Patents

Literature

35results about How to "Improve filter strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

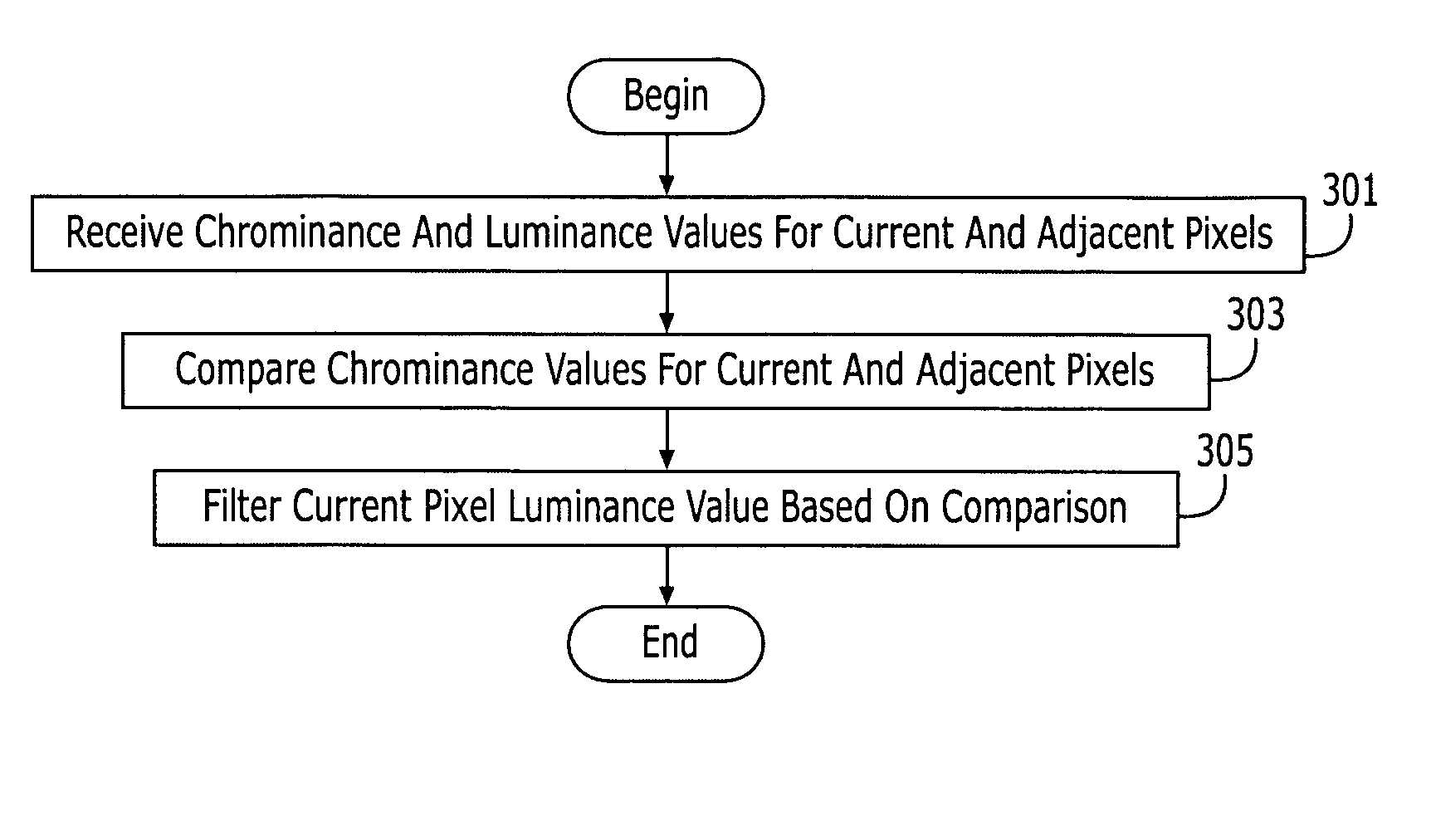

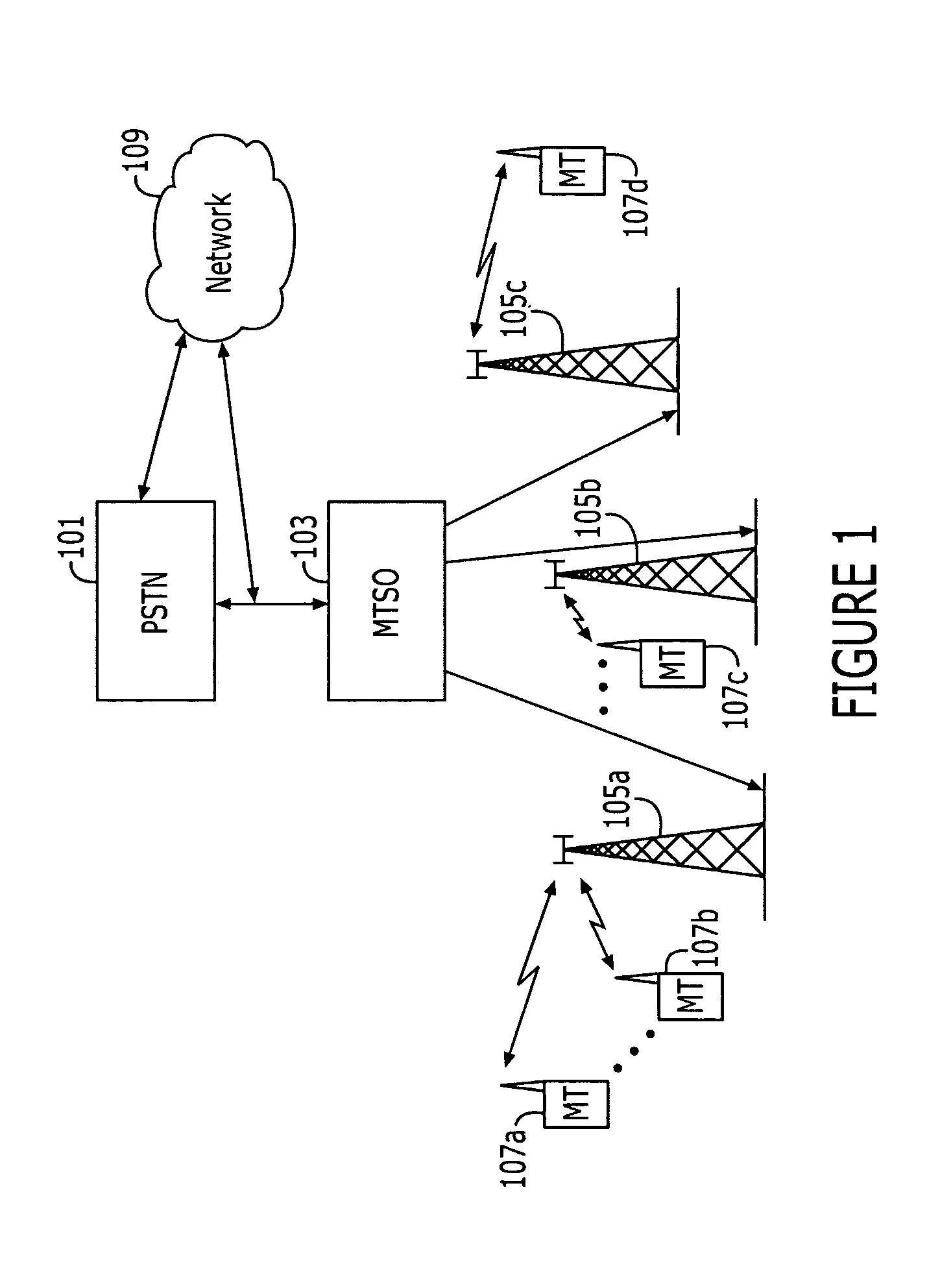

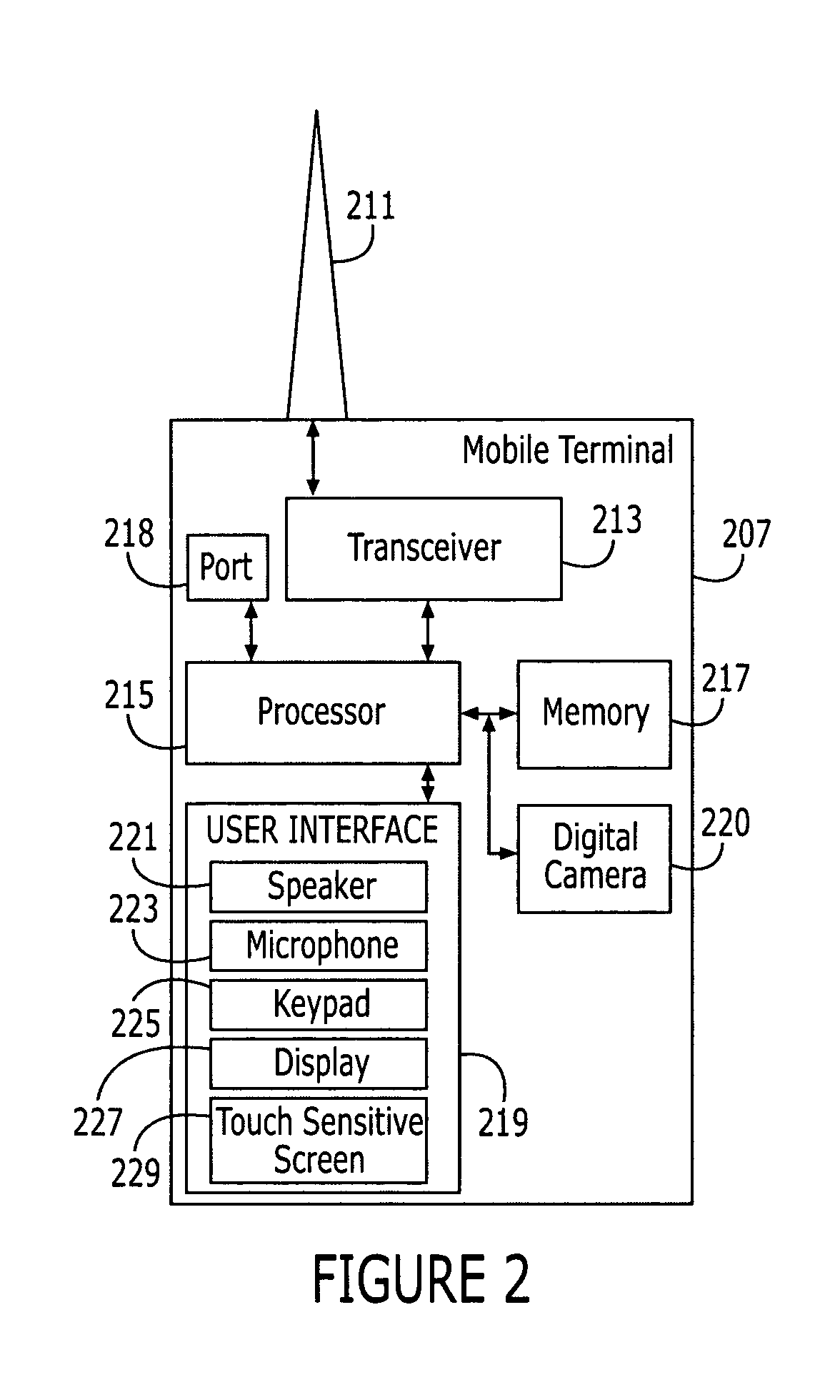

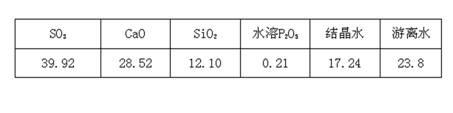

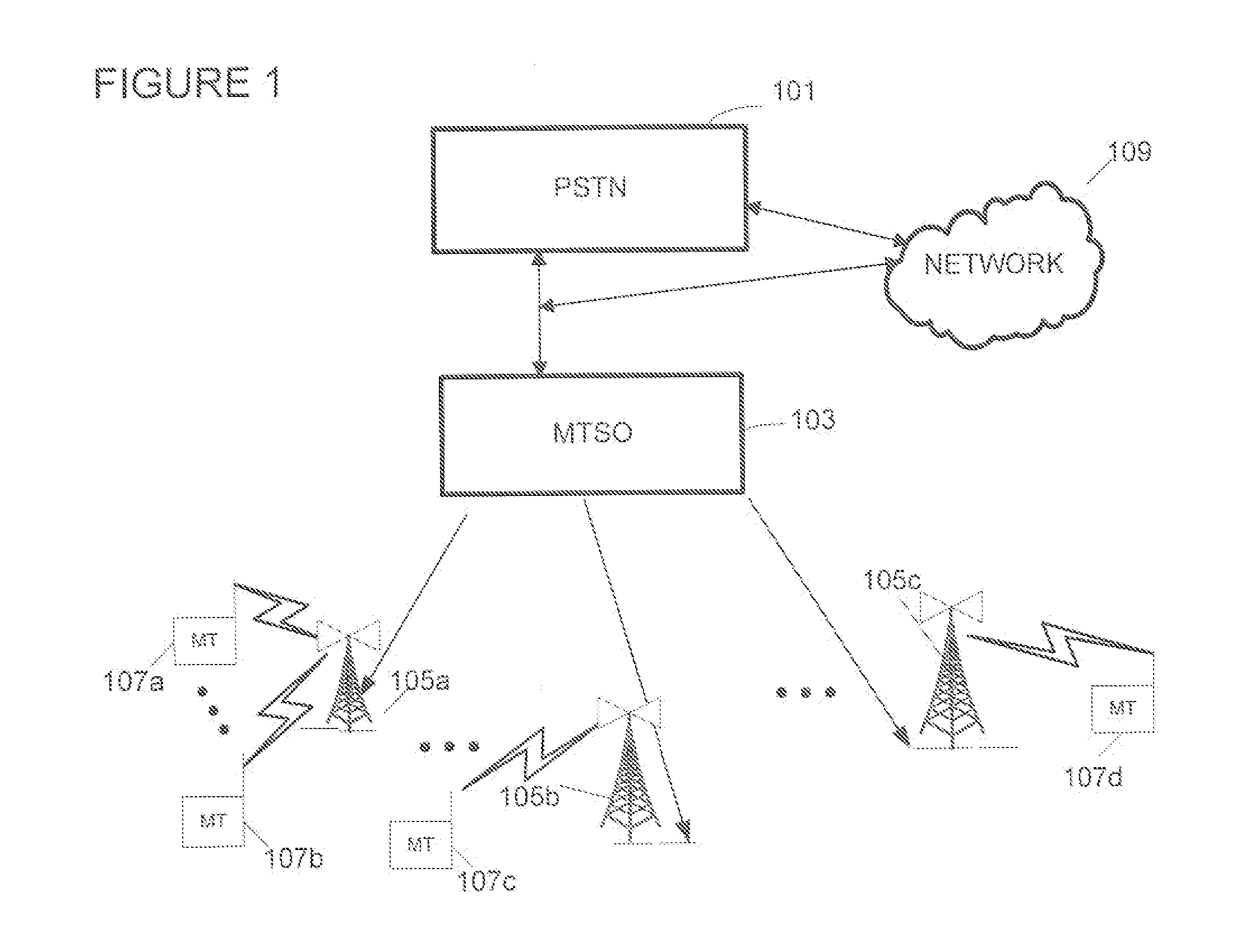

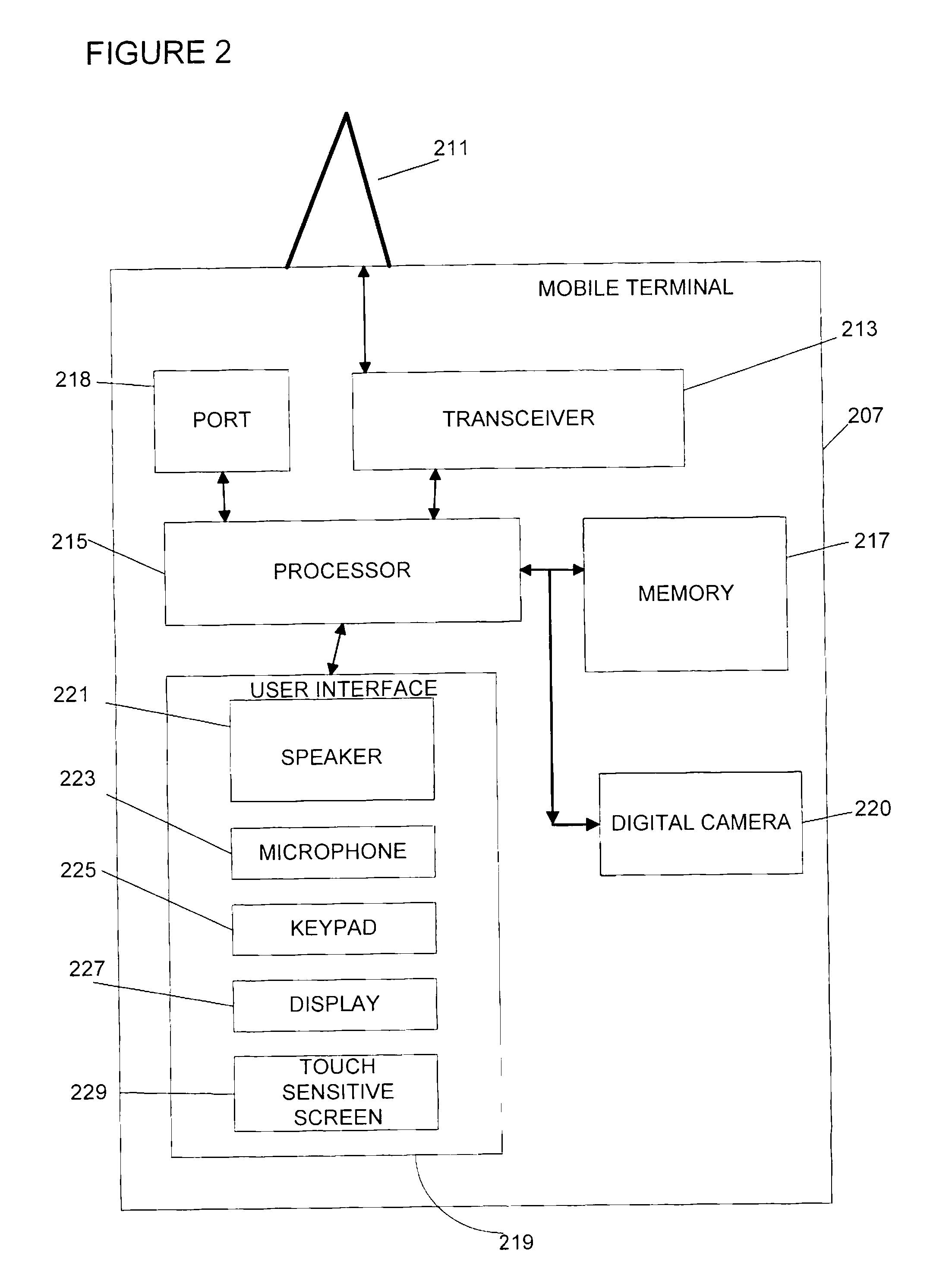

Methods of processing digital image and/or video data including luminance filtering based on chrominance data and related systems and computer program products

InactiveUS20050094003A1Reduced strengthIncreased strengthTelevision system detailsImage enhancementComputer programChrominance

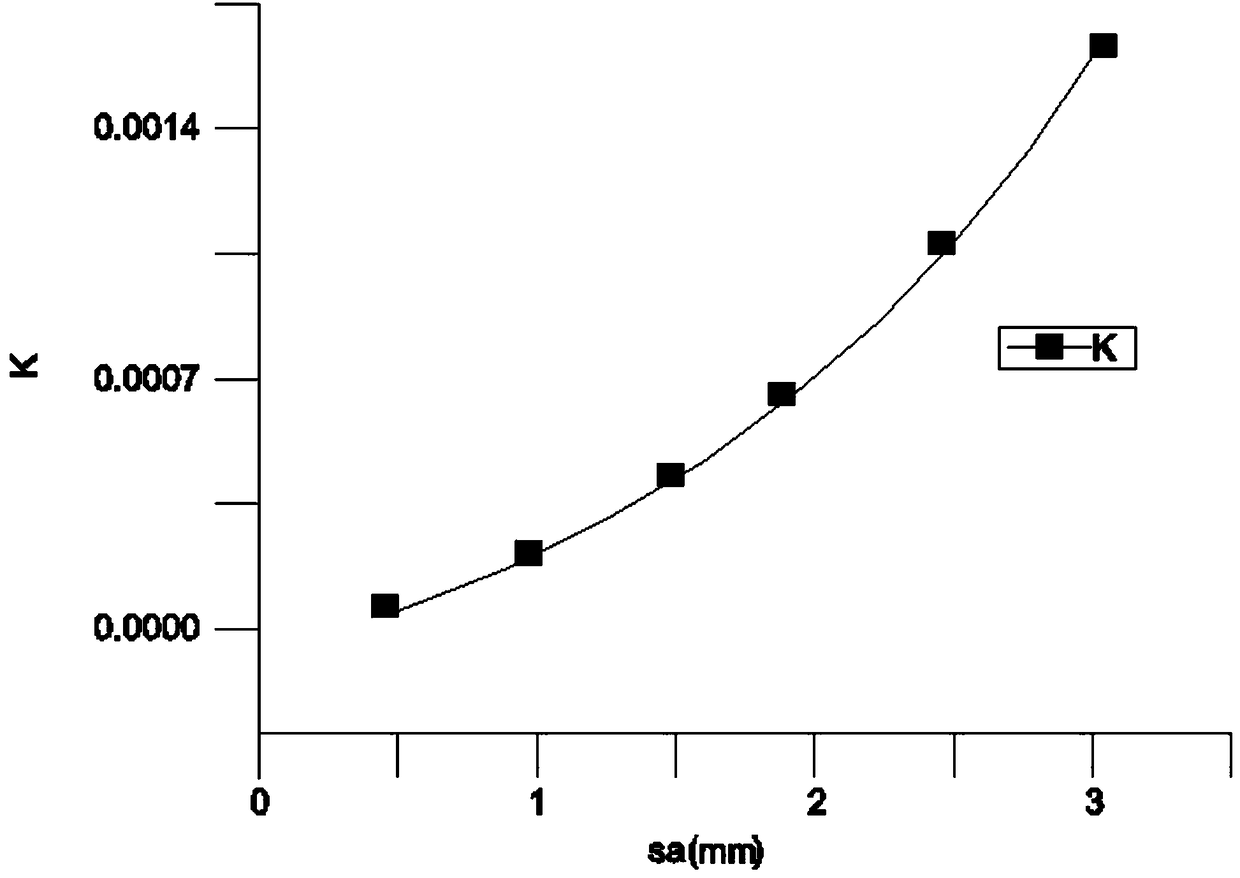

Digital image and / or video data is processed wherein a frame of the data comprises a plurality of rows and columns of pixels with data for each pixel including a luminance value and a chrominance value. Chrominance values and luminance values may be received for a current pixel and at least one adjacent pixel, and the chrominance values of the current pixel and the at least one adjacent pixel may be compared. The luminance value of the current pixel may be filtered wherein a strength of filtering the luminance value is based on the comparison of the chrominance values of the current and at least one adjacent pixels.

Owner:TELEFON AB LM ERICSSON (PUBL)

