Method for improving property of dihydrate wet-process phosphoric acid reaction slurry

A technology of wet-process phosphoric acid and reaction materials, which is applied in the direction of phosphoric acid, phosphorus oxyacids, chemical instruments and methods, etc., which can solve the problem of equipment production capacity, washing rate, phosphorus pentoxide recovery rate, and affecting reaction slurry filtration and washing performance , finely crushed phosphogypsum crystals, etc., to improve filtration and washing performance, increase filtration strength and device capacity, and increase filtration strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

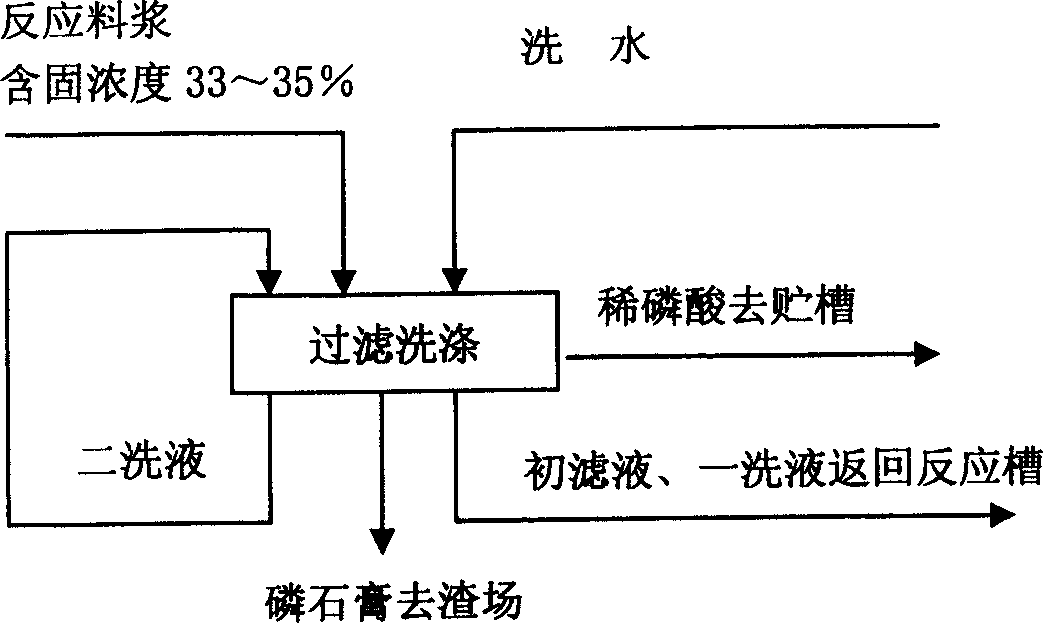

Problems solved by technology

Method used

Image

Examples

Embodiment 1

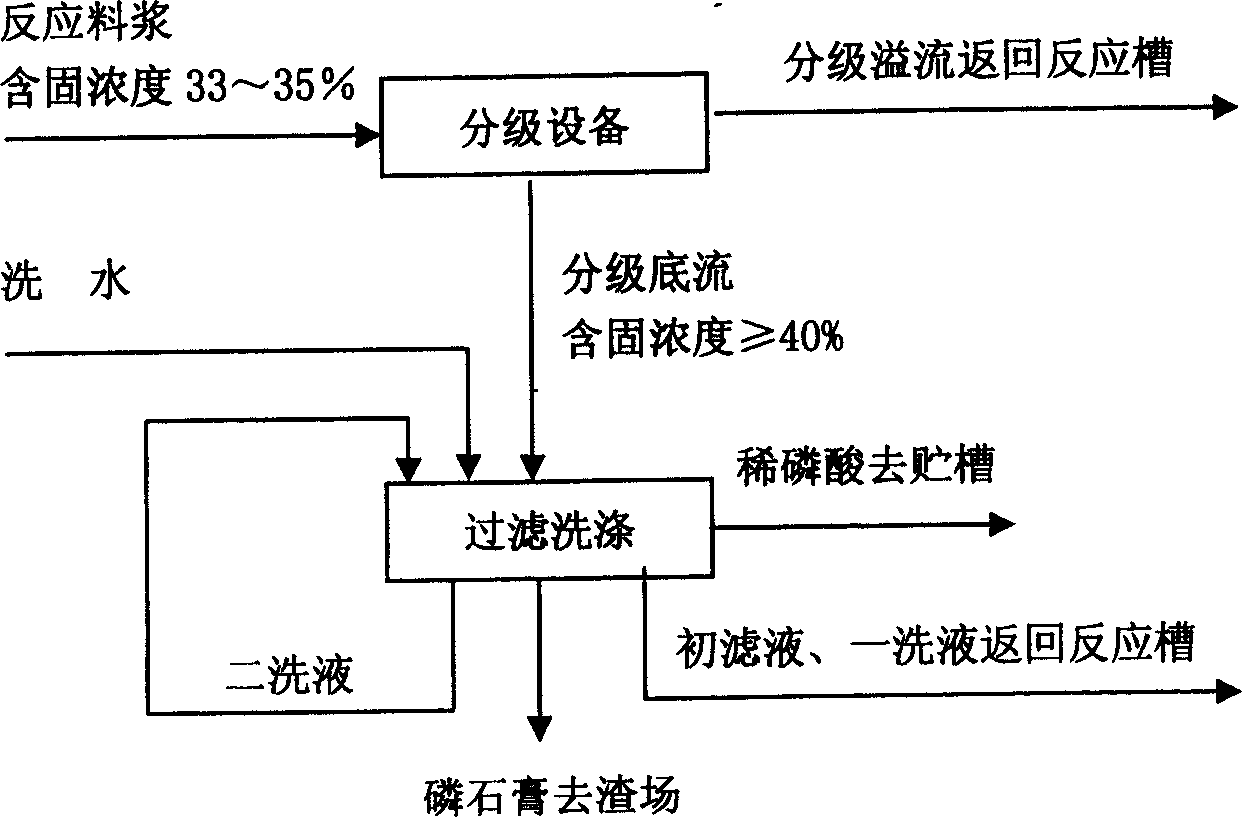

[0025] In Yunnan Sanhuan Chemical Co., Ltd. 70kt P 2 o 5 / a On the dihydrate wet-process phosphoric acid production unit, the cyclone is used to classify the reaction slurry. Then the phosphogypsum crystal particle size is 91% of +40um particles, 54% of +100um particles, 22% of +150um particles, and the graded underflow with a solid concentration of 43% is sent to the filter for filtration and wash.

