A kind of separation and purification process of polyphenylene sulfide

A polyphenylene sulfide and process technology, which is applied in the field of separation and purification of polyphenylene sulfide, can solve problems such as material leakage, achieve the effects of long continuous use time, increase labor productivity, and reduce product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

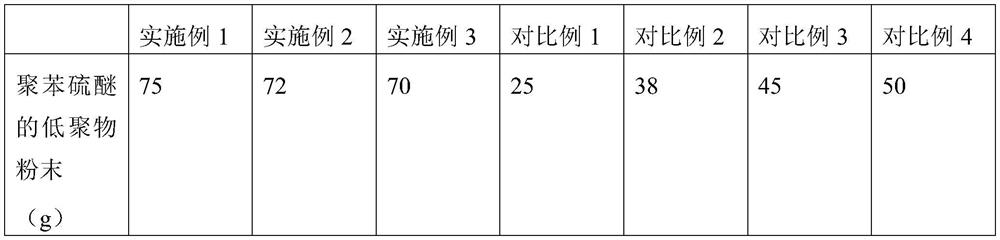

Embodiment 1

[0034] A separation and purification process of polyphenylene sulfide, the specific steps are as follows:

[0035] (1) The mixture containing polyphenylene sulfide produced by 1Kg of industrial production is first separated by a centrifuge to separate granular polyphenylene sulfide, and the remaining mixture and diatomaceous earth are mixed in a mixing tank (containing a mixture of polyphenylene sulfide and diatoms) The mass ratio of soil is 100:1) fully stir and mix in the mixing tank (the time of stirring and mixing at 20-30°C is 15 minutes, the stirring speed is 16.5 rpm), and the mixture A is prepared;

[0036] (2) The outlet of the mixing kettle is connected with the pump, and the outlet of the pump is connected with the self-operated control valve, and the self-operated control valve is connected with the Ama filter, and the mixture A is transported to the Ama filter by the action of the pump, and filtered to obtain Oligomer powder and filtrate B of polyphenylene sulfide...

Embodiment 2

[0042] A separation and purification process of polyphenylene sulfide, the specific steps are as follows:

[0043] (1) The mixture containing polyphenylene sulfide produced by 1Kg of industrial production is first separated by a centrifuge to separate granular polyphenylene sulfide, and the remaining mixture and diatomaceous earth are mixed in a mixing tank (containing a mixture of polyphenylene sulfide and diatoms) The mass ratio of soil is 100:0.5) and fully stirred and mixed in the mixing tank (the stirring and mixing time is 30 minutes at 20-30°C, and the stirring speed is 10 rpm), and the mixture A is prepared;

[0044] (2) The outlet of the mixing kettle is connected with the pump, and the outlet of the pump is connected with the self-operated regulating valve, and the self-operated regulating valve is connected with the Ama filter, and the mixture A is transported to the Ama filter by the action of the pump, and filtered to obtain Oligomer powder and filtrate B of polyp...

Embodiment 3

[0050] A separation and purification process of polyphenylene sulfide, the specific steps are as follows:

[0051] (1) The mixture containing polyphenylene sulfide produced by 1Kg of industrial production is first separated by a centrifuge to separate granular polyphenylene sulfide, and the remaining mixture and diatomaceous earth are mixed in a mixing tank (containing a mixture of polyphenylene sulfide and diatoms) The mass ratio of soil is 100:2) fully stir and mix in the mixing tank (the time of stirring and mixing at 25°C is 20 minutes, the stirring speed of the mixing tank is 20 rpm), and the mixture A is prepared;

[0052] (2) The outlet of the mixing kettle is connected with the pump, and the outlet of the pump is connected with the self-operated control valve, and the self-operated control valve is connected with the Ama filter, and the mixture A is transported to the Ama filter by the action of the pump, and filtered to obtain Oligomer powder and filtrate B of polyphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com