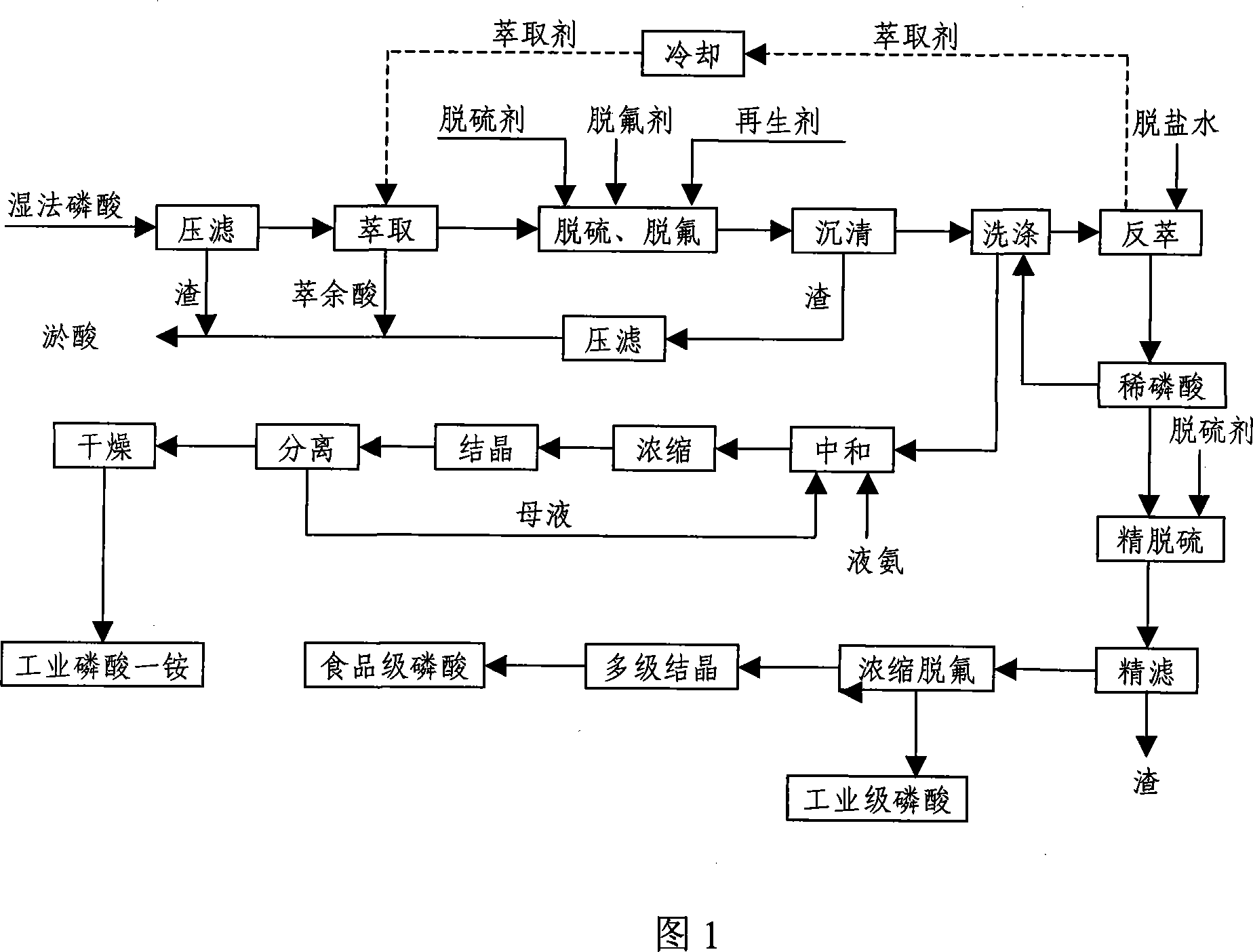

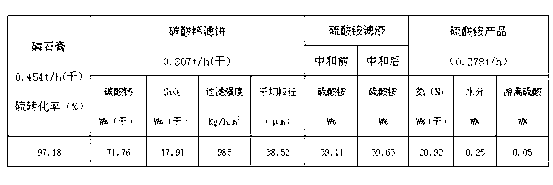

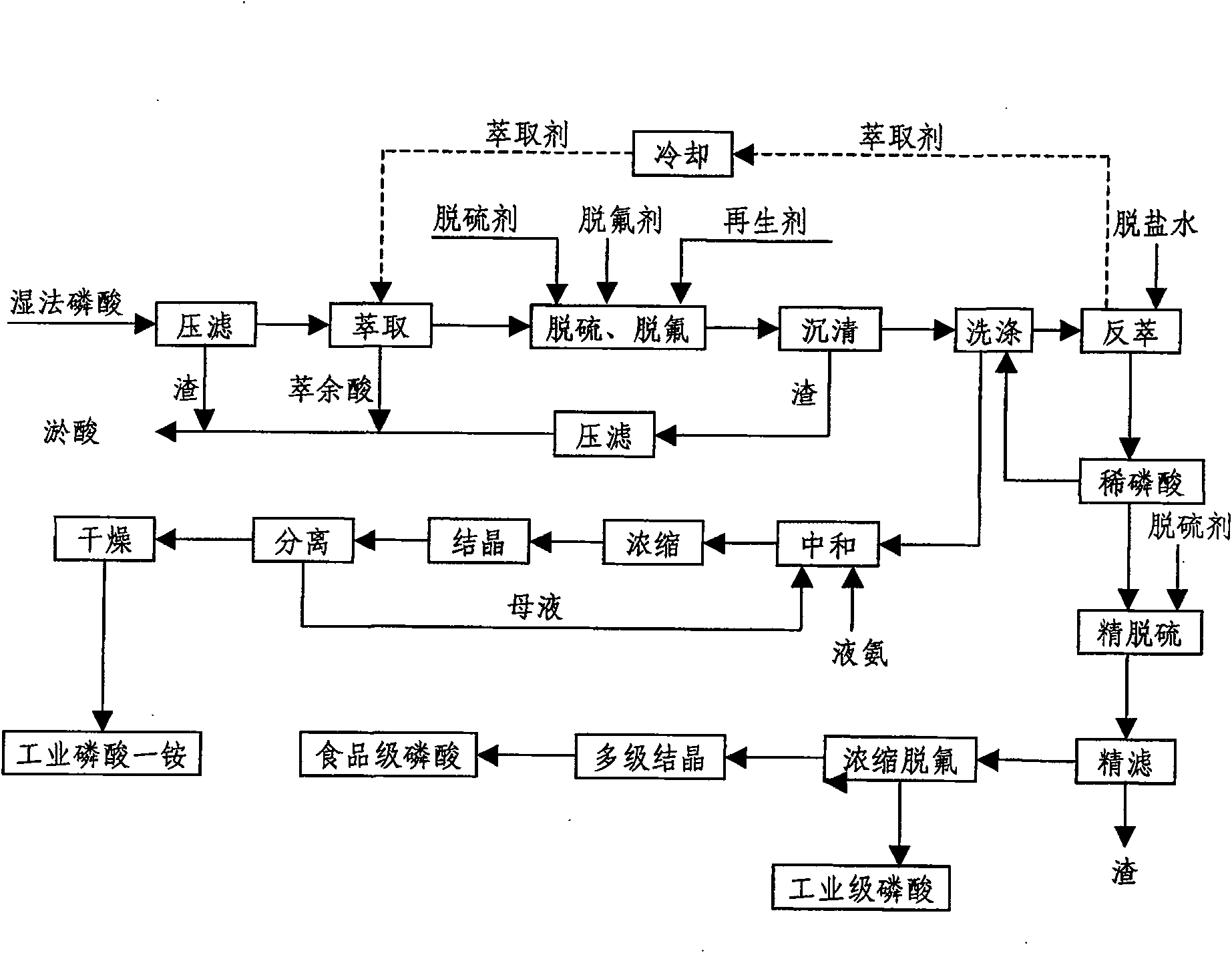

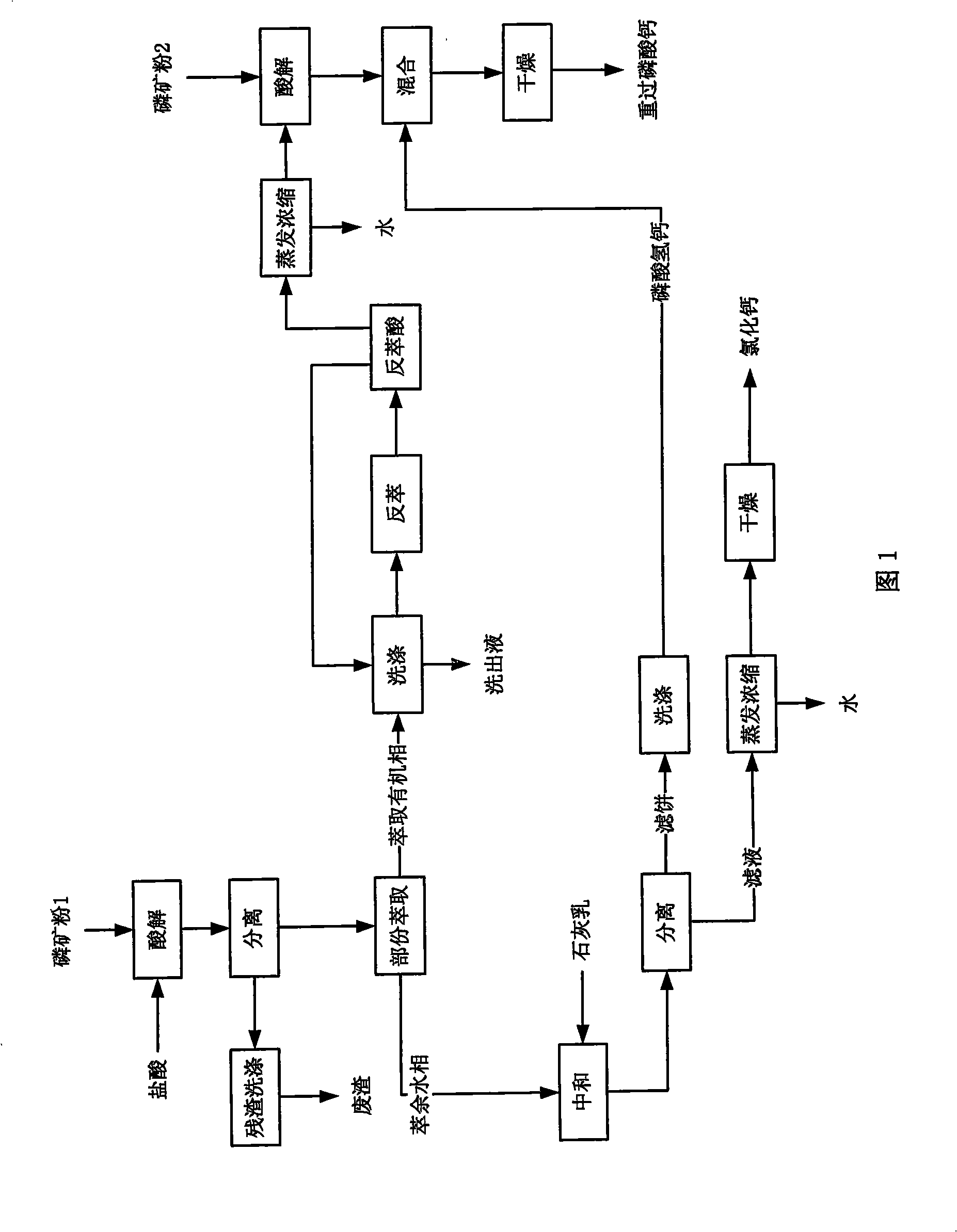

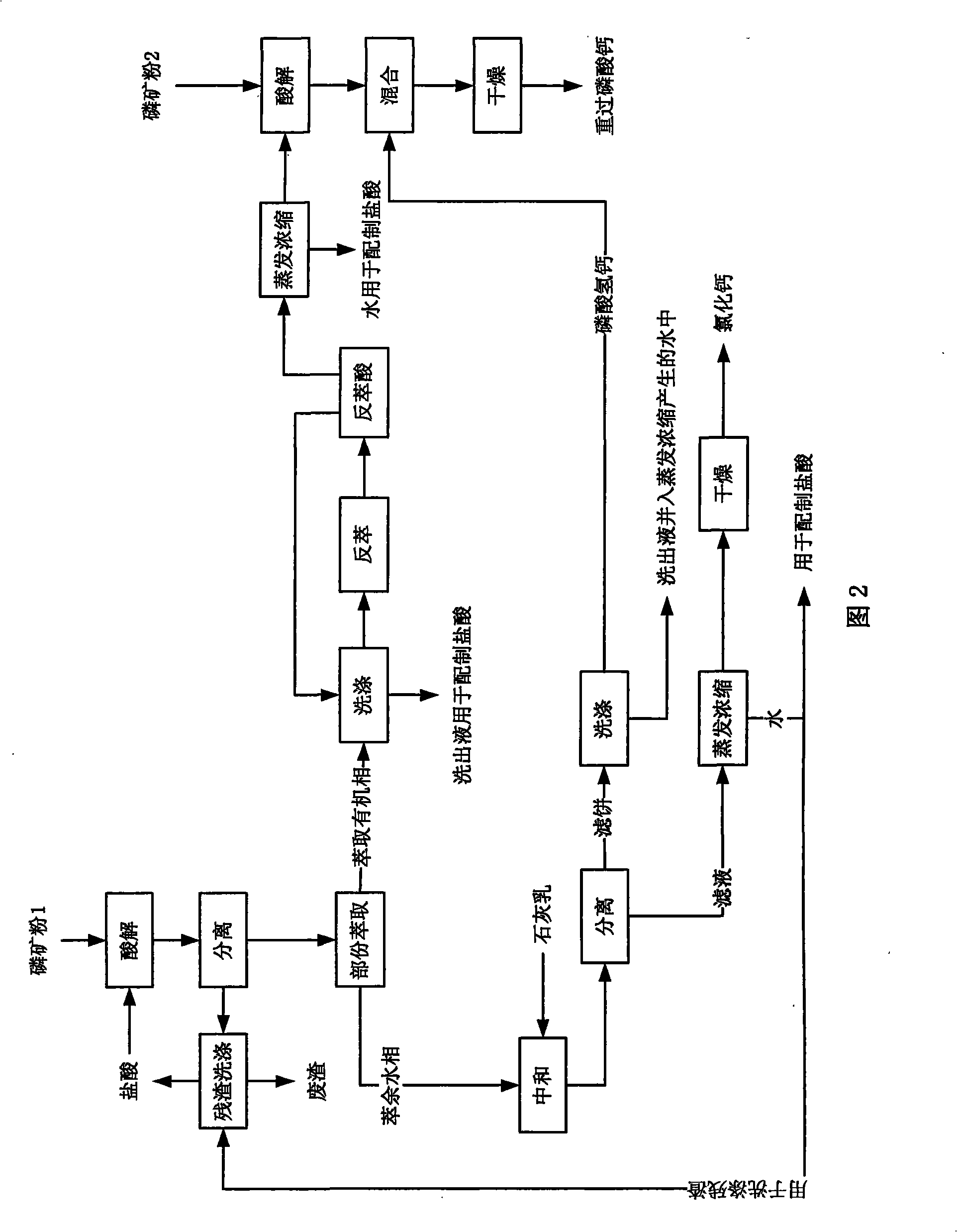

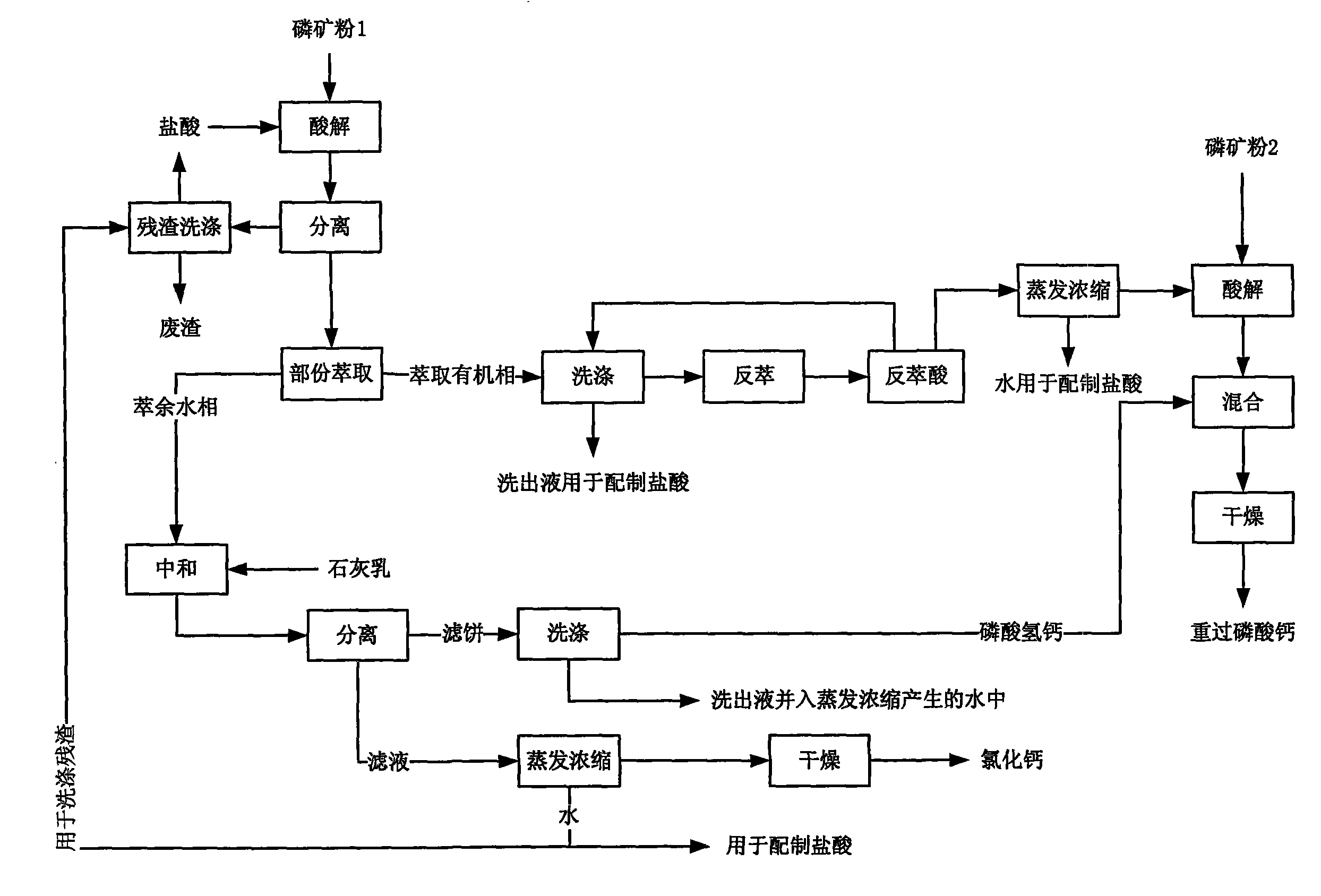

Method for producing technical grade ribose phosphate, food grade ribose phosphate and industry ammonium diacid phosphate using wet-process ribose phosphate

The invention discloses a method of using wet phosphoric acid to prepare industrial grade phosphoric acid, food grade phosphoric acid and industrial ammonium diacid phosphate, which is characterized in using wet phosphoric acid as the material, and preparing industrial grade phosphoric acid and food grade phosphoric acid respectively by using a series of compound purifying technologies such as chemical sedimentation and extracting by organic solvent and concentration and recrystallization and other technologies; meanwhile, the invention uses a part of purified diluted phosphoric acid to prepare industrial ammonium diacid phosphate. The invention has the advantages of reasonable cascade utilization of the wet phosphoric acid, high additional value of phosphorus, and further exploitation of the lower industrial and food grades phosphate.

