube side is provided with a plurality of filter elements. The time sequence automatic control procedure is adopted in the whole operation process, comprises the steps of feeding, online cleaning of filter cloth, re-feeding, pre-filtering, filtering, draining feed liquid, exhausting air and removing filter cakes, wherein the whole filtering process lasts for 12-20 minutes, preferably 14 minutes. The thickening process of coarse adipic acid solves the problems of high fault rate, poor production continuity and limited capacity of the conventional thickener. By the thickening process, the operation period is short, the fault rate of equipment is low, the continuous operation period of a thickening system is as long as one year, and the production capacity of equipment is greatly improved, so that the thickening process has high industrial application value.

Owner:CHINA TIANCHEN ENG +1

Container drying device

InactiveUS9097460B2Increase device capacityRobust and sturdyDrying solid materials without heatDrying chambers/containersMechanical engineeringEngineering

Container drying device of the spin-dryer type includes at least two booths, each being adapted to accommodate at least one stack of containers, the at least one stack of containers being loaded into the at least two booths in a loading direction, an axis of rotation about which the container drying device being rotatable, extending in a direction substantially perpendicular to the loading direction, and being arranged centrally in the container drying device; and a closing device being movable between a closed position in which the closing device closes the at least two booths at least partially and an open position in which the at least one stack of containers may be loaded into and / or removed from each of the at least two booths, the at least two booths being arranged excentrically, symmetrically on opposite sides of the axis of rotation and substantially in parallel with each other.

Owner:SEMI STAAL

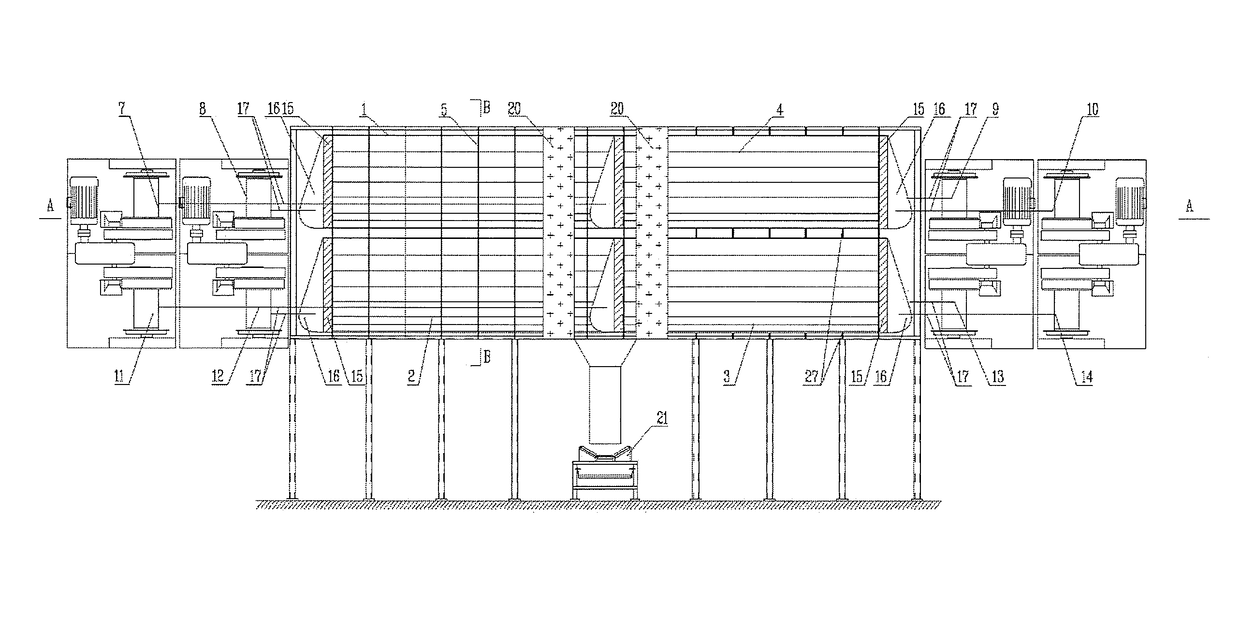

Sludge recycling treatment system of urban sewage plant

ActiveUS9944531B2Increase device capacityLow investment costSludge treatment by de-watering/drying/thickeningCarbon compoundsResource utilizationEngineering

A sludge recycling treatment system of an urban sewage plant includes solar sludge drying and sludge roasting and activated carbon manufacturing devices. The solar sludge drying device has a sealing box, flat plate conveyor belts, and a conveyor belt traction device. The sludge roasting and activated carbon manufacturing device has a rotary kiln and feeding, conveyor, discharging, and flue gas recycling apparatuses. The flat plate conveyor belts are stepped and concave-convex manufactured from stainless or anti-corrosion carbon steel. Sludge roasting and activated carbon manufacturing is implemented mainly by a rotary kiln to heat a rotary drum wall therein to heat materials. The kiln has automatic feeding and discharging apparatuses. Harmless treatment and resource utilization of urban sludge converts the sludge from waste to wealth, and fully utilizes solar energy to reduce energy consumption during sludge treatment. During production and operation, no reagent is needed, and no secondary pollution is caused.

Owner:YIXING NEW JINSHAN ENVIRONMENTAL PROTECTION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com