[0026] The contained phosphogypsum crystal grain size is -40um particle proportion rate is 82%, -100um particle proportion rate is 100%, the graded overflow with solid concentration of 30% is sent back to the reaction tank, and the finely divided particles contained in the graded overflow Phosphogypsum crystals are used as seeds to further grow and increase in the reaction tank.

[0027] The filtered and washed phosphogypsum is sent to the slag yard, the dilute phosphoric acid is sent to the storage tank, and the primary filtrate and a washing liquid are returned to the reacti...

Embodiment 2

[0030] Except that described grading equipment adopts inclined plate classifier, other production process is identical with embodiment 1.

Embodiment 3

[0032] Repeat Example 1, with the following differences: the contained phosphogypsum crystal grain size is 95% of +40um particles, 65% of +100um particles, and 35% of +150um particles, and the solid concentration is 50% % of the graded underflow is sent to the filter for filtration and washing. Send the phosphogypsum crystalline particle size of -40um particles to 85%, the proportion of -100um particles to 100%, and the grading overflow with a solid concentration of 20% to be sent back to the reaction tank. Phosphogypsum crystals are used as seeds to further grow and increase in the reaction tank. Comprehensive effect of implementation: the filtration strength of the reaction slurry is increased by 16.8%, and the washing rate is increased by 0.65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com