Owner:中化重庆涪陵化工有限公司

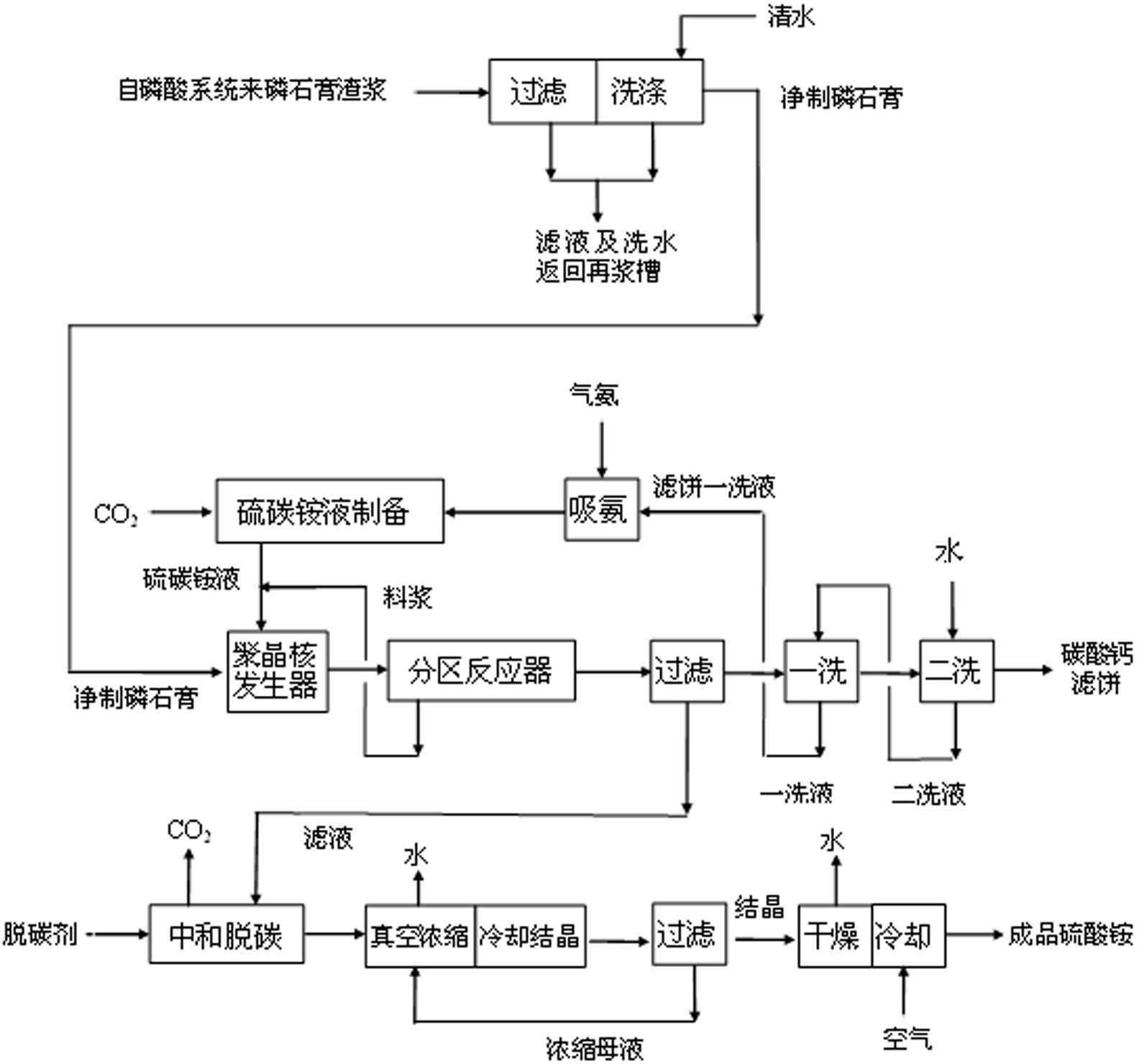

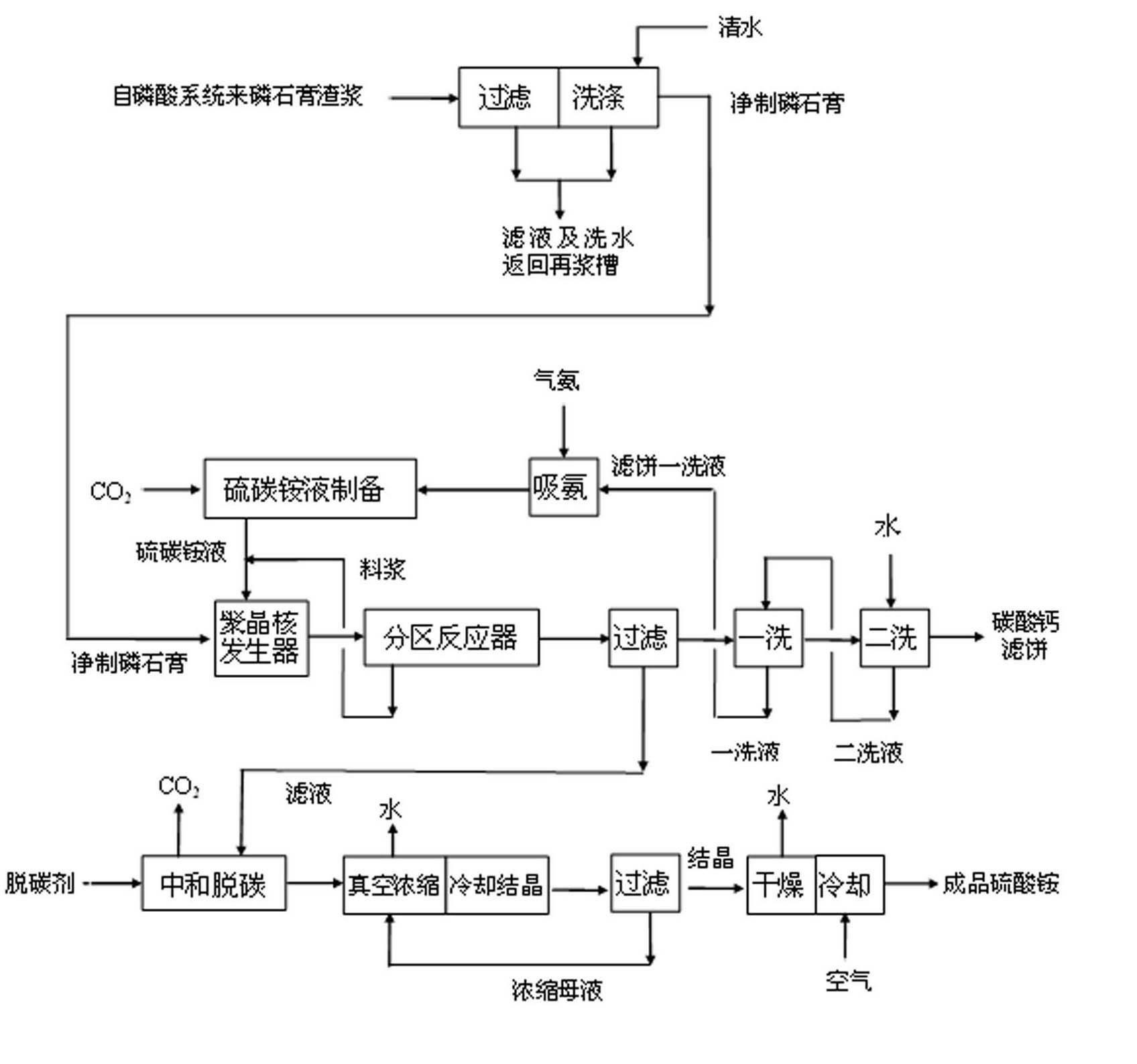

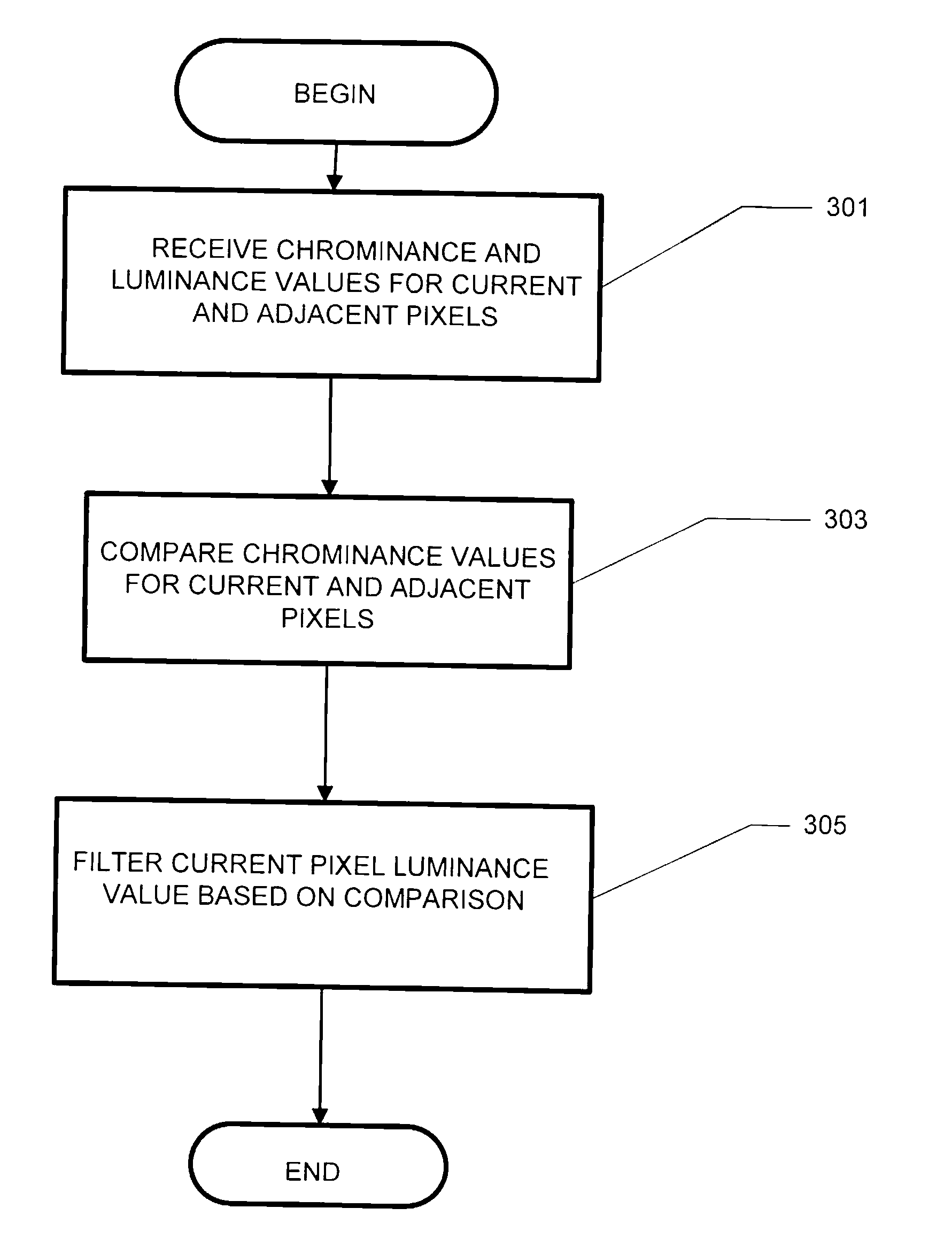

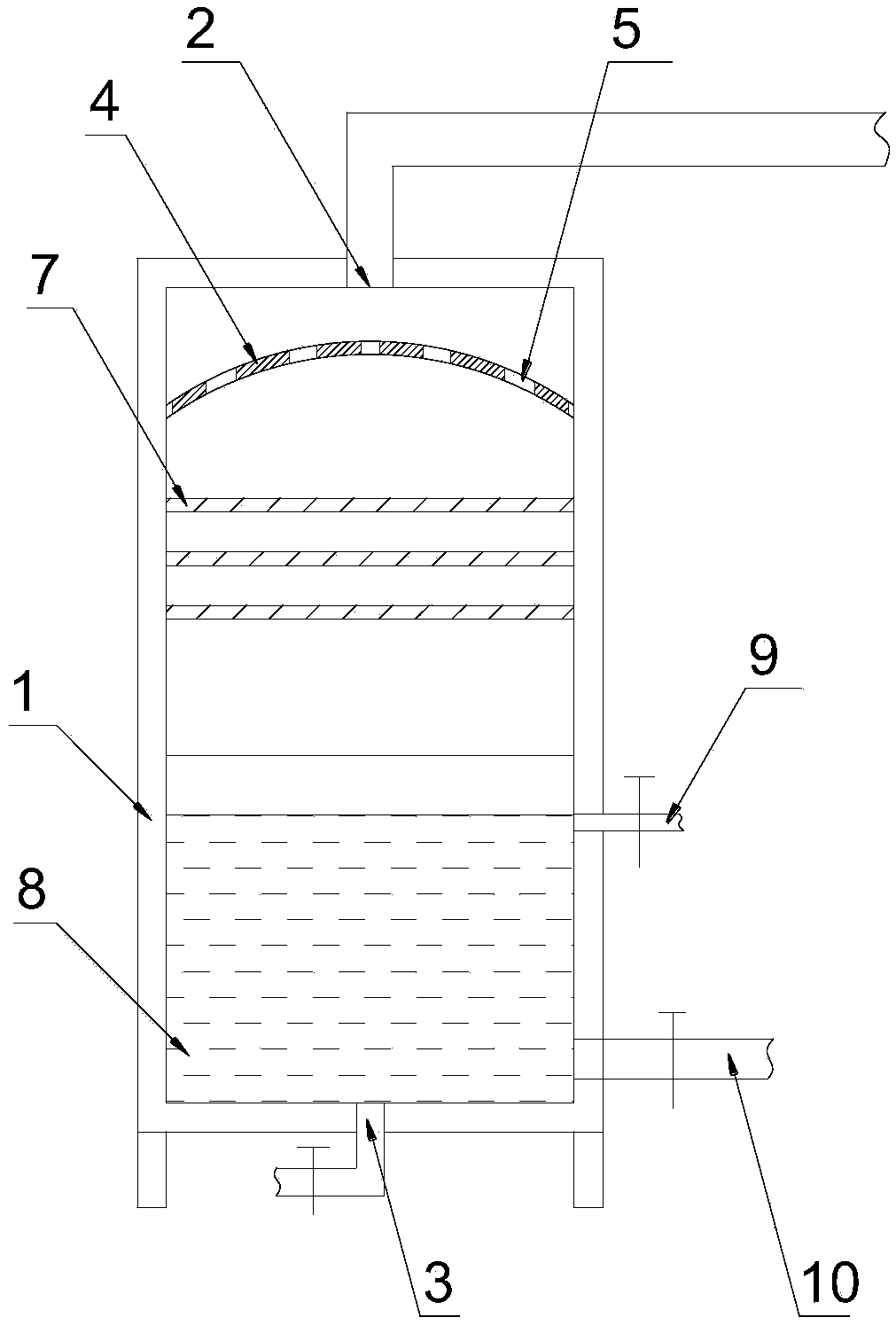

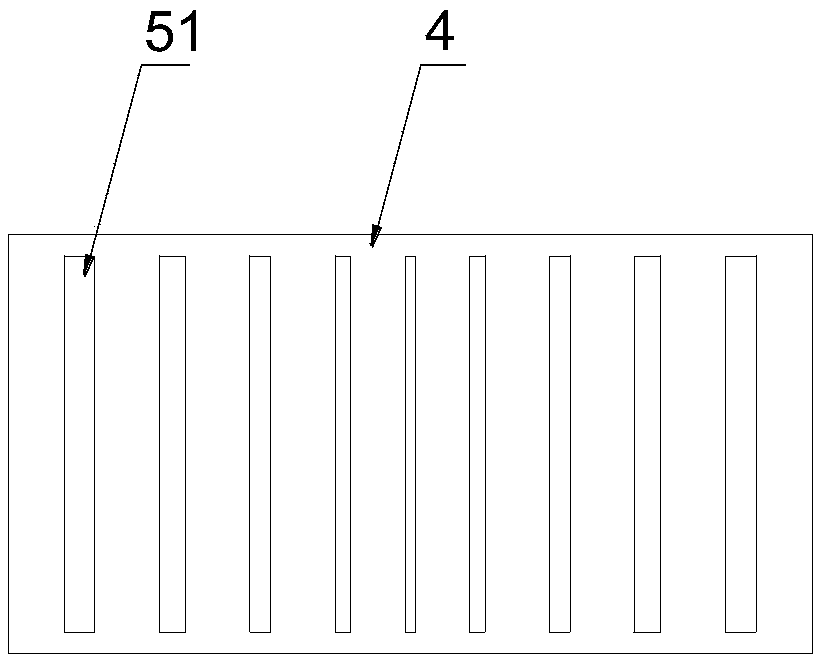

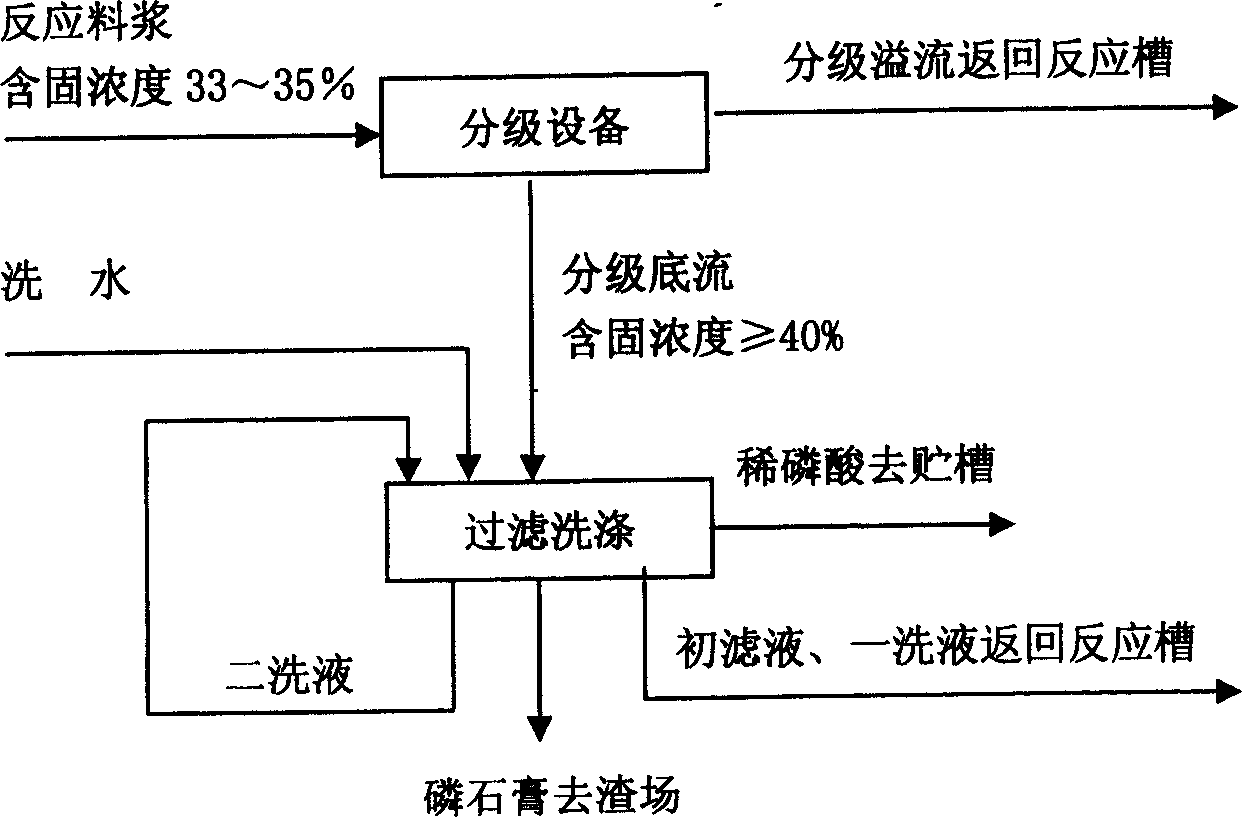

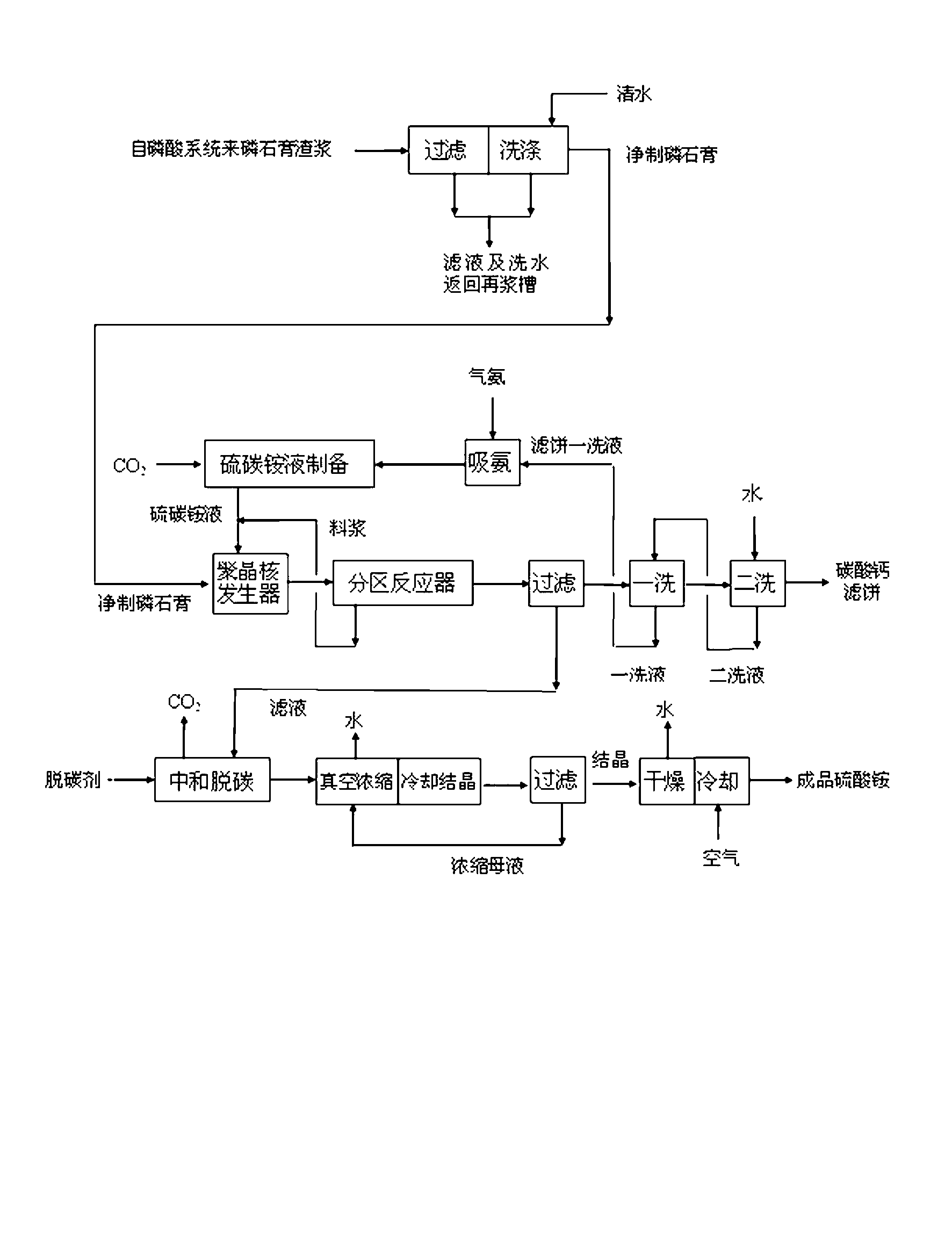

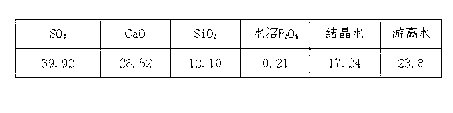

Method for preparing ammonium sulfate by conversion of phosphogyspum with polycrystalline method

ActiveCN102303874AImprove filter strengthEmission reductionAmmonium sulfatesChemical industryO-Phosphoric Acid

The invention relates to a method for preparing ammonium sulfate by continuous conversion of phosphogyspum with a polycrystalline method, belonging to the technical fields of resource comprehensive utilization and chemical industry, and relates to a method for producing ammonium sulfate by conversion of phosphogyspum with a polycrystalline method based on a byproduct phosphogyspum in a (sulfuric acid) wet phosphoric acid industry as a main raw material. The production process comprises the following steps: (1) pretreating the raw material of phosphogyspum discharged in the wet phosphoric acidindustry so as to obtain purified phosphogyspum; (2) absorbing ammonia and carbon dioxide with a ammonia-sulfate-containing primary lotion which is produced by washing a calcium carbonate filter cakewith water in a filtration process in a carbonation tower so as to produce an ammonia sulfate and carbonate solution; (3) connecting a calcium carbonate polycrystalline nucleus generator with a multiple-tank or multiple-partition groove type reactor with a stirrer in series to constitute a conversion crystallizer; (4) filtering a reaction material slurry discharged from the conversion crystallizer so as to obtain a filter cake and filtrate containing 38-40% by weight of ammonium sulfate; (5) carrying out secondary countercurrent washing on the filter cake obtained in the step (4) with clear water, and feeding the ammonia-sulfate-containing primary lotion to the carbonation tower for absorbing gas ammonia and carbon dioxide so as to produce an ammonia sulfate and carbonate liquid; and (6) neutralizing and decarburizing the filtrate containing ammonium sulfate from the step (4) with sulfuric acid, then centrifugally separating so as to obtain a crystal containing wet ammonium sulfate, separating out a mother liquid, carrying out cycle concentration on the mother liquid, and drying the crystal containing wet ammonium sulfate so as to obtain a finished product ammonium sulfate.

Owner:YUNNAN CHEM RES INST

Methods of processing digital image and/or video data including luminance filtering based on chrominance data and related systems and computer program products

ActiveUS20070291141A1Reduce filter strengthImprove filter strengthTelevision system detailsImage enhancementDigital imageComputer science

Digital image and / or video data is processed wherein a frame of the data comprises a plurality of rows and columns of pixels with data for each pixel including a luminance value and a chrominance value. Chrominance values and luminance values may be received for a current pixel and at least one adjacent pixel, and the chrominance values of the current pixel and the at least one adjacent pixel may be compared. The luminance value of the current pixel may be filtered wherein a strength of filtering the luminance value is based on the comparison of the chrominance values of the current and at least one adjacent pixels.

Owner:OPTIS WIRELESS TECH LLC

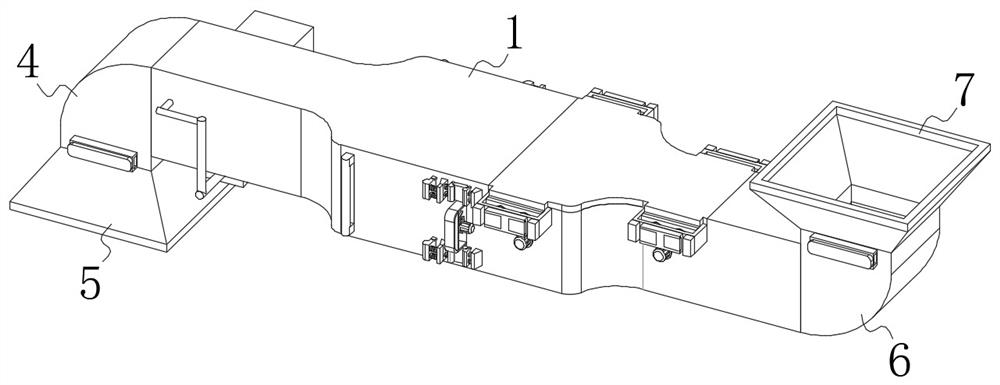

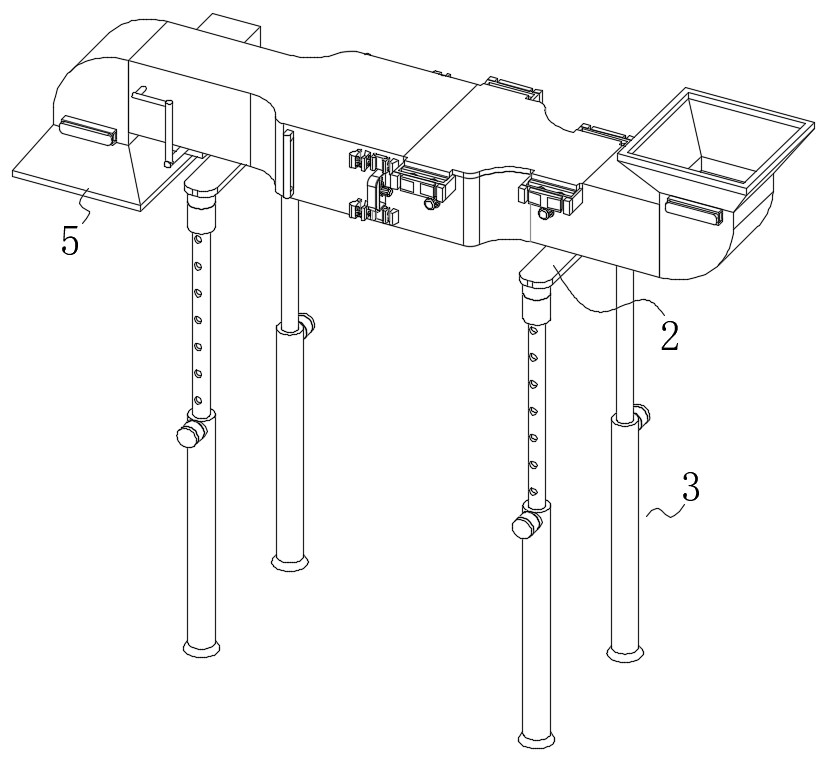

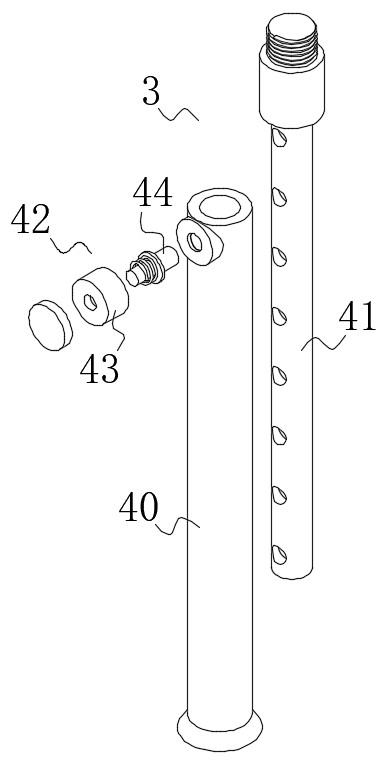

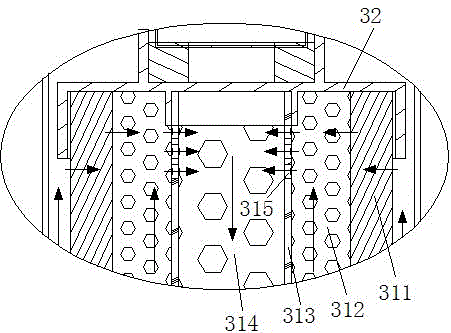

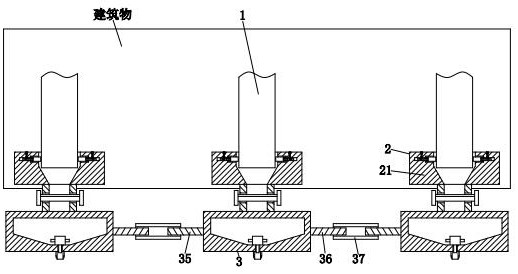

Equipment for recovering cooling liquid for machining tool

InactiveCN108654203AAvoid concentrationAvoid damageFiltration circuitsMaintainance and safety accessoriesEngineeringFilter effect

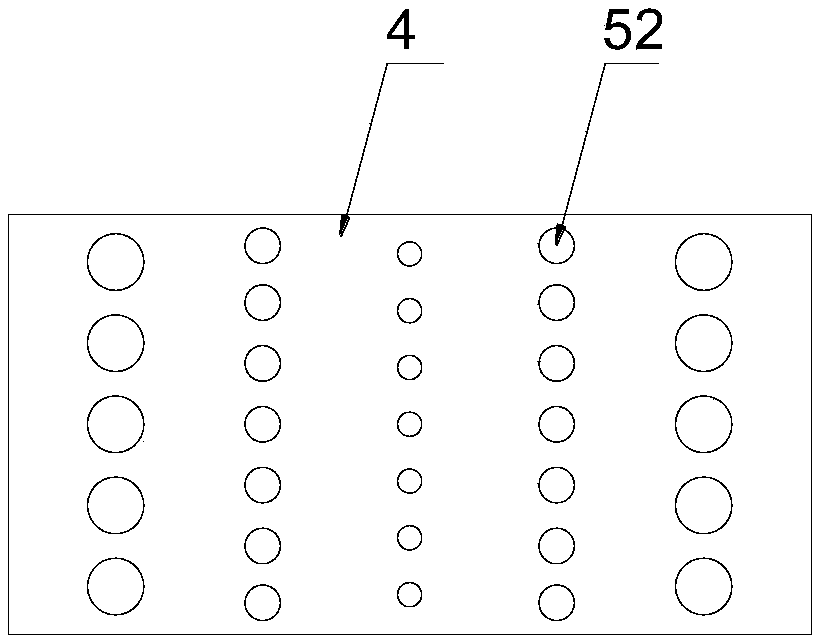

The invention discloses a piece of equipment for recovering a cooling liquid for a machining tool. The equipment comprises a recovering tank, a splitter plate and multiple layers of filter plates, thesplitter plate and the multiple layers of filter plates are arranged in the inner part of the recovering tank, the equipment further comprises a drainage pipe and a liquid outlet pipe; a liquid inletport used for connecting a liquid inlet pipe is arranged on the middle position of the top part of the recovering tank; the splitter plate is arranged at the upper part of the inner part of the recovering tank; the splitter plate is an arc plate, the middle part of the arc plate protrudes upwards, the width of the splitter plate is less than the width of the recovering tank; the splitter plate isprovided with a plurality of through holes; the filter plates are horizontally installed in the recovering tank, a plurality of layers of filter plates are vertically arranged and are arranged belowthe splitter plate; a storage cavity for placing the cooling liquid is formed at the lower part of the recovering tank; a first port and a second port are arranged on the side wall of the recovering tank; and a drainage end port used for connecting a water discharge pipe is arranged at the bottom part of the recovering tank. In the equipment, the cooling liquid is recycled, the filtering effect ofthe cooling liquid is good, and the equipment saves the energy and protects the environment.

Owner:芜湖中驰机床制造有限公司

Preparation method of nanometer silicon dioxide

ActiveCN102502669AImprove surface activityAvoid reunionSilicaNanotechnologyActive agentAmmonium fluorosilicate

The invention discloses a preparation method of nanometer silicon dioxide, which comprises the following steps of: adding lauryl sodium sulfate into ammonium fluorosilicate solution as a surfactant; introducing ammonia solution and carrying out ammoniation reaction on the ammonium fluorosilicate solution, wherein the adding quantity of ammonia is 110-150 percent of theoretical amount; reacting at a normal temperature, strictly controlling the agitating speed, the adding speed of the ammonia and the reaction time, controlling the aging time within 60-150 min, adding polypropylene solution as a filter aid and carrying out solid-liquid separation after agitation; and calcining after the silicon dioxide is precipitated, washed and dried to obtain silicon dioxide powder with a median grain size of between 38-55 nm. The preparation method has the beneficial effects that as the ammonium fluorosilicate and the ammonia are taken as raw materials to prepare the nanometer silicon dioxide, and the lauryl sodium sulfate is taken as the surfactant, the surface activity of the silicon dioxide is improved; the reaction conditions are strictly controlled to prepare a silicon dioxide product with excellent performance; and the integrity of silicon dioxide powder crystals is ensured.

Owner:WENGFU (GRP) CO LTD

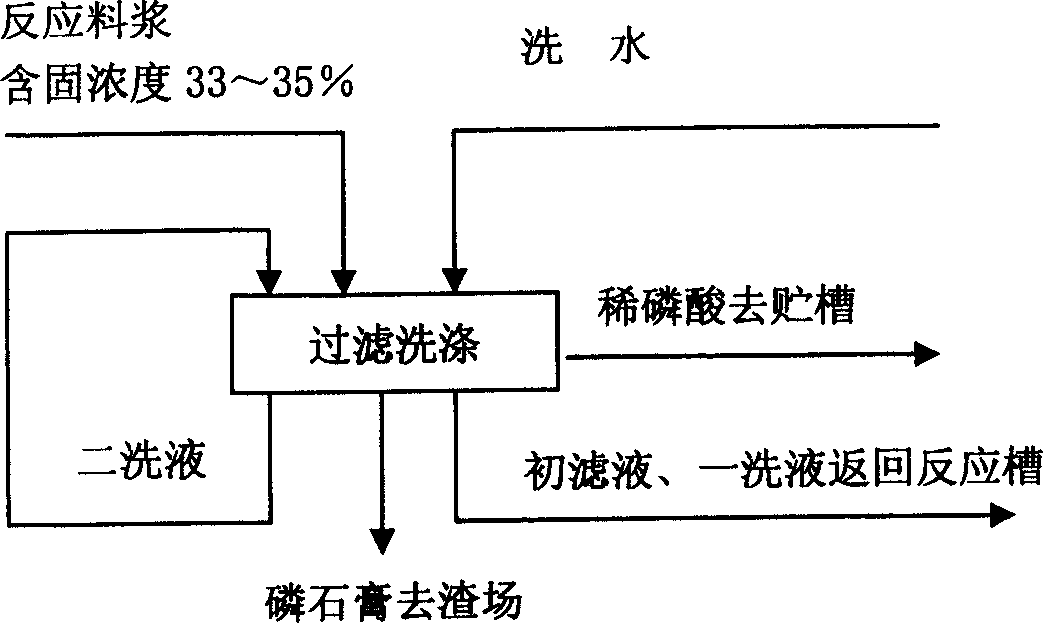

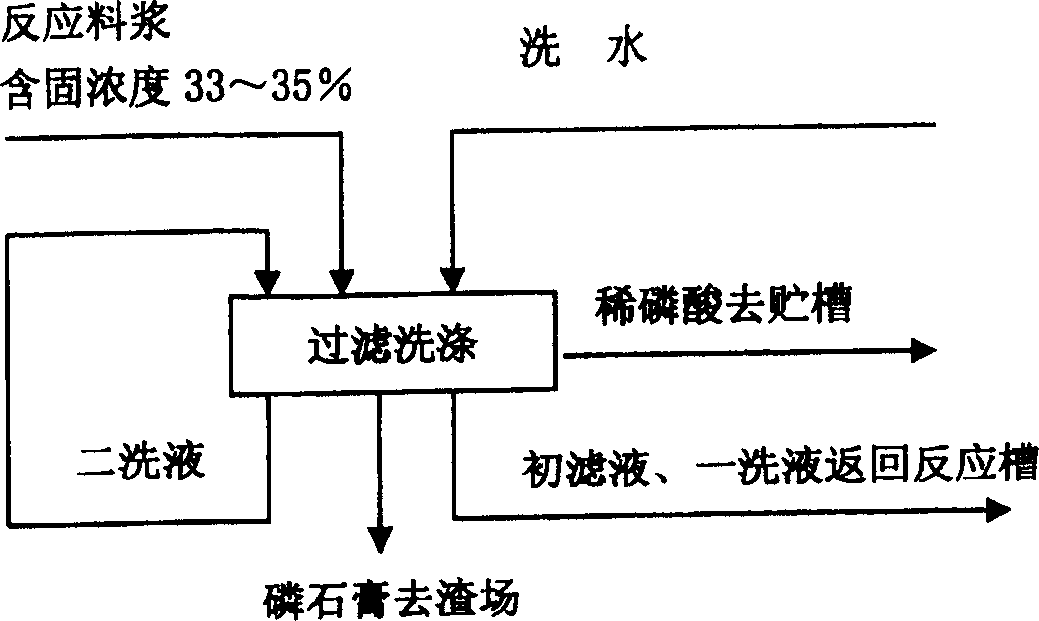

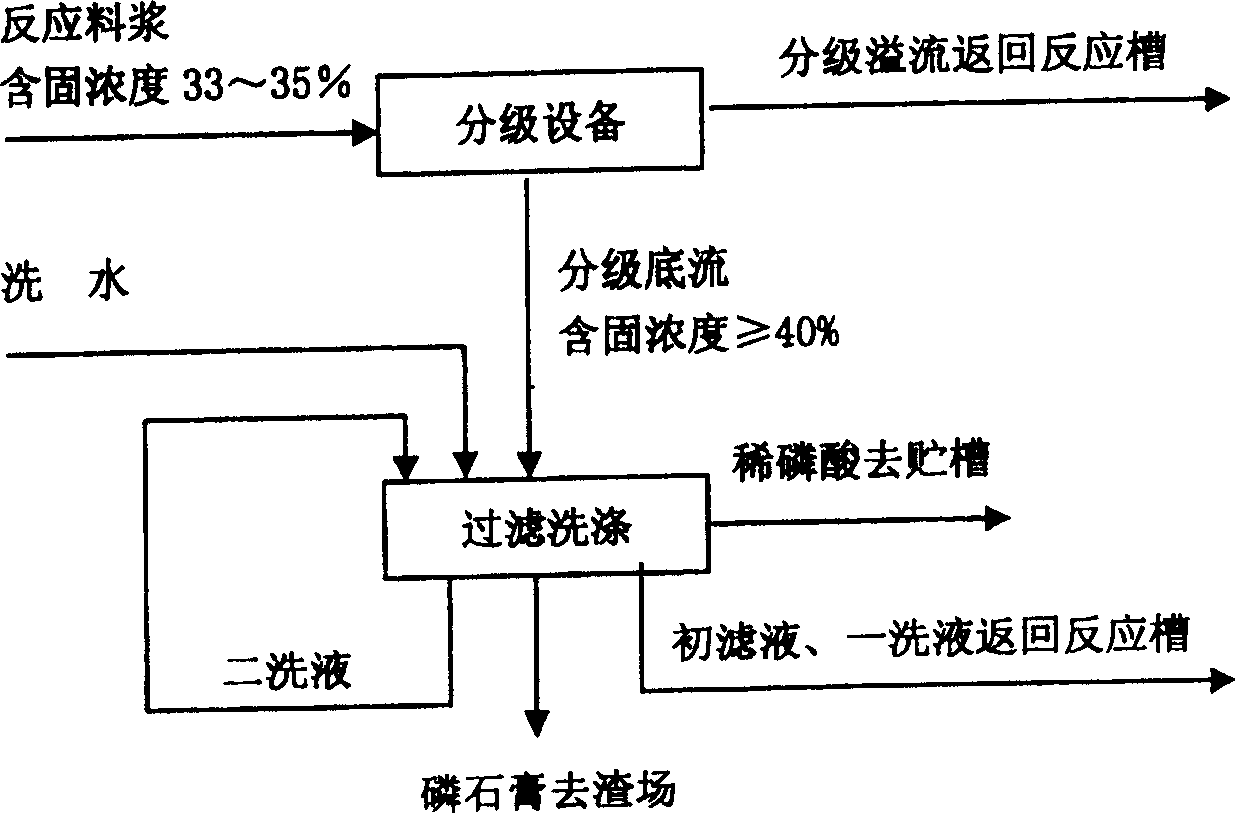

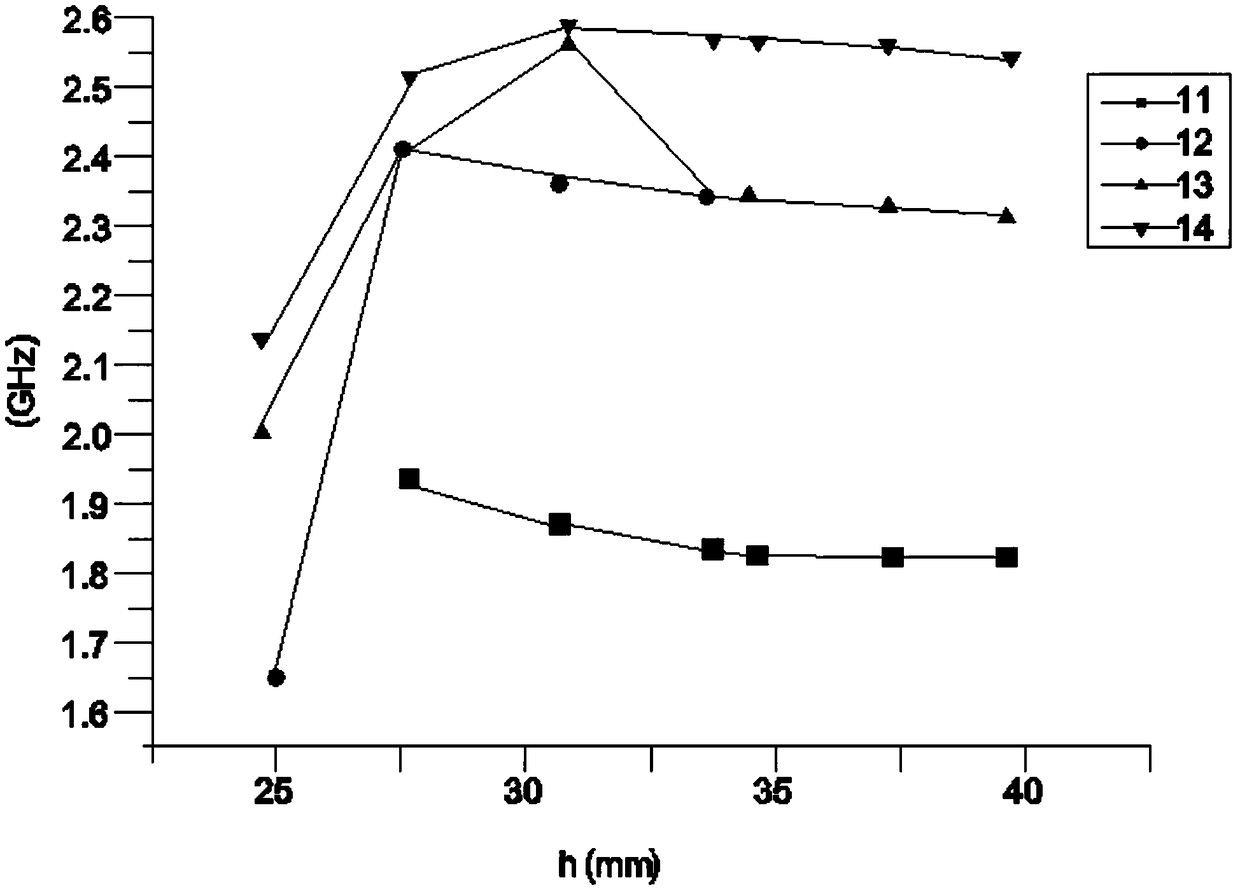

Method for improving property of dihydrate wet-process phosphoric acid reaction slurry

The invention discloses a method for improving the performance of dihydrate wet methods phosphoric acid reaction stuff, which comprises the following steps: Classify treating the stuffs by a classifier, the ardealite crystal size of classification bottom current is: the proportion of particles of +40 um size is 90%-95%, 100 um size is 50%-65%, +150 um size is 20%-35%. Filtering and washing the classification bottom current in a filter. The ardealite crystal size of classification overflow is: the proportion of particles of -40 um size is 80%-85%, -100 um size is 100%. Growing and increasing further have the classification overflow in a seed crystal reaction tank and entering the next classified cycle. Taking the ardealite filtrated and washed to the slag ground, and taking the diluted phosphoric acid to the storage tank, returning the preliminary filter liquid and 1st cleaning solution to the reaction tank, and quadratic countercurrent washing the 2nd cleaning solution in the filter.

Owner:云南云天化国际化工有限公司

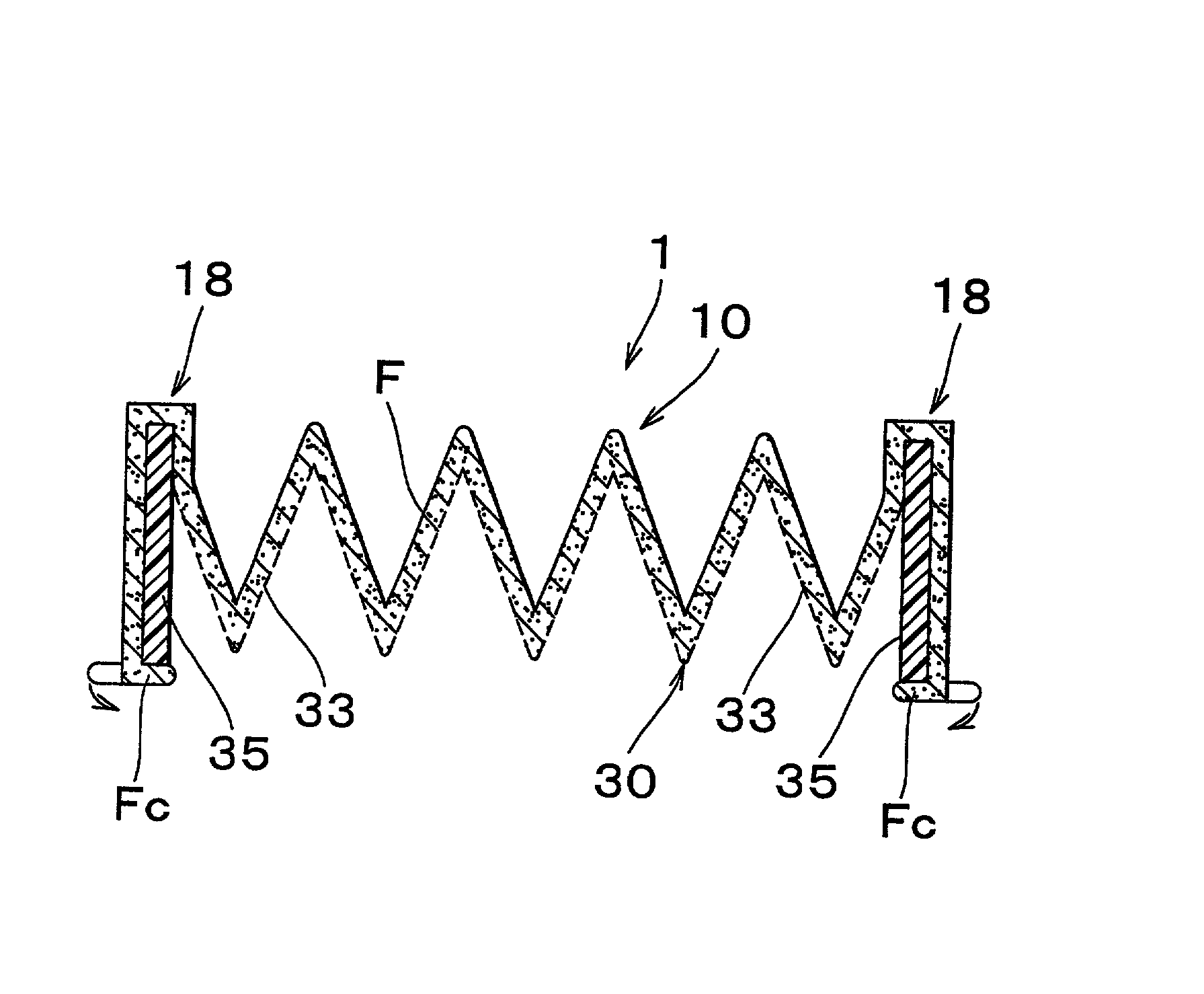

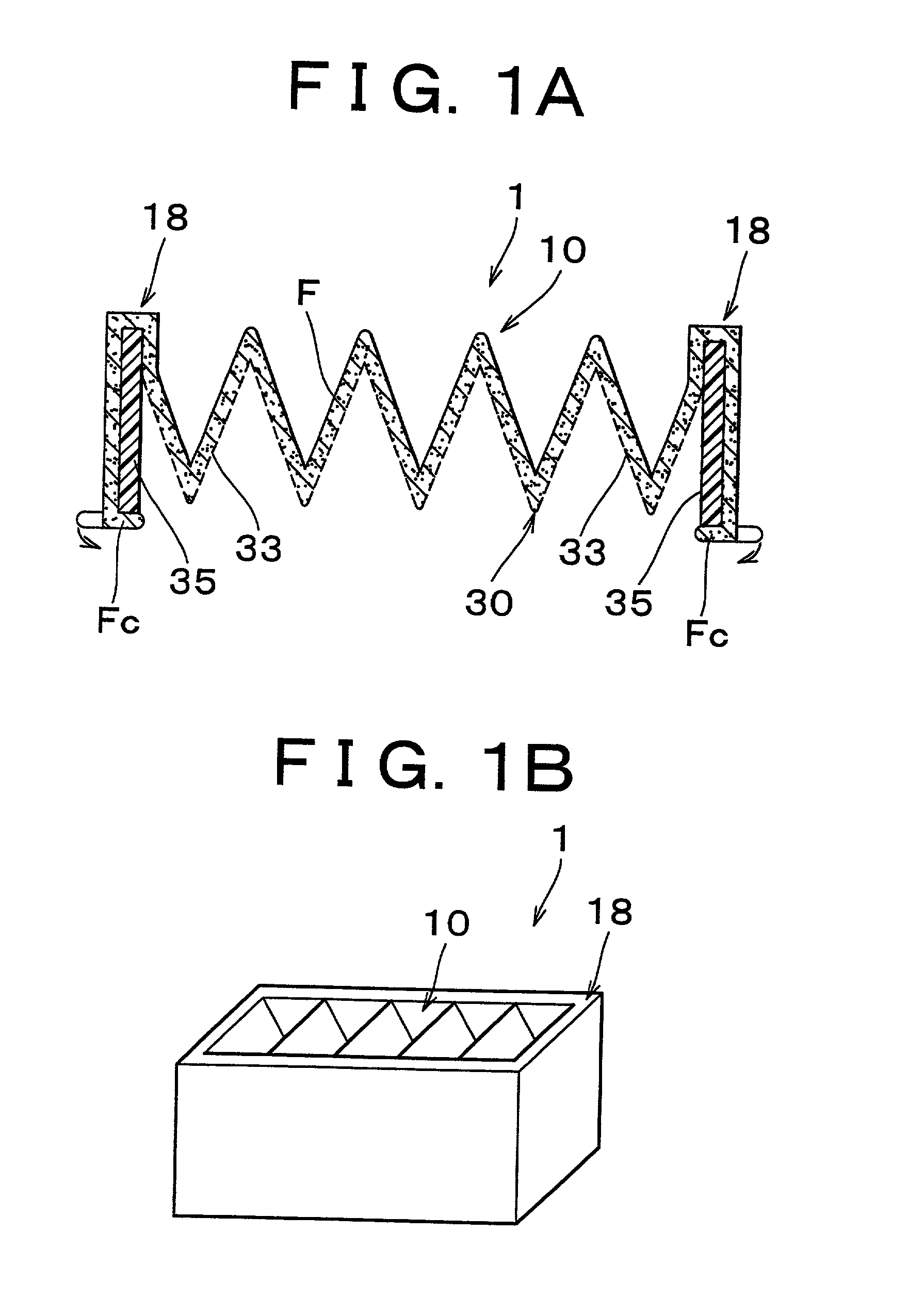

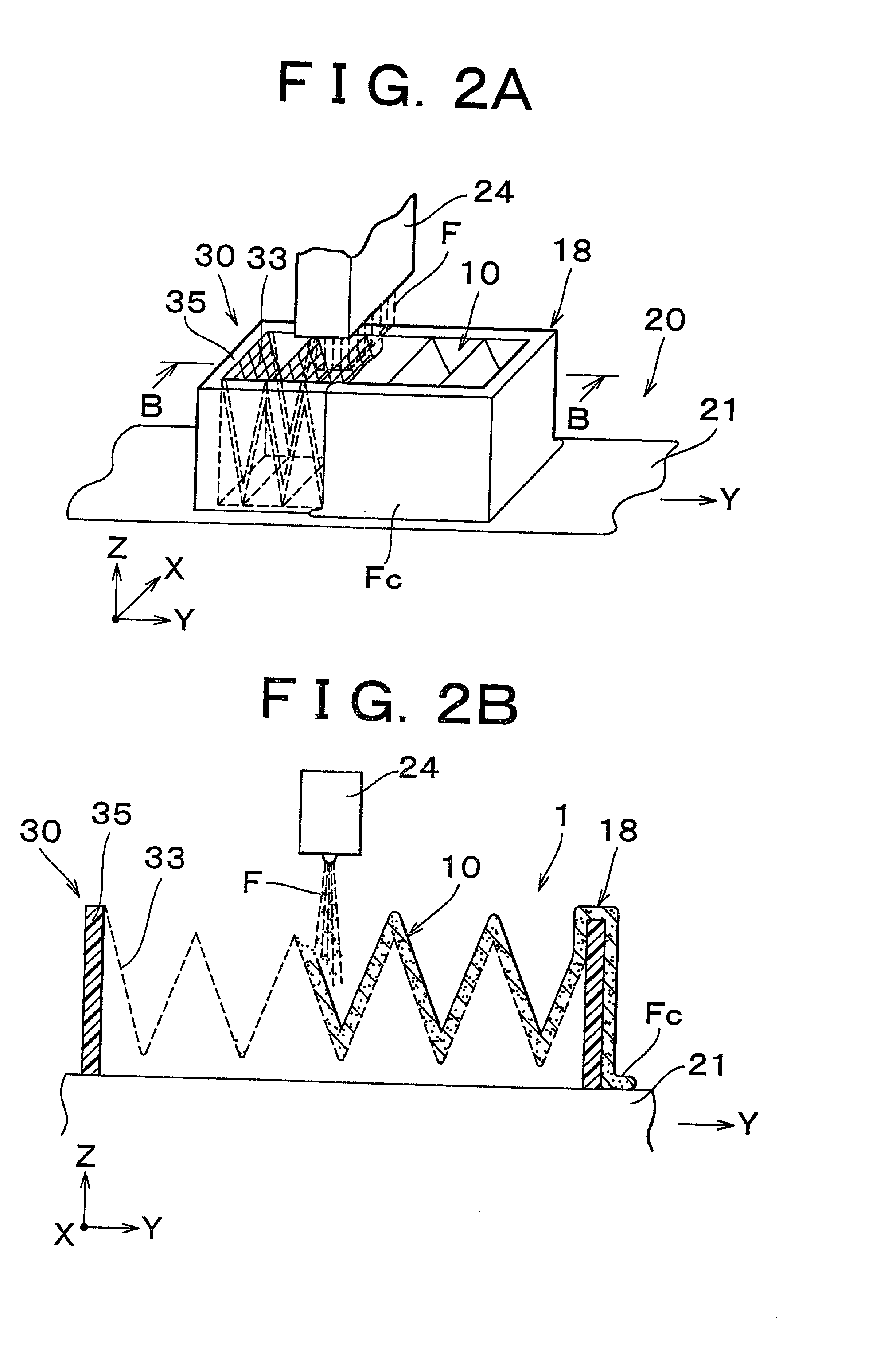

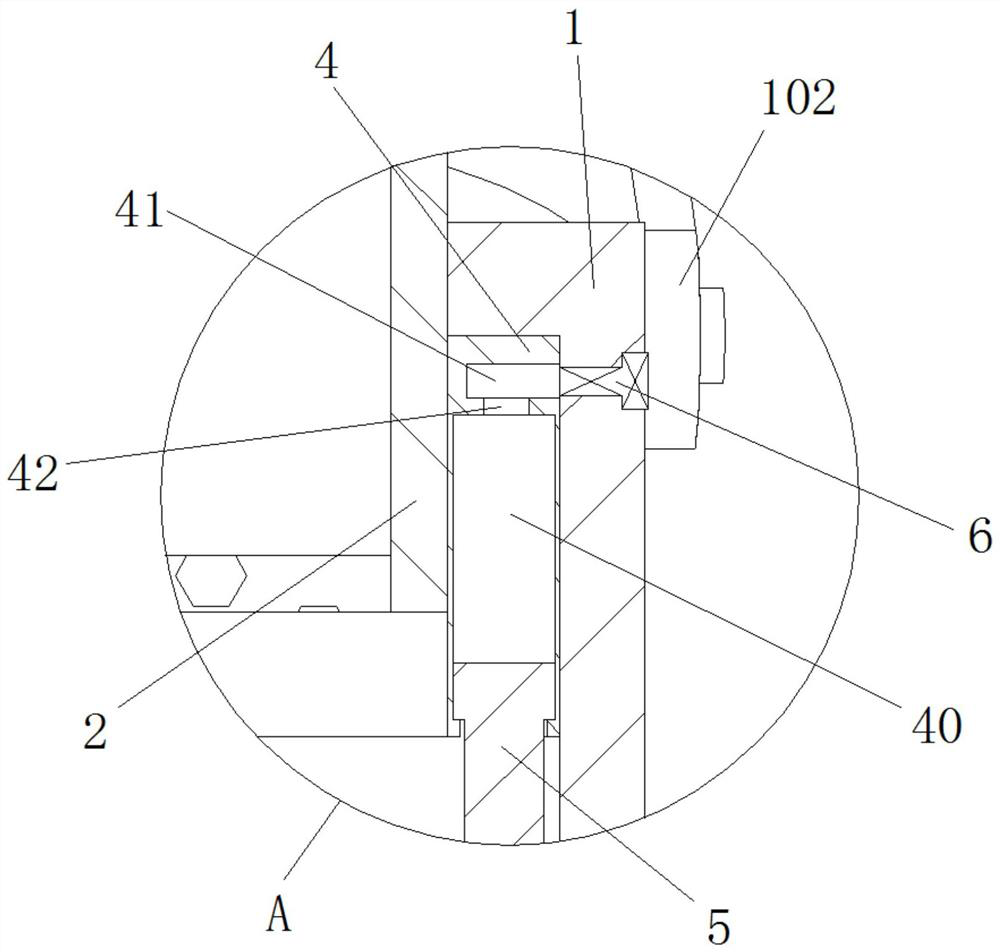

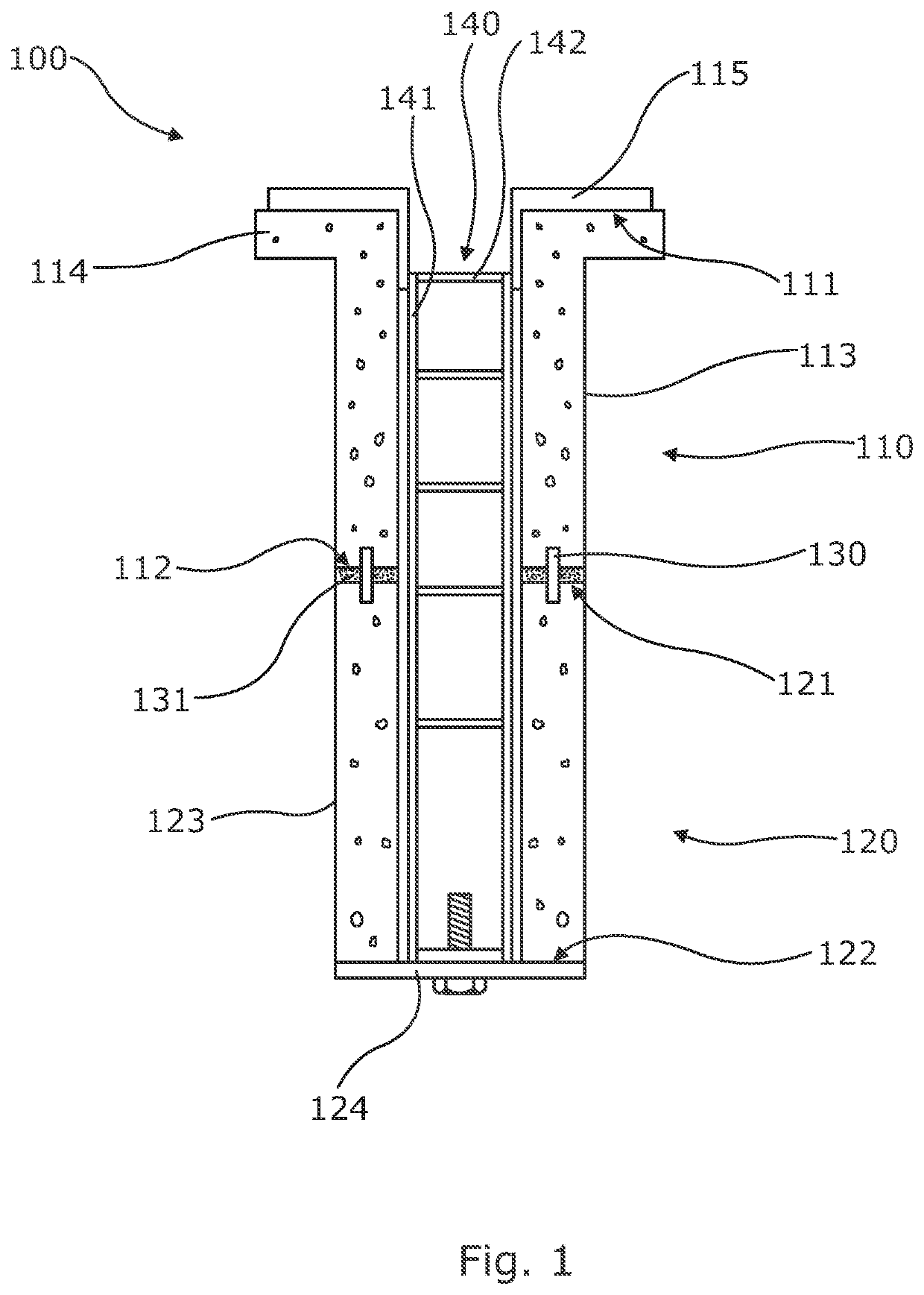

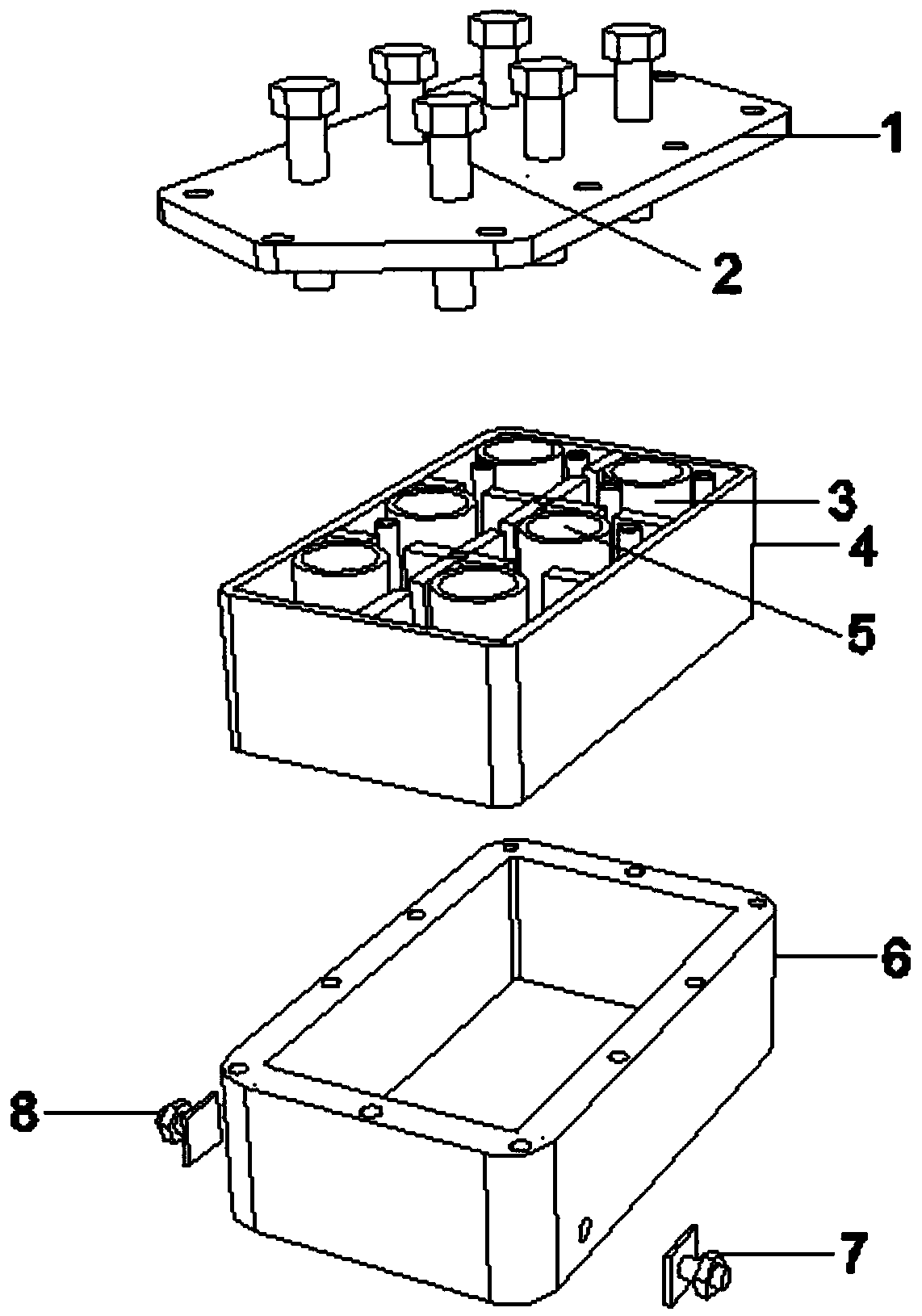

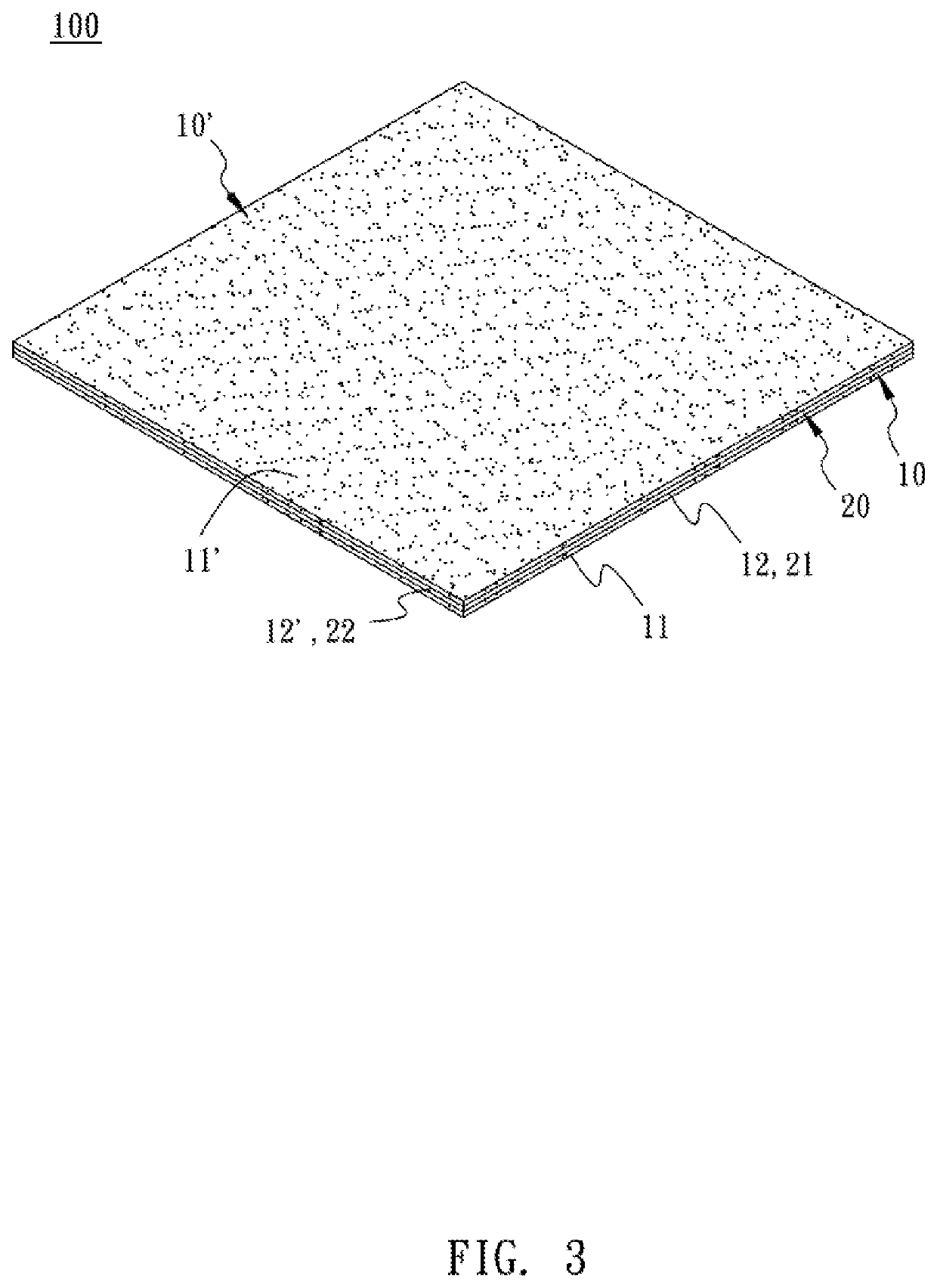

Filter and method for manufacturing the filter

InactiveUS20020129587A1Easy to manufactureImprove filter strengthDispersed particle filtrationWood working apparatusMolten stateFiber

A filter and a method of manufacturing the filter which is formed by spinning a fiber in a semi-molten state onto a mold such that the mold is provided as a filter structural member. The method obviates the need to remove the filter from the mold and thus simplifies the manufacture of the filter.

Owner:TOYOTA BOSHOKU KK

Method for preparing ammonium sulfate by conversion of phosphogyspum with polycrystalline method

ActiveCN102303874BImprove filter strengthEmission reductionAmmonium sulfatesChemical industryO-Phosphoric Acid

The invention relates to a method for preparing ammonium sulfate by continuous conversion of phosphogyspum with a polycrystalline method, belonging to the technical fields of resource comprehensive utilization and chemical industry, and relates to a method for producing ammonium sulfate by conversion of phosphogyspum with a polycrystalline method based on a byproduct phosphogyspum in a (sulfuric acid) wet phosphoric acid industry as a main raw material. The production process comprises the following steps: (1) pretreating the raw material of phosphogyspum discharged in the wet phosphoric acid industry so as to obtain purified phosphogyspum; (2) absorbing ammonia and carbon dioxide with a ammonia-sulfate-containing primary lotion which is produced by washing a calcium carbonate filter cake with water in a filtration process in a carbonation tower so as to produce an ammonia sulfate and carbonate solution; (3) connecting a calcium carbonate polycrystalline nucleus generator with a multiple-tank or multiple-partition groove type reactor with a stirrer in series to constitute a conversion crystallizer; (4) filtering a reaction material slurry discharged from the conversion crystallizer so as to obtain a filter cake and filtrate containing 38-40% by weight of ammonium sulfate; (5) carrying out secondary countercurrent washing on the filter cake obtained in the step (4) with clear water, and feeding the ammonia-sulfate-containing primary lotion to the carbonation tower for absorbing gas ammonia and carbon dioxide so as to produce an ammonia sulfate and carbonate liquid; and (6) neutralizing and decarburizing the filtrate containing ammonium sulfate from the step (4) with sulfuric acid, then centrifugally separating so as to obtain a crystal containing wet ammonium sulfate, separating out a mother liquid, carrying out cycle concentration on the mother liquid, and drying the crystal containing wet ammonium sulfate so as to obtain a finished product ammonium sulfate.

Owner:YUNNAN CHEM RES INST

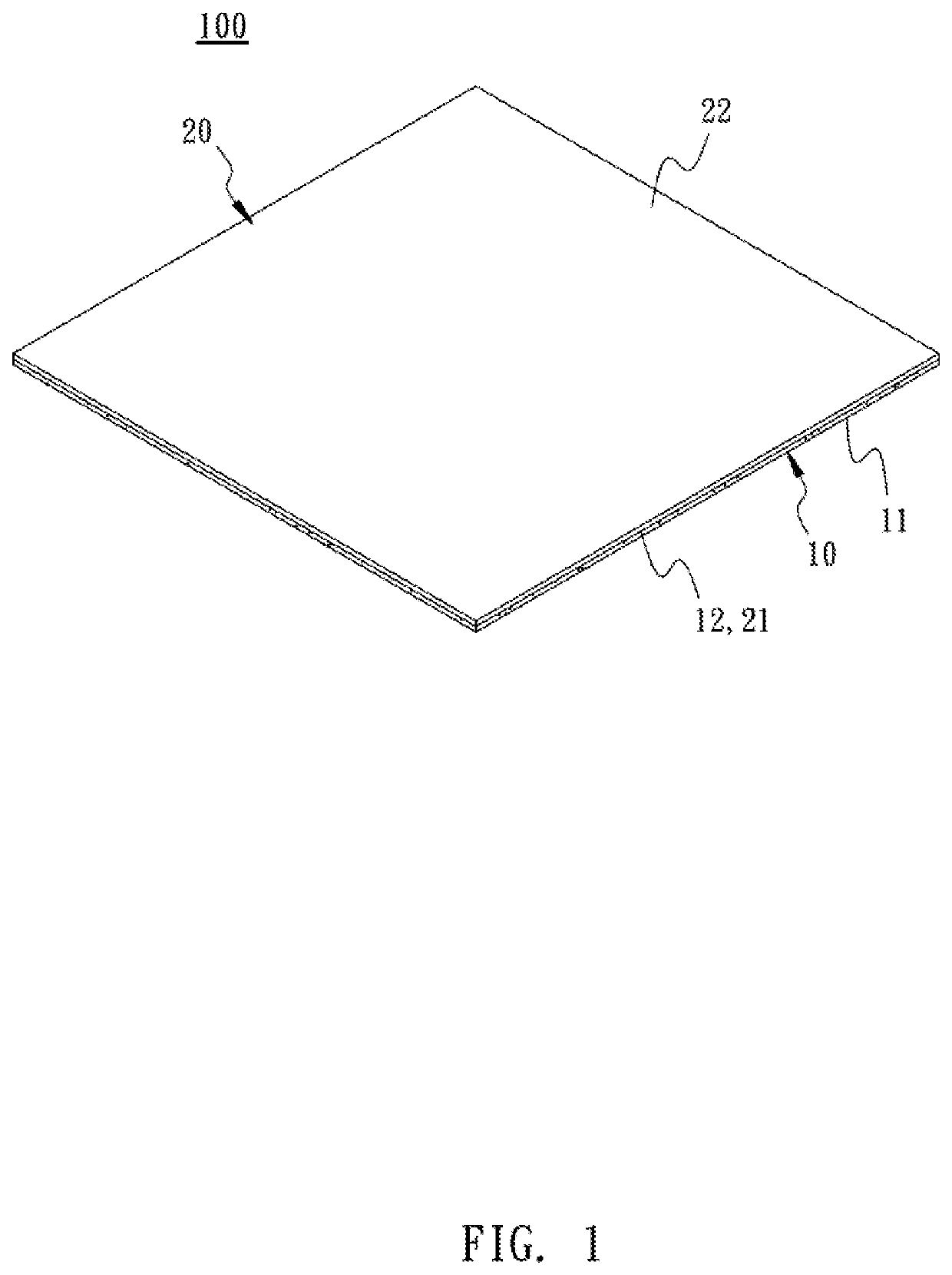

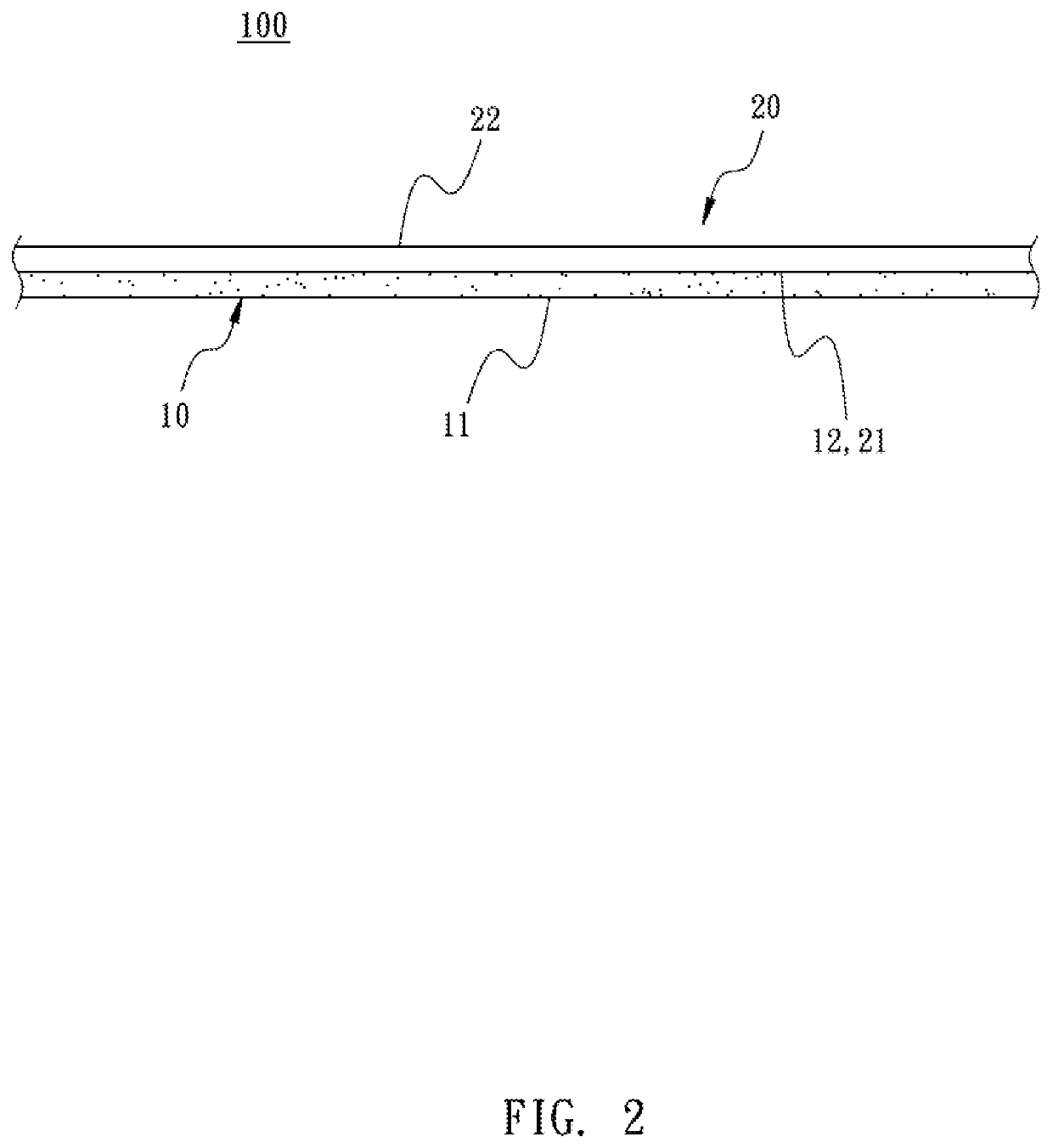

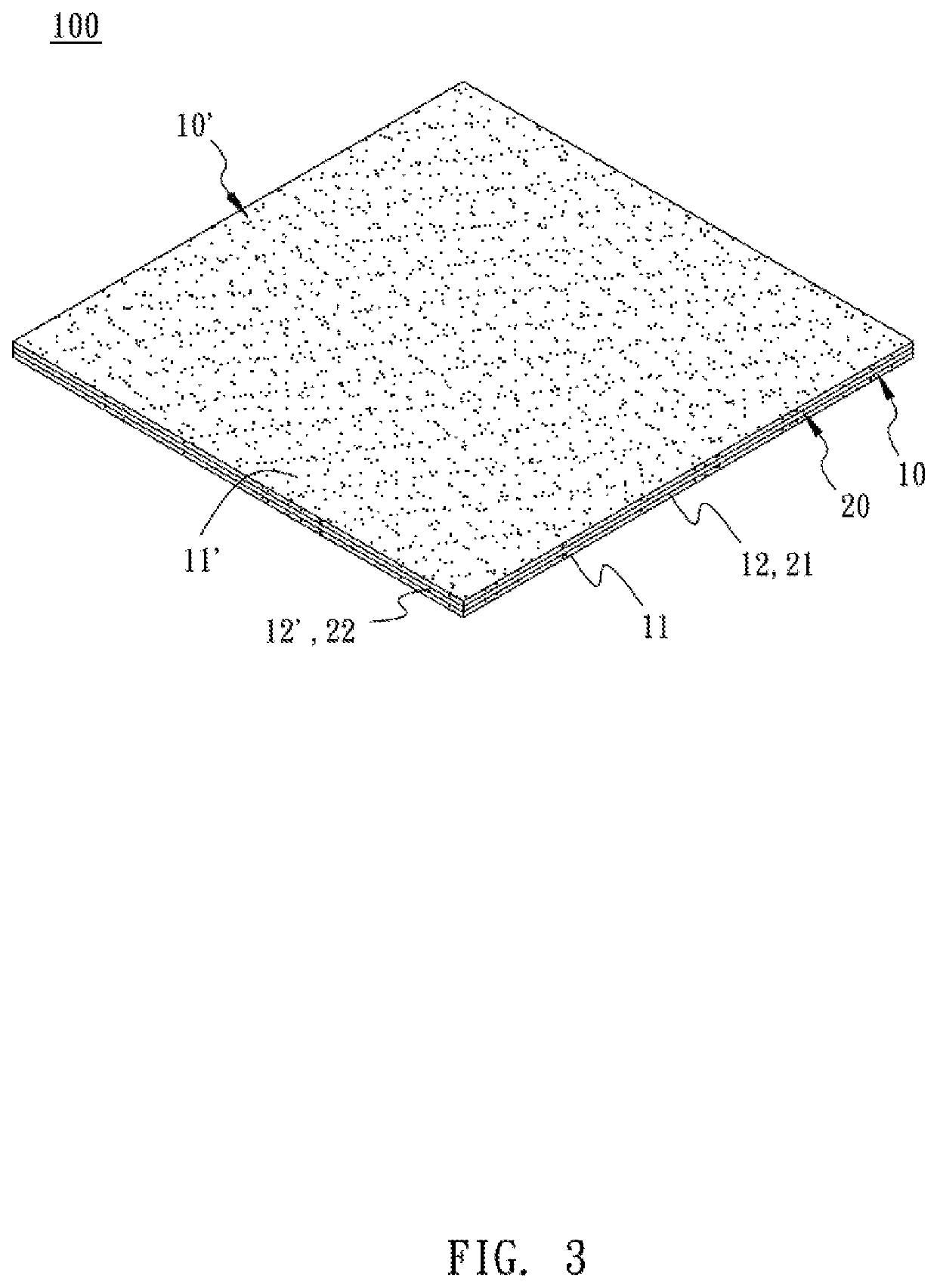

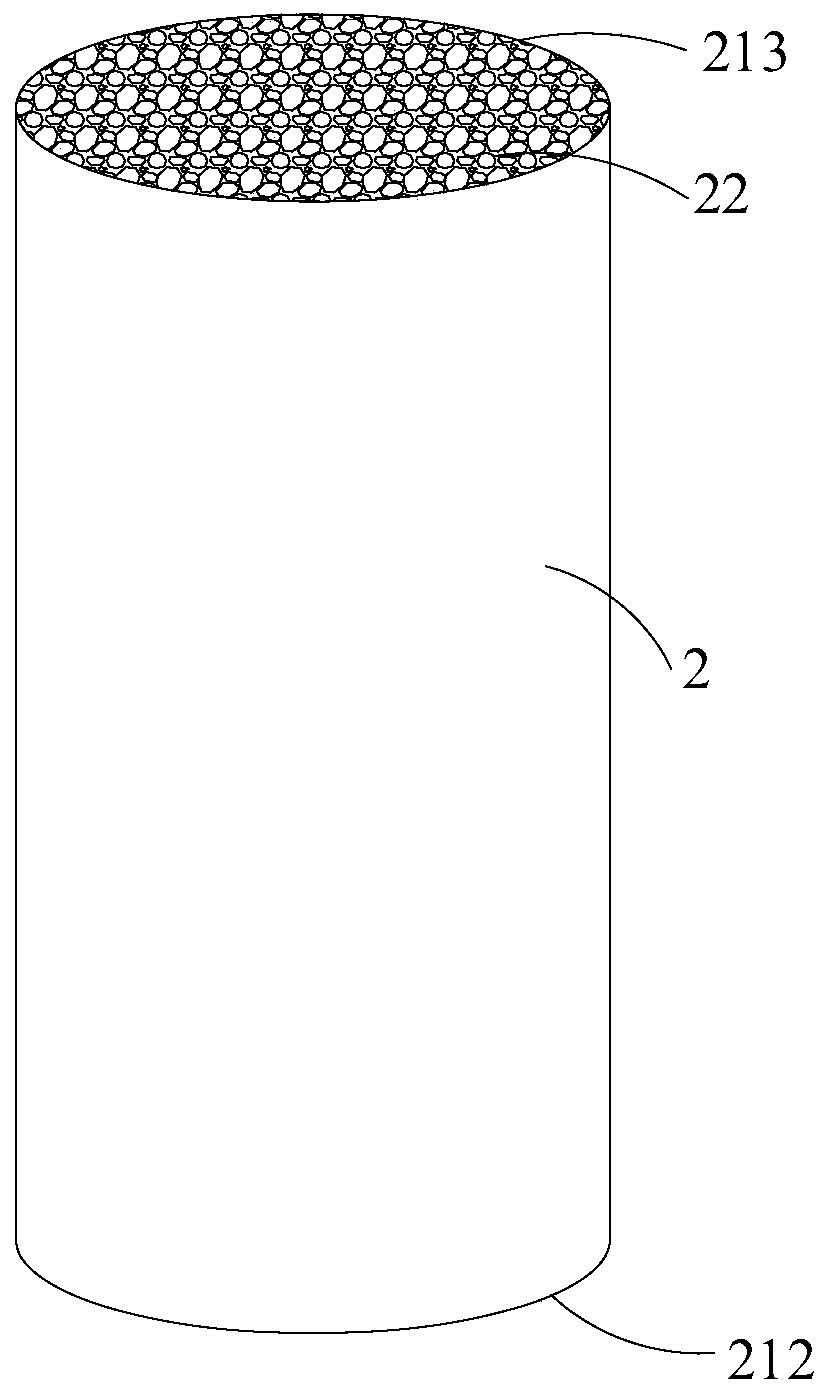

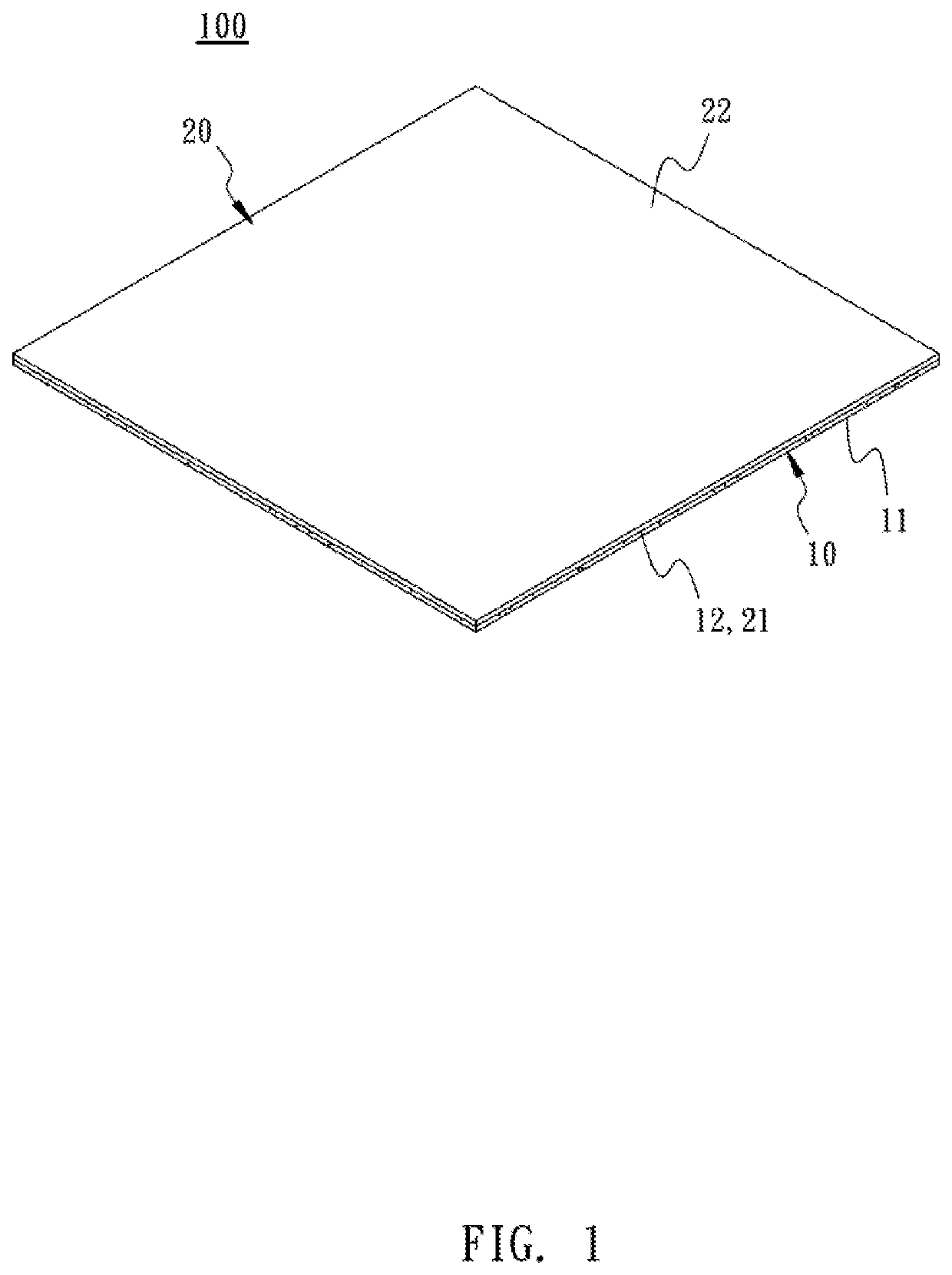

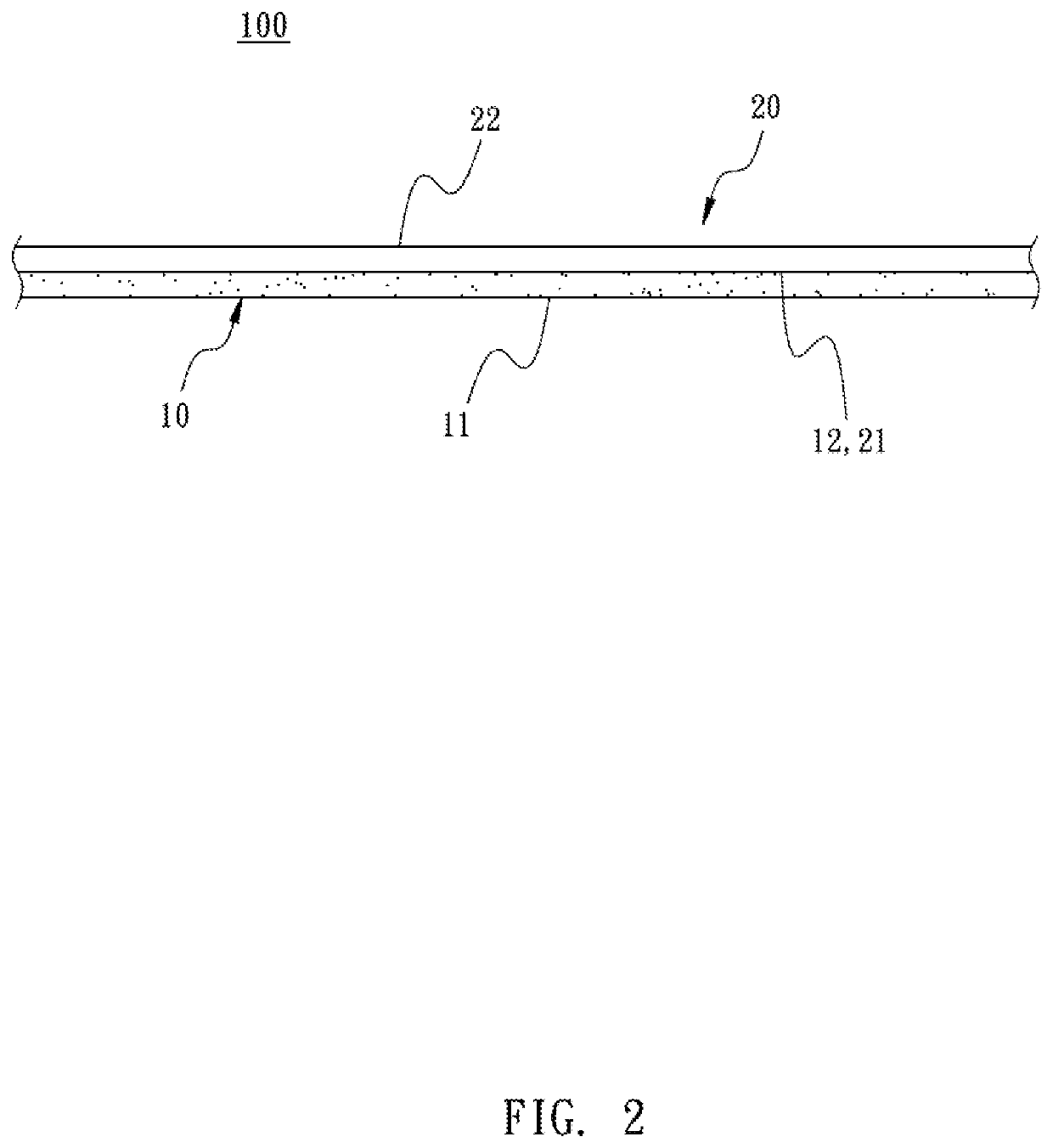

Multilayer filter screen and manufacturing method thereof

ActiveUS20190374893A1Improve filter strengthImprove abilitiesDispersed particle filtrationTransportation and packagingUltimate tensile strengthMaterials science

A multilayer filter screen and the manufacturing method thereof are provided. The multilayer filter screen includes a conductive powder layer and a plastic powder layer. The conductive powder layer and the plastic powder layer are stacked up through a solidifying process. Therefore, the mechanical structural strength and the anti-static electricity function of the multilayer filter screen are improved.

Owner:FANNO TECH CO LTD

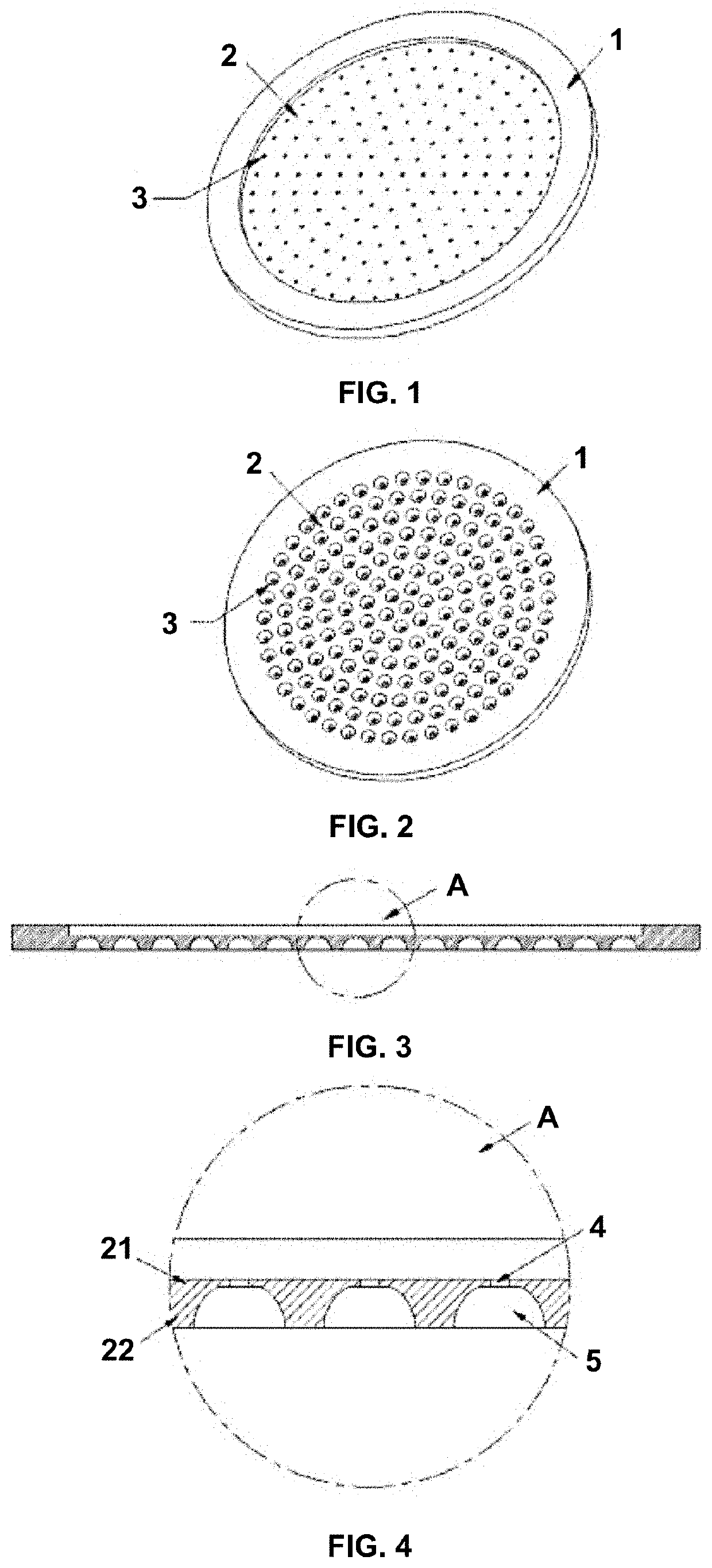

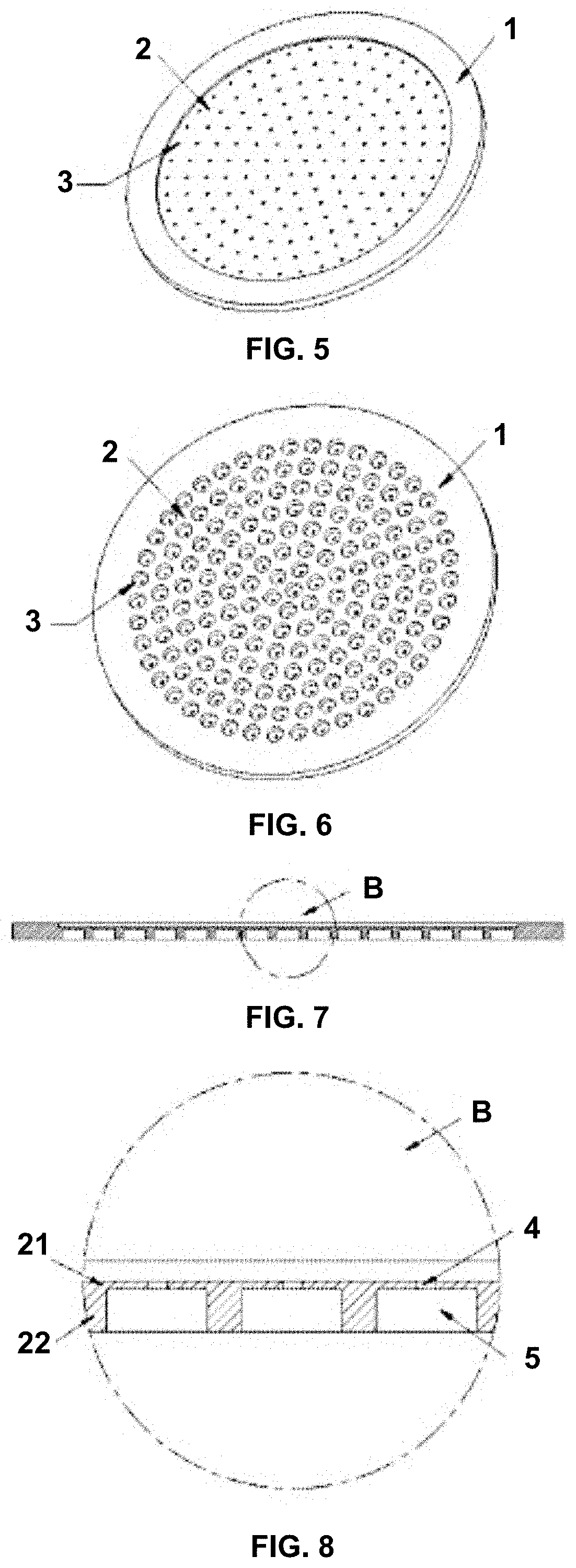

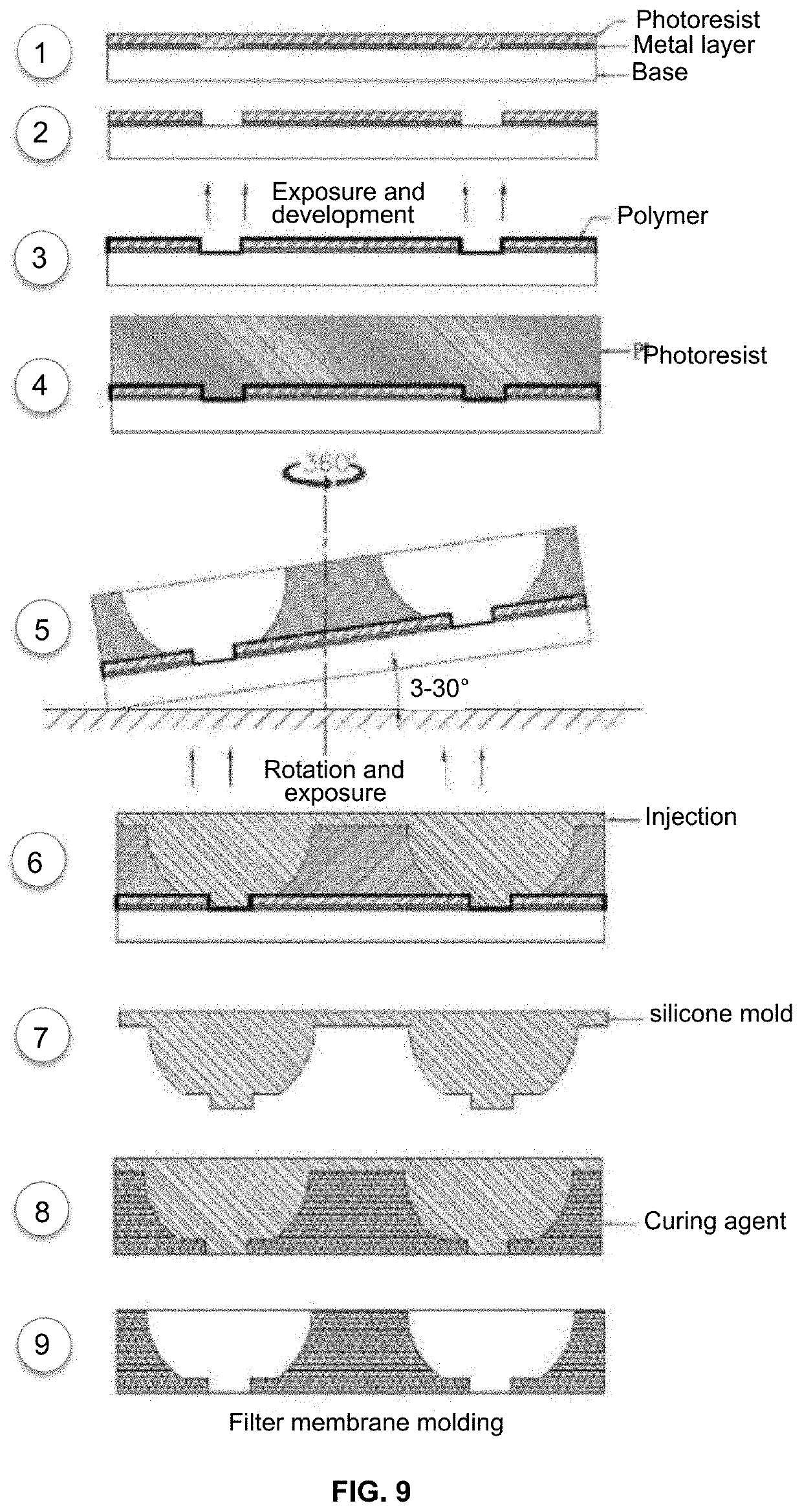

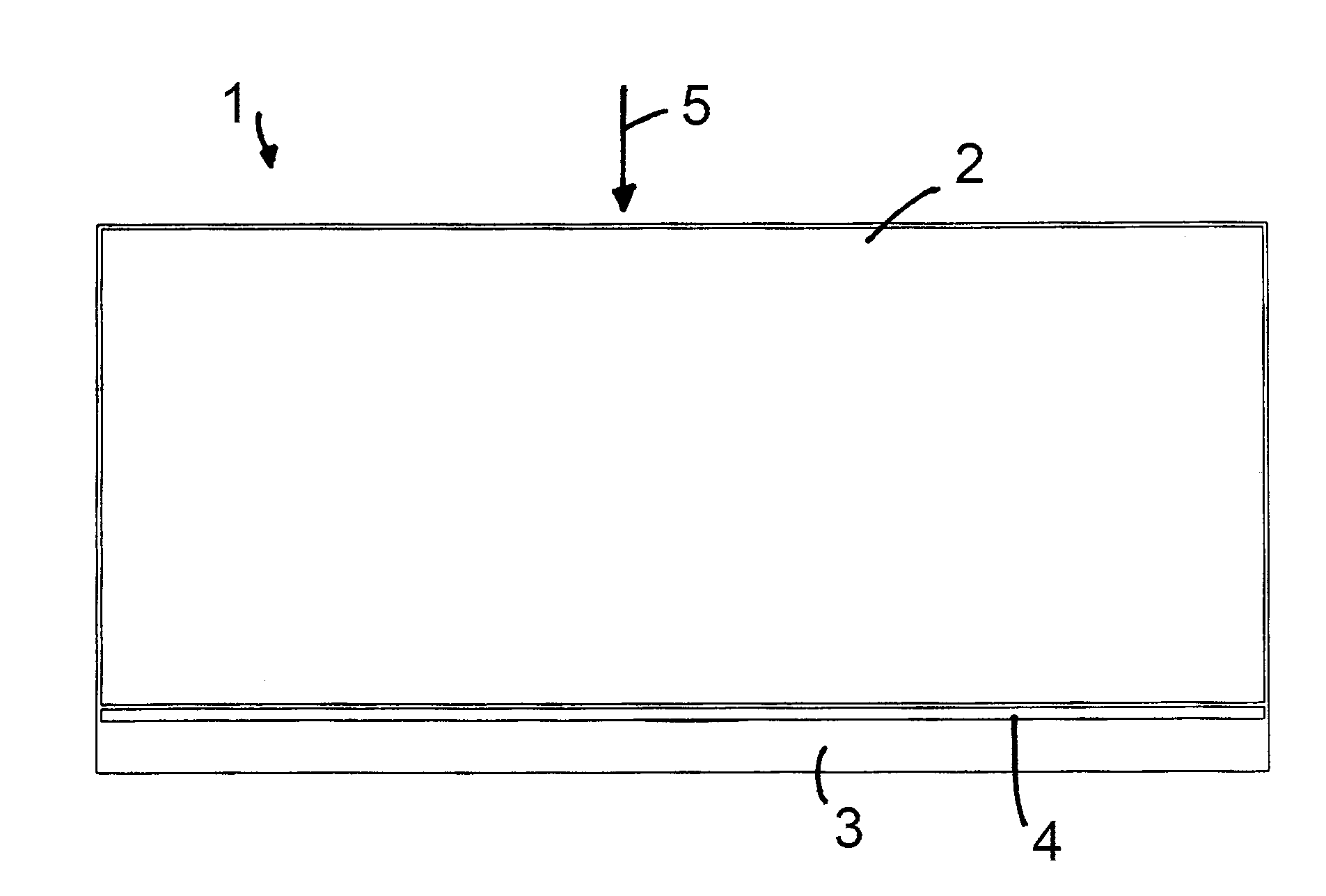

High-Flux Filter Membrane with Three-Dimensional and Self-Aligned Micropores Arrays and Method for Manufacturing Same

PendingUS20210299615A1Reduce thicknessPore diameter of low poreMembranesUltrafiltrationThermodynamicsHigh flux

The present invention discloses a high-flux filter membrane with three-dimensional self-aligned micropores arrays and a method for manufacturing the same. The filter membrane has an operating area and a filter area. The operating area is located around the filter membrane. The filter area is located in the middle of the filter membrane. The filter area is relatively concave to the operating area. Three-dimensional and self-aligned micropores are provided on the filter area and are upper pores and lower pores, which are coaxial pores. The upper pores connect with the lower pores. In the present invention, in one aspect, a fluid flux is increased by reducing the thickness of upper pores and increasing the pore diameter of the lower pores, and, in another aspect, mechanical strength of the filter membrane is increased by use of the lower pores.

Owner:GUANGZHOU ANFANG BIOTECH CO LTD

Method for improving property of dihydrate wet-process phosphoric acid reaction slurry

Owner:云南云天化国际化工有限公司

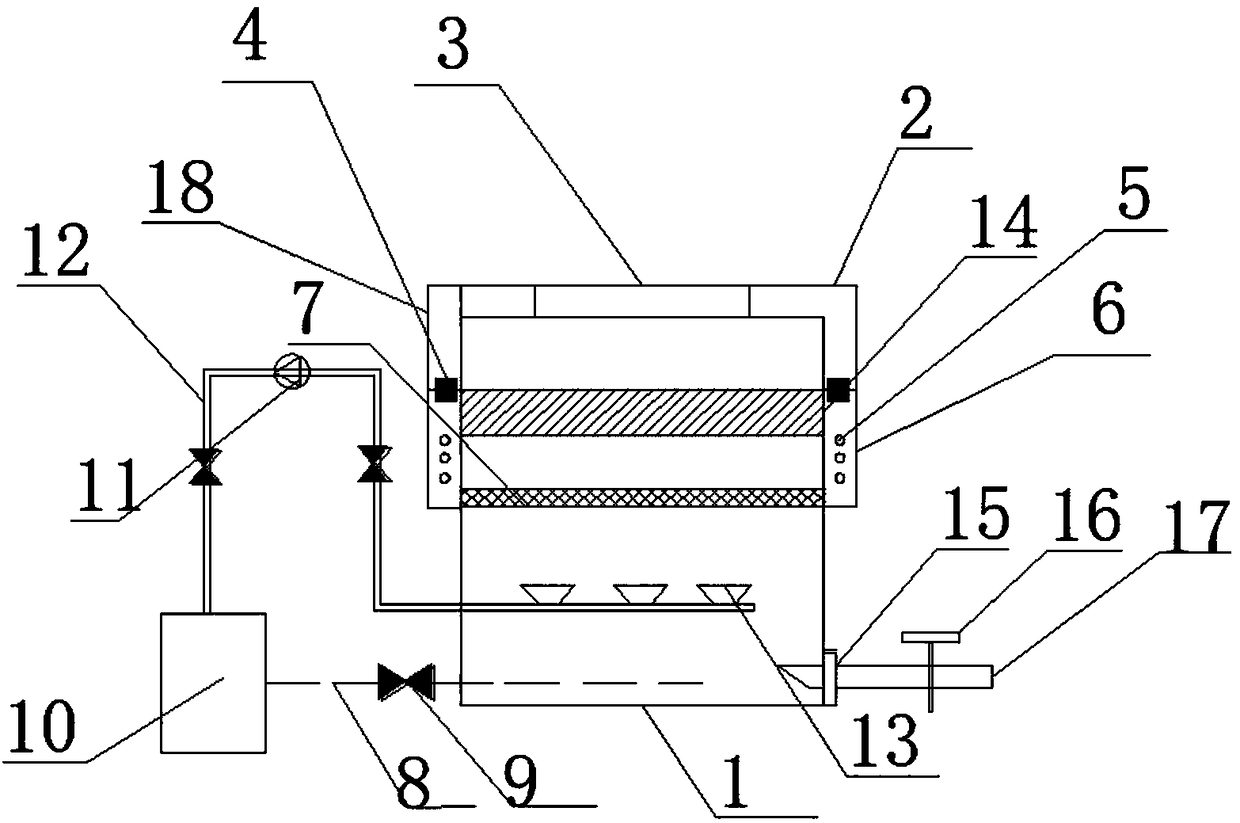

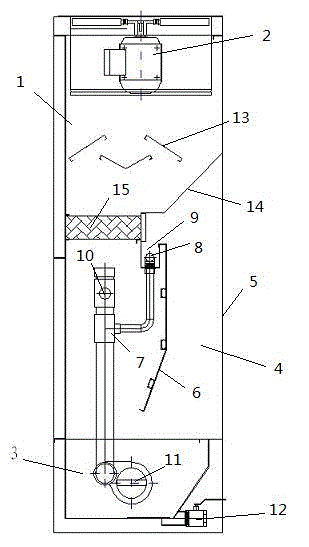

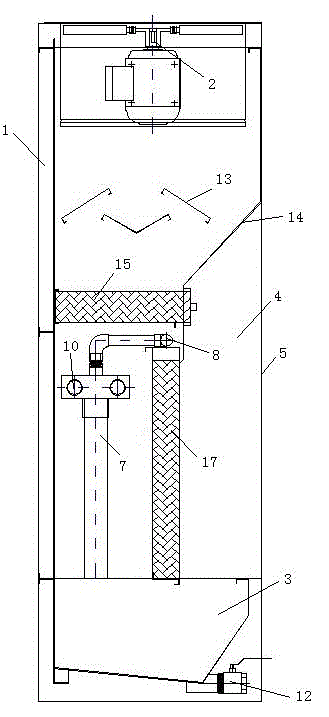

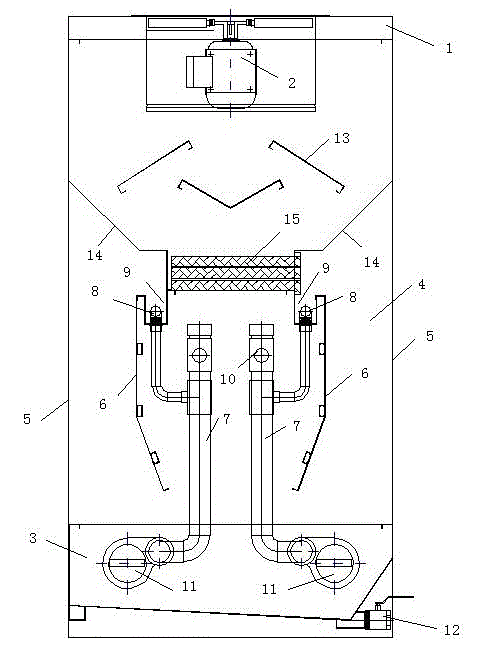

Industrial sewage treatment equipment

InactiveCN108455769AReduce purification costsMeet the needs of different water qualityWater/sewage treatment by irradiationSpecific water treatment objectivesRefluxSlag

The invention discloses industrial sewage treatment equipment. The industrial sewage treatment equipment comprises a casing, wherein a mud and water separating device and a nanofiltration membrane filtering net are sequentially and fixedly arranged in the casing from top to bottom; a glass hollow plate is fixedly arranged at the periphery of the side wall of the casing by a hinge between the mud and water separating device and the nanofiltration membrane filtering net; ultraviolet sterilizing lamps are uniformly distributed in the glass hollow plate at equal intervals; the top part of the casing is clamped with a top cover in a sealing way; a liquid inlet hole is formed in the center of the top cover; a slag discharge door is arranged at the side wall of one end, near the mud and water separating device, of the casing; a water drain pipe is arranged at the side wall, near the bottom end, of the casing; a dirt discharge pipe is arranged under the mud and water separating device, and isembedded and communicated with a plurality of filtrate funnels; the other end of the dirt discharge pipe extends out of the casing, and is communicated with a dirt sucking and water purifying device;the dirt discharge pipe is sequentially and fixedly connected with a dirt discharge pump and a valve; a water outlet of the dirt sucking and water purifying device is communicated with one end of a reflux pipe, and the other end of the reflux pipe is communicated with the bottom part of the casing.

Owner:FOSHAN XIHUA TECH CO LTD

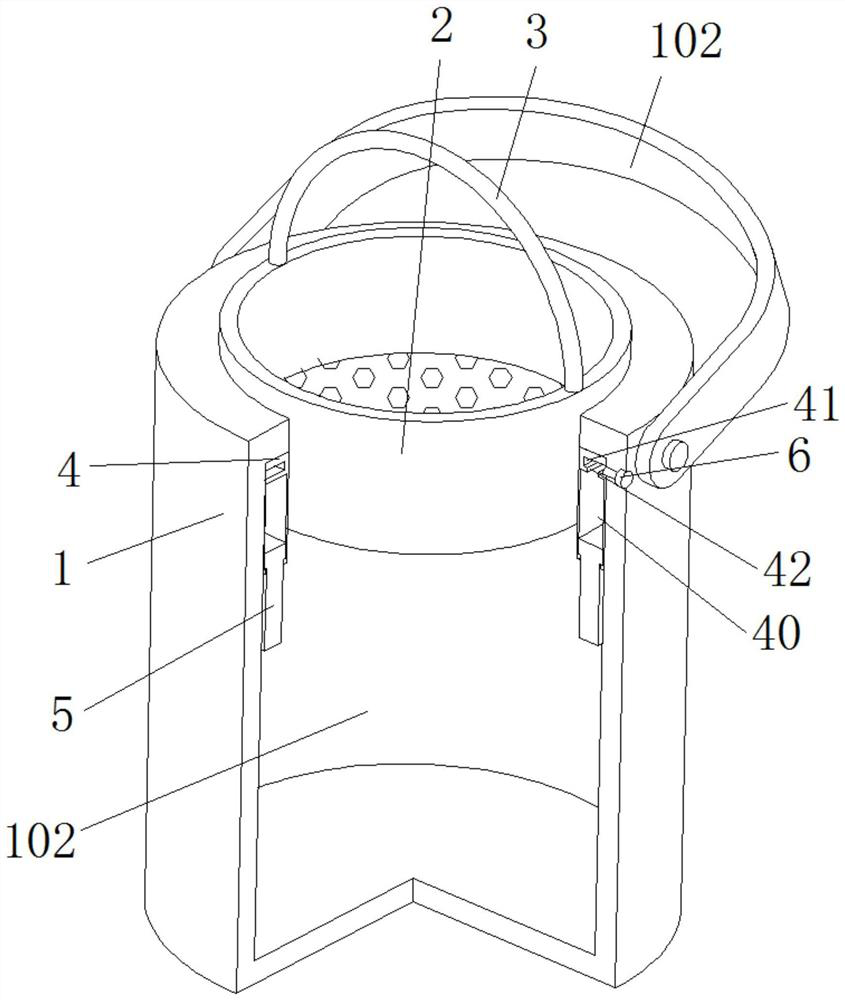

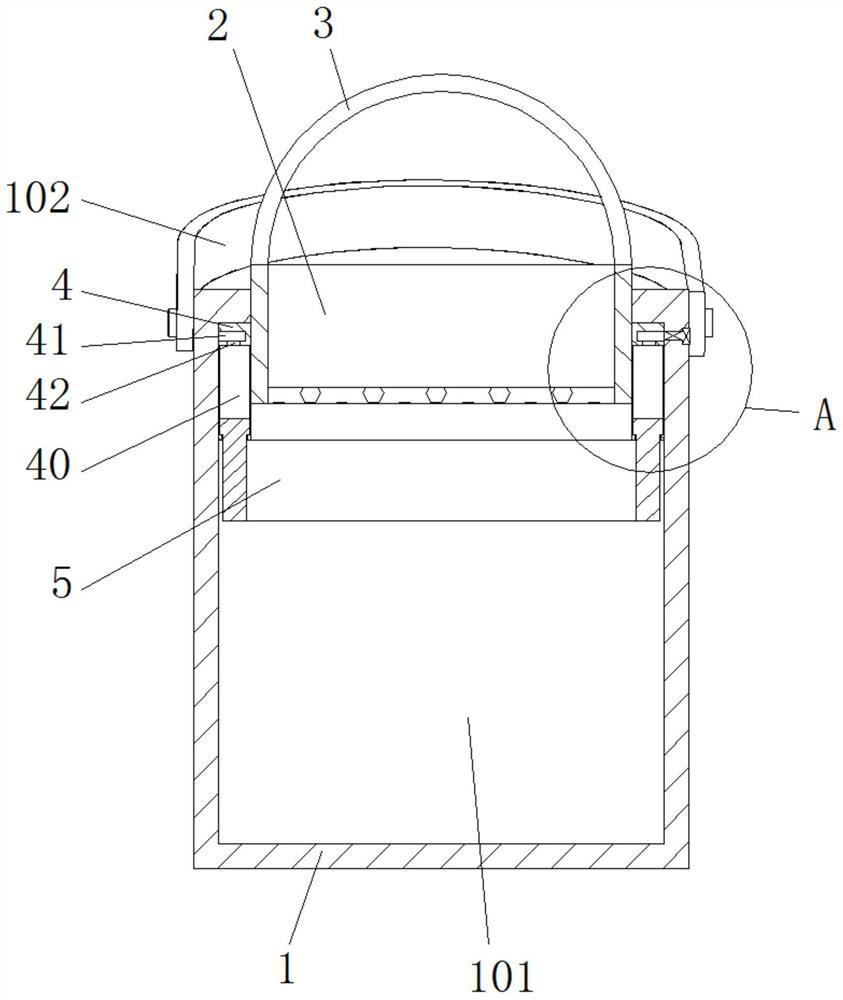

Household sewage treatment barrel

ActiveCN113617085ALearn about storageImplement filteringWaste collection and transferStationary filtering element filtersSewageSewage treatment

The invention relates to the related field of advanced environmental protection industry, and discloses a household sewage treatment barrel which comprises a barrel body, a storage cavity with an upward opening is formed in the inner wall of the barrel body, a barrel handle is movably installed at the top of the side wall of the barrel body, and the inner wall of the barrel body is movably sleeved with a supporting block. The inner wall of the barrel body is movably sleeved with the supporting block, a filter cartridge is fixed to the inner wall of the supporting block, and the floating block is installed at the bottom of the supporting block, so that after the bottom of the filter cartridge is blocked, the gravity of sewage gathered by the filter cartridge is increased, the filter cartridge is pressed downwards, airflow in the storage cavity overflows from the bottom of the filter cartridge, an air flow channel between filter cartridge and the storage cavity is dredged, and sewage in filter cartridge is filtered. Meanwhile, the floating block floats on the sewage in the storage cavity, so that not only is the filter cartridge supported, but also a user can intuitively know the storage condition of the sewage in the storage cavity through the height of the floating block jacking up the filter cartridge, and finally, the purposes of anti-blocking filtering and sewage storage warning are achieved.

Owner:云南太龙塑业有限公司

Sanding room dust removal cabinet

ActiveCN103706217BImplement filteringEfficient exclusionCombination devicesDust controlMechanical engineering

Owner:江西柏司得环保设备有限公司

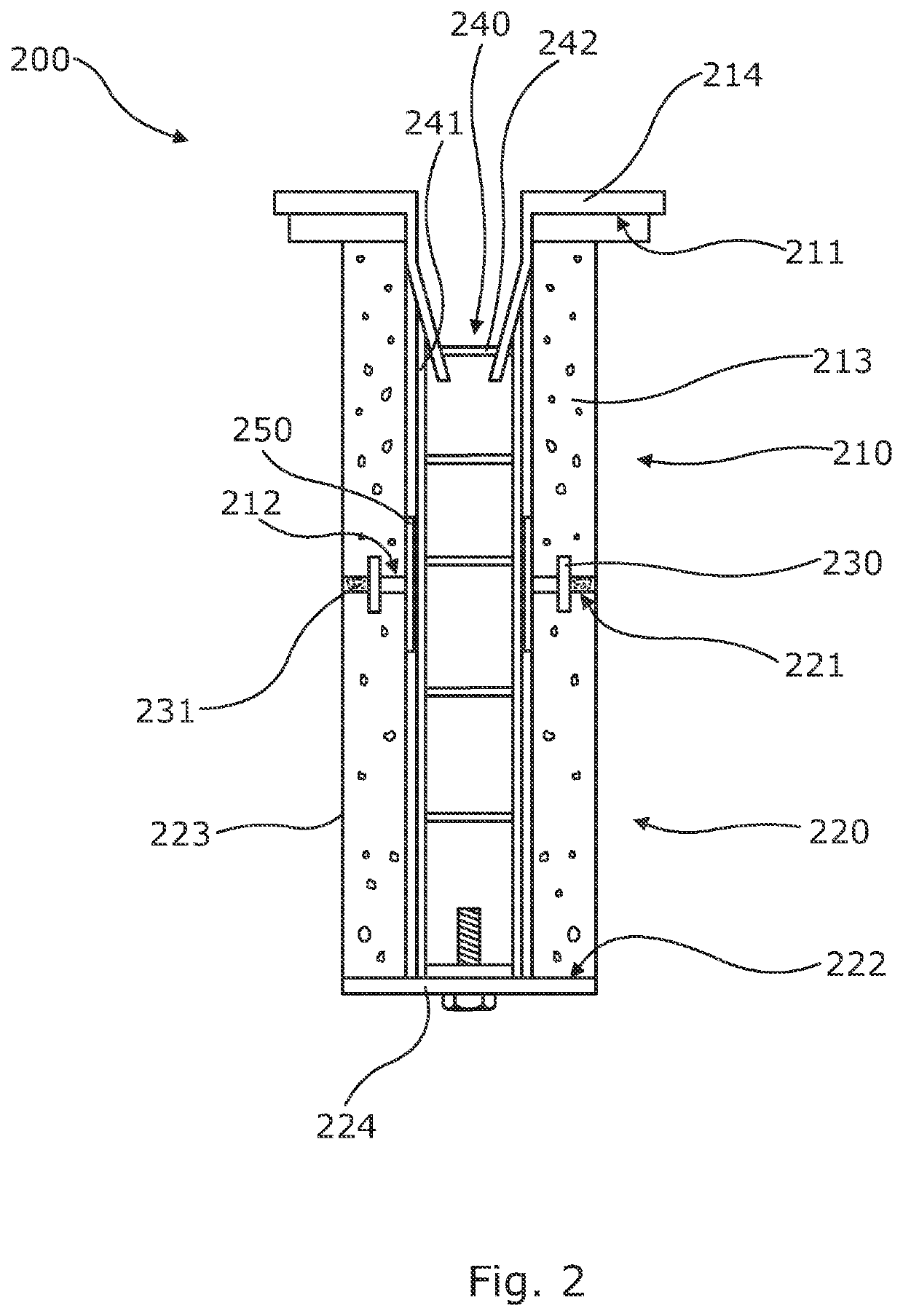

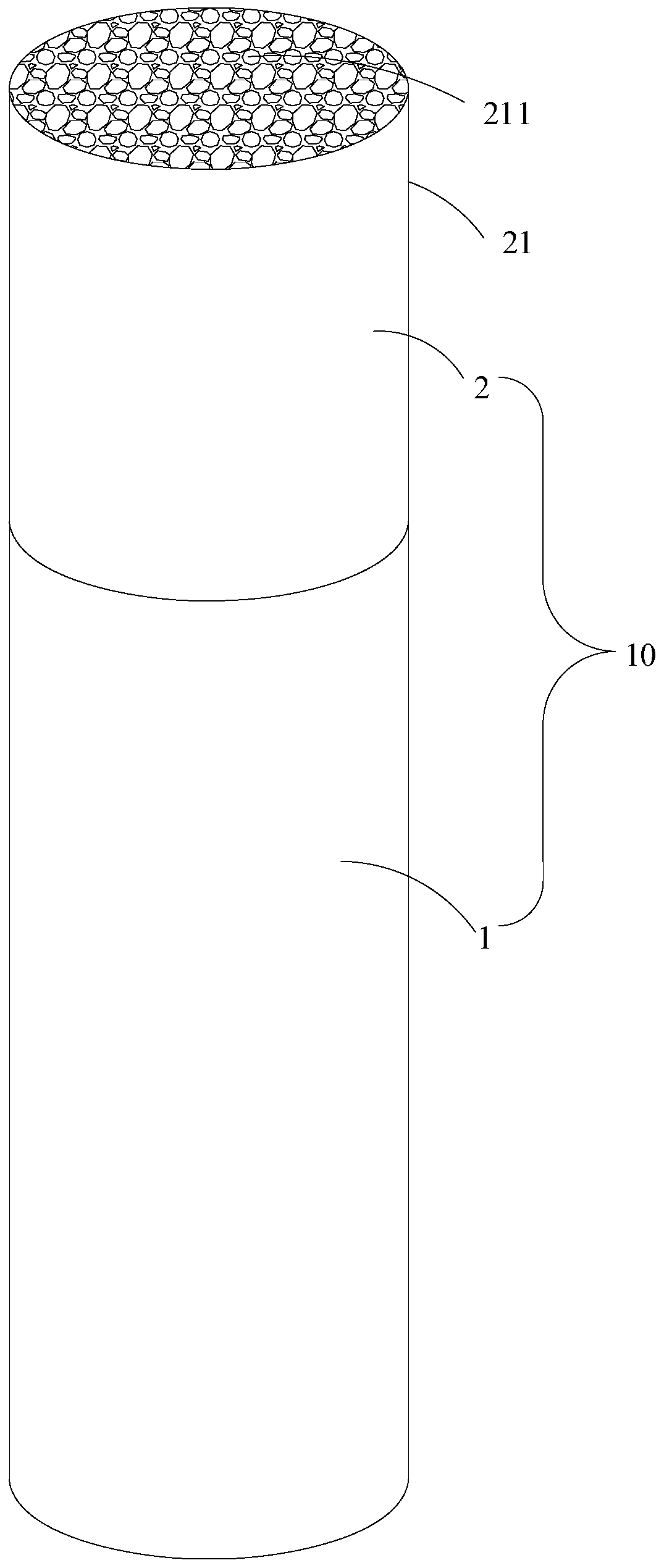

Modular filter element

PendingUS20210245085A1Improve lateral strengthReduce weightDispersed particle filtrationTransportation and packagingEngineeringMechanical engineering

The present invention relates to a modular filter element comprising a first elongate hollow body, a second elongate hollow body and connection means for connecting the first elongate hollow body to the second elongate hollow body, wherein the connection means comprises a connection member that extends into a lower wall of the first elongate hollow body and into the upper wall of the second elongate hollow body to provide a gas-tight seal between the first elongate hollow body and the second elongate hollow body.

Owner:MADISON FILTER 981 LTD

Filter Element for Liquid Filtration

InactiveUS20150034550A1High strengthReduce proportionLamination ancillary operationsLayered product treatmentSecondary layerCellulose

A filter element for liquid filtration has a first layer and a second layer. The first and second layers are arranged one behind the other in the direction of flow. The first layer is a filter layer of cellulose, and the second downstream layer is a nonwoven of plastic fibers, wherein the second layer has a smaller thickness than the first layer.

Owner:MANN HUMMEL GMBH

Filter tip and tobacco

InactiveCN109691690AEliminates free radicalsImprove antioxidant capacityCigar manufactureTobacco devicesFiber bundleTar

The invention belongs to the technical field of filtration of tobacco, and particularly relates to a filter tip and tobacco. The filter tip comprises molding paper and a filter section, wherein the molding paper is connected end to end to form a tubular structure; a hollow cavity is formed in the molding paper; the filter section is arranged in the hollow cavity and located in the radial directionof the tubular structure; the filter section comprises multiple filter fiber bundle layers and multiple corn bract layers, and the filter fiber bundle layers and the corn bract layers are arranged ina stacked manner. The filter section of the filter tip comprises the filter fiber bundle layers and the corn bract layers which are arranged in a stacked manner, that is, two filter layers with different substances are formed, so that filtration intensity is increased, and tar, nicotine and part of heavy metal can be effectively filtered. Corn bracts contain a large quantity of flavonoids, and flavonoids have stronger effects of eliminating free radicals and resisting oxidization and can prevent variation caused by tar compounds and prevent cancer. By means of arrangement of the filter section for the filter tip, harm of smoking to a smoker is reduced.

Owner:FUJIAN GREEN GOLD BIOTECH CO LTD

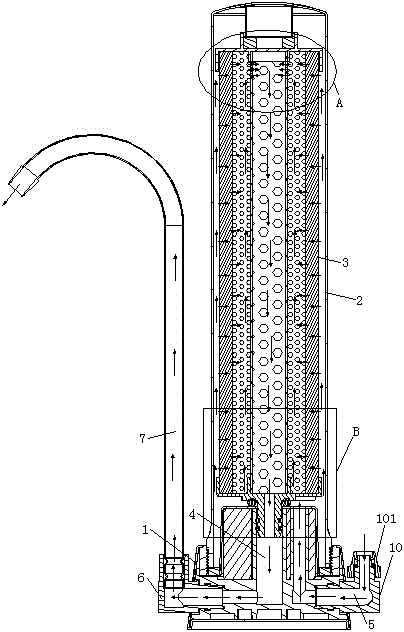

Industrial machine exhaust device with multi-stage filtering function and application thereof

InactiveCN112246027AImprove maintenance convenience and practicalityImprove filter strengthDispersed particle filtrationTransportation and packagingExhaust gasProcess engineering

The invention discloses an industrial machine exhaust device with a multi-stage filtering function, which belongs to the technical field of waste gas treatment. The device comprises a filtering box body, two mounting plates are fixedly connected to one surface of the filtering box body, two supporting assemblies are in threaded connection to one surface of each mounting plate, an air inlet base isfixedly connected to one surface of the filtering box body, an air inlet hopper is arranged on one surface of the air inlet base, an exhaust base is fixedly connected to one surface of the filteringbox body, an exhaust hopper is arranged on one surface of the exhaust base, two fixing assemblies are fixedly connected to onebase, each fixing assembly comprises a U-shaped seat, one surface of eachU-shaped seat is fixedly connected with the air inlet seat and the air outlet seat at the corresponding positions, and a set of sliding rods b are slidably connected to the inner wall of each U-shapedseat. Through the design of the first-stage filtering assembly, the second-stage filtering assembly and the third-stage filtering assembly, the problem that an existing exhaust device is poor in practicability due to the fact that the exhaust gas filtering strength is low and maintenance is inconvenient is solved.

Owner:南京多脉智能设备有限公司

Faucet water purification device

ActiveCN104275022BCompact structureImprove filter strengthTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsEngineeringWeight increasing

The invention relates to a water purifier, and particularly relates to a faucet water purifier. The faucet water purifier comprises a base and a shell, wherein the periphery of the lower end of the shell is connected with the base via threads; a filter core of which the upper end is propped against the top of the shell is arranged in the shell; a water outlet tip of the lower end of the filter core extends into a water outlet pipe in the base and is in water-sealing connection with the base; an up-turning intake pipe communicated with an internal hollow cavity of the shell is also arranged at one side end of the base; fluid flowing into the intake pipe is filtered by the filter core and then flows out from the water outlet pipe; the water outlet pipe is communicated with an arc faucet through a corner-shaped joint; and a high magnetic block and weight increasing blocks which are arranged on two sides of the high magnetic block are also embedded into the lower part, at two sides of the intake pipe and the water outlet pipe, of the base. The faucet water purifier is compact in structure, and high in purifying efficiency.

Owner:FUJIAN OSPRING TECH & DEV

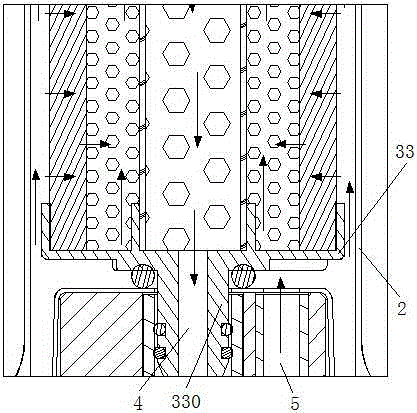

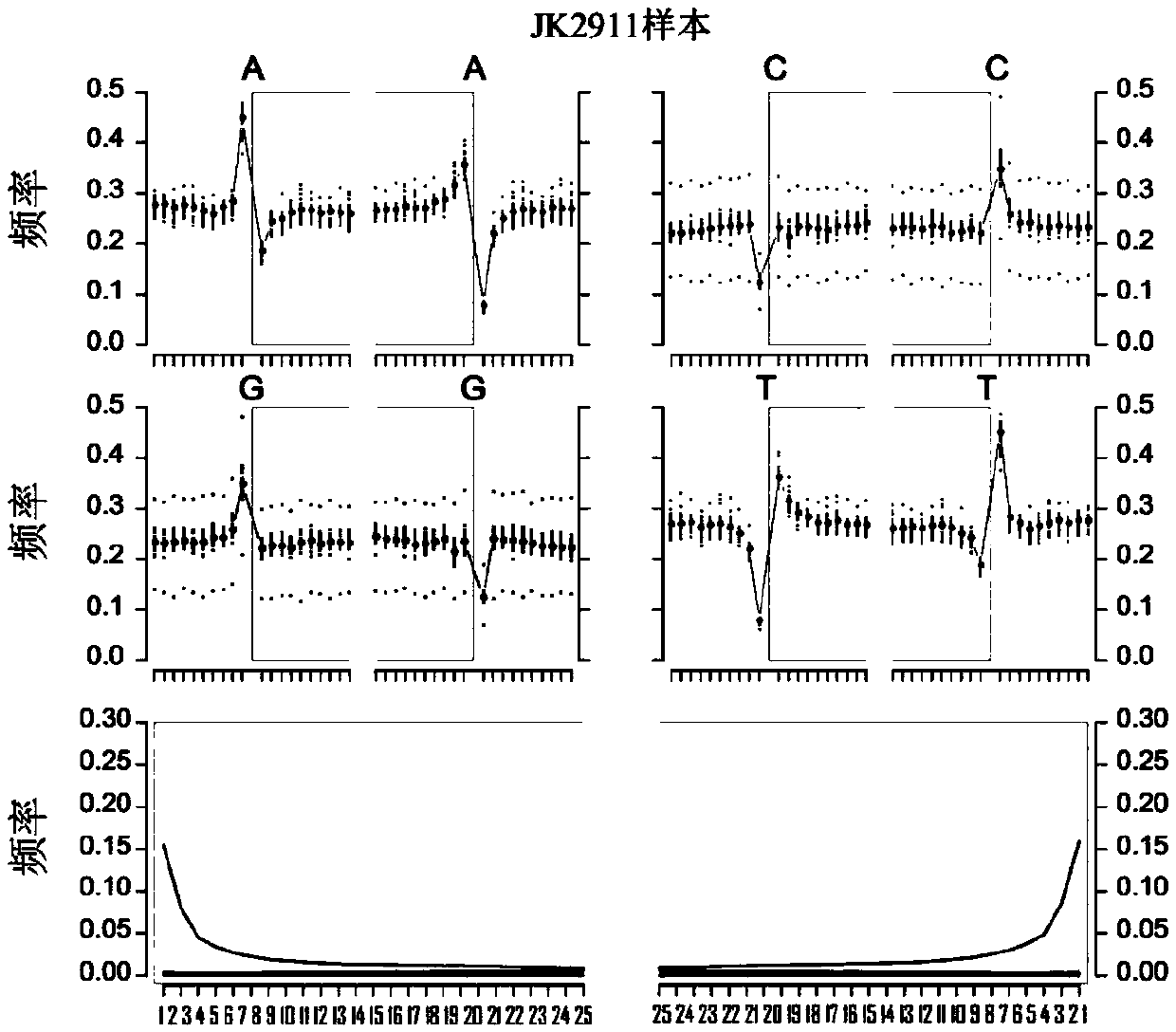

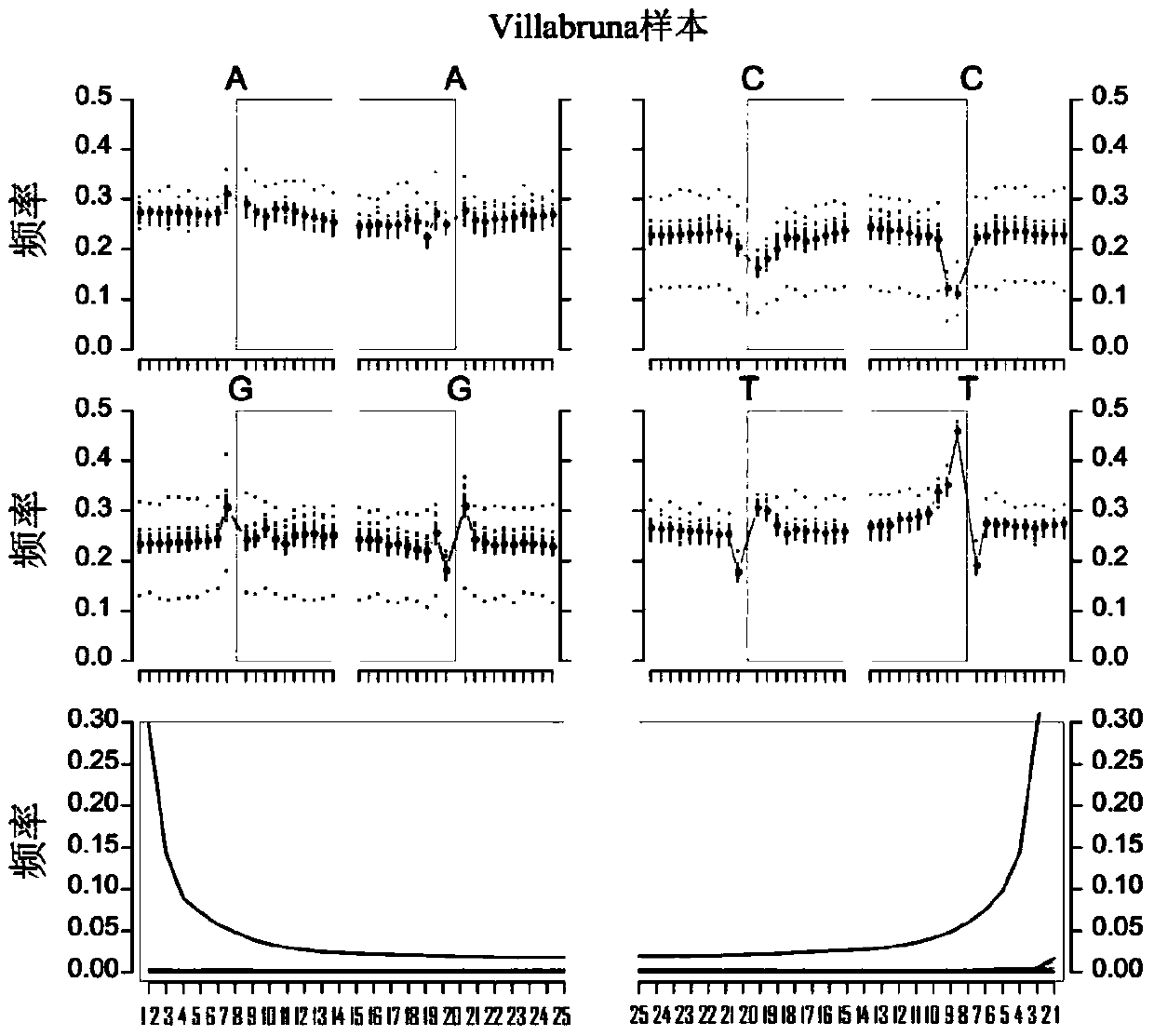

Method for filtering modern DNA pollution from ancient DNA data and application thereof

PendingCN110970086AGeneral usabilityImprove filter strengthProteomicsGenomicsDNA deaminationOriginal data

The invention discloses a method for filtering modern DNA pollution from ancient DNA data and an application thereof. The method comprises a step: carrying out paleo-DNA feature filtering on Illuminanext-generation sequencing original data of paleo-DNA, and specifically comprises the following steps: performing modern DNA pollution filtration on Illumina next-generation sequencing original data according to paleo-DNA deamination characteristics, namely reserving at least N C->T mutations at the 5' end and / or at least M C->T mutations at the 3' end caused by paleo-DNA deamination after filtration. According to the method provided by the invention, the Illumina platform data which is widely used at present can be processed; the method employs a comparison algorithm and parameters most suitable for ancient DNA, can enable the pollution rate after filtering to reach 0 under the suitable N and M values, is one of methods with the maximum filtering intensity at present, and lays a foundation for subsequent deep research of the ancient DNA.

Owner:SHENZHEN BGI AGRI & CYCLE ECONOMIC TECH

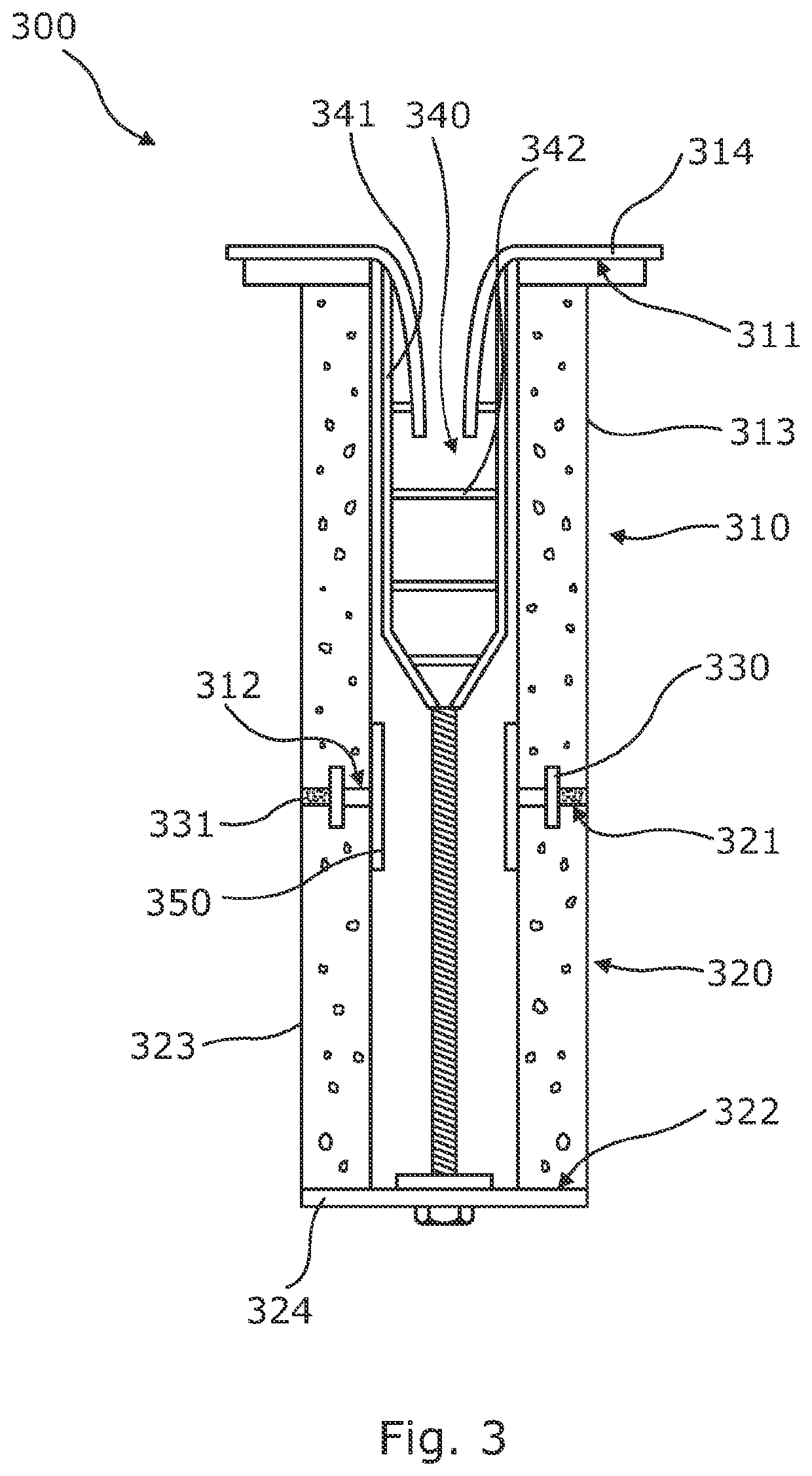

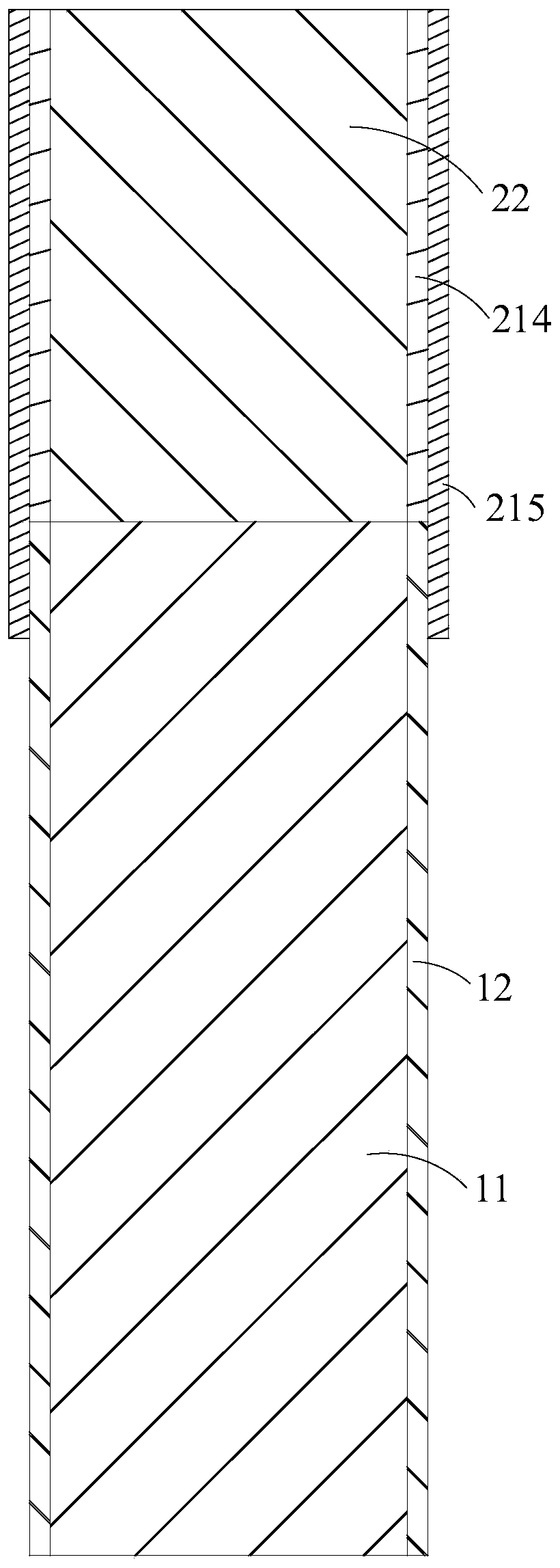

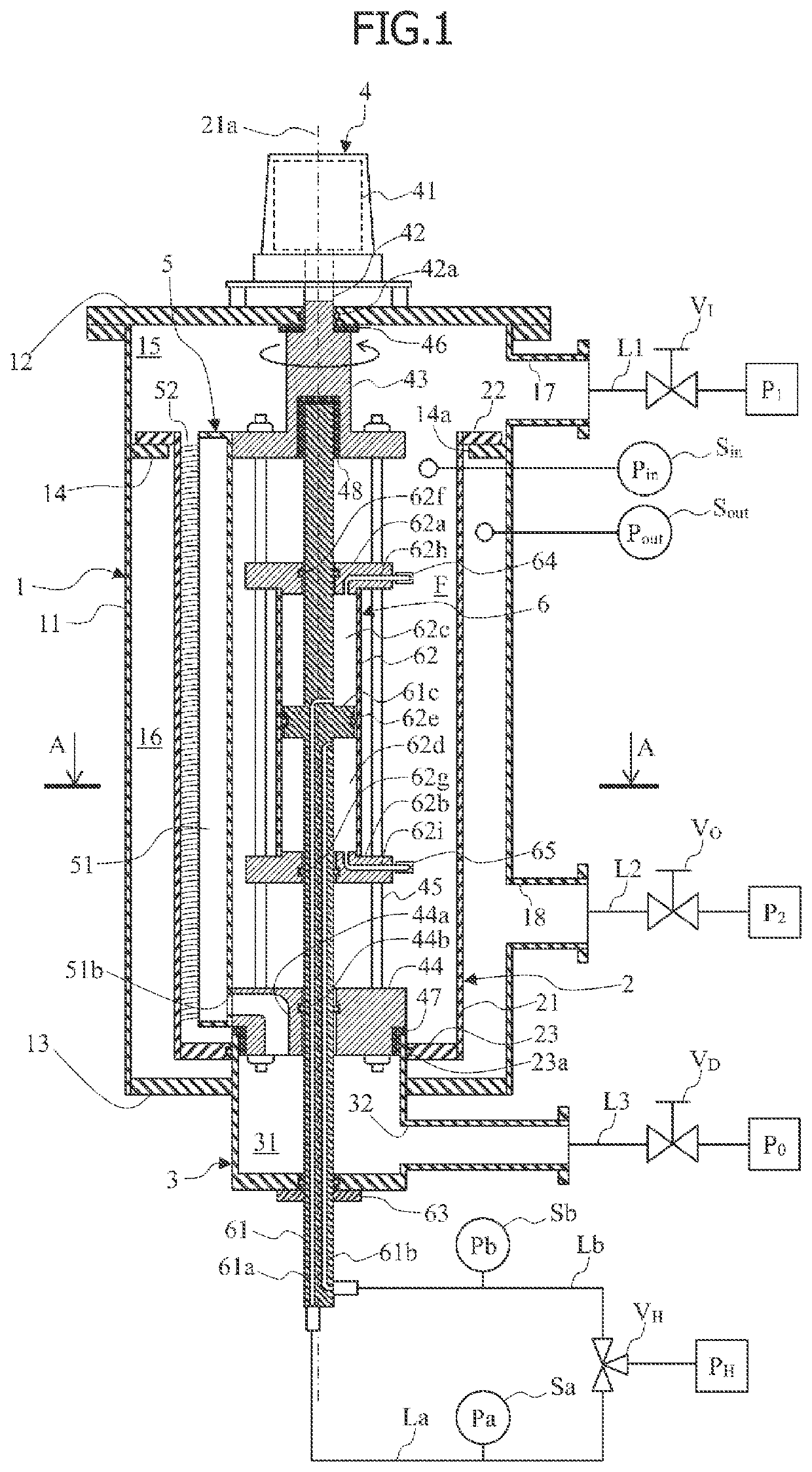

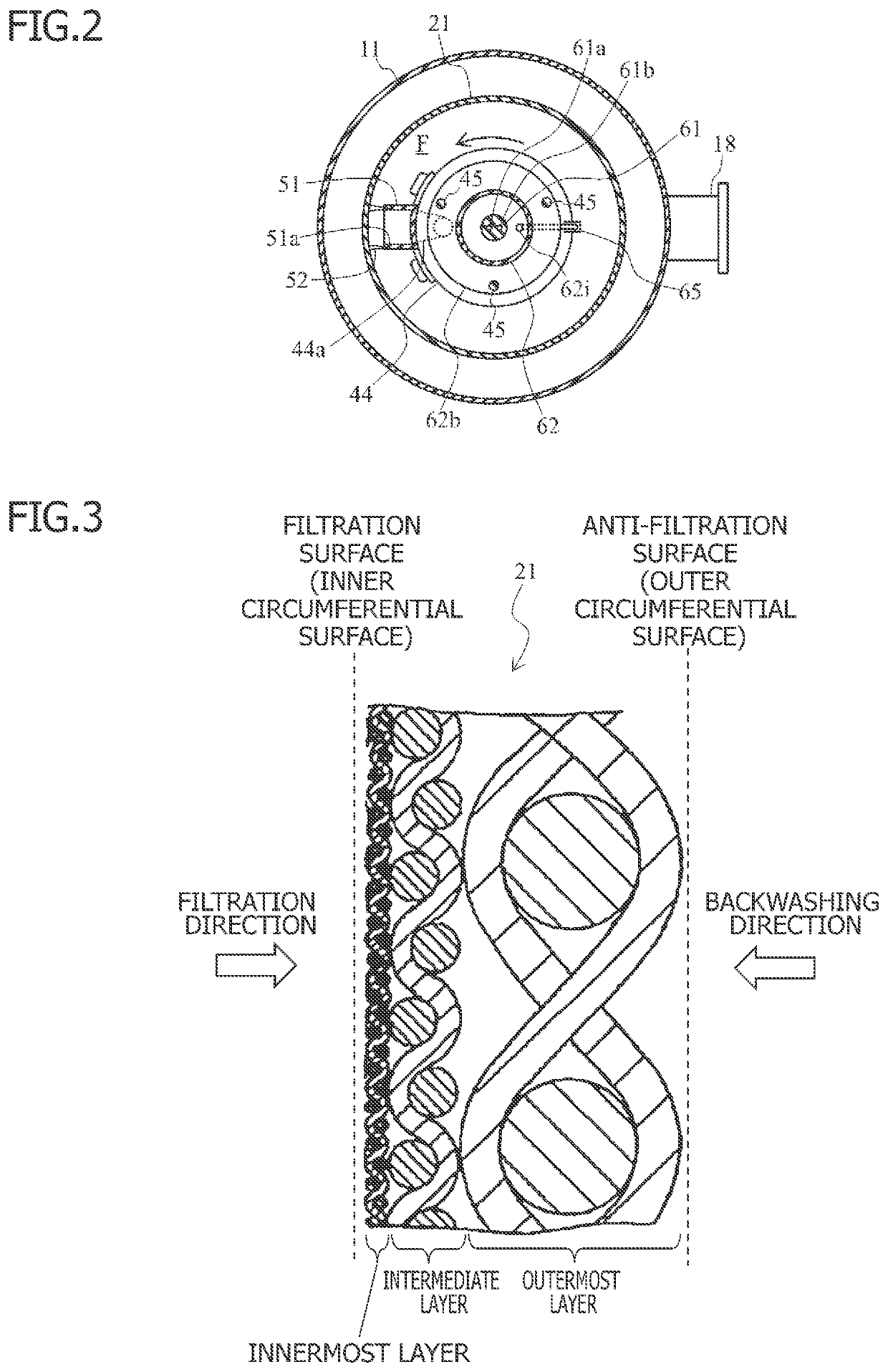

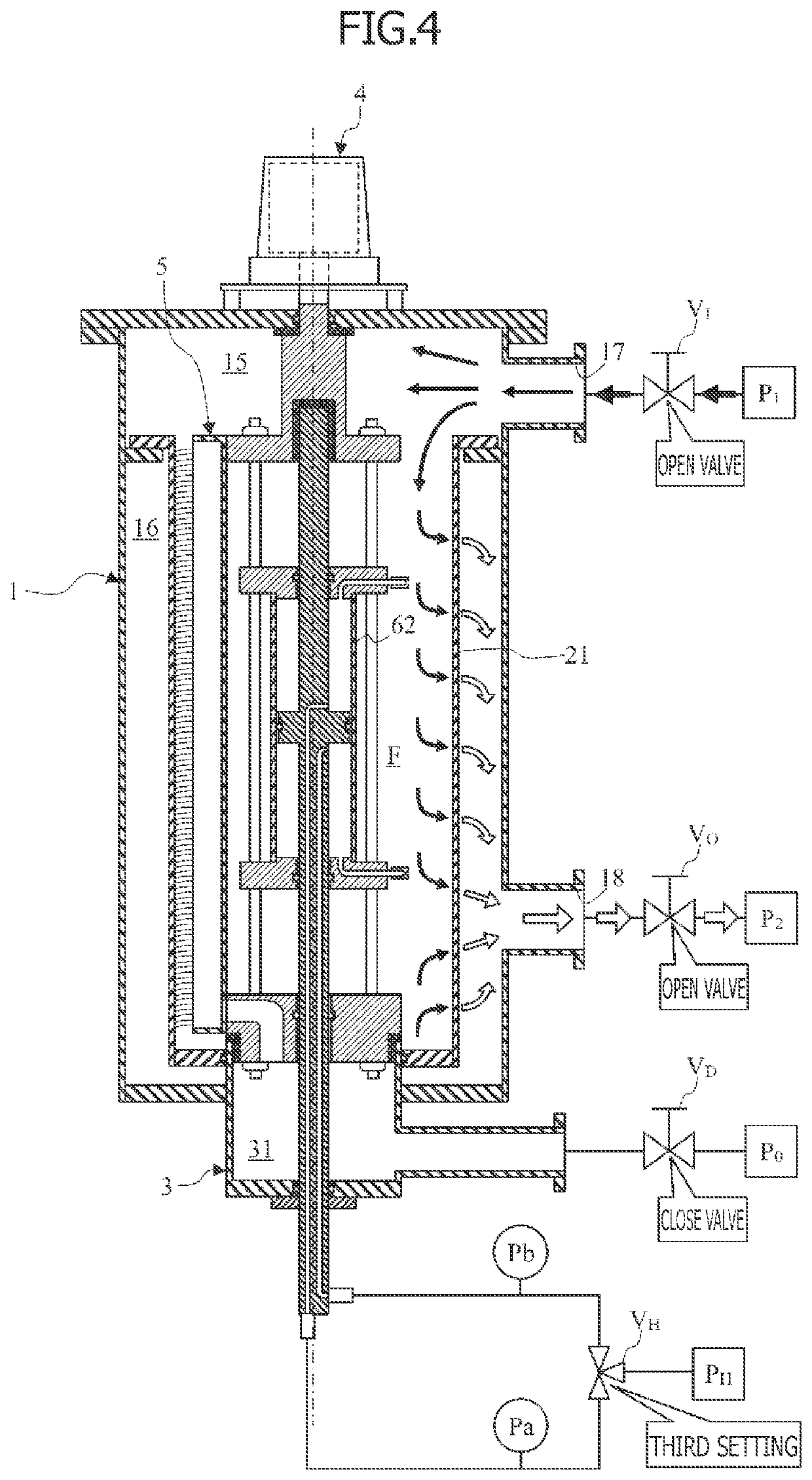

Filtration apparatus and filter washing method therefor

PendingUS20220288510A1Reduced dimensionImprove filter strengthDispersed particle filtrationTransportation and packagingControl theoryMechanical engineering

A filtration apparatus includes: a cylindrical filter element formed in a cylindrical shape to filter a target fluid guided through an one end opening of the filter element in such a manner that the target fluid passes in a direction from an inside toward an outside of the filter element; a backwashing mechanism drawing the filtered fluid in a direction from the outside toward the inside of the filter element; a high-pressure washing mechanism injecting a high-pressure fluid so as to pass through the filter element in the direction from the inside toward the outside of the filter element; and a rotary drive mechanism rotating the backwashing mechanism and the high-pressure washing mechanism around an axial line of the filter element in an internal space of the filter element.

Owner:FUJI FILTER MFG

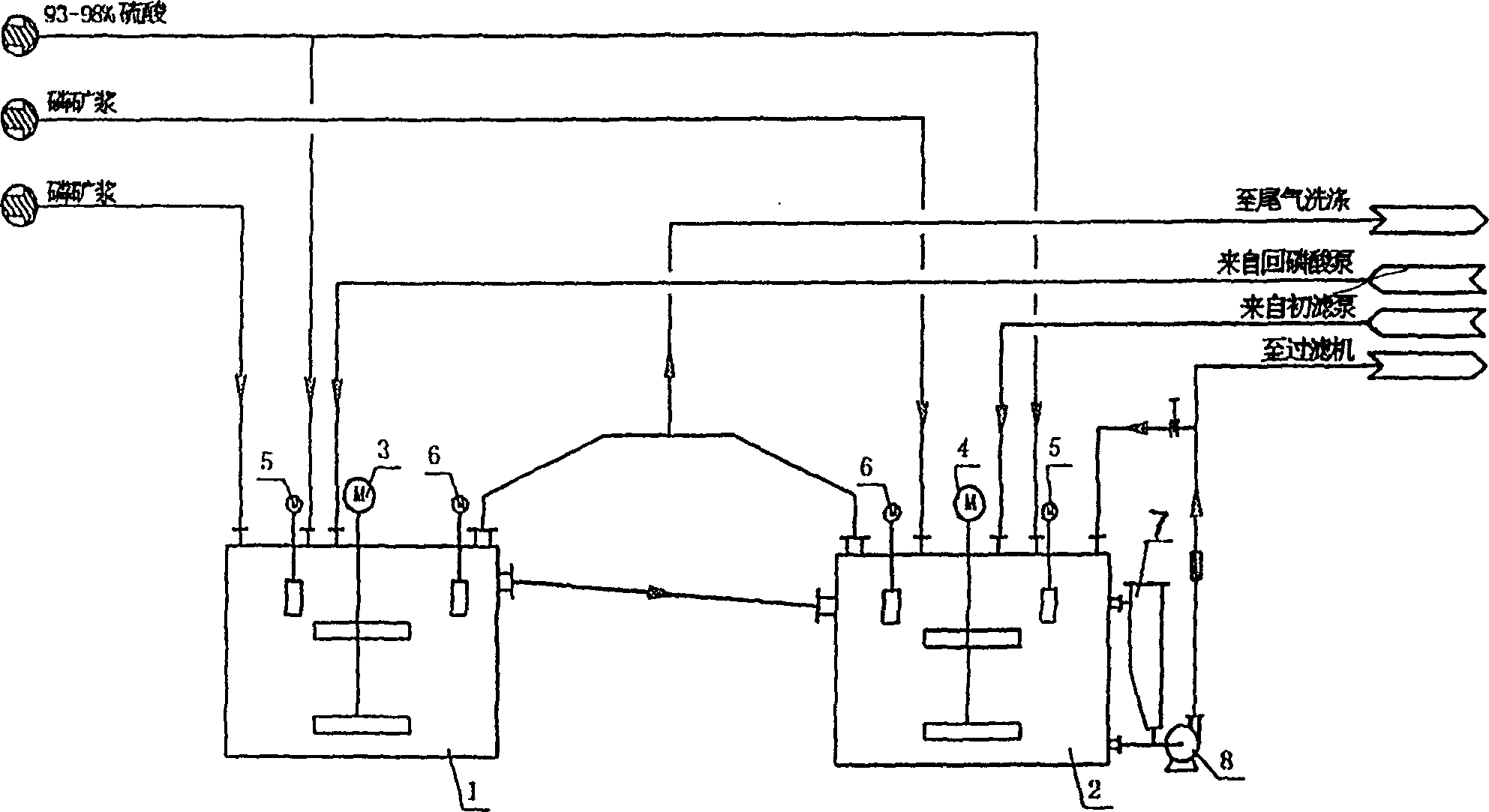

Method for producing phosphoric acid by using (93-98)% concentrated sulfuric acid to extract phosphate rock and its equipment

InactiveCN1233552CLess process equipmentLess investmentPhosphorus compoundsO-Phosphoric AcidWater vapor

Owner:EAST CHINA ENG SCI & TECH

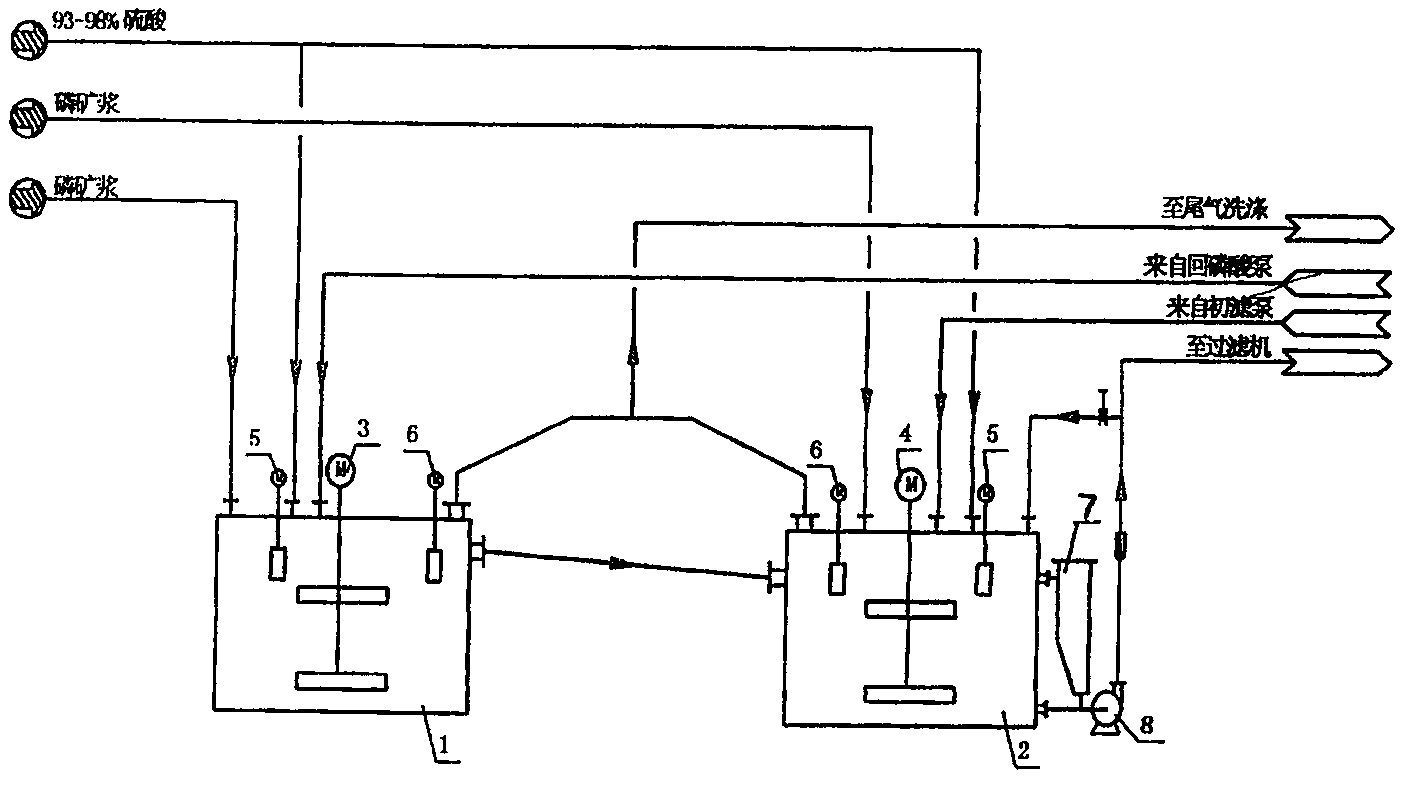

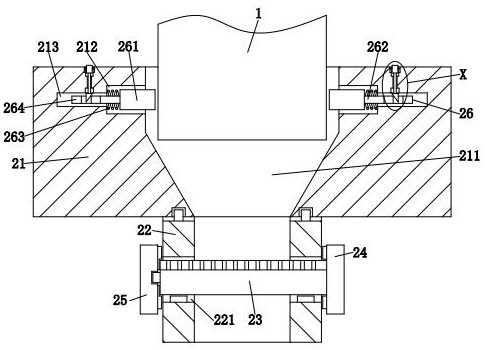

Communication signal filter

The invention relates to a communication signal filter, which comprises a cover plate, a tuning rod, an energizing medium, a cavity, a resonant column, a shell, an output terminal and an input terminal. The outer side of the cavity is provided with a shell, and the shell is connected with the cavity through a clamping mode; The left outer wall of the shell is provided with an input end, and one end of the input end is connected with the shell through a mosaic mode; The right outer wall of the shell is provided with an output end, and the output end is connected with the shell through a mosaicmode; The cavity is provided with a resonant column, and the resonant column is connected with the cavity through a mosaic mode; The outer side of the resonant column is provided with an energizing medium, and the energizing medium is connected with the resonant column through a sleeve mode; The invention has the advantages of reducing the loss, thoroughly filtering and simple structure through the improvement of a communication signal filter, thereby effectively solving the problems and shortcomings proposed in the background of the invention.

Owner:苏州市矩光达通讯技术有限公司

Method for producing technical grade ribose phosphate, food grade ribose phosphate and industry ammonium diacid phosphate using wet-process ribose phosphate

The invention discloses a method for preparing industrial-grade phosphoric acid, food-grade phosphoric acid and industrial monoammonium phosphate with wet-process phosphoric acid. Using wet-process phosphoric acid as raw material, the wet-process phosphoric acid is subjected to a series of chemical precipitation + organic solvent extraction + concentration + recrystallization, etc. Composite purification technology prepares industrial-grade phosphoric acid and food-grade phosphoric acid respectively; at the same time, the present invention uses partially purified dilute phosphoric acid to prepare industrial monoammonium phosphate. The co-production of industrial-grade phosphoric acid, food-grade phosphoric acid and industrial monoammonium phosphate in the present invention enables rational graded utilization of wet-process phosphoric acid, increases the added value of phosphorus, and further develops downstream industrial-grade and food-grade phosphates.

Owner:中化重庆涪陵化工有限公司

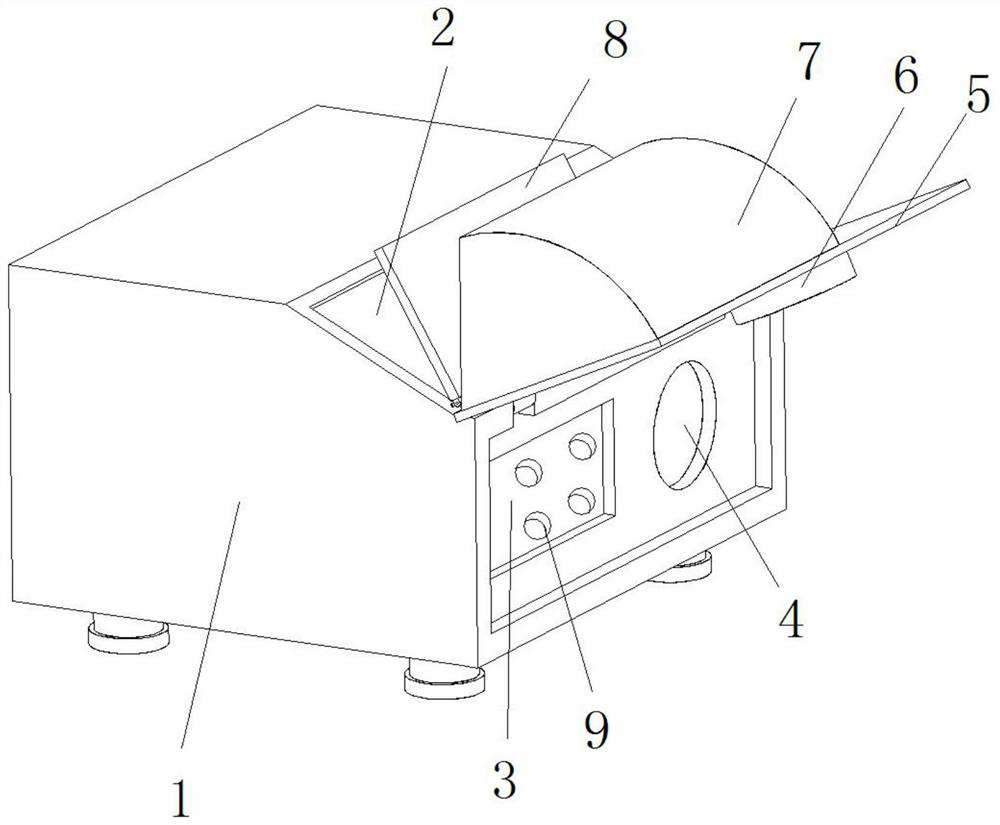

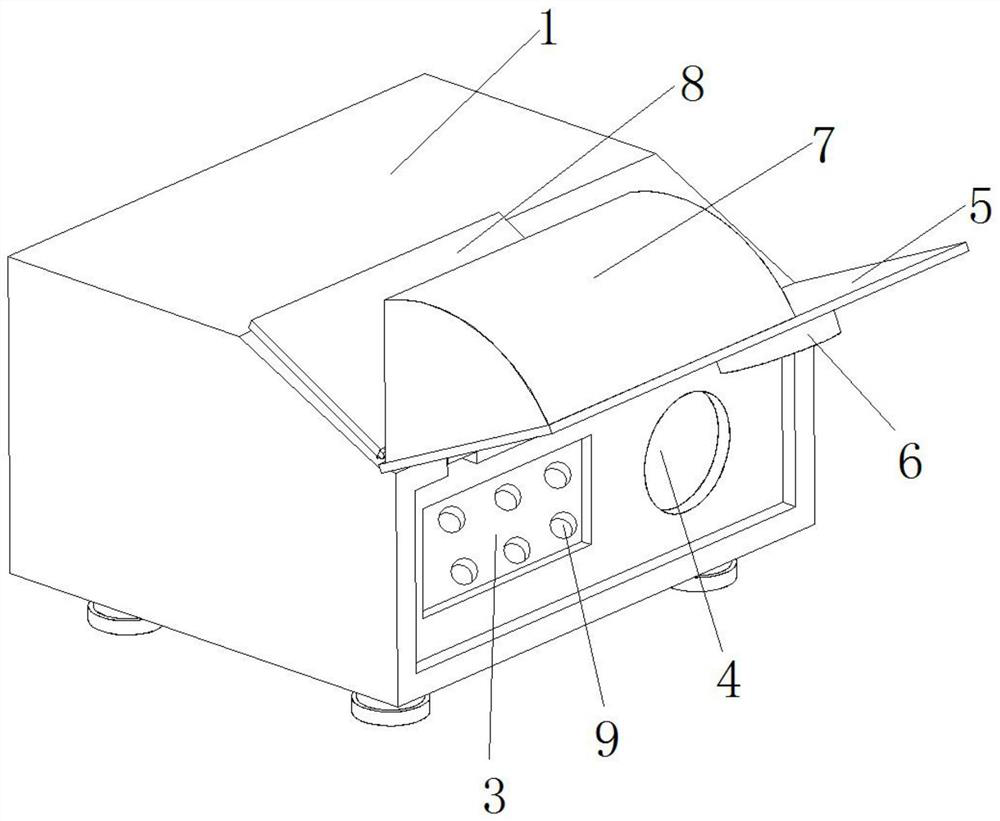

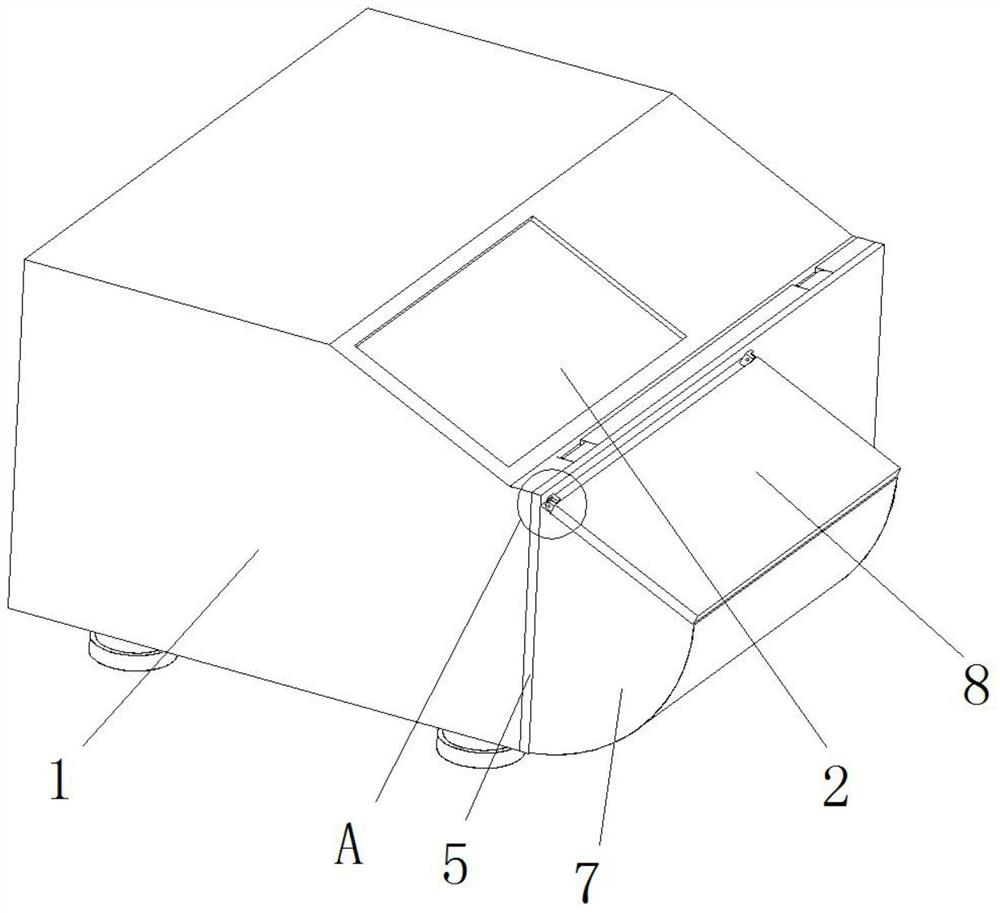

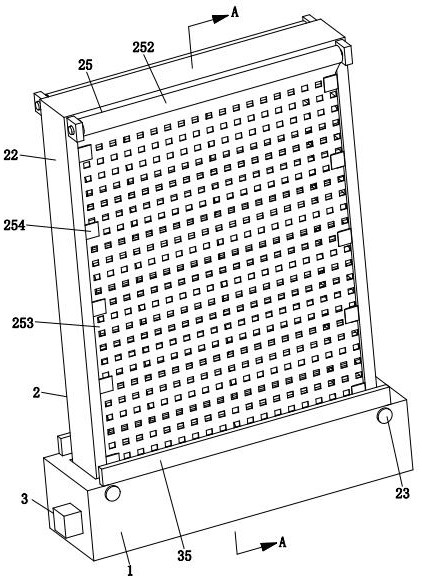

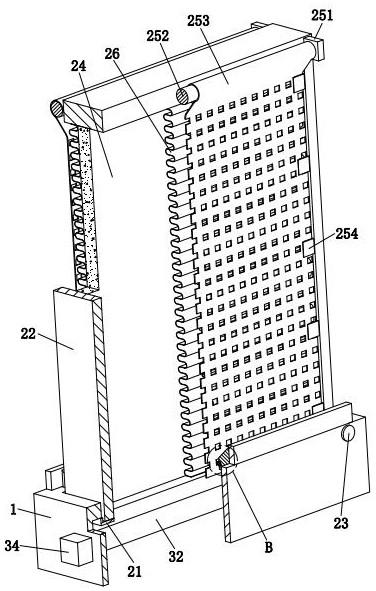

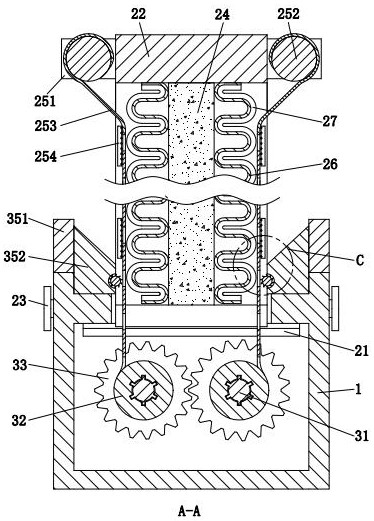

Projection equipment for multifunctional rotary teaching platform for art education

InactiveCN113823128AAchieve normal imagingEnhance lifting strengthDispersed particle filtrationProjectorsProjection lensMechanical engineering

The invention relates to the related technical field of multimedia teaching, and discloses projection equipment for an art education multifunctional rotating teaching platform. The equipment comprises a shell, the outer side of the shell is provided with an air inlet duct communicated with the inner cavity of the shell, the side wall of the shell is provided with an air outlet duct for discharging airflow in the inner cavity of the shell, the air outlet duct is provided with an air outlet groove, a projection lens located on one side of the air outlet channel is fixedly installed on the side wall of the shell, and a dustproof plate used for shielding the air outlet channel and the projection lens is hinged to the top of the side wall of the shell. According to the equipment, the dustproof plate is hinged to the shell, the air outlet channel communicated with the inner cavity of the shell is formed in the shell, when the projection lens is used, the dustproof plate is lifted through air flow blown out of the air outlet channel, and normal imaging of the projection lens is achieved; and meanwhile, according to the air flow intensity of the air flow blown out of the air outlet channel, whether the air inlet duct is blocked or not can be obviously seen, and finally the purposes of autonomously protecting the projection lens and monitoring blocking in real time are achieved.

Owner:DEZHOU VOCATIONAL & TECHN COLLEGE

An air purifier filter element

ActiveCN113769511BPrevent flying outAvoid spills outside the collection boxDispersed particle filtrationForeign matterAir purifiers

The invention relates to the technical field of air purification, in particular to an air purifier filter element, comprising a collection box, a filter unit and an ash removal unit, a filter unit is installed on the upper end of the collection box, and an ash removal unit is arranged on the filter unit; the current air The filter element of the purifier has the following problems: the current air purifier filter element can only replace the dust removal layer. If the dust removal layer is not replaced in time, it will cause blockage of the dust removal layer, which will cause blockage of the filter element, thereby affecting the air purification effect. The similar filter element cannot realize multi-stage filtration, and the degree of filtration is low, so it affects the purification effect of the air; this application effectively prevents the dust from clogging the present invention, can enhance the purification effect of the air, and facilitates the unified removal of the collected dust ; The present invention can increase the filter strength of dust and foreign matter in the air, and then can enhance the filter effect of the present invention to air.

Owner:徐州高鑫电子科技有限公司

Method for producing triple superphosphate and co-producing calcium chloride by middle-low grade phosphate rock

InactiveCN101456545BOvercoming the Prejudice of Not being able to Produce TSPLow grade requirementsCalcium/strontium/barium chloridesPhosphorus compoundsPhosphoric acidEvaporation

Owner:SICHUAN UNIV

An automatic rainwater collection and reuse processing device

ActiveCN113089770BEasy to collect and reuseDischarge fullyFatty/oily/floating substances removal devicesSewerage structuresWater storageEnvironmental engineering

An automatic rainwater collection and reuse processing device provided by the present invention includes a drainage pipe, a connecting unit and a filtering unit. A filter unit is provided; the present invention can solve the problem that "generally, when rainwater is collected, the rainwater is mostly flowed into the water collection chamber through the drain pipe, and because the drain pipe and the water collection chamber cannot be fixed, it is easy to cause rainwater to splash out, and The rainwater needs to be manually transferred to the storage tank, and the rainwater in the water collection chamber cannot be completely discharged, so that the rainwater is easy to cause corrosion on the inner wall of the water collection chamber; after the current rainwater is collected, most of it is not filtered. Putting it into use, because rainwater contains a lot of microelements is not suitable for crops, and rainwater is easily mixed with impurities during the collection process, so it is easy to cause damage to crops” and other issues.

Owner:NANJING FORESTRY UNIV

Multilayer filter screen and manufacturing method thereof

ActiveUS10874968B2Improve filter strengthImprove abilitiesDispersed particle filtrationTransportation and packagingEngineeringMechanical engineering

A multilayer filter screen and the manufacturing method thereof are provided. The multilayer filter screen includes a conductive powder layer and a plastic powder layer. The conductive powder layer and the plastic powder layer are stacked up through a solidifying process. Therefore, the mechanical structural strength and the anti-static electricity function of the multilayer filter screen are improved.

Owner:FANNO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com